Press release

Digital Twin Technology in Manufacturing Poised for Hypergrowth to USD 713.61 Billion by 2032, Led by IIoT Integration and Sustainability-Driven Process Optimization | Key Players - Siemens, GE Digital, PTC

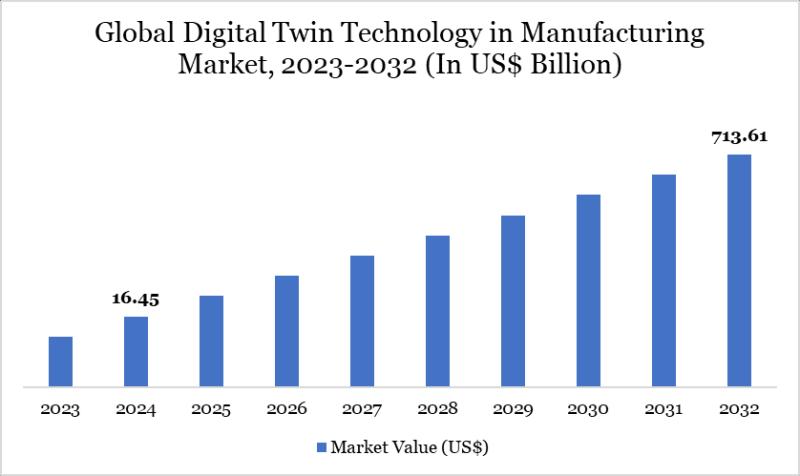

Global Digital Twin Technology in Manufacturing Market reached US$ 16.45 billion in 2024 and is expected to reach US$ 713.61 billion by 2032, growing with a CAGR of 60.20% during the forecast period 2025-2032.Market is primarily driven by the rapid acceleration of Industry 4.0 initiatives and the increasing adoption of smart manufacturing practices across developed and emerging economies. Manufacturers are leveraging digital twin technology to create real-time virtual replicas of physical assets, production lines, and entire facilities to enhance operational visibility, predictive maintenance, and process optimization. The growing demand for cost reduction, minimized downtime, and improved production efficiency is pushing companies to integrate advanced simulation and modeling tools into their manufacturing ecosystems. Additionally, the surge in adoption of Industrial Internet of Things (IIoT) devices and connected sensors enables continuous data flow from machinery to digital twin platforms, allowing manufacturers to detect anomalies, forecast equipment failures, and improve asset lifecycle management. Rising investments in automation, robotics, and cloud-based platforms further strengthen market growth. Moreover, increasing pressure to achieve sustainability goals, reduce carbon emissions, and optimize energy consumption is encouraging manufacturers to deploy digital twins for resource optimization and environmental monitoring. The growing complexity of global supply chains and the need for resilient, data-driven decision-making also contribute significantly to the expansion of digital twin adoption in the manufacturing sector.Technological advancements in artificial intelligence (AI), machine learning (ML), big data analytics, cloud computing, and edge computing are significantly enhancing the capabilities and benefits of digital twin technology in manufacturing. Modern digital twin platforms now enable real-time simulation, advanced predictive analytics, and scenario-based modeling, empowering manufacturers to test process changes virtually before implementing them physically. AI-driven digital twins improve accuracy in forecasting equipment failures, optimizing maintenance schedules, and enhancing quality control by identifying production defects early in the cycle. The integration of 5G connectivity further strengthens data transmission speed and reliability, ensuring seamless synchronization between physical assets and their digital counterparts. Cloud-based deployment models provide scalability, flexibility, and reduced infrastructure costs, making digital twin solutions accessible to small and medium-sized manufacturers. Furthermore, advanced visualization technologies such as augmented reality (AR) and virtual reality (VR) allow engineers and plant managers to interact with digital replicas in immersive environments, improving training, remote collaboration, and operational planning. Collectively, these technological advancements enable faster product development cycles, improved asset performance, enhanced operational efficiency, and stronger competitive advantage, thereby accelerating the exponential growth trajectory of the digital twin technology market in manufacturing.

Get a Free Sample PDF Of This Report (Get Higher Priority for Corporate Email ID):- https://www.datamintelligence.com/download-sample/digital-twin-technology-in-manufacturing-market?prtk

Key Industry Developments

✅ November 2025: Siemens USA launched a digital twin platform for manufacturing, enabling real-time simulation, predictive maintenance, and process optimization across smart factories. The system enhances production efficiency and reduces downtime.

✅ October 2025: GE Digital introduced a cloud-based digital twin solution for industrial equipment, integrating IoT sensors, AI analytics, and predictive insights to improve operational performance. The platform supports manufacturers in reducing costs and improving quality.

✅ September 2025: PTC Inc. expanded its digital twin offerings with AR/VR-enabled visualization and simulation tools, enabling real-time monitoring and optimization of complex manufacturing processes. The system enhances decision-making and operational efficiency.

✅ June 2025: Chiyoda Corporation implemented Visionaize's V-Plant 3D digital twin solution at Mitsubishi Gas Chemical Company Inc.'s Niigata Plant. This platform manages plant operation data using 3D models, optimizing maintenance costs, boosting productivity, and improving worker safety.

✅ November 2025: Fujitsu developed multi-AI agent collaboration technology incorporating digital twin elements to optimize supply chains in manufacturing. The solution launched joint trials, enhancing efficiency in Japanese industrial processes.

✅ September 2025: Leading Japanese automotive manufacturers advanced digital twin implementations for vehicle design and production, simulating modifications without physical prototypes to accelerate development and improve quality.

Key Players

Siemens AG | Dassault Systèmes | Microsoft Corporation | Autodesk | Oracle Corporation | IBM | Altair Engineering | Hexagon AB

Buy Now & Unlock 360° Market Intelligence:https://www.datamintelligence.com/buy-now-page?report=digital-twin-technology-in-manufacturing-market?prtk

Market Drivers

• Acceleration of Industry 4.0 and Smart Manufacturing Initiatives: The global shift toward Industry 4.0 and connected factory ecosystems is propelling digital twin adoption, as manufacturers seek to integrate IoT, automation, and real-time data into production systems.

• Expansion of Predictive Maintenance Capabilities: Increasing demand for proactive equipment monitoring and predictive maintenance is driving manufacturers to deploy digital twins to predict failures, reduce unplanned downtime, and optimize asset life and maintenance costs.

• Integration of IoT, AI and Advanced Analytics: The convergence of connected devices, artificial intelligence, machine learning, and big data analytics enables real-time simulation, forecasting, and decision-making, enhancing process efficiency, quality, and responsiveness.

• Need for Process Optimization and Operational Efficiency: Manufacturers are increasingly using digital twins to simulate, analyze, and optimize workflows - improving throughput, resource utilization, and performance visibility across the production lifecycle.

• Growing Demand from Defense & Specialized Industrial Sectors: Increased demand for advanced simulation and optimization in defense and high-complexity manufacturing sectors is further stimulating digital twin deployment to improve design validation, logistics, and mission readiness.

Regional Insights

North America: Largest share at 39% of the digital twin manufacturing market, driven by high technology adoption, strong IoT integration, and advanced manufacturing infrastructure.

Europe: Holds about 27% market share, led by Germany, UK, and France with Industry 4.0 and sustainability-focused manufacturing initiatives.

Asia Pacific: Accounts for roughly 25% of the global market, with rapid industrial automation and smart factory transformation in China, Japan, South Korea, and India.

Latin America: Contributes around 6%, with increasing adoption in Brazil and Mexico for manufacturing and industrial monitoring pilots.

Middle East & Africa: Makes up about 10% of the market, supported by investments in energy, infrastructure, and smart city digital twin initiatives.

Speak to Our Analyst and Get Customization in the report as per your requirements: https://www.datamintelligence.com/customize/digital-twin-technology-in-manufacturing-market?prtk

Key Segments

By Type:

The market is segmented into product digital twins, process digital twins, and system digital twins. Product digital twins hold a significant share due to their extensive use in product design, simulation, and lifecycle management, enabling manufacturers to optimize performance before physical production. Process and system digital twins are rapidly growing as manufacturers increasingly adopt smart factory models to enhance operational efficiency, predictive maintenance, and production planning.

By Deployment Mode:

Based on deployment, the market is divided into on-premise and cloud-based solutions. Cloud-based deployment is witnessing faster growth due to scalability, lower upfront investment, real-time data accessibility, and easier integration with IoT and AI platforms. However, on-premise solutions remain relevant among large enterprises requiring high data security, customization, and regulatory compliance.

By Enterprise Size:

The segmentation includes large enterprises and small & medium-sized enterprises (SMEs). Large enterprises dominate the market owing to higher capital investment capacity and early adoption of advanced manufacturing technologies. Meanwhile, SMEs are increasingly adopting digital twin solutions as cloud-based and subscription models reduce implementation costs and improve accessibility.

By Application:

Applications include product design and development, predictive maintenance, production planning, quality management, and supply chain optimization. Predictive maintenance and product design account for major adoption, as digital twins enable real-time monitoring, reduce downtime, and shorten product development cycles. Supply chain and quality management applications are also expanding with the rise of Industry 4.0 initiatives.

By End-User Industry:

Key end-user industries include automotive, aerospace & defense, electronics & electrical, industrial machinery, energy & utilities, and others. The automotive and aerospace sectors lead the market due to their strong focus on precision engineering, simulation, and lifecycle management. Electronics and industrial machinery sectors are also witnessing increasing integration of digital twin technology to enhance operational efficiency and reduce production errors.

Unlock 360° Market Intelligence with DataM Subscription Services: https://www.datamintelligence.com/reports-subscription

Power your decisions with real-time competitor tracking, strategic forecasts, and global investment insights all in one place.

✅ Competitive Landscape

✅ Sustainability Impact Analysis

✅ KOL / Stakeholder Insights

✅ Unmet Needs & Positioning, Pricing & Market Access Snapshots

✅ Market Volatility & Emerging Risks Analysis

✅ Quarterly Industry Report Updated

✅ Live Market & Pricing Trends

✅ Import-Export Data Monitoring

Have a look at our Subscription Dashboard: https://www.youtube.com/watch?v=x5oEiqEqTWg

Contact Us -

Company Name: DataM Intelligence

Contact Person: Sai Kiran

Email: Sai.k@datamintelligence.com

Phone: +1 877 441 4866

Website: https://www.datamintelligence.com

About Us -

DataM Intelligence is a Market Research and Consulting firm that provides end-to-end business solutions to organizations from Research to Consulting. We, at DataM Intelligence, leverage our top trademark trends, insights and developments to emancipate swift and astute solutions to clients like you. We encompass a multitude of syndicate reports and customized reports with a robust methodology.

Our research database features countless statistics and in-depth analyses across a wide range of 6300+ reports in 40+ domains creating business solutions for more than 200+ companies across 50+ countries; catering to the key business research needs that influence the growth trajectory of our vast clientele.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Digital Twin Technology in Manufacturing Poised for Hypergrowth to USD 713.61 Billion by 2032, Led by IIoT Integration and Sustainability-Driven Process Optimization | Key Players - Siemens, GE Digital, PTC here

News-ID: 4395065 • Views: …

More Releases from DataM intelligence 4 Market Research LLP

Operational Technology Market Poised for Rapid Growth to USD 364.74 Billion by 2 …

Global Operational Technology (OT) Market size was valued at USD 210.06 billion in 2024 and is projected to grow to USD 364.74 billion by 2030, expanding at a strong CAGR of 9.6% from 2025 to 2031.Market is witnessing significant growth, driven primarily by the increasing adoption of smart manufacturing and industrial automation across various sectors. Rising demand for real-time monitoring, predictive maintenance, and enhanced operational efficiency is fueling investments in…

Deception Technology Market Set for Strong Growth to USD 5.7 Billion by 2030, Le …

The Global Deception Technology Market reached US$ 2.4 billion in 2024 and is expected to reach US$ 5.7 billion by 2030, growing with a CAGR of 12.1% during the forecast period 2025-2030. Market is witnessing robust growth, driven primarily by the increasing frequency and sophistication of cyberattacks across enterprises. Organizations are under pressure to strengthen their cybersecurity infrastructure, making proactive threat detection tools such as deception technology highly attractive. Rising…

United States Agricultural Commodity Market to Grow US$ 11,201.04 billion by 203 …

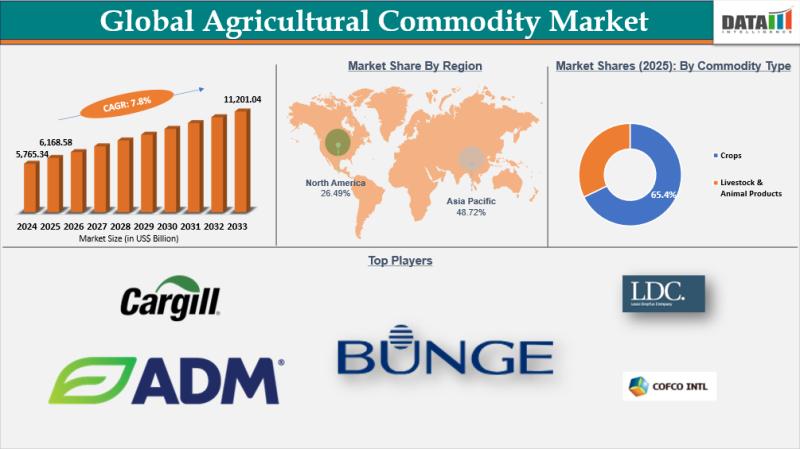

Market Size and Growth

agricultural commodity market reached US$ 5,765.34 billion in 2024, rising to US$ 6,168.58 billion in 2025 and is expected to reach US$ 11,201.04 billion by 2033, growing at a strong CAGR of 7.8% during the forecast period from 2026 to 2033.

In 2025, the Asia-Pacific region led the global agricultural commodity market, capturing a 48.72% revenue share, fueled by its large population, robust food demand, extensive agricultural infrastructure,…

Astaxanthin Market to Grow US$ 3.47 Billion by 2033 | Growth Drivers, Trends & M …

Market Size and Growth

astaxanthin market was valued at US$ 1.61 Billion. The global Astaxanthin market size reached US$ 1.73 Billion in 2024 and is expected to reach US$ 3.47 Billion by 2033, growing at a CAGR of 8.1% during the forecast period 2025-2033.

Download Free Sample PDF Report (Get Higher Priority for Corporate Email ID):- https://datamintelligence.com/download-sample/astaxanthin-market?kb

astaxanthin a powerhouse antioxidant that's not just a pretty face in nature but a rising star…

More Releases for Industry

Hydro Lubricants Market Size, Analysis, and Forecast Report 2018 to 2026(By Indu …

The rising demand for hydro lubricants from manufacturing sector is also multiplying at a faster rate, on the back of their competency in upgrading the service-life of machinery. The hydro lubricants market is primarily driven on account of its low-friction attributes, which makes it highly likely to outshine the synthetic variants. Moreover, the demand for hydro lubricants for machinery assemblies is on the rise, as they facilitate in minimizing…

Hydro Lubricants Market Insights, Trends & Future Development Status Recorded du …

The rising demand for hydro lubricants from manufacturing sector is also multiplying at a faster rate, on the back of their competency in upgrading the service-life of machinery. The hydro lubricants market is primarily driven on account of its low-friction attributes, which makes it highly likely to outshine the synthetic variants. Moreover, the demand for hydro lubricants for machinery assemblies is on the rise, as they facilitate in minimizing…

Global Pyrite Market 2019 | Applications: Jewelry Industry, Sulfur Compounds Ind …

The major factor driving the pyrite market is the rising demand of jewelry and sulfur compounds market. This report researches the worldwide Pyrite market size (value, capacity, production, and consumption) in key regions like North America, Europe, Asia Pacific (China, Japan) and other regions. This study categorizes the global Pyrite breakdown data by manufacturers, region, type, and application, also analyzes the market status, market share, growth rate, future trends, market…

Lipase Enzymes Market Future Forecast Indicates Impressive Growth Rate (Segmenta …

Market Outlook

Increased consumption of processed food and dairy products among consumers has fuelled the demand and supply of lipase enzymes over the years. Lipase is an enzyme that catalyzes the hydrolytic reaction of fats, and reduces the formation of glycerol and fatty acids in all living organisms. It plays a vital role in the process of digestion by transporting and processing the ester bonds in triglycerides. Due to the varied…

Big Bag Connection System Market Segmented By technology Automatic, Semi-Automat …

Global Big Bag Connection System Market: An Overview

The key advancement in automation encourages manufacturers to adopt smart systems to increase productivity and to facilitate timely production. Owing to the perception of consumers as well as manufacturers regarding health and hygiene of product, the big bag connection system market is anticipated to propel during the forecast period. Big bag connection system ensure dust -free docking of big bags and provide flexibility…

Europe Plastic Pallet Market Size, Shares, Forecast Report 2016 : Food Industry, …

This report studies sales (consumption) of Plastic Pallet in Europe market, especially in Germany, UK, France, Russia, Italy, Benelux and Spain, focuses on top players in these countries, with sales, price, revenue and market share for each player in these Countries, covering

ShangHai Pallet Plastic Industry Co., Ltd.

Shanghai Lika Plastic Manufacturing Co., Ltd.

Guangzhou Plastic Industrial Corporation Ltd

Shandong Liyang Plastic Molding Co.,Ltd

Xinding Plastic

ZheJiang Primacy Plastic Industry Co., Ltd

Shanghai Qinghao Plastic Pallet Manufacture…