Press release

Fasto - China Top Professional Custom Carbon Steel Screws Company At EXPO FERRETERA

The international construction and hardware industry recently gathered at EXPO FERRETERA 2025 in Buenos Aires, Argentina, highlighting the ongoing evolution of global industrial partnerships. Among the prominent exhibitors, Fasto Industrial Co., Ltd. stood out as a China Top Professional Custom Carbon Steel Screws(https://www.fastoscrews.com/phillips-head-fine-thread-drywall-screw-product/) Company, showcasing advanced fastening technologies to a diverse audience of engineers and distributors.Custom Carbon Steel Screws are essential components in modern infrastructure, valued for their high tensile strength and versatility. These specialized fasteners undergo rigorous heat treatment and precision threading processes to ensure they can withstand the mechanical stresses found in heavy-duty industrial frameworks and automotive assemblies. By offering tailored dimensions and specific hardness levels, Fasto addresses the niche requirements of projects that demand more than off-the-shelf hardware.

Strategic Presence at EXPO FERRETERA 2025

At the company's designated exhibition space, the atmosphere was one of technical exchange rather than mere commercial transaction. The Fasto delegation engaged with South American partners to discuss the evolving needs of the regional construction market. The focus of their exhibition presence was to demonstrate how integrated manufacturing can bridge the gap between complex design requirements and on-site performance. Attendees had the opportunity to examine the tactile quality of various fastening solutions, ranging from heavy-duty structural bolts to high-precision customized components. This physical interaction allowed industry professionals to verify the consistency of thread geometry and surface finishes, which are critical factors in preventing installation failure and long-term structural degradation.

Technical Innovations in Metallurgical Bonding

A primary highlight of the event was the demonstration of the company's expertise in material science, particularly regarding their bimetal and custom carbon steel screws. These products are developed to solve specific engineering challenges, such as the need for rapid drilling combined with long-term load-bearing capacity. The technical team provided insights into how refining the interface structure between different metal alloys can significantly reduce the risk of hydrogen embrittlement-a common point of failure in high-strength steel applications. By addressing these metallurgical concerns at the manufacturing stage, Fasto provides a level of reliability that is increasingly sought after in large-scale energy and infrastructure projects across the globe.

Advancing Durability with Stainless Steel Screws and Bolts

Beyond the specialized carbon steel offerings, the company's expertise extends significantly into the realm of Stainless Steel Screws And Bolts. These components are indispensable in environments characterized by high humidity or chemical exposure, such as coastal construction and water treatment facilities. The inherent corrosion resistance of stainless steel, combined with Fasto's precision machining, ensures that these fasteners maintain their integrity over decades.

The exhibition served as a platform to explain the advantages of various grades, such as 304 and 316 stainless steel, and how they complement the more rigid custom carbon steel screws in a holistic building design. This dual capability allows project managers to source all necessary fasteners from a single, technically competent provider, streamlining the procurement process and ensuring material compatibility across the entire project.

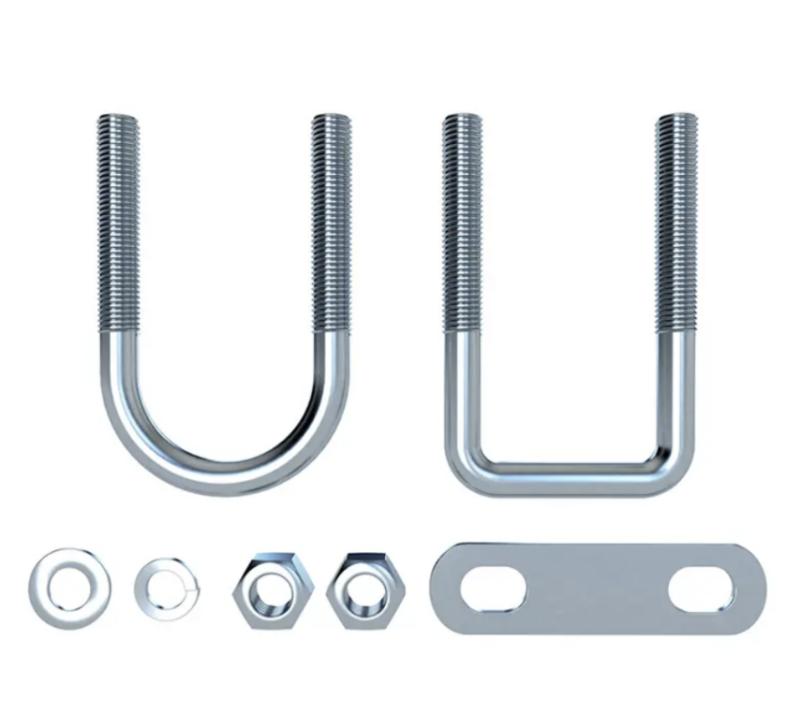

Comprehensive Product Range and Protective Coatings

The breadth of the product line is supported by a robust manufacturing infrastructure that includes more than just screws and bolts. The comprehensive catalog features rivets, nuts, washers, threaded rods, and anchors, all available in materials including titanium, copper, and various steel alloys. This variety is matched by an extensive array of protective coatings. Options such as mechanical galvanizing, hot-dip galvanizing (HDG), ruspert, and dacromet are applied to enhance the lifespan of the hardware under specific environmental stressors. For instance, the application of dacromet on custom carbon steel screws provides a high-performance barrier against salt spray, making them suitable for bridge construction where both strength and weather resistance are paramount.

Core Advantages and Supply Chain Reliability

The core advantage of partnering with a diversified manufacturer lies in the stability of the supply chain and the depth of technical support. Fasto has established production capabilities across multiple global hubs, which mitigates the risks associated with regional logistics disruptions. This geographical diversity ensures that international project demands are met with consistent lead times. Furthermore, the company's internal quality control protocols involve rigorous testing of raw materials and finished goods, ensuring that every batch conforms to international standards such as DIN, ANSI, or ISO. This commitment to transparency and measurable quality is what enables the firm to serve as a reliable single source for complete fastening solutions in the global market.

Application Scenarios in Global Infrastructure

The practical application of these products is visible in some of the world's most demanding sectors. In the renewable energy field, particularly wind and solar installations, the reliability of fasteners is non-negotiable. High-load environments require custom carbon steel screws that can resist vibration and thermal expansion without loosening. Similarly, in the marine industry, the use of specialized stainless steel screws and bolts prevents the galvanic corrosion that often plagues metal structures in saltwater environments. By understanding these specific use cases, the company does not just sell hardware; it provides engineered solutions that contribute to the safety and longevity of the built environment.

Multilingual Support and Field-Driven Design

Effective communication remains a cornerstone of the company's service philosophy. Operating with a multilingual support network, Fasto ensures that technical specifications and project requirements are accurately translated from the blueprint to the factory floor. This responsiveness was evident during the Expo Ferretera, where real-time problem-solving and technical consultations were a constant feature at the booth. By fostering direct dialogue between manufacturers and end-users, the company can iteratively improve its product designs based on field feedback, such as enhancing the drilling speed of bimetal screws or adjusting the coating thickness on custom carbon steel screws for better tool engagement.

Looking ahead, the role of specialized fastening technology will only grow as construction projects become more ambitious and environmental regulations become stricter. The demand for materials that offer both high performance and sustainability is driving innovation in coating technologies and alloy compositions. Fasto(https://www.fastoscrews.com/contact-us/) remains at the forefront of this shift, investing in precision manufacturing processes that reduce waste and improve the mechanical efficiency of their fasteners. The successful showcase in Buenos Aires confirms that the global industry values manufacturers who combine technical depth with a broad, reliable product range. Whether it is the high-strength requirements of custom carbon steel screws or the specialized longevity of stainless steel fasteners, the focus remains on delivering excellence through engineering.

For more information on the full range of fastening solutions and technical specifications, please visit: https://www.fastoscrews.com/.

Fasto Industrial Co., Ltd.

Room A-907, Greenland Center, NO.9 Jinye Road, Yan Ta District, Xi'an, China

info@fastoscrews.com

FASTO is a leading specialist in high-performance Bimetal Self-Drilling Screws, serving global construction and energy projects where reliability is essential. Fasto Bimetal Self-Drilling Screws are engineered from high-performance metal combinations to provide reliable drilling performance in demanding applications, including coastal and high-load environments.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fasto - China Top Professional Custom Carbon Steel Screws Company At EXPO FERRETERA here

News-ID: 4381102 • Views: …

More Releases from Fasto Industrial Co., Ltd.

Aesthetic & Durable Fastening: OEM Custom Color Carbon Steel Screws Factory From …

Imagine a high-end commercial gallery where the minimalist charcoal-grey metal ceiling appears to float, unblemished by the glint of silver hardware. Or consider a sprawling coastal residential complex where the deep navy roofing must withstand salt-laden winds for decades without a single streak of rust bleeding from the joints.

In these scenarios, the difference between a project that looks unfinished and one that exudes premium craftsmanship often comes down to…

China Fasto's Customized Stainless Steel Screws And Bolts Solutions For Corrosiv …

In some of the coastal citys like Tianjin,China, where the humid, salt-laden air poses a constant challenge to infrastructure, a specialized solar farm expansion recently faced a critical engineering hurdle. The project required fasteners that could withstand decades of electrochemical stress without compromising structural integrity.

This scenario is common across the global construction and energy sectors, where the demand for Customized Stainless Steel Screws(https://www.fastoscrews.com/screws/) and Bolts Solutions(https://www.fastoscrews.com/bolts-nuts/) From China has…

Top-Rated Stainless Steel Screws & Bolts Producer Fasto Showcasing At SAUDI BIG …

The Saudi construction market is currently witnessing an unprecedented transformation, driven by the ambitious goals of Vision 2030. As Riyadh and Jeddah evolve into global hubs for architecture and infrastructure, the demand for high-durability fastening components has reached a critical peak. Amidst this backdrop, Fasto Industrial Co., Ltd. (Fasto), a Top-rated Stainless Steel Screws and Bolts Producer(https://www.fastoscrews.com/products/), is set to showcase its latest engineering breakthroughs at the upcoming SAUDI BIG…

High Quality Bimetal Self Drilling Screws Supplier In China: Fasto's ETA Certifi …

On a coastal construction site where the salt-heavy breeze meets the structural demands of a modern industrial complex, engineers face a persistent silent enemy: corrosion. Traditional carbon steel fasteners may provide initial strength but often succumb to rust, while pure stainless steel alternatives lack the hardness required to pierce heavy-duty steel framing without pre-drilling.

Fasto Industrial Co., Ltd., a High Quality Bimetal Self Drilling Screws Supplier(https://www.fastoscrews.com/screws/) In China, contributes ongoing efforts…

More Releases for Screws

Construction And Furniture Industries Fueling Structural Wood Screws Market Grow …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

Structural Wood Screws Market Size Growth Forecast: What to Expect by 2025?

The market size of the structural wood screws industry has seen consistent growth in the past few years. It's projected to expand from a value of $4.76 billion in 2024 to $5 billion in 2025, representing a…

What is the difference between drywall screws VS wood screws?

Sinsun Fasteners is a leading manufacturer of all kind of screws. We specialize in drywall screw [https://www.sinsunfastener.com/drywall-screw/]s and wood screws. Many customers are interested in understanding the differences between these widely used screws.

Today we will compare and explain the differences between them from the aspects of what they are, what they are used for, head shape, thread, tip, etc.

1. Comparison of main uses of plasterboard screws and wood screws

Comparison…

Orthopedic Screws Market Overview, Trends Analysis

"The new report published by The Business Research Company, titled ""Orthopedic Screws Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033"", delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the orthopedic screws market size has grown strongly in recent years. It will grow from $1.19 billion in…

Balls Screws Market Size 2024 to 2031.

Market Overview and Report Coverage

A ballscrew, also known as a ball bearing screw, is a mechanical device used to convert rotational motion into linear motion. They are commonly used in industrial machinery and automation equipment to provide precise and efficient linear motion.

The ballscrews market is expected to grow at a CAGR of 5.94% during the forecasted period. The market is driven by the increasing demand for automation and…

Unlocking Prosperity: Orthopedic Screws Market Insights

Growth Market Reports, a prominent Market research firm, has recently released a comprehensive report on the 𝐎𝐫𝐭𝐡𝐨𝐩𝐞𝐝𝐢𝐜 𝐒𝐜𝐫𝐞𝐰𝐬 𝐌𝐚𝐫𝐤𝐞𝐭. This report offers a complete overview of the key aspects of the market, providing a robust assessment of the current Market situation and its anticipated scope. The report spans the forecast period from 2024 to 2032.

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐎𝐫𝐭𝐡𝐨𝐩𝐞𝐝𝐢𝐜 𝐒𝐜𝐫𝐞𝐰𝐬 𝐌𝐚𝐫𝐤𝐞𝐭 𝐬𝐢𝐳𝐞 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐔𝐒𝐃 𝟏.𝟐𝟎 𝐁𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬…

Self-Drilling Screws from Challenge Europe

The concept of self-drilling screws came out of the need for speed and the realisation that by putting a cutting face on the end of a power driven screw it could cut its own hole and immediately generate a female thread, so saving a considerable amount of time. In the case of self-drilling Tek type screws, with integral sealing washer, this time saving is increased, together with the added functional…