Press release

ULTRASONIC PUMP PROTECTION FOR ALL LIQUIDS AND MULTI-PHASE MIXTURES

Bases of the new technology of IBJ Technology of an dry running protection for pumps (also: Pump protection) are new realizations for the propagation of surface waves. The characteristics of Rayleigh-waves are used in new sensors for applications in liquids and multi-phase mixtures. The new ultrasonic sensors are protected as utility model and the procedure are announced with the German patent office to the patent. The new technology differs from the well-known state of the art, like time of flight or pulses technology, by its independence from the transmission characteristics of the liquids. The well-known procedures for reason lying idea, the evaluation of flutter echoes in a gate far outside of tube sheet reflections and reflections in the sensor (diaphragm and own decaying), can be used both for measurement by the wall (no contact of the sensor with the medium), and for measurement with screwing in sensors in the tubing or container wall. However bad transmission characteristics of the liquid have an unfavorable effect. Against it if Rayleigh-waves to the attendance supervision or detection are used by liquid phases, are the transmission characteristics of the liquid without influence on the function of the sensors. Thus screwing in sensors for the Low cost range, and fastidious measurements can be realized by the wall at containers and aggregates. With screwing in sensors thereby an optimal signal transmission is guaranteed. The height of the transmission tension can be minimized therefore. Also with unfavorable reflectors (curved tube sheets, pump impellers etc.), which so not sufficient echoes causes, can therefore the presence of a liquid be determined. For all processes and applications, where the sensor contact with the medium does not disturb, thereby a simple pump protection is possible. The measurements by the wall adhering the lack of problematic start-up (couple conditions between sensor and tube sheet should be defined and as reproducible as possible) becomes groundless thereby. Particularly for solid-loaded liquids, salt solutions or suspensions generally, this technology is favourably applicable.Company

In January 2003 IBJ -Technology as partner of the industry for the interests of the process measuring technique one based.

Owner of the engineer's office for innovative measuring technique is

Mr. Dipl.-Ing. (TH), Dipl.-Ing.-Oek. Frank- Michael Jäger.

Our activity and thus our experiences in the process measuring technique for fastidious applications justify themselves on one over 15 years activity in the project management and development in research establishments of the chemistry, the natural gas industry and the mining industry.

The practical use of measurement principles and sensor technologies under most difficult operating conditions is supplemented by one over 12 years advisory activities to the employment and the use from process measuring technique to the benefit of the customers within all ranges of the economy.

As independent and reliable partners of the industry we offer comprehensive solutions in all questions of the process measuring technique.

Particularly with fastidious applications of the ultrasonic technology we can repair problems with new solutions.

Many innovative solutions for measuring tasks in the most different industries were protected in a multiplicity by patents and utility models.

Contact:

IBJ Technology

Colkwitzer Weg 7

04416 Markkleeberg

Tel.:+49(0)3413380172

Fax:+49(0)3413380449

info@ibj-technology.de

http://www.ibj-technology.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release ULTRASONIC PUMP PROTECTION FOR ALL LIQUIDS AND MULTI-PHASE MIXTURES here

News-ID: 6061 • Views: …

More Releases from IBJ Technology

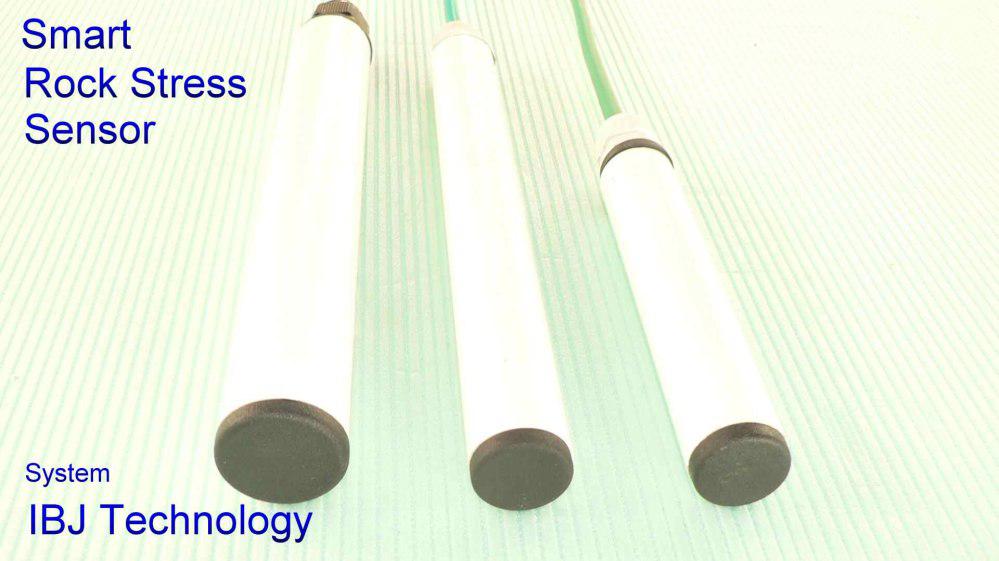

.Smart Rock Stress Sensor with MEMS

The RSS-X series of acousto elastic sensors from IBJ Techhnology is used to measure variations in compressive stress and load, which allows stress evaluation when the material’s modulus of elasticity is unknown or anisotropic and inhomogeneous. Typical examples are concretes and drill holes in the rocks, where these instruments can be used include:

• Mining

• Tunnel supports

• Deformations of pillars

• Dams and nuclear power plants

• Structural members of buildings and bridges

•…

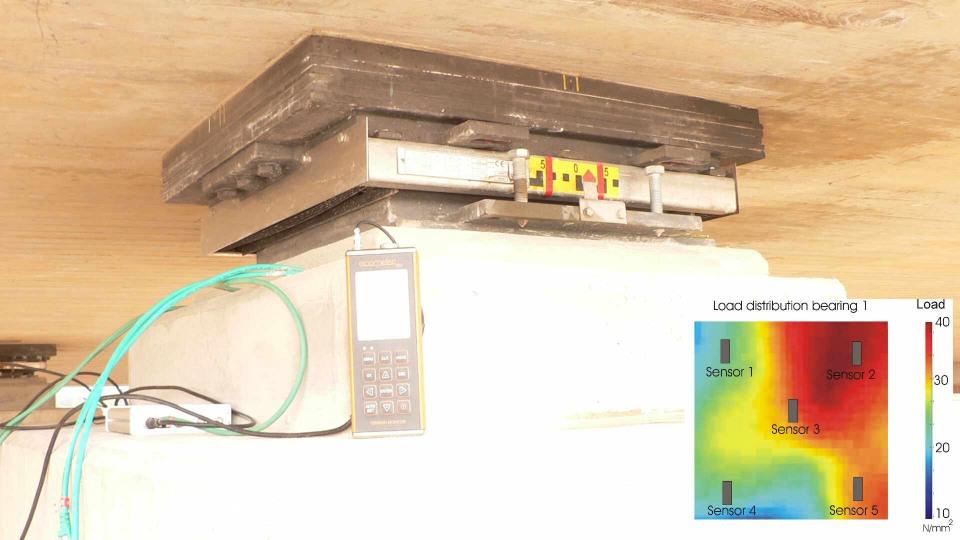

Smart Bridge - bridge bearings load control

The distribution can be determined of the load under bridge bearing load-bearing pillars or foundations with multiple sensors BBS 10_DS from IBJ technology. Uneven load entry can detect but also subsequently through still attached directly with sensors built into the bearing plate in the concrete.

The applications range from the direct voltage measurement in the component to the measurement and monitoring of dynamic loads in real time.

With the sensors is the…

Acousto-elastic concrete strain sensors for heavy duty applications

Acousto elastic concrete strain sensors are used to detect the metrological

Expansion or compression of steel building components as well as for measurements in reinforced and unreinforced concrete bodies used. The thickness of the susceptor (diameter of the bars) may be selected according to the strength reinforcement.

The acousto elastic concrete strain sensors can also be mounted on the outside parts of the structure of steel. With flanges or angle mounting is…

With high speed in the concrete

With the sensor BBS 10_DS from IBJ Technology, surface pressure in concrete components can be determined also afterwards. The applications range from the direct stress measurement in the component to the measurement and monitoring of dynamic loads in real time.

Ultrasonic captures the stress in the structure directly and in real time. All changes can be transferred online via the Internet or satellite radio. The sensors are either placed directly in…

More Releases for Dry

Rising Prevalence Of Dry Eye Conditions Boosts Growth In Dry Eye Products Market …

The Dry Eye Products Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Expected Dry Eye Products Market Size During the Forecast Period?

In recent years, there has been a significant expansion in the market size of dry eye products. The market is projected…

Dry Powder Inhalers Market - Breathe Freely: Dry Powder Inhalers Empowering Asth …

Newark, New Castle, USA: The "Dry Powder Inhalers Market" provides a value chain analysis of revenue for the anticipated period from 2023 to 2031. The report will include a full and comprehensive analysis of the business operations of all market leaders in this industry, as well as their in-depth market research, historical market development, and information about their market competitors.

Dry Powder Inhalers Market: https://www.growthplusreports.com/report/dry-powder-inhalers-market/8762

This latest report researches the industry structure,…

Dry Eye Market - Advancing Eye Wellness: Dry Eye Solutions Revolutionizing Relie …

Newark, New Castle, USA - new report, titled Dry Eye Market The report has been put together using primary and secondary research methodologies, which offer an accurate and precise understanding of the Dry Eye market. Analysts have used a top-down and bottom-up approach to evaluate the segments and provide a fair assessment of their impact on the global Dry Eye market. The report offers an overview of the market, which…

Dry Lubricants Market Size to Hit $ 813.78 Million by 2028 | Dry Lubricants Indu …

According to our experience research team, Dry Lubricants Market was valued at USD 755.42 Million in 2021, and the global Dry Lubricants industry is projected to reach a value of USD 813.78 Million by 2028, at a CAGR of 1.2% during the forecast period 2022-2028

The report is focused on gaining various Dry Lubricants market trends, dynamics, growth drivers, opportunities, weaknesses, strengths, and threats restraining the market growth. Further, the global…

Dry Ice Market In-Depth Analysis | Key Participants Dry Ice Corp., Dry Ice UK Lt …

Demand for dry ice is expected to magnify with the development of dry ice machines industry across the globe. Manufacturers in large multinational organizations and private firms have been contributing prominently in the revenue growth of dry ice market. Dry ice being a cost-effective product is expected to bolster its demand across various applications in the near future. Rising number of fire accidents leads to increasing demand for dry ice,…

Dry Screw Vacuum Pumps

Swam Dry vacuum pumps are the latest development in the vacuum pump industry. They offer a number of advantages over traditional vacuum pump designs. Best process gas blowers. There is “NO OIL / NO WATER” contact with the process vapours, which is why they are considered extremely environmentally friendly.

Visit us for more info - http://swamatics.com/ProductDetails.aspx?prod=Process%20Gas%20Blowers/Gas%20Boosters

The definition of a dry vacuum pump is a pump that does not use any…