Press release

Coco Peat Manufacturing Plant Cost 2026: Detailed Project Report & Profit Analysis

The global coco peat manufacturing industry represents a rapidly expanding segment of sustainable agriculture and horticulture, providing eco-friendly growing media solutions that address environmental concerns while supporting modern cultivation practices. Coco peat, also called coir pith, is a natural by-product derived from processing coconut husks. It consists of fine particles and fibers remaining after the extraction of coir fiber. Known for its excellent water retention, porosity, and aeration properties, coco peat improves soil structure and supports healthy plant growth. It is naturally biodegradable, renewable, and resistant to fungal and bacterial growth, making it an eco-friendly alternative to traditional growing media.Coco peat comes in multiple forms, like compressed blocks, briquettes, grow bags, and loose material, providing flexible options for diverse applications. Widely used in horticulture, agriculture, landscaping, and hydroponics, it provides an effective, sustainable solution for enhancing soil fertility, plant hydration, and root development. The market is primarily driven by rising adoption of sustainable agricultural practices, increasing demand for organic growing media, expanding horticulture and floriculture activities, and the growing popularity of soilless cultivation techniques. The manufacturing process encompasses coconut husk collection, washing, retting, drying, screening, grinding, compression, block/briquette formation, quality inspection, and packaging, transforming agricultural waste into valuable horticultural products supporting sustainable farming and gardening practices globally.

MARKET OVERVIEW AND GROWTH POTENTIAL

The global coco peat market demonstrates steady growth trajectory reflecting increasing adoption of sustainable agricultural practices and eco-friendly growing media solutions worldwide. The global coco peat market size was valued at USD 3.74 Billion in 2025, establishing a solid foundation supporting diverse horticultural and agricultural applications across multiple geographic regions. According to market projections, the market is expected to reach USD 5.37 Billion by 2034, exhibiting a CAGR of 4.1% from 2026 to 2034.

This consistent growth reflects multiple converging market drivers including rising awareness of sustainable farming techniques, expanding greenhouse and controlled environment agriculture, growing home gardening and urban farming trends, and increasing preference for peat moss alternatives addressing environmental concerns. The coco peat sector is on a path of gradual expansion, driven by awareness of eco-friendly techniques for agriculture and soil conservation. High-quality coco peat products are considered the main factor for strong demand, mainly used in greenhouses, urban gardening, and hydroponic cultivation which are all moving toward advanced and more sustainable agriculture. Industry reports reveal that nearly 55% of American families do some sort of gardening, amounting to roughly 71.5 million households engaged in gardening and about 185.9 million individuals.

The U.S. is one of the top three countries in the world when it comes to gardening participants. Through use of organic inputs, the government and agricultural sector are planning to cut down on chemical fertilizers use, contributing to market growth. Agitations against peat moss are making coco peat a favored, eco-friendly alternative. The huge amount of coconut husks in processing areas guarantees consistent raw materials supply, allowing production to be scaled up. Strong export markets, especially from countries with very little arable land and water resources, continue to propel international trade, and coco peat is being recognized as a crucial part of sustainable horticulture and agriculture worldwide.

IMARC Group's report, "Coco Peat Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The coco peat manufacturing plant cost report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

PLANT CAPACITY AND PRODUCTION SCALE

The proposed coco peat manufacturing facility is designed with an annual production capacity ranging between 10,000 - 20,000 MT, strategically positioned to achieve economies of scale while maintaining operational flexibility essential for serving diverse market segments and product formats. This capacity level enables efficient production supporting multiple applications including soil conditioning for agricultural land improvement, hydroponics for soilless farming systems, nursery planting for seedling propagation, greenhouse cultivation for controlled environment production, potting mixes for container gardening, seed germination for commercial propagation operations, and landscaping for soil enhancement projects. The production scale supports diverse product portfolios including compressed blocks for retail distribution, briquettes for convenient handling, grow bags for direct planting applications, and loose material for bulk customers serving professional growers and agricultural operations.

The facility's capacity structure enables optimization of production planning across seasonal demand variations, efficient raw material utilization through continuous processing of coconut husks, and flexibility to respond to market opportunities across agriculture, horticulture, floriculture, landscaping, greenhouse farming, and retail gardening sectors. This production volume positions the plant competitively within regional and potentially international markets, capable of fulfilling both large-scale supply contracts with greenhouse operators and horticultural distributors while maintaining ability to serve retail packaging requirements for home gardening markets and specialized applications requiring customized product specifications.

Request for a Sample Report: https://www.imarcgroup.com/coco-peat-manufacturing-plant-project-report/requestsample

FINANCIAL VIABILITY AND PROFITABILITY ANALYSIS

The coco peat manufacturing project demonstrates exceptionally healthy profitability potential under normal operating conditions, supported by favorable cost structures, strong demand dynamics, and value-added processing transforming agricultural waste into premium horticultural products. Gross profit margins typically range between 35-45%, reflecting efficient processing operations utilizing low-cost agricultural by-products, value addition through processing and compression, and premium pricing for sustainable eco-friendly growing media serving quality-conscious horticultural and agricultural markets. The project achieves net profit margins within the 15-20% range, indicating remarkably strong operational efficiency and controlled cost management throughout the production cycle while maintaining competitive pricing structures serving diverse customer segments from commercial greenhouse operators to retail gardening consumers.

These profitability metrics showcase the business's exceptional revenue generation capabilities and highly attractive investment returns for stakeholders participating in the sustainable agriculture supply chain converting coconut processing waste into valuable horticultural inputs. The financial projections have been developed based on realistic assumptions related to capital investment requirements, operating cost structures dominated by raw material procurement and processing utilities, production capacity utilization rates, pricing trends across agricultural and horticultural market segments, and comprehensive demand outlook assessments considering sustainable farming adoption, greenhouse expansion, and urban gardening growth trajectories. These projections provide stakeholders with a comprehensive view of the project's financial viability, return on investment (ROI) potential, profitability trajectories, and long-term sustainability prospects. The analysis encompasses detailed break-even calculations, net present value (NPV) assessments, and internal rate of return (IRR) projections that validate the investment's financial attractiveness across various market scenarios and agricultural commodity cycles.

OPERATING COST STRUCTURE

The operating cost structure of a coco peat manufacturing plant reflects the processing-intensive nature of transforming coconut husks into finished horticultural products through washing, drying, grinding, and compression operations. Raw materials constitute approximately 50-60% of total operating expenses (OpEx), with coconut husks representing the primary input sourced from coconut processing facilities as agricultural by-products. This significant raw material component emphasizes the critical importance of establishing reliable supplier relationships with coconut fiber extraction operations, coir processing facilities, and coconut oil mills generating husk waste streams, implementing effective procurement systems ensuring consistent husk quality and supply volumes, and potentially developing direct relationships with coconut processing clusters to secure favorable pricing while ensuring steady material availability supporting continuous production operations. Utilities account for 20-25% of operating expenses, representing substantial energy requirements for drying operations removing moisture from washed husks, grinding equipment reducing material to appropriate particle sizes, hydraulic presses compressing loose material into blocks and briquettes, and processing equipment operations throughout the manufacturing sequence.

The utility cost component covers electricity for processing machinery and material handling systems, water for washing operations removing impurities and salt content, and drying energy whether through natural sun drying or mechanical drying systems depending on climate conditions and production requirements. Key raw materials required include coconut husk as the sole primary input, with sourcing strategies focusing on establishing relationships with coconut processing facilities generating consistent husk volumes, negotiating favorable procurement pricing leveraging the agricultural waste nature of the input material, and maintaining optimal inventory levels balancing supply security against storage space requirements. Additional operational costs encompass transportation for raw material collection from coconut processing facilities and finished product distribution to agricultural and horticultural customers, packaging materials for compressed blocks, briquettes, and retail packaging formats, salaries and wages for production staff and quality control personnel, depreciation on processing equipment and compression machinery, taxes and regulatory compliance costs, repairs and maintenance ensuring equipment reliability, and other miscellaneous operational requirements essential for continuous production meeting quality specifications serving agricultural and horticultural applications.

CAPITAL INVESTMENT REQUIREMENTS

Establishing a coco peat manufacturing plant requires comprehensive capital investment across multiple essential categories to ensure operational readiness and long-term competitive positioning. The total capital expenditure (CapEx) encompasses land and site development costs, civil works costs, machinery costs, and other capital costs, each representing critical investment components for successful facility establishment.

Land acquisition and site development constitute substantial initial investments, covering land registration charges, boundary development expenses, site preparation including grading and drainage systems, and foundational infrastructure development ensuring safe and efficient plant operations with adequate space for raw material receiving, processing operations, drying areas, and finished product storage.

Civil works costs include factory building construction optimized for coco peat processing operations with appropriate ventilation and material handling capabilities, administrative office facilities, warehousing structures for bulk husk storage and finished product inventory management, and comprehensive utility infrastructure development including electrical distribution, water supply systems, and drainage facilities supporting production requirements.

Machinery costs account for the largest portion of total capital expenditure, comprising essential processing equipment for coco peat manufacturing including:

• Husk crushers for initial size reduction

• Washing units for cleaning and impurity removal

• Dryers for moisture reduction (natural or mechanical)

• Sieving machines for particle size classification

• Grinders for final particle size reduction

• Hydraulic presses for compression into blocks and briquettes

• Automatic packing machines for finished product packaging

All machinery selections must comply with agricultural processing industry standards, operational efficiency requirements, and reliability benchmarks ensuring consistent production quality meeting horticultural specifications. Other capital costs cover pre-operative expenses including regulatory approvals, licensing fees, environmental compliance certifications, initial working capital requirements for raw material inventory and operational launch, and prudent contingency reserves addressing unforeseen costs during facility establishment and commissioning phases.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=14980&flag=C

MAJOR APPLICATIONS AND MARKET SEGMENTS

Coco peat serves diverse applications across multiple agricultural and horticultural sectors:

• Agriculture - Used as a soil amendment and moisture-retaining medium improving soil structure, water retention, and nutrient availability for crop production. Agricultural applications support field cultivation, organic farming operations, and soil rehabilitation projects requiring sustainable soil enhancement solutions.

• Horticulture and Floriculture - Ideal for nurseries and ornamental plants providing optimal growing conditions for plant propagation and ornamental production. Horticultural applications encompass commercial nursery operations, flower production facilities, and ornamental plant cultivation requiring premium growing media.

• Greenhouse Farming - Preferred substrate for controlled cultivation environments providing consistent moisture retention and aeration properties essential for intensive production systems. Greenhouse applications support vegetable production, specialty crops, and year-round cultivation operations requiring reliable growing media performance.

• Hydroponics - Acts as a growing medium in soilless farming systems providing physical support, moisture retention, and aeration for plant roots in nutrient solution culture. Hydroponic applications serve commercial vegetable production, vertical farming operations, and controlled environment agriculture requiring inert growing substrates.

• Home Gardening - Used in potting mixes and garden soil conditioning for residential gardening applications serving urban gardeners, container gardening enthusiasts, and home vegetable production. Retail gardening represents growing market segment driven by urban farming trends and sustainable gardening practices.

WHY INVEST IN COCO PEAT MANUFACTURING?

• Growing Shift Toward Organic and Sustainable Farming Practices: Rising adoption of eco-friendly agricultural methods is driving demand for natural growing media like coco peat. Environmental awareness and sustainable farming certification requirements support market expansion for renewable, biodegradable growing media alternatives.

• Increasing Global Demand for Eco-Friendly Soil Alternatives: The need for sustainable and biodegradable soil substitutes fuels market growth for coco peat. Environmental regulations restricting peat moss extraction and consumer preferences for sustainable products drive adoption of coconut-based growing media.

• Abundant Availability of Raw Materials: Easy access to coconut husks ensures steady supply of raw material for coco peat production. Coconut processing industries generate substantial husk volumes as waste by-products, providing reliable, low-cost input materials supporting profitable manufacturing operations.

• Strong Export Opportunities Across Europe, Asia, and the Middle East: High international demand presents significant export potential for coco peat producers. Markets with limited arable land, water scarcity, or environmental restrictions on peat moss use represent substantial export opportunities for sustainable growing media products.

• Scalable Production with Low Technological Complexity: Coco peat manufacturing is easily scalable and requires minimal technological investment, supporting efficient production expansion. Processing technology is relatively simple, capital requirements are moderate, and production can be scaled incrementally aligned with market development.

Buy Now: https://www.imarcgroup.com/checkout?id=14980&method=2175

INDUSTRY LEADERSHIP

The global coco peat manufacturing industry features several prominent companies with extensive production capacities and diverse product portfolios serving agricultural and horticultural markets. Leading manufacturers include:

• Dutch Plantin Coir Pvt. Ltd.

• Samarasinghe Brothers International

• Sai Coco Peat Export Private Limited

• Kumaran Coir

• Fibre family

• CoirGreen coco Solution

• Dynamic International

• Nature's Bounty PLC

All of which serve critical end-use sectors including agriculture, horticulture, floriculture, landscaping, greenhouse farming, and retail gardening industries across global markets. These industry leaders demonstrate market maturity, processing capabilities, and operational benchmarks against which new entrants can evaluate their strategic positioning.

Recent industry developments illustrate ongoing innovation and market expansion strengthening sector prospects:

• December 2025: India's urban local bodies, under the Swachh Bharat Mission, transformed coconut waste into economic and environmental value. Coconut husks were processed into coir, ropes, compost, and high-demand cocopeat, powering sustainable livelihoods, accelerating farmer income, and supporting circular economy models across cities like Chennai, Indore, Bhubaneswar, and Patna.

• July 2025: Kerala's NCRMI developed Cocoaura, a patented air-freshener gel made from biodegradable coir pith, using natural oils for fragrance. Lasting up to 22 days, it promotes in-vehicle air quality with minimal environmental impact. Technology transfer deals target overseas markets, including the UAE, highlighting coir pith's sustainable commercial potential.

These developments underscore the industry's dynamic nature with government initiatives supporting coconut waste valorization and circular economy development, innovative product applications expanding beyond traditional growing media, and international market development creating export opportunities for value-added coir products demonstrating versatility of coconut processing by-products.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factoring Auditing

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Coco Peat Manufacturing Plant Cost 2026: Detailed Project Report & Profit Analysis here

News-ID: 4393994 • Views: …

More Releases from IMARC Group

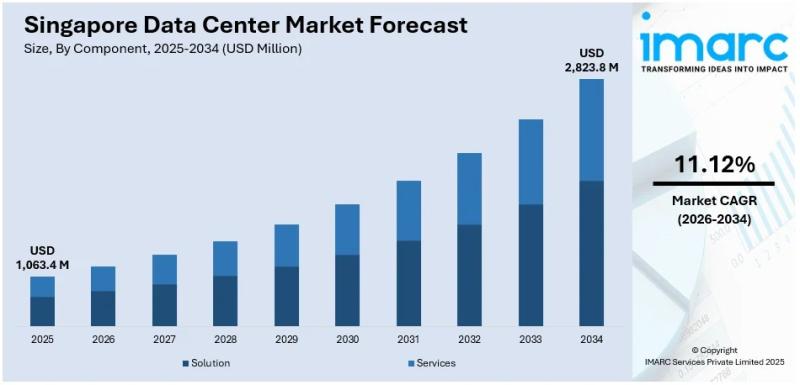

Singapore Data Center Market Size, Share, Trends, Industry Analysis, Growth & Fo …

Report ID: SR112026A23728 | Format: PDF + Excel | Verified by: IMARC Group

Market At-A-Glance: Key Statistics (2026-2034):

• Market Size (2025): USD 1,063.4 Million

• Forecast Value (2034): USD 2,823.8 Million

• Growth Rate (CAGR): 11.12% (2026-2034)

• Leading Component: Solution (65.8% Share)

• Key Trend: Green Data Centers & High-Density Computing

What is the Singapore Data Center Market Size, Share, Trends, and Growth Forecast (2026-2034)?

According to the latest analysis by IMARC Group, the Singapore data center market size reached USD…

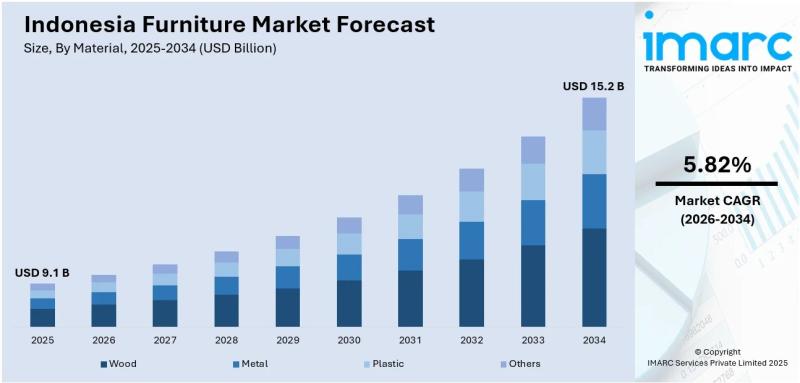

Indonesia Furniture Market to Reach USD 15.2 Billion by 2034: Growth Report

Report ID: SR112026A13864 | Format: PDF + Excel | Verified by: IMARC Group

Market At-A-Glance: Key Statistics (2026-2034):

• Market Size (2025): USD 9.1 Billion

• Forecast Value (2034): USD 15.2 Billion

• Growth Rate (CAGR): 5.82% (2026-2034)

• Leading Segment: Wood Furniture

• Key Trend: Eco-friendly & Multifunctional Designs

What is the Indonesia Furniture Market Size, Share, Trends, and Growth Forecast (2026-2034)?

According to the latest analysis by IMARC Group, the Indonesia furniture market size reached USD 9.1 Billion in 2025. Driven…

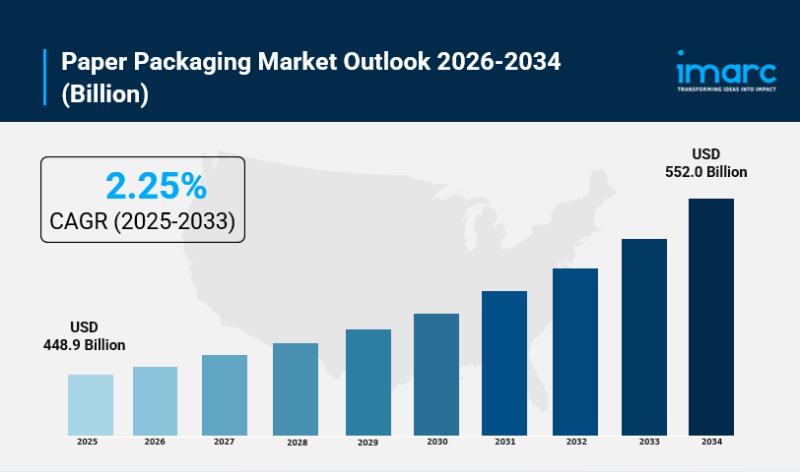

Paper Packaging Market Size, Trends, Key Players, Future Scope and Business Oppo …

IMARC Group, a leading market research company, has recently released a report titled "Paper Packaging Market Size, Share, Trends and Forecast by Product Type, Grade, Packaging Level, End Use Industry, and Region, 2026-2034." The study provides a detailed analysis of the industry, including the global paper packaging market size, trends, share and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Paper…

Lithium Iron Phosphate (LiFePO4) Battery Manufacturing Plant Cost: Feasibility S …

The global lithium iron phosphate (LiFePO4) battery manufacturing industry represents a critical technological frontier supporting the worldwide transition toward sustainable energy storage and electric mobility solutions. Lithium iron phosphate (LiFePO4) batteries are a type of lithium-ion battery that uses lithium iron phosphate as the cathode material. They are known for their high energy density, thermal stability, and safety characteristics. Unlike traditional lithium-ion batteries, LiFePO4 batteries offer excellent thermal and chemical…

More Releases for Coco

Coco Peat for Hydroponics Market Hits New High | Major Giants Cocogreen, Pelemix …

HTF MI recently introduced Global Coco Peat for Hydroponics Market study with 143+ pages in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status (2025-2033). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence and some of the key players from the complete study are Cocogreen, Pelemix, Sai Cocopeat, Dutch Plantin, Allwin Coir,…

Coconut Water Drinks Market May See Big Move | Major Giants Real Coco, Blue Monk …

HTF MI just released the Global Coconut Water Drinks Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

Major companies profiled in Coconut Water Drinks Market are:

Vita Coco,…

Coco Peat Market Continues To Impress| Coco Green, Cocopeat India, Sri Lanka Coc …

HTF MI just released the Global Coco Peat Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

Major Giants in Coco Peat Market are:

Coco Green, Cocopeat India, Sri…

Coconut Foods Market Report Analysis, Research Studies | Cargill, Hain Celestial …

DataM Intelligence has published a new research report on "Coconut Foods Market Size 2024". The report explores comprehensive and insightful Information about various key factors like Regional Growth, Segmentation, CAGR, Business Revenue Status of Top Key Players and Drivers. The purpose of this report is to provide a telescopic view of the current market size by value and volume, opportunities, and development status.

Get a Free Sample Research PDF -…

Coconut Charcoal Briquettes Market Rapid Growth, Industry Competition Outlook An …

LOS ANGELES, United States: The global Coconut Charcoal Briquettes market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Coconut Charcoal Briquettes market. For instance, the market dynamics section digs deep into the drivers, restraints,…

Organic Coconut Sugar Market is Set to Fly High in Years to Come | Coco Sugar, C …

Advance Market Analytics published a new research publication on "Organic Coconut Sugar Market Insights, to 2027" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Organic Coconut Sugar market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample…