Press release

SABIC Innovative Plastics’ Exatec** Team Opens Window to New World of Light Weight Auto Glazing

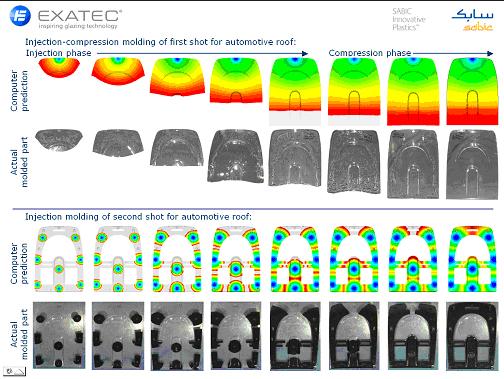

SABIC Innovative Plastics’ Exatec** Team Opens Window to New World of Light Weight Auto Glazing with Unique Injection-Compression Molding SimulationBERGEN OP ZOOM, The Netherlands – August 27, 2008 — With the latest advances in design and aerodynamics and the increasing use of lightweight materials for improved fuel efficiency, the use of transparent polycarbonate (PC) window surfaces is expected to increase in the years to come. In response to this development, two-component injection-compression molding means lower stress and higher optical quality in PC auto glazing. Now, SABIC Innovative Plastics’ Exatec** team has created a new and unique CAE method to model the 2K ICM process. Using a prototype roof, computer-predicted results have been correlated with real-life trials of the injection-compression molding process. With new software tools that can accurately predict the molding process and the special support only available from SABIC Innovative Plastics’ Exatec team, designers will be able to achieve clearly superior lightweight glazing with Lexan* polycarbonate with both wet and plasma coats.

# # #

* Lexan is a trademark of SABIC Innovative Plastics IP BV

** Exatec is a trademark of Exatec, LLC

SABIC Innovative Plastics Media Contacts

Global

Anne Clement

SABIC Innovative Plastics,

Automotive

Bergen op Zoom, The Netherlands

Tel: +31 164 29 3148

E-Mail: anne.clement@sabic-ip.com

Agency Media Contacts

The Americas

Jim Allison

AH&M Marketing Communications,

Pittsfield, Mass.

Tel: +1 413 448 2260, Ext. 25

E-Mail: jallison@ahminc.com

Brazil

Gabriela Bruschi

Edelman Brazil, Sao Paulo, Brazil

Tel: 55 11 3017 5300, x221

E-Mail: gabriela.bruschi@edelman.com

Europe

Tessa Vroegop

Marketing Solutions, Bergen op Zoom,

The Netherlands

Tel: +31 164 317 013

E-Mail: tvroegop@marketingsolutions.be

Japan

Mitsu Sugino

Tokyo PR Inc., Tokyo, Japan

Tel: +81 332 732 731

E-Mail: sugino@tokyopr.co.jp

China

Shona Liu

Edelman, Shanghai, China

Tel: +86 21 6289 2929 x470

E-Mail: shona.liu@edelman.com

About SABIC Innovative Plastics

SABIC Innovative Plastics is a leading, global supplier of engineering thermoplastics with a 75-year history of breakthrough solutions that solve its customers’ most pressing challenges. Today, SABIC Innovative Plastics is a multi-billion-dollar company with operations in more than 25 countries and over 10,500 employees worldwide. The company continues to lead the plastics industry with customer collaboration and continued investments in new polymer technologies, global application development, process technologies, and environmentally responsible solutions that serve diverse markets such as automotive, electronics, building & construction, transportation, and healthcare. The company’s extensive product portfolio includes thermoplastic resins, coatings, specialty compounds, film, and sheet. SABIC Innovative Plastics (www.sabic-ip.com) is a wholly owned subsidiary of Saudi Basic Industries Corporation (SABIC), one of the world’s top five petrochemicals manufacturers.

# # #

* Trademarks of SABIC Innovative Plastics IP BV.

Media Note: The proper name of the company is SABIC Innovative Plastics, and excludes any abbreviations or variations when referring to the company. As an acronym, SABIC should be all caps whenever it appears in print.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SABIC Innovative Plastics’ Exatec** Team Opens Window to New World of Light Weight Auto Glazing here

News-ID: 52105 • Views: …

More Releases from SABIC Innovative Plastics

SABIC Launches Portfolio of Antimicrobial Compounds at MD&M West to Help Custome …

According to a 2011 report by the World Health Organization, in 2002 in the United States alone approximately 99,000 deaths were linked to healthcare associated infections (HCAIs).1 Here at MD&M West (booth #1701), SABIC’s Innovative Plastics business today introduced powerful new tools to help medical device manufacturers reduce HCAIs among patients and clinicians. SABIC’s nine new antimicrobial compounds featuring silver technology have been tested for log reduction values – the…

SABIC’s 3D-Formed LEXAN™ Sheet Increases Visibility, Safety, Comfort and Per …

Operators of logging equipment require exceptional visibility and protection against debris or large objects that may enter their cabin and cause serious injury in forest environments, such as tree limbs and other machinery parts. So when Rottne Industry AB needed a high-performance glazing material for the windshields and windows of its harvesters and forwarders, it turned to

SABIC’s Innovative Plastics business for support. Working with SABIC and its distributer, Vink…

Mitsubishi Motors Corporation Selects SABIC NORYL GTX™ Resin for 2013 Outlande …

SABIC’s Innovative Plastics business today announced that Mitsubishi Motors Corporation (MMC) has chosen SABIC’s next-generation NORYL GTX™ 989 resin for the front fenders of its 2013 Outlander Sport crossover. The vehicle’s fenders are the first to be produced using 2-cavity injection molding with NORYL GTX resin, allowing MMC to cut cycle times in half and reduce tooling costs. Other major benefits of the SABIC material include weight savings vs. steel…

SABIC Makes a Splash at Fakuma with New NORYL™ Resin, Meeting Tightening Globa …

Here at the Fakuma trade fair, booth #B5-5506, SABIC’s Innovative Plastics business today announced a new NORYL™ resin that not only complies with current European and global sustainability regulations governing materials used in potable water systems, but also with new, tougher regulations slated to go into effect in 2016. Developed at SABIC’s Fluid Engineering Center of Excellence in the Netherlands, NORYL FE1630PW resin is a 30-percent glass-reinforced polyphenylene ether (PPE)…

More Releases for Exatec

Lightweight Materials Market: Things to Focus on to Ensure Long-term Success | S …

This research study presents a comprehensive compilation of insightful findings concerning key aspects of the global Lightweight Materials industry, impacting its growth trajectory over the forecast period from 2023 to 2029. The report sheds light on the evolving sales trends of various tech products across different regions and countries, highlighting both growth and decline. A detailed regional analysis is a crucial part of this Lightweight Materials report, offering a meticulous…

SABIC and ULVAC Announce Availability of New ULGLAZE System for High-volume Plas …

SABIC’s Innovative Plastics business, a world leader in engineering thermoplastics and advanced material solutions, and ULVAC, Inc., a leader in mass-production vacuum technologies, today announced the commercial availability of the new, state-of-the-art ULGLAZE system for high-volume production of plasma-coated polycarbonate (PC) components for automotive glazing applications. The ULGLAZE machine is manufactured at ULVAC’s facility in Chiagasaki, Japan and was developed as part of a two-year collaboration between SABIC and ULVAC.…

New Research by SABIC Innovative Plastics Underscores Importance of Lexan* PC Au …

BERGEN OP ZOOM, The Netherlands – May 10, 2011 – At the VDI conference

SABIC Innovative Plastics has announced compelling new findings on the benefits of Lexan* polycarbonate (PC) glazing. Lexan PC automotive glazing has already established itself as a weight reducing technology that can result in lower fuel consumption and lower carbon dioxide emissions. Now, advanced computer analyses of the thermal insulation benefits of Lexan* PC automotive glazing have…

Exatec*, ULVAC Announce Technology Collaboration for Mass Production of Coating …

BERGEN OP ZOOM, The Netherlands – July 21, 2010 – Exatec*, a wholly owned subsidiary of SABIC Innovative Plastics, and ULVAC, a leader in mass-production vacuum technologies, today announced their collaboration to accelerate cost-effective, high-volume production of weatherable, scratch-resistant, plasma-coated Lexan* polycarbonate (PC) resin for vehicle windows. Under the agreement, ULVAC will manufacture turnkey mass production systems that leverage its’ expertise in high-volume vacuum equipment and Exatec’s proprietary plasma coating…

SABIC Innovative Plastics Announces Exatec* World-Class Capabilities for Leading …

BERGEN OP ZOOM, The Netherlands – June 17, 2010 – SABIC Innovative Plastics today announced new scratch and abrasion evaluation capabilities – including new methods and processes – to differentiate, measure, test and prevent surface damage to polycarbonate (PC) glazing for high-performance automotive glazing applications. The announcement underscores SABIC Innovative Plastics’ R&D excellence and illustrates how the company’s Exatec* glazing technology and analytical tools are helping automotive manufacturers succeed by…

3D Backlight of “ix-onic” Concept Highlights Newest Hyundai and SABIC Innova …

BERGEN OP ZOOM, The Netherlands – March 25, 2009 – Polycarbonate glazing has become an important tool for automakers to differentiate their vehicles. This technology offers greater design freedom, higher performance and lighter weight than traditional glass. To create a distinctive backlight for its new compact “ix-onic” SUV concept, recently on display at the 79th Salon International de L’Automobile, Hyundai Motor Company collaborated with SABIC Innovative Plastics to take advantage…