Press release

SABIC Innovative Plastics Completes its Portfolio of Valox* SHF Resins, Enabling Electrical & Automotive Part Manufacturers to Go with the Flow

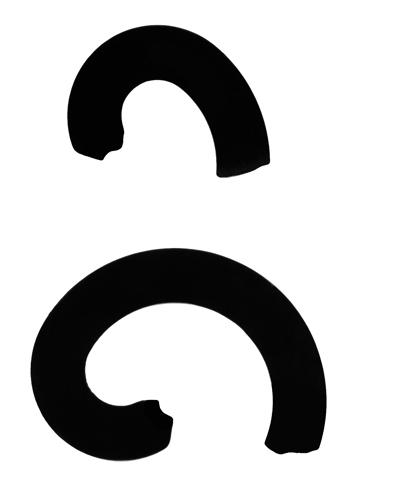

Thirty Percent Glass-Filled Flame Retardant Super High Flow PBT (bottom) Offers Twice the Flow Length of Thirty Percent Glass-Filled FR PBT (top)

SABIC Innovative Plastics has raised the bar with a complete portfolio of glass filled Super High Flow Valox* SHF resins offering twice the flow length of standard glass filled polybutylene terephthalate (PBT). With this comprehensive PBT product family, electrical and automotive part manufacturers have many choices when molding thin-wall parts such as connectors and excess voltage cut-off switches.

“More than ever, our customers are under tremendous pressure to rapidly produce electrical components with less weight and mass, and at a lower price,” said Arthur van Dijk, industry manager, Electrical and Lighting, SABIC Innovative Plastics. “Our full line of Super High Flow Valox resins relieves the stress by providing greater design flexibility and increased productivity and capacity compared to other PBT resins. Now that we’ve added new grades featuring enhanced hydrolytic stability, low warpage, and better weathering, Valox SHF resins can be used even more widely – in warm, moist under-hood environments and for small, highly precise connectors, for example.”

Many Potential Benefits from One Resin Family

By doubling the flow performance of traditional glass-filled PBT resins, Valox SHF resin grades offer several important benefits:

• Thinner-wall parts and more-complex designs (part consolidation) than were previously possible.

• Reduced part stress, resulting in better dimensional stability and performance.

• Reduced system costs by eliminating short shots (scrap), minimizing tool maintenance due to lower injection pressure, and reducing the amount of resin required. Also, because Valox SHF resin can be processed at a lower temperature than conventional PBT resins, less energy for heating/cooling is needed.

• Reduced cycle time by up to 25 percent due to faster injection rate and reduced cooling time, leading to more parts per min.

A Broad Range of Properties

The Valox SHF resin portfolio offers customers both flame-retardant and non-flame-retardant grades. Glass fiber levels range from 15 to 40 percent. And there are low warpage and hydrolytically stable choices available. All grades offer best-in-class performance, beginning with superior flow properties combined with chemical resistance, mechanical and heat performances.

In addition to replacing traditional glass-filled PBT resins, Valox SHF resin grades can be substituted for liquid crystalline polymers (LCPs) in applications where higher heat is not needed. The SABIC Innovative Plastics’ materials offer comparable flow but are much easier to process than LCPs and are significantly less expensive.

For additional information on SABIC Innovative Plastics’ Valox SHF resins, please go to www.sabic-ip.com.

About SABIC Innovative Plastics

SABIC Innovative Plastics is a leading, global supplier of engineering thermoplastics with a 75-year history of breakthrough solutions that solve its customers’ most pressing challenges. Today, SABIC Innovative Plastics is a multi-billion-dollar company with operations in more than 25 countries and over 10,500 employees worldwide. The company continues to lead the plastics industry with customer collaboration and continued investments in new polymer technologies, global application development, process technologies, and environmentally responsible solutions that serve diverse markets such as automotive, electronics, building & construction, transportation, and healthcare. The company’s extensive product portfolio includes thermoplastic resins, coatings, specialty compounds, film, and sheet. SABIC Innovative Plastics (www.sabic-ip.com) is a wholly owned subsidiary of Saudi Basic Industries Corporation (SABIC), one of the world’s top five petrochemicals manufacturers.

Kevin Noels

Marketing Solutions

Lelyweg 6

4612 PS, Bergen op Zoom,

The Netherlands

Tel: +31 164 317 011

E-Mail: knoels@marketingsolutions.be

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SABIC Innovative Plastics Completes its Portfolio of Valox* SHF Resins, Enabling Electrical & Automotive Part Manufacturers to Go with the Flow here

News-ID: 66437 • Views: …

More Releases from SABIC Innovative Plastics

SABIC Launches Portfolio of Antimicrobial Compounds at MD&M West to Help Custome …

According to a 2011 report by the World Health Organization, in 2002 in the United States alone approximately 99,000 deaths were linked to healthcare associated infections (HCAIs).1 Here at MD&M West (booth #1701), SABIC’s Innovative Plastics business today introduced powerful new tools to help medical device manufacturers reduce HCAIs among patients and clinicians. SABIC’s nine new antimicrobial compounds featuring silver technology have been tested for log reduction values – the…

SABIC’s 3D-Formed LEXAN™ Sheet Increases Visibility, Safety, Comfort and Per …

Operators of logging equipment require exceptional visibility and protection against debris or large objects that may enter their cabin and cause serious injury in forest environments, such as tree limbs and other machinery parts. So when Rottne Industry AB needed a high-performance glazing material for the windshields and windows of its harvesters and forwarders, it turned to

SABIC’s Innovative Plastics business for support. Working with SABIC and its distributer, Vink…

Mitsubishi Motors Corporation Selects SABIC NORYL GTX™ Resin for 2013 Outlande …

SABIC’s Innovative Plastics business today announced that Mitsubishi Motors Corporation (MMC) has chosen SABIC’s next-generation NORYL GTX™ 989 resin for the front fenders of its 2013 Outlander Sport crossover. The vehicle’s fenders are the first to be produced using 2-cavity injection molding with NORYL GTX resin, allowing MMC to cut cycle times in half and reduce tooling costs. Other major benefits of the SABIC material include weight savings vs. steel…

SABIC Makes a Splash at Fakuma with New NORYL™ Resin, Meeting Tightening Globa …

Here at the Fakuma trade fair, booth #B5-5506, SABIC’s Innovative Plastics business today announced a new NORYL™ resin that not only complies with current European and global sustainability regulations governing materials used in potable water systems, but also with new, tougher regulations slated to go into effect in 2016. Developed at SABIC’s Fluid Engineering Center of Excellence in the Netherlands, NORYL FE1630PW resin is a 30-percent glass-reinforced polyphenylene ether (PPE)…

More Releases for PBT

Track Polybutylene Terephthalate (PBT) Price Report Historical and Forecast

Executive Summary

Polybutylene Terephthalate (PBT) prices have demonstrated a mixed but generally subdued trend across global regions in 2025. In North America, stable feedstock costs and cautious downstream demand have maintained marginal price oscillations, with the average PBT price for Q3 2025 at approximately USD 3,247.67/MT FOB New York. APAC markets, led by Japan, reflected limited volatility with average prices of USD 2,924.33/MT, while Europe, particularly Germany, experienced a notable 5.44%…

Polybutylene Terephthalate (PBT) Market Research Report 2024

The global Polybutylene Terephthalate (PBT) market was valued at US$ 1933 million in 2023 and is anticipated to reach US$ 1826.1 million by 2030, witnessing a CAGR of -0.8% during the forecast period 2024-2030.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-34N2300/Global_Polybutylene_Terephthalate_PBT_Market_Insights_Forecast_to_2026

Polybutylene Terephthalate (PBT) is semi-crystalline, white or off-white polyester similar in both composition and properties to polyethyleneterephthalate (PET). It is a thermoplastic engineering polymer that is used as an insulator in the electrical, electronics,…

Flame Retardant PBT Granules Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Flame Retardant PBT Granules Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Flame Retardant PBT Granules players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Flame Retardant PBT…

Polybutylene Terephthalate (PBT) Plastic Market Size, Share, Development by 2024

LP INFORMATION offers a latest published report on Polybutylene Terephthalate (PBT) Plastic Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Polybutylene Terephthalate (PBT) Plastic market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million…

Polybutylene Terephthalate (PBT) Plastic Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Polybutylene Terephthalate (PBT) Plastic Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Polybutylene Terephthalate (PBT) Plastic players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Polybutylene Terephthalate (PBT)…

Global Polybutylene Terephthalate(PBT) Depth Research Report 2019

In its recently published report, QY Research has provided unique insights about global Polybutylene Terephthalate(PBT) market for the given period. One of the main objectives of this report is to categorize the various dynamics of the market and to offer latest updates such as mergers and acquisitions, various technological developments, new entrants in the market, which make an impact on different segments of the global Polybutylene Terephthalate(PBT) market.

Request Sample Report and Full…