Press release

Capacitor Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Project Cost

The global capacitor manufacturing industry is witnessing robust growth driven by its increasing consumption in pulp and paper bleaching, rising demand for eco-friendly oxidation agents in chemical processing, and expanding use in healthcare and sanitation applications. At the heart of this expansion lies a critical industrial chemical-capacitor. As industries transition toward environmentally preferred oxidizing agents and sustainable manufacturing practices, establishing a capacitor manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and chemical investors seeking to capitalize on this growing and essential market.IMARC Group's report, "Capacitor Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The capacitor manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for Sample Report: https://www.imarcgroup.com/capacitor-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global capacitor market demonstrates strong growth trajectory, valued at USD 26.70 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 44.69 Billion by 2034, exhibiting a robust CAGR of 5.89% from 2026 to 2034. This sustained expansion is driven by increasing consumption in pulp and paper bleaching, rising demand for eco-friendly oxidation agents in chemical processing, expanding healthcare and sanitation applications, and growing adoption of chlorine-free bleaching technologies across developing economies.

Hydrogen peroxide, identified by its chemical formula H2O2, is one of the most powerful oxidizing agents and has been used as the mainstay of chemical reactions. Apart from being a highly reactive and powerful agent, it is also a clear and colorless liquid that can be used in various ways as an industrial chemical intermediate, a bleaching agent, and even sometimes as a disinfectant. The anthraquinone auto-oxidation process is the most common way to produce capacitor which results in the production of aqueous solutions of varying concentrations as the final product. Hydrogen peroxide is regarded as non-toxic and thus replacing chlorine-based oxidizers as it converts to water and oxygen. It is an unstable compound, it is graded into technical, food grade, and pharmaceutical grades based on purity and stabilization requirements.

The capacitor market is mainly influenced by the rise in demand for chemical solutions that are eco-friendly and the adoption of sustainable industrial practices. The pulp and paper industry continues to be the largest capacitor consumer as manufacturers are gradually moving away from the use of chlorine-based bleaching agents. Chemical manufacturing is also contributing to this growth, as capacitor is mostly used as an oxidant in the synthesis of specialty and fine chemicals. Besides, the growing awareness of hygiene and infection control in the healthcare and sanitation sectors, especially in emerging markets, is driving demand from these sectors. Furthermore, the restructuring of operations by major chemical manufacturers reflects that the industry is trying to adapt to supply chain changes and changing market priorities.

Plant Capacity and Production Scale

The proposed capacitor manufacturing facility is designed with an annual production capacity ranging between 50,000-100,000 MT per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from pulp and paper to chemical manufacturing, healthcare, and textiles-ensuring steady demand and consistent revenue streams across multiple industry verticals.

Financial Viability and Profitability Analysis

The capacitor manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 35-40%

• Net Profit Margins: 15-20%

These margins are supported by stable demand across industrial sectors, value-added specialty chemical positioning, and the critical nature of capacitor in bleaching and oxidation applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established chemical manufacturers looking to diversify their product portfolio in the industrial chemicals sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a capacitor manufacturing plant is primarily driven by:

• Raw Materials: 60-70% of total OpEx

• Utilities: 10-15% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with hydrogen being the primary input material along with oxygen, anthraquinone, solvents, and hydrogenation catalysts. Establishing long-term contracts with reliable hydrogen and chemical suppliers helps mitigate price volatility and ensures consistent raw material supply, which is critical given that hydrogen price fluctuations represent the most significant cost factor in capacitor manufacturing.

Capital Investment Requirements

Setting up a capacitor manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to hydrogen, oxygen, and chemical suppliers. Proximity to target markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized production equipment essential for manufacturing. Key machinery includes:

• Specialized reactors for chemical synthesis under controlled conditions

• Hydrogenation units for hydrogen processing and reaction

• Oxidation columns for conversion processes

• Extractors for product separation and purification

• Distillation systems for concentration and refining

• Storage tanks for raw materials and finished product

• Safety control systems for monitoring and emergency response

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should be optimized with separate areas for raw material storage, reaction zone, extraction unit, distillation section, quality control laboratory, finished goods warehouse, utility block, and administrative block.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Buy Now: https://www.imarcgroup.com/checkout?id=8741&method=2175

Major Applications and Market Segments

Hydrogen peroxide products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Pulp and Paper: Used as a chlorine-free bleaching agent that can improve the quality and brightness of the fibers while having a lesser impact on the environment.

Chemical Processing: Serves as a non-polluting oxidizing agent in the manufacture of organic and inorganic chemicals, specialty chemicals, and their precursors.

Healthcare and Sanitation: Used for cleaning wounds, disinfecting surfaces, and sterilization due to its antimicrobial effects and decomposition that leaves no residue.

Textiles: Used in the bleaching and finishing of fabrics to obtain a perfect white color without harming the fibers.

End-use industries include pulp and paper, chemical manufacturing, healthcare, textiles, and environmental applications, all of which contribute to sustained market demand.

Why Invest in Capacitor Manufacturing?

Several compelling factors make capacitor manufacturing an attractive investment opportunity:

Essential Industrial Chemical: Hydrogen peroxide is the necessary component for the processes of bleaching, oxidation, and disinfection in the pulp and paper industry, chemical processing, and healthcare. That is why it has become a regularly used commodity chemical with a constant demand for it.

Environmentally Preferred Product: As easy to decompose in water and oxygen, it causes capacitor to be a green alternative to chlorine-based chemicals which is, in turn, a sustainable practice in accordance with global environmental and regulatory trends.

Steady Demand from Core Industries: The growth of key sectors like paper packaging, specialty chemicals, and healthcare infrastructure is providing a steady and long-term consumption for capacitor manufacturers.

Policy and Sustainability Support: The strict environmental regulations regarding wastewater discharge and chlorine consumption are facilitating the transition of many industries to capacitor-based processes.

Regional Manufacturing Advantage: Establishing production facilities in the area minimizes the dangers linked to the transportation of hazardous materials and also guarantees the nearby located industrial clusters a constant supply of the product.

Diverse Application Portfolio: The versatility of capacitor across multiple industries-from paper bleaching to wound care-provides manufacturers with diversified revenue streams and reduced market concentration risk.

Manufacturing Process Excellence:

The capacitor manufacturing process involves several precision-controlled stages using the anthraquinone process:

Hydrogenation: Anthraquinone is hydrogenated in the presence of catalysts to form anthrahydroquinone

Oxidation: Anthrahydroquinone is oxidized with air or oxygen to produce capacitor and regenerate anthraquinone

Extraction: Hydrogen peroxide is extracted from the organic solution using water

Concentration: The aqueous solution is concentrated through distillation to achieve desired product specifications

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=8741&flag=C

Industry Leadership

The global capacitor industry is led by established chemical manufacturers with extensive production capabilities and diverse application portfolios. Key industry players include:

• Airedale Group

• Arkema S.A.

• Evonik Industries AG

• Mitsubishi Gas Chemical Company Inc.

• National Peroxide Limited

• Nouryon

• OCI COMPANY Ltd

• Solvay S.A.

• Taekwang Industrial Co., Ltd.

These companies serve diverse end-use sectors including pulp and paper, chemical manufacturing, healthcare, textiles, and environmental applications, demonstrating the broad market applicability of capacitor products.

Conclusion

The capacitor manufacturing sector presents a strategically positioned investment opportunity at the intersection of industrial chemicals, environmental sustainability, and diverse market applications. With favorable profit margins ranging from 25-35% gross profit and 15-20% net profit, strong market drivers including rising adoption of chlorine-free bleaching technologies, growing demand for eco-friendly oxidizing agents, expanding healthcare and sanitation applications, and supportive environmental policies promoting sustainable chemical processes, establishing a capacitor manufacturing plant offers significant potential for long-term business success and sustainable returns.

The combination of essential industrial chemical status, environmentally preferred positioning, steady demand from core industries, and diverse application portfolio creates an attractive value proposition for serious chemical investors committed to quality manufacturing and operational excellence.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: +1-201-971-6302

About IMARC Group:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Capacitor Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Project Cost here

News-ID: 4394003 • Views: …

More Releases from IMARC Group

Coco Peat Manufacturing Plant Cost 2026: Detailed Project Report & Profit Analys …

The global coco peat manufacturing industry represents a rapidly expanding segment of sustainable agriculture and horticulture, providing eco-friendly growing media solutions that address environmental concerns while supporting modern cultivation practices. Coco peat, also called coir pith, is a natural by-product derived from processing coconut husks. It consists of fine particles and fibers remaining after the extraction of coir fiber. Known for its excellent water retention, porosity, and aeration properties, coco…

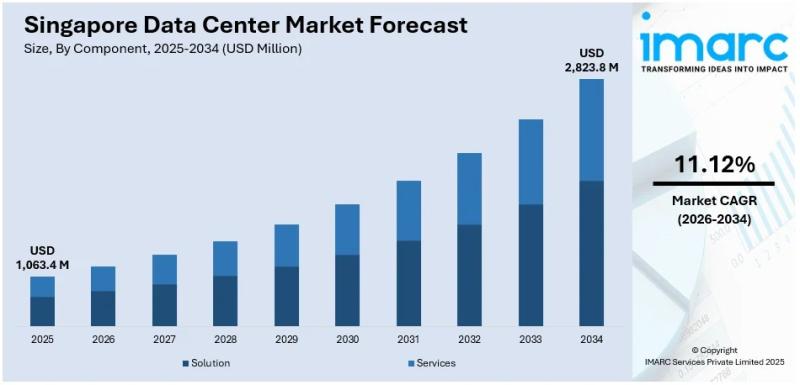

Singapore Data Center Market Size, Share, Trends, Industry Analysis, Growth & Fo …

Report ID: SR112026A23728 | Format: PDF + Excel | Verified by: IMARC Group

Market At-A-Glance: Key Statistics (2026-2034):

• Market Size (2025): USD 1,063.4 Million

• Forecast Value (2034): USD 2,823.8 Million

• Growth Rate (CAGR): 11.12% (2026-2034)

• Leading Component: Solution (65.8% Share)

• Key Trend: Green Data Centers & High-Density Computing

What is the Singapore Data Center Market Size, Share, Trends, and Growth Forecast (2026-2034)?

According to the latest analysis by IMARC Group, the Singapore data center market size reached USD…

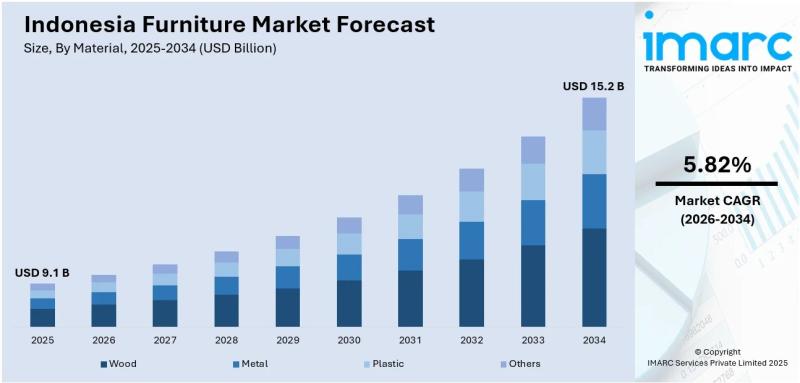

Indonesia Furniture Market to Reach USD 15.2 Billion by 2034: Growth Report

Report ID: SR112026A13864 | Format: PDF + Excel | Verified by: IMARC Group

Market At-A-Glance: Key Statistics (2026-2034):

• Market Size (2025): USD 9.1 Billion

• Forecast Value (2034): USD 15.2 Billion

• Growth Rate (CAGR): 5.82% (2026-2034)

• Leading Segment: Wood Furniture

• Key Trend: Eco-friendly & Multifunctional Designs

What is the Indonesia Furniture Market Size, Share, Trends, and Growth Forecast (2026-2034)?

According to the latest analysis by IMARC Group, the Indonesia furniture market size reached USD 9.1 Billion in 2025. Driven…

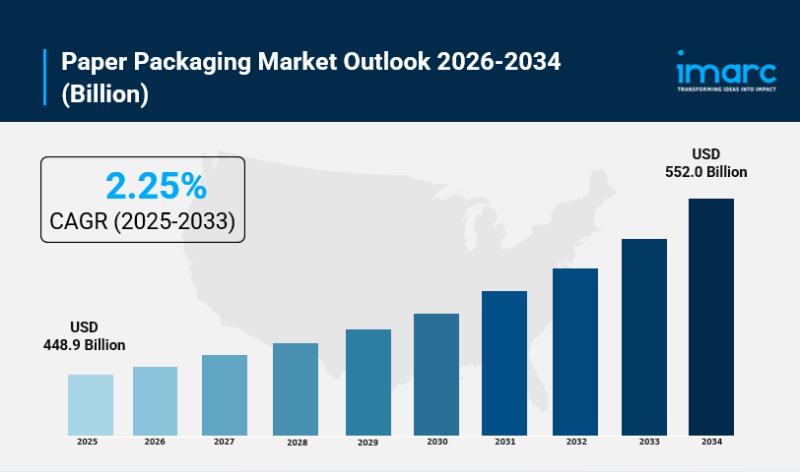

Paper Packaging Market Size, Trends, Key Players, Future Scope and Business Oppo …

IMARC Group, a leading market research company, has recently released a report titled "Paper Packaging Market Size, Share, Trends and Forecast by Product Type, Grade, Packaging Level, End Use Industry, and Region, 2026-2034." The study provides a detailed analysis of the industry, including the global paper packaging market size, trends, share and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Paper…

More Releases for Manufacturing

Manufacturing the Future: Exploring the In-Space Manufacturing Market

Rapid improvements in space technology have created new opportunities for in-space production, transforming the space sector. The in-space manufacturing sector is expanding rapidly as space agencies and private companies investigate ways to manufacture products and structures in space. According to MarketsandMarkets' thorough market research analysis, the worldwide in-space manufacturing market is predicted to expand significantly in the next years. In this blog article, we will evaluate the recent trends and…

Global Miscellaneous Market by Types (Gasket, Packing, and Sealing Device Manufa …

The global Miscellaneous market was valued at xx million in 2020 and is projected to reach US$ xx million by 2027, at a CAGR of xx% during the forecast period.

Global Miscellaneous Market overview

Miscellaneous Market research report offers great insights into the market and consumer data and their interpretation through various figures and graphs.

Miscellaneous markets have experienced significant growth in recent years. The main reason for this is the increasing…

Smart Factory Transforming from “Manufacturing” to “Intelligent Manufactur …

The concept of “Industry 4.0” was officially announced by the German government in 2013 at the Hannover Messe. Since then, its influence has taken the world by storm. From steam mechanization to power automation to data informatization, the Industry 4.0, driven by “intelligentization”, will completely subvert the expectations, changing perceptions of productivity and production relations in the traditional manufacturing industry by way of qualitative change – an immortal monument, perhaps,…

Additive & Conventional Manufacturing – Hybrid Manufacturing Techniques From C …

Croft Filters, based in Warrington, England, have been supplying custom filtration and separation solutions for over 31 years. Over this time, Croft has developed a reputation for their quality, bespoke service through manufacturing a variety of products for specific requirements. These products have included Filtration Cones, Baskets & Screens, Disc Filters and Filtration Housings amongst others, and they are made with Wire Mesh, Wedge Wire and Perforated Plate, depending on…

Digital Meter Market 2017 - Al-Jon Manufacturing, Environmental Manufacturing, H …

The Global Digital Meter Market 2017 Industry Research Report focused on global and regional market, major manufacturers, as well as the current state of the Digital Meter industry. First, "Global Digital Meter Industry 2017" report analyzed the basic scope of this industry like definition, specification, classification, application, industry policy, news analysis and Digital Meter industry chain structure.

Major Companies Covered in this report:-

Al-Jon Manufacturing

Heitman Laboratories

Kws Manufacturing Company

Kmb Systems

Obvius Holdingd Llc

Lubecorp Manufacturing

Quadlogic…

Competitive Segmentation of Global Mixed-mode Manufacturing Market 2016 Industry …

The market research report titled Mixed-mode Manufacturing Market Research Report 2016 provides a detailed overview of the global Mixed-mode Manufacturing market, in terms of crucial market factors such as the demand drivers, challenges, market segments, key companies, and the recent market trends. The quantitative and the qualitative information presented in this research study is based on primary and secondary sources of information. Moreover, much of the information contained in this…