Press release

Industrial Production of Microholes by Usage of Ultrashort Pulse Lasers

The drilling of microholes with well-defined geometry is becoming increasingly important in various branches of industry. Applications range from injection nozzles (automotive) over cooling openings in turbine stator vanes (aerospace) and emitter-wrap through perforations (solar) to spinnerets required to adopt more and more complex shapes for the fabrication of functional fibres (textile industry).Besides electric discharge machining, being very successfully applied in many branches, laser processes are scrutinized and optimized for microhole fabrication due to its inherent, enormous flexibility for many years.

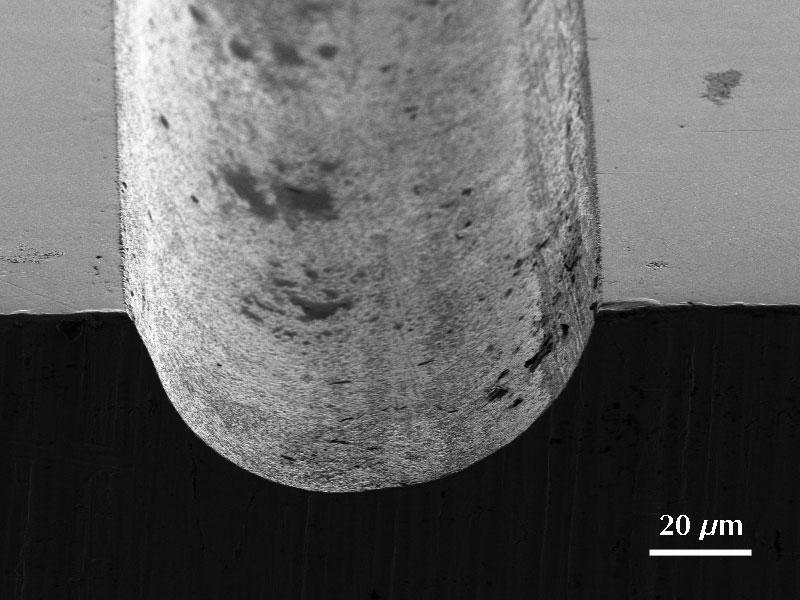

It turned out that many parameters must be very precisely controlled in order to enable the generation of holes of just several 10 µm diameter in materials of a few millimetre thickness. For example, copper-vapour lasers, the beam profile of which can be optimized very well to comply with a flat-top profile, can be deployed for the fabrication of holes possess-ing very good circularity and directrix quality. The manifold capabilities of laser micromachining, however, are not fully capitalized when just stationary laser beams are used (as in the case of percussion drilling).

In the current perspective, the greatest flexibility can be achieved by using the technically very sophisticated concept of drilling with a moved laser beam. Under the latter technology, trepanning as well as helical drilling are subsumed. Upon trepanning, the laser beam is moved along the surface of a cone with customizable opening angle and is in parallel accomplishing a circular movement with defined diameter on the surface of the work piece.

Helical drilling distinguishes itself by the fact that in addition to the toggling movement of the laser the laser beam is rotating about its axis of propagation. The latter feature helps eliminate imperfections of the beam profile and provides the capability of drilling holes at highest perfection. Helical drilling requires the utilisation of high-definition drilling heads, the core component of which is a hollow-shaft motor bearing an image rotator, e.g., a Dove prism, as well as adjustment modules for adapting the angle of laser impact and the diameter of the circle scribed on the work piece.

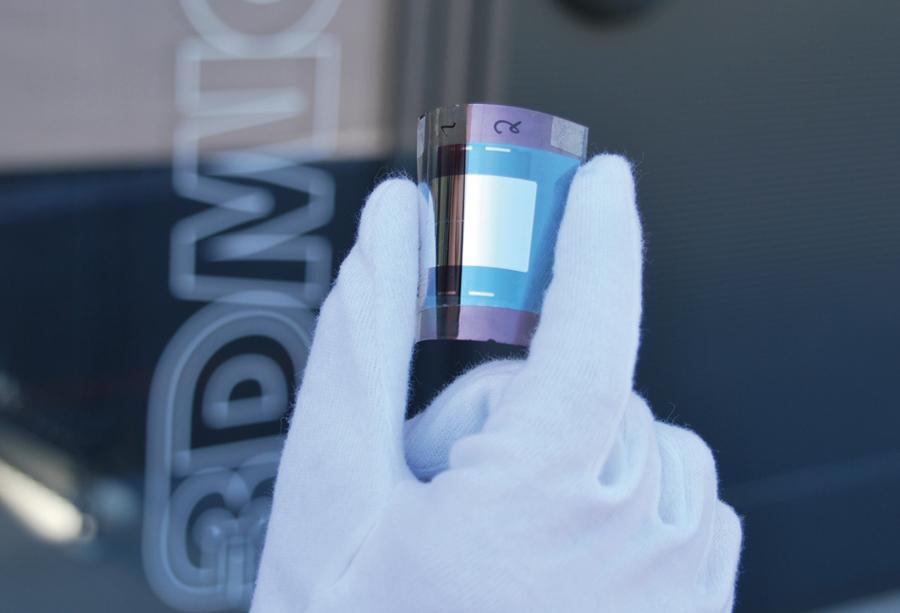

For the first time 3D-Micromac AG has combined helical drilling technology with ultrashort pulses (ps laser) in industrial applications. The highest quality of achieved machining results is already now becoming apparent that micromachining utilizing the combination of helical drilling and ultrashort pulses is going to become an integral part of industrial laser application.

Further information and pictures:

3D-Micromac AG

Mrs. Mandy Möckel

Marketing/ Sales

Annaberger Str. 240

D-09125 Chemnitz, GERMANY

Phone: +49 (0)371 400 43-0

Fax: +49 (0)371 400 43-40

E-Mail: info@3d-micromac.com

Web: http://www.3d-micromac.com

About 3D-Micromac AG

3D-Micromac AG, a leading supplier of customized laser micro machining systems, has gained an established position in the international market over the past several years.

As a developer and manufacturer of complex workstations, as a service provider for materials and surface machining or as a solution provider for the development of specific production processes - we are able to find the best solution for every customer’s task.

More: http://www.3d-micromac.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industrial Production of Microholes by Usage of Ultrashort Pulse Lasers here

News-ID: 46867 • Views: …

More Releases from 3D-Micromac AG

Increase in efficiency for thin-film solar modules: 3D-Micromac launches an inno …

Chemnitz, 03 June 2013. This June, 3D-Micromac from Chemnitz (Germany) will launch the first production equipment worldwide that can conduct the integrated series-connection of a thin-film solar module on one single platform and in one single production step. The new One-Stop-Patterning process (OSP) only structures the modules once all of the functional layers have been deposited on the substrate. This significantly simplifies the production process. In addition, the new…

3D-Micromac receives „Green Photonics Award 2011“

SPIE honors research in the field of organic photovoltaics

On January 26, 2011 3D-Micromac was honored with the “SPIE 2011 Green Photonics Award”. Tino Petsch, CEO of 3D-Micromac received the prize for the scientific publication “Laser processing of organic solar cells in a roll-to-roll manufacturing process” at the “Photonics West” in San Francisco. With this award, SPIE pays tribute to the outstanding research work of the company in the field of…

ISL 2010 - International Symposium on Laser-Micromachining at 3D-Micromac taking …

Experts in the field of laser micromachining meet at ISL 2010 in Chemnitz, Germany for the third time

Following the success of the ISL 2008 – 2nd International Symposium on Laser-Micromachining taken place in Chemnitz, Germany and ISL 2009 Asia held in HongKong, China, we are pleased to announce the ISL 2010 – 3rd International Symposium on Laser-Micromachining which will take place in Chemnitz, Germany on 27th – 28th October,…

ISL 2008 - 2nd International Symposium on Laser-Micromachining at 3D-Micromac AG

Experts in the field of laser micromachining meet at ISL 2008 in Chemnitz, Germany at second time

In the last years laser technologies not only confirmed their outstanding role for micro-machining but expanded it impressively. With enhancements in the areas of shorter pulses and shorter wavelengths there are growing possibilities to generate micro structures in all manufacturing sectors.

Applications related to practice and latest trends will be presented by laser manufacturers and…

More Releases for Hole

Global Post Hole Borer Market Size by Application, Type, and Geography: Forecast …

According to Market Research Intellect, the global Post Hole Borer market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The Post Hole Borer Market is experiencing stable growth, fueled by increasing demand in agriculture, construction, and…

Hole Shoes Market: Increasing Fashion Consciousness and Demand for Unique Footwe …

Global Hole Shoes Market Overview:

The Hole Shoes market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Hole Shoes market has experienced significant growth, driven by factors such as increasing consumer demand, technological advancements, and globalization. This growth has created both…

Sand Control Systems Market By Applications (Onshore, Offshore) and By Well Type …

Whipsmartmi.com offers "Global Sand Control Systems Market 2021-2027" from its research database.

Increasing oil and gas production, high day rates for offshore rigs, increased drilling activities in the Asia Pacific region, ease of gas drilling and production, and an increase in the number of wells are the major drivers for market growth. Gravel pack, frac pack, sand screens, inflow control units, and others are separated by technique. Other options include…

Fully automatic deep hole drilling

TBT loading system allows unmanned shifts

Along with other precision machined components, GLUMANN Maschinenbau in Chemnitz, Germany specialises in producing long rotating shaft type parts. Deep Hole Drilling plays an important role the production of these items and so in order to keep up with the growing volume demands from an engineering customer, the contract manufacturer (GLUMANN) decided to equip their new Deep Hole Drilling Machine from TBT with a fully…

Diamond Hole Saw Market Projected to Witness a Single-Digit CAGR During 2018 to …

Diamond Hole Saw Market: Introduction

Diamond hole saw is a type of power cutting tool which is used for drilling circular holes in various applications such as glass, cement board, and ceramic tiles, among others. Diamond hole saw is available in different type of sizes according to respective end use applications. Diamond hole saws have different type of cutting edges such as vacuum brazed, electroplated, among others. Diamond hole saw are…

Deep Hole Drilling Service Market Is Booming Worldwide | HOLE SPECIALISTS, Carls …

HTF MI recently introduced new title on “2018-2025 Deep Hole Drilling Service Report on Global and United States Market, Status and Forecast, by Players, Types and Applications” from its database. The report provides study with in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status to 2025. The Report gives you competition analysis of top manufacturer with sales volume, price, revenue (Million USD) and market…