Press release

Disposing of old refrigerators correctly, but also recycling them

When refrigerators are recycled, the focus is still on recovering the environmentally-harmful chlorofluorocarbons (CFCs). However, today high prices of raw materials – for example for iron, copper and aluminium – mean that recycling refrigerators is not only environmentally friendly but also cost-effective.When refrigerators are recycled, nitrogen fulfils two roles: thanks to it being extremely cold, liquid nitrogen enables the greenhouse gas CFC to be frozen out of the exhaust gas of the recycling plant and, in a gaseous form, also provides protection against dust explosions while the refrigerators are being broken up. Each month the industrial gas specialist Messer supplies 100,000 m² of liquid nitrogen for the refrigerator recycling plant of Noex AG, a company belonging to Entsorgungsgesellschaft Niederrhein mbH. In Grevenbroich, near Cologne, Noex operates one of the most modern recycling plants in Germany. Noex disposes of around 300,000 to 400,000 refrigerators a year; a large percentage of these are still devices which contain CFC.

Environmentally-harmful chlorofluorocarbons were used as cooling and foaming agents in refrigerators in Germany until they were banned in 1995. The inactive CFCs will remain in the stratosphere for 120 years and are regarded as “ozone killers”. The propellant (and greenhouse) gas is contained, for example, in polyurethane foam, which insulates the refrigerators. Consequently, when used refrigerators are stored and transported, it must be ensured that the insulation is not damaged. In state-of-the-art refrigerator recycling plants the CFC vapours which are produced when the devices are broken up are extracted specifically. The CFC vapours are condensed an frozen out from the off-gas using nitrogen, leaving pure air behind. Nitrogen, which comprises 79% of the air we breathe, has a temperature of minus 196°C when in its liquid form – it is referred to as a cryogenic, in other words an ultra-cold, gas. In Grevenbroich more than 99.9% of the CFCs can be recovered from the waste gas. They are then subjected to controlled destruction in Germany's only CFC cracking plant and converted into hydrofluoric acid and hydrochloric acid.

Through its chemical properties, nitrogen displaces the air in the shredder, thereby ensuring that crushing processes are safe and dust explosions or fires are avoided. In Noex's state-of-the-art refrigeration recycling plant, refrigerators are broken up until the composites are completely decomposed, and the polyurethane foam is milled finely to open all the pores. In newer refrigerators the insulating materials are generally foamed with pentane instead of CFCs. Pentane released in the shredder can lead to potentially explosive atmospheres and endanger the safety of people and machinery. Nitrogen is therefore not just used to recover the CFCs or pentane; it is also simultaneously injected into the shredder in gaseous form to prevent fires and explosions. In addition to the plastics, pure iron, aluminium, copper and glass are left behind. Noex recycles the various components – in view of the shortage of raw materials this is a cost-effective strategy.

According to the Federal Ministry, “When compared with the rest of Europe, Germany is far ahead in terms of the requirements for refrigerator recycling. It satisfies the requirements of the EG Directive governing materials that lead to a reduction in the ozone layer, and also those of the guidelines for old electrical and electronic equipment.” The Technical Instructions on Air Quality (TA-Luft) of the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety demand that CFCs should be collected and destroyed during the recycling process. Thanks to the technology employed and the use of nitrogen, the refrigerator recycling plant of the Entsorgungsgesellschaft Niederrhein satisfies all the requirements for the recovery of CFCs such as R11 and R12, in contrast to some other refrigerator recycling plants in Germany. In May 2008 the Deutsche Umwelthilfe (DUH – German Environmental Relief) published new calculations for CFC emissions and speaks of the “inadequate disposal of refrigerators in Germany” which continues to pollute the air far more than need be, considering the technology available. According to the DUH, Germany ranks among the worst countries in Europe in terms of disposing of refrigerators.

Messer is one of the leading industrial gas companies, and is active in over 30 countries in Europe and Asia, as well as Peru, with over 60 operating companies. Its international activities are managed from Frankfurt am Main, whilst management of core technical functions – logistics, engineering, production and applications engineering – is undertaken from Krefeld. In 2007, about 4,400 employees generated consolidated sales of €705 million.

From acetylene to xenon, the Messer Group has one of the most diverse product portfolios on the market – it produces industrial gases such as oxygen, nitrogen, argon, carbon dioxide, hydrogen, helium, shielding gases for welding, specialty gases, medical gases and many different gas mixtures.

The Messer Group has state-of-the-art research and competence centers in which it develops applied technologies for the use of gases in almost every sector of industry, in food technology and environmental technology, medicine as well as research and science.

Messer Group GmbH

Vice President

Corporate Communications

Diana Buss

Gahlingspfad 31

47803 Krefeld

Phone: +49 (0) 2151 7811-251

Fax: +49 (0) 2151 7811-598

Email: diana.buss@messergroup.com

www.messergroup.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Disposing of old refrigerators correctly, but also recycling them here

News-ID: 61577 • Views: …

More Releases from Messer Group GmbH

Messer consolidates its position in China

Three new air separation units opened in western China

In March, the largest privately managed industrial gases specialist, Messer, put three new air separation units into operation in the western Chinese province of Sichuan. The total investment comes to approximately 80 million euros. Two of the three new facilities will each produce around 30,000 normal cubic metres of air gases such as argon, oxygen and nitrogen per hour, and will…

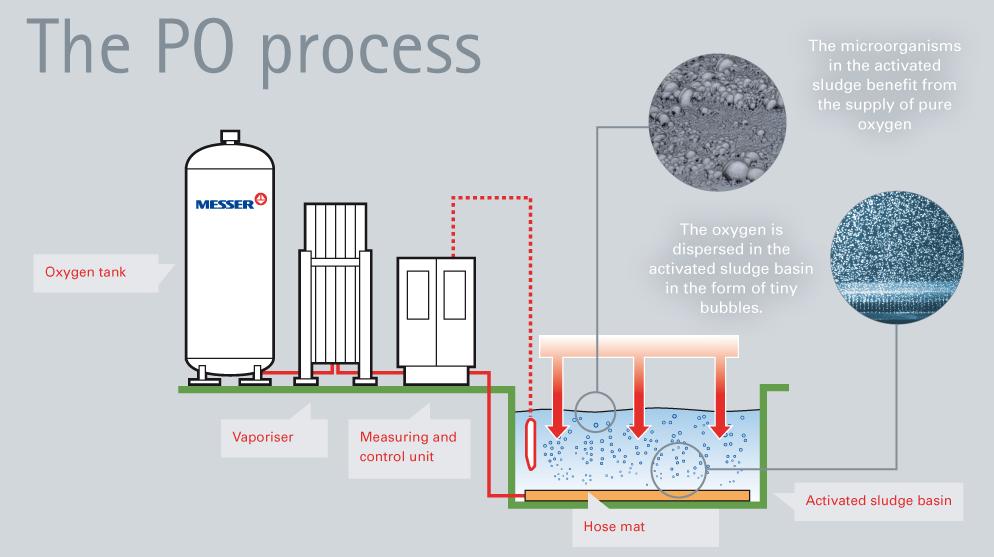

Pure air thanks to pure oxygen

Messer, the largest privately run industrial gases specialist, is supplying Südzucker AG in Ochsenfurt, Germany, with pure oxygen in order to eliminate oxygen deficiency in settling ponds – and to prevent recurrences in the future. Oxygen injection here supports the natural purification processes.

The large quantities of water which Südzucker uses to wash beets are treated in a wastewater treatment plant. The wastewater is stored temporarily in settling ponds. Aerobic bacteria…

Blechexpo 2011 in Stuttgart – Industrial gases specialist Messer showcases its …

Messer will be showcasing its diverse product portfolio of welding and cutting gases at Blechexpo in Stuttgart from 6 to 9 June 2011. At Stand 7309 in Hall 7, the largest privately run industrial gases specialist will be provid-ing information on its range of shielding gases for welding, giving both lower-volume users and bulk customers valuable insight into these product lines.

Insight into the Messer World

The 270 m2 Messer World stand…

Messer consolidates market position in Austria

On 2 May 2011, Messer Austria acquired the gas business of Sapio Gase GmbH.

Messer Austria, the Austrian subsidiary of Messer, the largest privately run specialist for industrial gases, intends to consolidate its market position in Upper Austria through its purchase of the gas business of Sapio Gase GmbH. The transaction was completed on 2 May 2011. Sapio Gase, a subsidiary of SAPIO, an Italian company, has a strong presence in…

More Releases for CFC

Global Continuous Fiber Composites (CFC) for Aerospace Market Growth Forecast Re …

Global Info Research's report is a detailed and comprehensive analysis for global Continuous Fiber Composites (CFC) for Aerospace market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the Continuous Fiber Composites (CFC) for Aerospace market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across…

Chlorofluorocarbons (CFC) Market Key Insights, Profiling Companies and Growth St …

The recent report titled as Global Chlorofluorocarbons (CFC) Market published by Report Consultant is a focused study encompassing the market segmentation primarily based on type and application. The report investigates the key drivers leading to the growth of the Chlorofluorocarbons (CFC) market during the forecast period and analyzes the factors that may hinder the market growth in the future. Besides, the report highlights the potential opportunities for the market players…

Global Continuous Fiber Composites (CFC) for Aerospace Market Expected to Witnes …

LP INFORMATION recently released a research report on the Continuous Fiber Composites (CFC) for Aerospace market analysis, which studies the Continuous Fiber Composites (CFC) for Aerospace's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global “Continuous Fiber Composites (CFC) for Aerospace Market 2020-2025” Research Report categorizes the global Continuous Fiber Composites (CFC) for Aerospace market by key players, product type, applications…

CFC for Aerospace Market to Witness Robust Expansion by 2024

LP INFORMATION offers a latest published report on CFC for Aerospace Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the CFC for Aerospace market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019.…

CFC for Aerospace Market to Witness Robust Expansion by 2024

LP INFORMATION offers a latest published report on CFC for Aerospace Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the CFC for Aerospace market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019.…

Global Chlorofluorocarbons (CFC) Sales Market 2017-2022 Trends & Forecast Report

Orbis Research always aims to bring their clients the best research material and in-depth analysis of the information for any market. This new report Global Chlorofluorocarbons (CFC) Sales Market for 2017 aims to fulfill the needs of the clients looking for a fresh outlook towards the Global Chlorofluorocarbons (CFC) Sales Market, or fill in the knowledge gaps with the data available in the report. The well-presented and curated report is…