Press release

Techsil Launch New Flexible Mould Making Silicones from Momentive

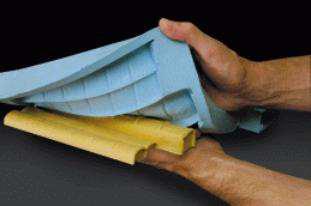

Flexible moulding is a very popular go-to system across many industries when faced with a part reproduction application. It is more cost effective than 3D Printing for small runs and a great alternative to solid mould processes such a liquid injection moulding or resin transfer moulding.The Rapid Prototyping Industry has adopted flexible moulding for a wide range of applications including automotive casting, aviation and consumer electronics. This process is also making an impact with large volume production tasks, architectural element production, and composite manufacturing and even with art reproduction and restoration projects.

UK based distributor Techsil is launching 3 new flexible mould making grades from Momentive Performance Materials, a global leader in silicones and advanced materials. These new products will join the already very popular RTV664, an addition cure silicone system that can be used in compliance with US FDA food grade regulations. Momentive’s comprehensive mould making range includes 21 addition and 8 condensation cure silicones for prototyping applications and making moulds for complex precision parts.

TSE3478T *NEW* - TSE3478T is a 2-part addition cure silicone; this oil bleed system is easy to degas, has a handy 10:1 mix ratio and works to standard cure conditions. The product cures to a translucent rubber with a tensile strength of 6.0MPa, hardness of 40 (Type A), 380% elongation and extremely low shrinkage.1

TSE3480T *NEW* - TSE3480T is a 2-part addition cure silicone; a non-oil bleed system that offers improved mould life. As with TSE3478T, this system has a handy 10:1 mix ratio and works to standard cure conditions. The product cures to a translucent rubber with a tensile strength of 6.0MPa, hardness of 37 (Type A), 380% elongation and extremely low shrinkage.1

RTV664 - RTV664 is a 2-part addition cure silicone; it is a non-oil bleed system with a high cured shore hardness and can be used in compliance with US FDA regulations. This product has a shorter work life and demould time at room temperature than the new materials, but which cannot be further shortened with the addition of heat. RTV664 cures to a 62 Shore A, light blue rubber with very good tensile strength (6.4 MPa), 245% elongation and very low linear shrinkage.1

RTV7888-20 *NEW* - RTV7888-20 is a 2-part condensation cure silicone; this non-oil bleed system is best suited for soft mould making. Again, it has a handy 10:1 mix ratio and works to standard cure conditions; however unlike TSE3478T & TSE3480T, RTV7888-20’s work life and demould time cannot be shortened with heat. The product cures to a soft 20 Shore A light pink rubber with a tensile strength of 3.4MPa, 350% elongation and low shrinkage.1

During controlled testing, the above Momentive flexible mould making silicones excelled in performance compared to other silicone offerings, providing a greater number of releases and showing better mould life.

Momentive flexible moulding silicones offer excellent transfer of pattern detail, a moderate to long mould life and extremely high casting temperature restrictions. These are features and benefits that are not typically seen in other flexible mould materials such as latex, polysulfide, and PVC – which generally do not tolerate exotherms higher than 65°C and have very short mould life.

Although the relative material cost of silicone for flexible mould making is high compared to latex and PVC, the increased economic costs of silicone can be offset by its performance attributes required for fine detail castings and productivity.

1 These typical properties are average data and are not to be used as or to develop specifications

About Techsil

Techsil are industrial suppliers of RTV silicones, adhesives, sealants, encapsulants, conformal coatings, tapes, casting and mould making materials to a wide range of manufacturing industries across Europe including Aerospace, Automotive, Medical, Electronics, Railway, Lighting and Rapid Prototyping.

Techsil’s success has led it to become the largest RTV silicone distribution partner in Europe for Momentive Performance Materials. Through good partnerships with our suppliers, we are able to offer a complete range of sealing and bonding solutions to include well-established product ranges and new, technologically advanced materials.

Techsil Ltd

34 Bidavon Industrial Estate

Waterloo Road

Bidford on Avon

Warks B50 4JN

technical@techsil.co.uk

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Techsil Launch New Flexible Mould Making Silicones from Momentive here

News-ID: 440311 • Views: …

More Releases from Techsil Ltd

New Techsil Catalogue Published - Adhesives, Sealants, Coatings, O-Rings & Tapes

UK based Techsil is a global distributor of industrial adhesives, sealants, encapsulants, coatings tapes, seals, o-rings and dispensing equipment. Supplying high performance materials to manufacturing industries such as electronics, aerospace, automotive, defence, lighting, packaging and medical devices; Techsil work together with customers and suppliers to deliver technical and application knowledge. They have been awarded A1 distributor status two years running from Momentive for going the extra mile.

Techsil has just published…

The Future is Orange - Techsil Launch New Biocompatible Plastics Adhesive which …

Adhesive specialists Techsil introduce a new orange, fluorescing, UV curing adhesive designed for bonding plastics. Manufactured by Panacol, Vitralit® 7311 FO is certified according to USP Class VI standards. A perfect adhesive for medical devices but it can also be used in electronics, optics and general assembly.

Vitralit® 7311 FO is a transparent acrylic adhesive that cures under UV or visible light. It offers very high bond strength to many…

Techsil Launch New Optically Clear Flexible Adhesive for Bonding Displays

Adhesive suppliers, Techsil have launched a new optically clear, low viscosity, UV curable adhesive into the UK market. Manufactured by Panacol, Vitralit® 50004 is a one-component acrylic adhesive so it requires no mixing. The adhesive has been designed to use for bonding display screens and laminating optics.

Vitralit® 50004 adheres to a variety of substrates including coated glass, PET and other plastics and films. Its low viscosity means that it can…

New Epoxy Potting Compound with Excellent Flow Properties

UK adhesive specialists Techsil have launched a new potting compound for electronics with medium viscosity and small filler particle size: Structalit® 5894-1 is the perfect choice for large-volume potting or glob top sealing of power electronics.

Structalit® 5894-1 is a black, one part epoxy resin which requires no mixing. The combination of optimised viscosity and the small particle size of its fillers means it flows well and makes an excellent electrical…

More Releases for Momentive

UV-Curable Fiber Optic Cable Coating Material Market | JSR, Momentive Performanc …

The global uv-curable fiber optic cable coating material market report is a comprehensive report that provides a detailed analysis of the current status and future trends of the uv-curable fiber optic cable coating material market worldwide. This report provides valuable information to industry stakeholders by offering an in-depth perspective on market dynamics, competitive landscape, growth opportunities, and key challenges faced by industry participants.

From the perspective of market dynamics, this report…

Electronic Silicone Rubber Market Size, Top Vendors, Industry Research and End U …

LOS ANGELES, United States: The research study presented in this report offers complete and intelligent analysis of the competition, segmentation, dynamics, and geographical advancement of the global Electronic Silicone Rubber market. It takes into account the CAGR, value, volume, revenue, production, consumption, sales, manufacturing cost, prices, and other key factors related to the global Electronic Silicone Rubber market. The authors of the report have segmented the global Electronic Silicone Rubber…

Global Quartz Glass Market 2019 - Heraeus, Tosoh, Momentive, QSIL

This new report by Eon Market Research, titled “Global Quartz Glass Market 2019 Research Report, 2015 – 2025” offers a comprehensive analysis of Quartz Glass industry at a global as well as regional and country level. Key facts analyzed in this report include the Quartz Glass market size by players, regions, product types and end industries, history data 2014-2018 and forecast data 2019-2025. This report primarily focuses on the study…

Quartz Glass Market 2017- Heraeus, Tosoh, Momentive

Marketreports.biz, recently published a detailed market research study focused on the "Quartz Glass Market" across the global, regional and country level. The report provides 360° analysis of "Quartz Glass Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Quartz Glass industry, and estimates the future trend of Quartz Glass market on…

Momentive appoints EMG to handle media relations

Bergen op Zoom, September 23, 2008 – Momentive Performance Materials, one of the world's largest producer of silicones and silicone derivatives, quartz and ceramics, has appointed EMG to manage their press relations activities in Europe, Middle East, India and Africa.

EMG, a leading international B2B marketing communications and media relations consultancy, was selected because of its specialization in media relations for the industrial and technology markets. Moreover, the company has a…

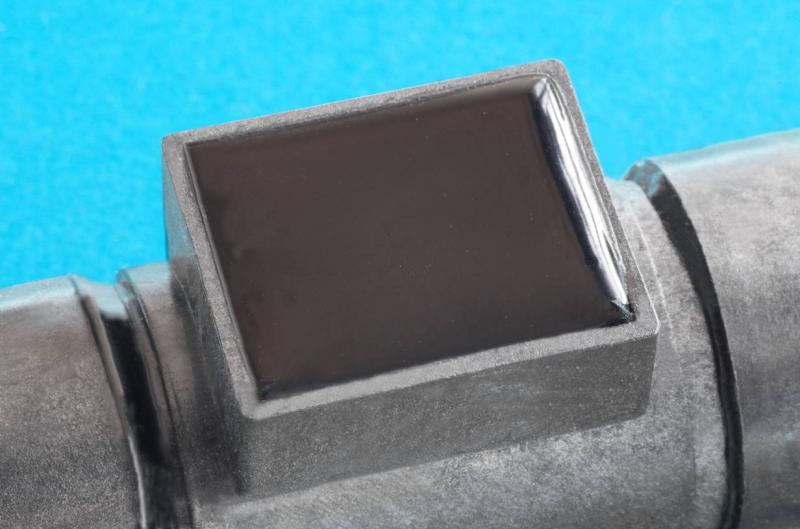

Crystal clear liquid silicone from Momentive Performance Materials

Crystal clear liquid silicone from Momentive Performance Materials enables top reproduction accuracy for camera-based driver assistance systems

LEVERKUSEN, GERMANY — AUGUST 25, 2008 - High transparency Liquid Silicone Rubber (LSR) from Momentive Performance Materials for use in camera-based driver assistance systems from KOSTAL. KOSTAL, the technology specialist for automotive electronics and mechatronics, introduces a compact front view camera which attaches to the windscreen. Its special construction combines functional and technical design…