Press release

UIP1000-Exd - 1.0kW ATEX Ultrasonic Mixer

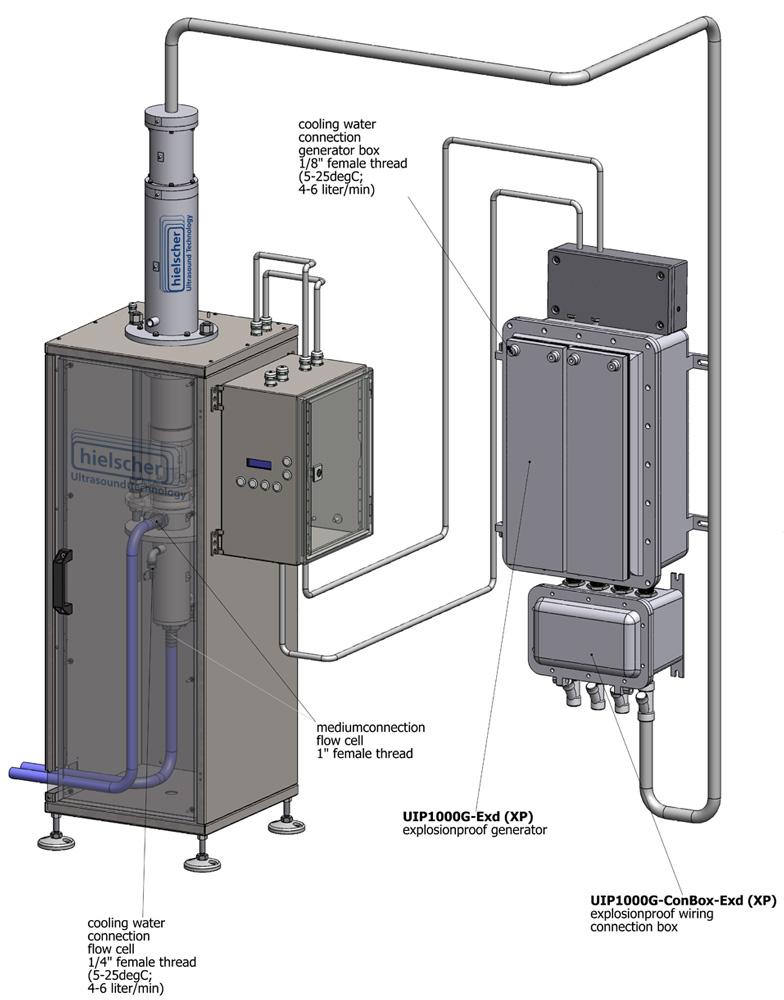

Hielscher introduces the new UIP1000-Exd – an 1.0kW ultrasonic mixer for the ultrasonication of flammable liquids, e.g. solvents in hazardous environments (ATEX, FM). It is used for applications, such as emulsifying, dispersing & particle fine milling, or homogenizing.The ATEX and FM certified UIP1000-Exd is manufactured for ultrasonic processing applications in hazardous areas. The UIP1000-Exd is ATEX certified in accordance with DIN EN 60079-0, 60079-1 and 60079-11 (EU-standards II 2G E Ex d IIA T4 ATEX and II 2G E Ex i IIA T4 ATEX) and FM certified in accordance with FM3600, FM3615 and FM3610. The UIP1000-Exd is a turn-key ultrasonication system for process R&D or industrial processing.

The transducer, and the flow cell are constructed in stainless steel. The sonotrode is made of titanium. Due to its explosion proof construction it can be used for the efficient inline mixing and dispersing of solvents, e.g. in the production of biodiesel or for the dispersing of solvent based paints or inks. The flow cell geometry can be easily adapted to the process requirements in terms of pipe/hose connections, internal volume or sonotrode size. Of course, the flow cell is pressurizable to up to 5.9barg (100psig) in order to work at higher cavitation intensities. The flow cell is jacketed for temperature control during ultrasonication.

The flow cell is located inside a stainless steel noise-insulating chamber. Typical processing capacities of the UIP1000-Exd range from 1 to 5m³ (220 to 1100 gallon) per day. The UIP1000-Exd is designed to require very little space. The complete ultrasonic system is 1.7m (67 inch) high and the footprint is approx. 0.25m² (2.7sqft). The operational ultrasonic unit weighs 110kg (243lbs). The UIP1000-Exd is available for 115V~ or 230V~ (single phase).

The explosion-proof design makes the UIP1000-Exd the perfect ultrasonic device for the manufacturing of paints, varnishes, inks, coatings and other chemical products. Further applications include the processing of fuels (e.g. biodiesel) or pharmaceutical applications (e.g. Hexane based extraction).

More information: http://www.hielscher.com/atex

Hielscher USA, Inc

19 Forest Rd, Ringwood, NJ 07456

t.: ++1 (973) 616 9136, f.: ++1 (973) 616 9131

email: usa@hielscher.com, web: www.hielscher.com

Hielscher supplies innovative ultrasonic devices from lab homogenizers to industrial processing reactors. Typical applications include, mixing and homogenizing, disintegration and sonochemistry.

Ultrasonic devices made by Hielscher cover the full range from sample homogenizing in the lab to the ultrasonication of large volumes in industrial production. Whether you need to sonicate 1.5mL in a test tube or 20 tons per hour, Hielscher offers you the perfect solution for it.

Hielscher USA, Inc.

19, Forest Road

NJ 07456 Ringwood, USA

Tel.: +1 973 616 9136

Mob.: +1 973 800 9537

Fax: +1 973 616 9131

email: usa@hielscher.com

Hielscher Ultrasonics GmbH

Warthestrasse 21

D-14513 Teltow, Germany

Tel.: +49 3328 437 420

Tel.: +49 3328 437 42

Fax: +49 3328 437 444

email: info@hielscher.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release UIP1000-Exd - 1.0kW ATEX Ultrasonic Mixer here

News-ID: 60718 • Views: …

More Releases from Hielscher USA, Inc.

Ultrasonic Transesterification of Oil to Biodiesel

Ultrasonication can improve the conversion processing of vegetable oils or animal fats to biodiesel by improved mixing and enhanced chemical activity.

The manufacturing of biodiesel from oils (e.g. soy, canola, sunflower seed) or animal fats, involves the base-catalyzed transesterification of fatty acids with methanol to give the corresponding methyl esters. The conventional esterification reaction in batch processing tends to be slow, and phase separation of the glycerol is time-consuming. Ultrasound…

More Releases for ATEX

Move Freely, Heal Naturally with ATEX Premium Kinesiology Tape | ATEX

ATEX is a prominent Korean manufacturer of kinesiology and spiral tape products that integrate advanced technology with therapeutic science. With years of dedicated research, the company has developed innovative taping solutions designed to support the body's natural mechanics, enhance recovery, and promote overall well-being. ATEX maintains the highest standards of quality in every stage of design, development, and manufacturing, ensuring reliable and effective products trusted by athletes, healthcare professionals, and…

Experience Freedom of Movement with ATEX Uncut Kinesiology Tape | ATEX

ATEX is South Korea's largest OEM manufacturer of kinesiology therapeutic tapes, with over 15 years of experience and exports to over 30 countries. The company's strong global presence is based on quality, innovation, and reliability, with a commitment to excellence throughout production. Continuous investment in R&D positions at ATEX at the forefront of therapeutic tape manufacturing, offering customized solutions for healthcare professionals, athletes, and wellness enthusiasts worldwide.

Uncut Kinesiology Tape…

Atex announces leadership team appointments

Atex announces three new appointments to its executive team, which will help strengthen Atex’s position as the leading provider of software and services for media-rich industries.

Joining Atex is Jeremy Wilson as Chief Financial Officer. Jeremy most recently served as Group CFO at Regenersis Plc and has a proven track record in high service blue chip corporations trading globally, including DHL Express, Honda Motor Europe Ltd and Electrocomponents…

TECTUS introduces ATEX UHF RFID Reader + ATEX TAGs for IN- / ON- METAL on the eu …

Moers, 20.04.2012 Companies being active in hazardous area can now rely on new product added by TECTUS to the broadest ATEX RFID portfolio from the RFID Experts and ATEX RFID market leader TECTUS.

The new ATEX UHF LongRange reader for zone 2/22 operates perfectly with the new innovative small ATEX certified passive Long Range UHF RFID transponders to be used for ON metal applications and for embedding UHF TAGs IN…

Atex announces new partnership with Dell

Atex, a global software company providing solutions for media-rich industries, has announced a new partnership with Dell China, which will strengthen its presence in the Asian media marketplace and its offering to existing customers.

The Asian media industry, which is recognised globally as a major emerging market, will now benefit from two leading suppliers. Atex provides a complete suite of integrated solutions which are already widely adopted internationally and Dell offers…

Atex announces InDesign integration with Atex Tablet Publishing

Leading global software company Atex has announced that it will be integrating InDesign with Atex Tablet Publishing (ATP). This major development, effective Q1, 2012 focuses on streamlining the editorial workflow, helping newsroom staff to meet the demands of an increasingly digital world, in just a few steps.

The InDesign integration gives full control and creative freedom in page layout and offers an alternative to the streamlined and template-based publishing workflow in…