Press release

Green Cement Manufacturing Plant Setup 2026: Complete DPR with Process Flow, Machinery & Profitability

The global green cement manufacturing industry is witnessing robust growth driven by the rapidly expanding construction sector and increasing demand for sustainable, low-carbon building materials. At the heart of this expansion lies a critical specialty construction material green cement. As the construction industry transitions toward eco-friendly and energy-efficient practices, establishing a green cement manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and construction material investors seeking to capitalize on this growing and essential market.Market Overview and Growth Potential

The global green cement market demonstrates strong growth trajectory, valued at USD 42.57 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 112.45 Billion by 2034, exhibiting a robust CAGR of 10.2% from 2026-2034. This sustained expansion is driven by rapidly expanding construction sector, increasing demand for low-carbon building materials, rising adoption of green building standards, and expanding sustainability requirements across developed and developing economies.

Green cement is an eco-friendly, low-carbon alternative to traditional Portland cement, produced using industrial by-products such as fly ash, blast furnace slag, silica fume, and other supplementary cementitious materials (SCMs). It appears as a fine grey powder with high binding strength and durability properties. Green cement contains reduced clinker content and incorporates industrial waste materials, making it an efficient low-emission binding agent used primarily in sustainable construction, green building projects, and infrastructure development. Due to its significantly lower carbon footprint, it helps reduce CO2 emissions in the construction sector and supports global decarbonization goals. Its high strength, durability, and compatibility with modern construction methods make it a preferred option in sustainable infrastructure and green building projects.

The green cement market is witnessing robust demand due to the rising need for sustainable construction materials that support green building certification systems such as LEED and BREEAM. Construction sectors increasingly transitioning toward low-carbon and energy-efficient building practices-particularly in commercial construction, infrastructure development, and residential projects-are driving large-scale adoption. According to the Global Construction Review 2024-25, the construction sector contributes nearly 13% to global GDP and is responsible for approximately 39% of global carbon emissions. Government-led green infrastructure programs, subsidies for sustainable construction materials, and carbon reduction mandates further strengthen market prospects.

Request for a Sample Report: https://www.imarcgroup.com/green-cement-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed green cement manufacturing facility is designed with an annual production capacity ranging between 200,000-500,000 MT per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from residential and commercial construction to infrastructure development, precast concrete products, and specialty construction applications-ensuring steady demand and consistent revenue streams across multiple industry verticals.

Financial Viability and Profitability Analysis

The green cement manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

Gross Profit Margins: 30-40%

Net Profit Margins: 12-18%

These margins are supported by stable demand across construction and infrastructure sectors, value-added sustainable building material positioning, and the critical nature of green cement in eco-friendly construction applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established construction material manufacturers looking to diversify their product portfolio in the sustainable building materials sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a green cement manufacturing plant is primarily driven by:

Raw Materials: 50-60% of total OpEx

Utilities: 20-25% of OpEx

Raw materials constitute the largest portion of operating costs, with fly ash, blast furnace slag, and supplementary cementitious materials being the primary input materials. Establishing long-term contracts with reliable fly ash and slag suppliers helps mitigate price volatility and ensures consistent raw material supply, which is critical given that supplementary cementitious material price fluctuations represent the most significant cost factor in green cement manufacturing.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=7568&flag=C

Capital Investment Requirements

Setting up a green cement manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to fly ash, slag, and supplementary cementitious material suppliers. Proximity to target construction markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for production. Key machinery includes:

• Raw material processing equipment for fly ash/slag conditioning and preparation

• Grinding mills for fine particle size reduction and blending of cementitious materials

• Blending and mixing systems for precise proportioning of supplementary cementitious materials

• Clinker kilns and pre-calciner systems for reduced-clinker green cement variants

• Pollution control equipment including bag filters and electrostatic precipitators

• Packaging lines for filling moisture-resistant bags for storage and transport

• Quality control laboratory equipment for strength, purity, and compliance testing

• Effluent treatment systems for managing dust and particulates ensuring environmental compliance

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should be optimized with separate areas for raw material storage, pre-processing zone, blending unit, grinding section, quality control laboratory, finished goods warehouse, utility block, emission control area, and administrative block.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Green cement products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Commercial Construction: Primary use as a low-carbon binding material in office buildings, retail complexes, hotels, and institutional buildings pursuing green building certifications such as LEED and BREEAM, particularly valuable in projects requiring reduced environmental impact and sustainable construction credentials.

Infrastructure Development: Specialized applications in roads, bridges, tunnels, dams, and public infrastructure projects where durability, strength, and reduced carbon footprint are critical requirements for meeting modern environmental and performance standards.

Residential Construction: Utilized in housing developments and residential projects where builders seek eco-friendly alternatives to conventional cement as part of sustainable development commitments and green building initiatives.

Precast Concrete Products: Applications in precast concrete panels, blocks, pipes, and structural elements where consistent quality, strength, and sustainability credentials are essential for meeting modern construction standards.

Industrial Applications: Specialized use in industrial flooring, warehouses, and manufacturing facilities where high-performance, durable, and cost-effective low-carbon solutions provide significant operational and sustainability benefits.

End-use industries include commercial construction, infrastructure development, residential building, precast concrete manufacturing, and industrial applications, all of which contribute to sustained market demand.

Buy Now: https://www.imarcgroup.com/checkout?id=7568&method=2175

Why Invest in Green Cement Manufacturing?

Several compelling factors make green cement manufacturing an attractive investment opportunity:

Essential Sustainable Building Material: Green cement serves as a critical sustainable building material supporting green construction practices, low-carbon infrastructure development, and environmental compliance, making it indispensable for modern construction operations focused on sustainability and decarbonization.

Rising Green Building Adoption: Construction sectors increasingly transitioning toward low-carbon and eco-friendly building practices-particularly in commercial construction, infrastructure development, and residential projects-are driving large-scale adoption of sustainable building materials like green cement.

Dual Environmental and Economic Benefits: The product's ability to significantly reduce CO2 emissions compared to conventional cement, combined with its competitive pricing from utilizing industrial by-products as raw materials, offers significant economic and environmental advantages positioning it favorably against conventional cement.

Carbon Regulation Compliance: The product's effectiveness in meeting increasingly stringent carbon emissions regulations and sustainability requirements positions it as a preferred building material in developed markets with strict environmental standards, particularly across Europe, North America, and progressive Asian economies.

Government Support: Government-led green infrastructure programs, subsidies for sustainable construction materials, carbon tax incentives, and environmental compliance mandates further strengthen market prospects and support industry growth.

Import Substitution Opportunities: Emerging economies such as India, China, Brazil, and Vietnam are expanding local green cement manufacturing as part of their strategy to reduce dependence on imported sustainable building materials while meeting domestic green construction demand, creating significant opportunities for domestic producers.

Urbanization and Infrastructure Boom: Rapid urbanization and expanding infrastructure investment in developing economies are expected to enhance long-term growth opportunities for green cement and other sustainable construction materials aligned with global decarbonization objectives.

Manufacturing Process Excellence

The green cement manufacturing process involves several precision-controlled stages:

• Raw Material Sourcing and Preparation: Fly ash, blast furnace slag, silica fume, and other supplementary cementitious materials are sourced, tested, and prepared according to quality specifications

• Pre-Processing and Conditioning: Raw materials undergo drying, screening, and conditioning to achieve optimal moisture content and particle characteristics for efficient blending and grinding

• Proportioning and Blending: Precisely measured quantities of SCMs and reduced-clinker content are blended according to formulation specifications to achieve target chemical composition

• Grinding: The blended materials are fed into grinding mills for fine particle size reduction to achieve the required fineness and surface area for optimal binding properties

• Quality Testing: Processed green cement undergoes rigorous testing for strength, setting time, fineness, chemical composition, and environmental compliance

• Silo Storage: Tested and approved green cement is transferred to storage silos for bulk storage prior to packaging or bulk dispatch

• Packaging: Product is filled into moisture-resistant bags or dispatched in bulk tankers for storage and transport to construction sites

Industry Leadership

The global green cement industry is led by established construction material manufacturers with extensive production capabilities and diverse application portfolios.

Key industry players include:

• ACC Ltd.

• CeraTech

• CRH plc

• CEMEX S.A.B. de C.V.

• LafargeHolcim Ltd

• Fortera Corporation

• Heidelberg Cement AG

• Kiran Global Chem Limited

• Taiheiyo Cement Corporation

• Votorantim Cimentos S.A.

• UltraTech Cement Ltd.

• Anhui Conch Cement Company Limited

• Siam Cement Public Company (SCG)

• CarbonCure Technologies Inc.

These companies serve diverse end-use sectors including commercial construction, infrastructure development, residential building, precast concrete manufacturing, and industrial applications, demonstrating the broad market applicability of green cement products.

Recent Industry Developments

May 2024: Holcim Group launched its next-generation ECOPact green concrete range globally, incorporating up to 100% recycled aggregates and low-carbon green cement. The new products are designed to reduce embodied carbon by up to 60% compared to conventional concrete, using advanced supplementary cementitious material formulations for superior strength and durability while significantly lowering the carbon footprint of construction projects.

Conclusion

The green cement manufacturing sector presents a strategically positioned investment opportunity at the intersection of sustainable construction, low-carbon building materials, and global decarbonization imperatives. With favorable profit margins ranging from 30-40% gross profit and 12-18% net profit, strong market drivers including rising adoption of green building standards, growing demand for low-carbon building materials, expanding sustainable construction practices, and supportive government policies promoting carbon reduction and eco-friendly infrastructure, establishing a green cement manufacturing plant offers significant potential for long-term business success and sustainable returns. The combination of dual environmental and economic efficiency, critical role in meeting carbon regulations, expanding urbanization and infrastructure requirements, and import substitution opportunities in emerging economies creates an attractive value proposition for serious construction material investors committed to quality manufacturing and operational excellence.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Green Cement Manufacturing Plant Setup 2026: Complete DPR with Process Flow, Machinery & Profitability here

News-ID: 4393584 • Views: …

More Releases from IMARC Group

Europe Recycled Plastics Market to Hit 20.2 Million Tons by 2034 with a Robust C …

The Europe recycled plastics market size reached 13.89 Million Tons in 2025 and is forecast to reach 20.2 Million Tons by 2034, with a CAGR of 4.2% from 2026 to 2034. This growth is driven by sustainable packaging emphasis, stricter environmental regulations, and wide adoption of extended producer responsibility programs. The market is also propelled by government policies promoting recycling infrastructure across packaging, automotive, and construction industries. Consumer preference for…

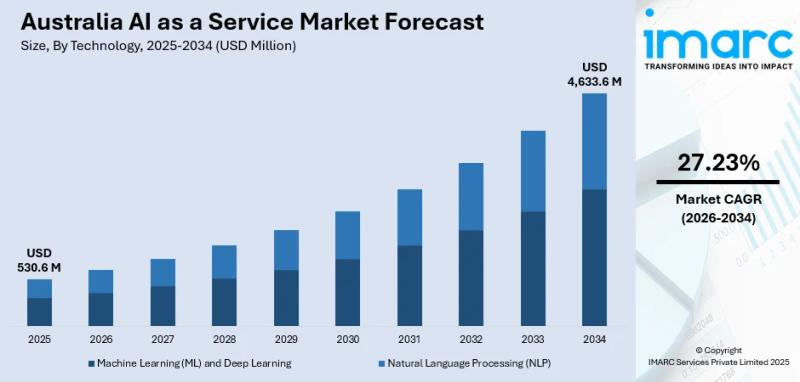

Australia AI as a Service Market Projected to Reach USD 4633.6 Million by 2034

Market Overview

The Australia AI as a Service market size reached USD 530.6 Million in 2025 and is projected to reach USD 4,633.6 Million by 2034. The market expansion is fueled by growing cloud adoption, government investments in AI research, and increased demand for AI-powered automation across multiple industries including healthcare and finance. The surge of AI startups and collaborations between tech firms and enterprises further propel the market's advancement. The…

Fuel Cells Manufacturing Plant Setup Report (DPR) 2026: Investment Guide and Dem …

The global fuel cells industry is experiencing one of the fastest growth trajectories in the clean energy sector, propelled by rising demand for hydrogen-based technologies, accelerating decarbonization commitments from major economies, and growing adoption of fuel cell electric vehicles for heavy-duty and long-range transportation. As governments worldwide deploy large-scale clean energy investment programs and industries seek reliable zero-emission alternatives to diesel generation, establishing a fuel cells manufacturing plant represents a…

Biomass Power Plant Cost Report 2026: Demand Analysis, CapEx/OpEx, & ROI Insight …

The global biomass power sector is experiencing accelerating growth, driven by rising demand for reliable and dispatchable renewable energy, government initiatives to reduce greenhouse gas emissions, and a growing focus on waste-to-energy solutions. As nations worldwide ramp up renewable energy capacity and phase out fossil fuels, biomass power plants-capable of delivering continuous, controllable electricity unlike intermittent solar and wind sources-present a strategically compelling business opportunity for energy investors and independent…

More Releases for Green

Green-Card.md Simplifies Green Card Application Process

Image: https://www.getnews.info/wp-content/uploads/2024/07/1722343980.png

Green-Card.md is a premier immigration consultancy firm. Specializing in green card applications, the company offers a wide range of services designed to assist individuals in obtaining permanent residency in the United States. With a commitment to personalized service and expert guidance, Green-Card.md is dedicated to helping clients achieve their immigration goals.

Green-Card.md, a leading immigration consultancy firm, is excited to announce its dedicated services aimed at assisting individuals in obtaining…

Green Logistics Market Is Flourishing worldwide with DHL, Green India Transport, …

Green logistics describes all attempts to measure and minimize the ecological impact of logistics activities. This includes all activities of the forward and reverse flows of products, information and services between the point of origin and the point of consumption. It is the aim to create a sustainable company value using a balance of economic and environmental efficiency. Green logistics has its origin in the mid-1980s and was a concept…

Green Logistics Market Is Thriving with DHL, Green India Transport, The Green Gr …

Green logistics describes all attempts to measure and minimize the ecological impact of logistics activities. This includes all activities of the forward and reverse flows of products, information and services between the point of origin and the point of consumption. It is the aim to create a sustainable company value using a balance of economic and environmental efficiency. Green logistics has its origin in the mid-1980s and was a concept…

A green hotel on a green island

Mitsubishi Electric Hydronics & IT Cooling Systems, through its brand Climaveneta, has recently supplied HVAC units to the new luxury hotel now under construction at Benitses Beach in Corfu, also known as the “Green Island” for its thick vegetation. The complex includes a 5-star hotel, 40 bungalows and furnished villas, with a total capacity of 893 beds. It is the first large hotel in Greece, designed to avoid the use…

Green Information Technology Services Market | #green IT #Green Technology @Adva …

Global Green Information Technology (IT) Services Market: Overview

Green information technology (IT) covers services related to environmentally sustainable computing and IT optimization. The technology aims at minimizing the negative impacts of IT operations by manufacturing, designing, and disposing of servers, computers, and other associated subsystems such as networking systems, communication systems, printers and monitors, and storage devices in an environmentally-friendly manner.

The motive behind deploying green IT practices is to reduce the…

Numerous Green Methods Shown at Home Green Life

Home Green Life is one home gardening blog that elucidates on the latest news related to the field and also provides a whole lot of tips about gardening, interior décor, home living, green building, furniture, ecological architecture and sustainable construction. In fact, Home Green Life is a fully equipped web guide that comes in with all the news that is relevant for having green homes, innovative buildings, ecological living,…