Press release

Asphalt Manufacturing Plant DPR 2026: Investment Cost, Market Growth & ROI

The global asphalt manufacturing industry is witnessing robust growth driven by the expanding road infrastructure projects, rising urbanization, and increasing investments in highway construction and maintenance across public and private sectors. At the heart of this expansion lies a critical construction material-asphalt. As governments across emerging and developed economies prioritize transportation infrastructure to support economic development, logistics efficiency, and urban mobility, establishing an asphalt manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and construction-sector investors seeking to capitalize on this growing and essential market.Market Overview and Growth Potential

The global asphalt market demonstrates a strong growth trajectory, valued at USD 271.8 Million in 2025. According to IMARC Group's comprehensive market analysis, the market is expected to reach USD 409.30 Million by 2034, exhibiting a CAGR of 4.7% from 2026 to 2034. This sustained expansion is driven by the expanding road infrastructure projects, rising urbanization, and increasing investments in highway construction and maintenance across public and private sectors.

Asphalt is a black, sticky substance which becomes highly adhesive when refined bitumen combines with crushed stone and sand and mineral fillers. The manufacturing process uses controlled heating and mixing techniques which create a uniform bitumen coating on aggregates. Asphalt serves as an ideal material for surface paving as it provides waterproofing protection together with high load-bearing strength and long-lasting durability and weather resistance. The formulation and temperature of asphalt determine its production as three different types of hot mix, warm mix, and cold mix asphalt which are designed for particular construction and environmental conditions.

The global asphalt market is primarily driven by rising investments in road construction, highway expansion, and infrastructure rehabilitation projects worldwide. Increasing vehicle ownership and traffic volumes are accelerating the need for durable and high-performance road surfaces, further strengthening asphalt demand. Moreover, technological advancements such as warm mix asphalt and recycled asphalt pavement (RAP) are gaining traction, enabling reduced energy consumption and lower emissions while improving sustainability. Furthermore, recent project awards and supply contracts highlight the rising demand for reliable asphalt suppliers as governments and private players accelerate investments in road and infrastructure development. For instance, in December 2025, ArisInfra Solutions secured an asphalt supply order worth about ₹35 crore through its subsidiary, Buildmex-Infra, underscoring the expanding asphalt market.

Plant Capacity and Production Scale

The proposed asphalt manufacturing facility is designed with an annual production capacity ranging between 200,000 - 500,000 MT, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from road infrastructure and airport construction to industrial zones and commercial projects-ensuring steady demand and consistent revenue streams across multiple industry verticals.

Request for a Sample Report: https://www.imarcgroup.com/asphalt-manufacturing-plant-project-report/requestsample

Financial Viability and Profitability Analysis

The asphalt manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

Gross Profit Margins: 25-35%

Net Profit Margins: 10-15%

These margins are supported by stable demand across road construction and infrastructure development sectors, value-added specialty asphalt positioning, and the critical nature of asphalt in national highway and urban mobility projects. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established construction material manufacturers looking to diversify their product portfolio in the specialty infrastructure materials sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for an asphalt manufacturing plant is primarily driven by:

Raw Materials: 70-80% of total OpEx

Utilities: 15-20% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with aggregates (stone, sand), bitumen, and filler materials being the primary input materials. Establishing long-term contracts with reliable aggregates and bitumen suppliers helps mitigate price volatility and ensures consistent raw material supply, which is critical given that bitumen price fluctuations-directly tied to crude oil price movements-represent the most significant cost factor in asphalt manufacturing.

Capital Investment Requirements

Setting up an asphalt manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development:

Selection of an optimal location with strategic proximity to aggregates (stone, sand), bitumen, and filler material suppliers. Proximity to target construction markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment:

The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for production. Key machinery includes:

• Cold aggregate feeder for controlled raw material intake

• Drying drum for aggregate drying to required moisture content

• Hot elevator for transporting dried aggregates to the mixing unit

• Vibrating screens for size classification of hot aggregates

• Mixing unit for uniform blending of aggregates and bitumen

• Bitumen storage tanks for heated storage of bitumen supply

• Conveyor system to move aggregates through the production process

• Dust collection and bag filter systems for environmental compliance

• Central control system for automated plant operation and monitoring

• Quality control laboratory for product testing and compliance verification

Civil Works:

Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should be optimized with separate areas for raw material storage, aggregate drying zone, mixing unit, bitumen storage, quality control laboratory, finished goods area, utility block, effluent treatment area, and administrative block.

Other Capital Costs:

Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=22773&flag=C

Major Applications and Market Segments

Asphalt products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Road Infrastructure:

Employed in national highways, expressways, rural and urban roads. Road infrastructure represents the primary and most significant application segment, driven by government-led highway expansion programs, urban road construction, and ongoing maintenance of existing road networks across both developed and emerging economies.

Airports:

Used in runways, taxiways, and aprons where asphalt's load-bearing strength, durability, and weather resistance make it an ideal material for high-traffic and heavy-load aviation infrastructure requiring precise surface quality.

Industrial Zones:

Utilized in heavy-duty pavements, logistics parks, and yards where the material's high compressive strength and resistance to heavy vehicle traffic make it a preferred choice for industrial infrastructure development.

Commercial Projects:

Employed in parking areas, access roads, and driveways where asphalt's cost-effectiveness, quick installation, and durability are vital for high-traffic commercial areas accompanying business growth and new facility construction.

Why Invest in Asphalt Manufacturing?

Several compelling factors make asphalt manufacturing an attractive investment opportunity:

Backbone of Infrastructure Development:

Asphalt serves as an essential material which creates road and pavement systems that support vital transportation networks which drive economic development and regional connectivity. Its critical role in all stages of infrastructure development ensures consistent and long-term market demand.

Strong Entry Demand with Scalable Operations:

Asphalt plants require high initial investment costs, but their operations can expand as they use common equipment and their work volume follows patterns established by upcoming infrastructure projects, offering excellent scalability as contract volumes grow.

Alignment with Global Infrastructure Push:

The world requires asphalt production as urban areas grow and smart cities develop while countries expand their highway systems and improve their airports. This global infrastructure push creates sustained long-term demand for high-quality asphalt supply.

Government and Policy Support:

The government maintains infrastructure development through its funding of public road, highway, and logistics corridor projects as well as its support of national infrastructure development, which generates ongoing need for asphalt production. Policy frameworks supporting recycled asphalt pavement (RAP) further support sustainable market growth.

Localized Production Advantage:

Asphalt production requires specific locations as transportation expenses affect the process, which enables local producers to deliver materials to nearby construction sites at lower costs, providing a critical competitive advantage over more distant suppliers.

Manufacturing Process Excellence

The asphalt manufacturing process involves several precision-controlled stages:

• Raw Material Sourcing: Aggregates and bitumen are sourced from suppliers and prepared for the manufacturing process

• Aggregate Drying: Aggregates are heated to the required mixing temperature in the drying drum

• Heating: Aggregates are heated and transported via hot elevator to the vibrating screens

• Screening: Vibrating screens classify hot aggregates by particle size for the mixing unit

• Bitumen Blending: Hot bitumen is added and blended uniformly with sized aggregates in the mixing unit

• Controlled Mixing: Components are mixed under controlled conditions to achieve the desired asphalt grade

• Quality Testing: Quality tests are conducted on the hot mixture to verify concentration, purity, and stability

• Packing: Finished asphalt is packed for storage and distribution to construction sites

Buy Now: https://www.imarcgroup.com/checkout?id=22773&method=2175

Industry Leadership

The global asphalt industry is led by established chemical and construction material manufacturers with extensive production capabilities and diverse application portfolios. Key industry players include:

• Aggregate Industries Ltd.

• Anglo American Plc

• Atlas Roofing Corporation

• BP Plc

• Cemex

• Chevron Corporation

• Exxon Mobil Corporation

• Imperial Oil Limited

• Owens Corning

• Petroleos de Venezuela S.A.

• Royal Dutch Shell plc

• Shell International

• Total SA

• United Refining Inc.

These companies serve diverse end-use sectors including road construction, infrastructure development, and industrial paving, demonstrating the broad market applicability of asphalt products.

Recent Industry Developments

June 2025: Gainwell Commosales successfully delivered multiple Linnhoff DRX1500 DurableMix asphalt mixing plants manufactured in India. Installed in West Bengal and Tamil Nadu, the advanced plants support major PWD and NHAI road projects. Featuring European engineering and energy-efficient automation, the DRX1500 units are designed to enhance construction quality, reliability, and environmental compliance.

March 2025: BioSpan Technologies unveiled a new partner program at the World of Asphalt 2025 exhibition in St. Louis. The initiative features tiered participation options for contractors, dealers, and distributors, supporting wider adoption of BioSpan's eco-friendly pavement preservation products, including its soy-based RePlay solution for roads, parking areas, and driveways.

Conclusion

The asphalt manufacturing sector presents a strategically positioned investment opportunity at the intersection of infrastructure development, specialty construction materials, and sustainable engineering practices. With favorable profit margins ranging from 25-35% gross profit and 10-15% net profit, strong market drivers including rising investments in road construction and highway expansion, growing demand for durable high-performance road surfaces, advancing warm mix and recycled asphalt pavement technologies, and supportive government policies promoting transportation infrastructure development, establishing an asphalt manufacturing plant with a production capacity of 200,000-500,000 MT per year offers significant potential for long-term business success and sustainable returns. The combination of localized production advantage, critical role in national highway and urban mobility projects, expanding infrastructure requirements across emerging economies, and government policy alignment creates an attractive value proposition for serious construction-sector investors committed to quality manufacturing and operational excellence.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. IMARC Group provides a comprehensive suite of market entry and expansion services, including market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Asphalt Manufacturing Plant DPR 2026: Investment Cost, Market Growth & ROI here

News-ID: 4393714 • Views: …

More Releases from IMARC Group

Waste Tyre Recycling Plant DPR 2026: Investment Cost, Market Growth and Machiner …

The global waste tyre recycling industry is experiencing significant momentum, driven by rising environmental concerns, stricter waste management regulations, increasing vehicle ownership, and growing demand for recycled rubber products across construction, automotive, and infrastructure sectors. At the heart of this transformation lies a critical industrial process-waste tyre recycling. As circular economy initiatives gain ground and landfill diversion mandates become more stringent, establishing a waste tyre recycling plant presents a strategically…

Solar Module Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/ …

The global renewable energy and clean technology sector is experiencing transformative growth driven by accelerating renewable energy adoption, supportive government policies, declining photovoltaic technology costs, grid decarbonization targets, and rising electricity demand from industrial and residential sectors. At the forefront of this solar energy revolution stands the solar module-a photovoltaic assembly valued for its ability to convert sunlight directly into electricity, durability across diverse climatic conditions, and scalable deployment across…

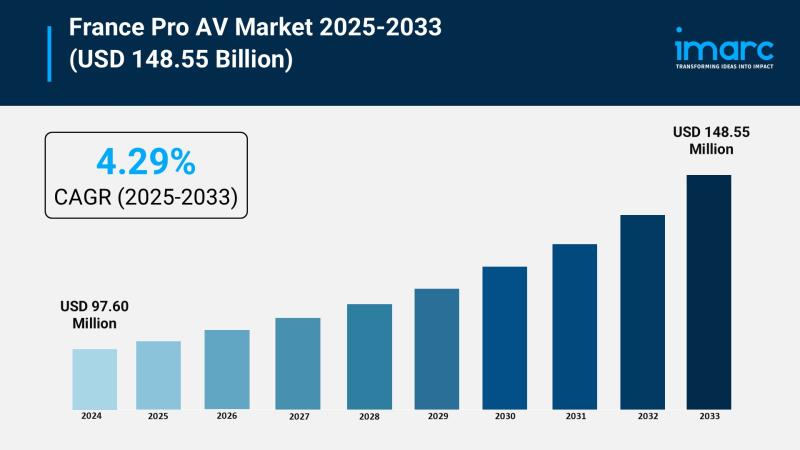

France Pro AV Market to Reach USD 148.55 Million by 2033, Growing at 4.29% CAGR

Market Overview

The France Pro AV market size reached USD 97.60 Million in 2024 and is forecasted to grow to USD 148.55 Million by 2033, registering a CAGR of 4.29% during the 2025-2033 period. This growth is driven by increased adoption of advanced audio-visual solutions in hybrid workplaces and public infrastructure, alongside rising investments in digital displays, conferencing tools, and AV integration supporting sectors like corporate, education, and government.

Study Assumption Years

• Base…

Pet Food Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx …

The global pet food manufacturing industry is witnessing robust growth driven by rising pet ownership, increased spending on premium products, and a growing preference for healthy, natural ingredients in pet food. At the heart of this expansion lies a critical consumer product-pet food. As pet owners across the world increasingly humanize their pets and demand higher-quality, nutritionally balanced food products for dogs, cats, and other companion animals, establishing a pet…

More Releases for Asphalt

Advance Asphalt Expands Premium Asphalt Services in Pembroke, MA

Image: https://www.getnews.info/wp-content/uploads/2024/09/1727111601.png

Pembroke, MA - September 24, 2024 - Advance Asphalt, a leader in high-quality asphalt services, proudly announces the expansion of its offerings in Pembroke, MA. Known for exceptional craftsmanship and reliable service, Advance Asphalt continues to deliver top-tier solutions for both residential and commercial clients.

Among the premier services now available is seal coating in Pembroke, MA. [https://www.google.com/maps?cid=11586809525069397860]This service ensures protection against the damaging effects of weather, oil, and traffic…

Tullahoma Asphalt Paving: Professional Paving Company For All Asphalt Needs

Image: https://www.getnews.info/wp-content/uploads/2024/09/1724949979.png

Tullahoma Asphalt Paving is a top company that offers a wide array of quality paving services, excellent customer service, and expertise. Its professional and knowledgeable paving contractors look for ways to find the best value for their clients' commercial or home projects.

Tullahoma, TN - Tullahoma Asphalt Paving is a leading provider of high-quality asphalt services in Tullahoma, TN, and nearby regions. The Asphalt Company Tullahoma [https://www.google.com/maps?cid=10079490256593890372] has established…

Dickson Asphalt Paving Shares Common Mistakes to Avoid in Asphalt Paving

Image: https://www.getnews.info/wp-content/uploads/2024/07/1720789699.jpeg

Dickson Asphalt Paving is a top-rated asphalt paving company. In a recent update, the company shared common mistakes to avoid in asphalt paving.

Dickson, TN - In a website post, Dickson Asphalt Paving shared common mistakes to avoid in asphalt paving.

The technicians mentioned that inadequate surface preparation is a frequent oversight in asphalt paving Dickson [https://maps.app.goo.gl/q5zz1UUdZ13ZvnAa8]. Skipping essential steps such as proper grading and compacting of the base can lead…

Professional and Quality Asphalt Paving Services by Licensed Asphalt Contractors

Image: https://www.getnews.info/wp-content/uploads/2024/07/1720802632.jpeg

Asphalt paving requires the services of a professional in the field for the installation and repair processes to get done well without hitches. Asphalt paving has numerous benefits, like improved driving experience and aesthetic appeal when properly installed. There are different asphalt paving companies in the industry, and selecting the best-qualified one improves one's chances of getting a remarkable service.

Brentwood, TN - Brentwood Asphalt Paving is a professional…

Apopka Asphalt Paving Shares Common Mistakes to Avoid in Asphalt Paving

Apopka Asphalt Paving is a premier asphalt paving company. In a recent update, the company shared common mistakes to avoid in asphalt paving.

Apopka, FL - In a website post, Apopka Asphalt Paving shared common mistakes to avoid in asphalt paving.

The experts noted that one frequent mistake in asphalt paving Apopka [https://apopkaasphaltpaving.com/kit-land-nelson-park-a-community-gem-in-apopka-fl/] is inadequate site preparation. Skipping or rushing through this step can result in an unstable foundation, leading to…

RSH Asphalt Rebrands as Hardtop Asphalt, Continues Serving Murfreesboro & Nashvi …

RSH Asphalt Maintenance continues to offer high-quality asphalt paving and repair services under their new name: Hardtop Asphalt. The rebrand was to ensure their name embodied the quality of work they focus on bringing to every client throughout Murfreesboro TN, Nashville TN, and the surrounding counties.

Murfreesboro, TN - Hardtop Asphalt, formerly known as RSH Asphalt, is excited to announce its rebranding and expansion of services in Murfreesboro and Nashville, TN.…