Press release

Top-Rated Stainless Steel Screws & Bolts Producer Fasto Showcasing At SAUDI BIG 5

The Saudi construction market is currently witnessing an unprecedented transformation, driven by the ambitious goals of Vision 2030. As Riyadh and Jeddah evolve into global hubs for architecture and infrastructure, the demand for high-durability fastening components has reached a critical peak. Amidst this backdrop, Fasto Industrial Co., Ltd. (Fasto), a Top-rated Stainless Steel Screws and Bolts Producer(https://www.fastoscrews.com/products/), is set to showcase its latest engineering breakthroughs at the upcoming SAUDI BIG 5 exhibition. Stainless steel screws and bolts are fundamental to the structural integrity of modern buildings, offering the essential corrosion resistance and mechanical strength required to withstand the harsh, saline, and high-temperature environments characteristic of the Middle East.Navigating Construction Excellence at the BIG 5 Saudi

The BIG 5 Saudi serves as the premier gateway for the international building and construction industry to engage with the Saudi market. For Fasto, participating in this event is more than a commercial exhibition; it is a strategic alignment with the region's shift toward high-quality, sustainable building practices. Currently, the industry faces significant challenges, particularly regarding material degradation in extreme climates. Traditional fasteners often succumb to oxidation or structural fatigue when exposed to the high humidity of coastal regions or the thermal expansion caused by desert heat.

This is where the expertise of a Chinese stainless steel screws and bolts producer becomes a decisive factor. China's fastener industry has undergone a massive technological upgrade over the last decade, transitioning from high-volume manufacturing to precision engineering. Chinese firms now lead the way in material science, particularly in the development of bimetal technologies and specialized coatings. By integrating advanced R&D with efficient supply chain management, companies like Fasto provide the Middle Eastern market with a balance of high-end performance and logistical reliability that is difficult to match elsewhere.

Engineering Reliability: The Fasto Product Philosophy(https://www.fastoscrews.com/contact-us/)

Central to the company's presence at the BIG 5 is its specialized product line. As a dedicated stainless steel screws and bolts producer, the company focuses on the meticulous selection of alloys, including stainless steel, steel, titanium, and copper. The performance of these fasteners is further enhanced through a variety of sophisticated finishes. Depending on the specific project requirements, products can be treated with electroplating, ruspert, mechanical galvanize, hot-dip galvanizing (HDG), dacromate, or phosphate.

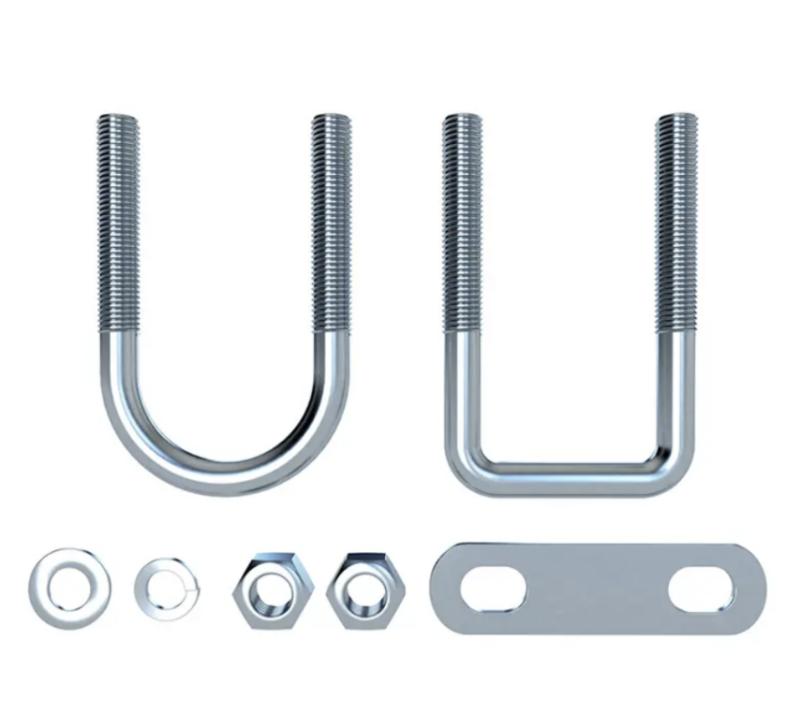

These coatings are not merely aesthetic; they are engineered layers designed to extend the lifecycle of the fastener. For instance, in solar energy installations-a booming sector in Saudi Arabia-the use of stainless steel screws and bolts ensures that mounting systems remain secure for decades, resisting the abrasive nature of sandstorms and UV exposure. The versatility of the product range allows Fasto to serve as a single-source provider, offering everything from rivets, nuts, and washers to complex, customized components for heavy industrial use.

The Bimetal Innovation and Material Synergy

One of the most significant contributions to the industry is the development of Bimetal Self-Drilling Screws (Bimetal SDS). These components represent a hybrid engineering success, combining a hardened carbon steel drill point with a stainless steel body. This allows the screw to penetrate thick steel substrates without the need for pre-drilling while maintaining the permanent corrosion resistance of stainless steel.

As a stainless steel screws and bolts producer with global reach, the manufacturer has refined this technology to meet the rigorous standards of international energy and construction projects. The ability to manufacture these high-performance items across multiple global hubs ensures that even the largest infrastructure projects maintain their timelines through a consistent and responsive supply chain. This localized support, combined with multilingual communication, bridges the gap between complex engineering specifications and on-site implementation.

Strategic Impact in Middle Eastern Infrastructure

The effectiveness of these solutions is best illustrated through real-world applications within the region. In a recent large-scale commercial development in Dubai's coastal zone, the humidity and salt spray posed a severe threat to standard fasteners used in the building's facade system. By implementing high-grade stainless steel screws and bolts, the project team was able to guarantee long-term safety and reduce maintenance costs significantly.

Similarly, in a major renewable energy project in Saudi Arabia, the company's heavy-duty anchors and thread rods were utilized to secure large-scale solar arrays. The choice of a specialized stainless steel screws and bolts producer allowed the contractors to source fasteners that were specifically tested for high-torque applications and thermal stability. These cases highlight the importance of selecting hardware that is "fit for purpose" rather than opting for generic alternatives that may lead to catastrophic failure in the demanding Middle Eastern climate.

Advancing the Future of Fastening Solutions

As the construction landscape continues to prioritize safety and longevity, the role of specialized hardware becomes increasingly prominent. The evolution of the stainless steel screws and bolts producer from a simple supplier to a technical partner is essential for the success of mega-projects. By focusing on precision, material diversity, and specialized coatings, Fasto demonstrates how high-performance fastening solutions are engineered for the world's most demanding environments.

The commitment to quality is backed by comprehensive capabilities that include not only standard screws and bolts but also anchors and customized components tailored to unique architectural visions. As the industry gathers at the SAUDI BIG 5, the focus remains on building structures that are not only grand in scale but also resilient at the most fundamental level-the joints and connections that hold them together.

For further information on high-performance fastening solutions and technical specifications, please visit the official website: https://www.fastoscrews.com/.

Fasto Industrial Co., Ltd.

Room A-907, Greenland Center, NO.9 Jinye Road, Yan Ta District, Xi'an, China

info@fastoscrews.com

FASTO is a leading specialist in high-performance Bimetal Self-Drilling Screws, serving global construction and energy projects where reliability is essential. Fasto Bimetal Self-Drilling Screws are engineered from high-performance metal combinations to provide reliable drilling performance in demanding applications, including coastal and high-load environments.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Top-Rated Stainless Steel Screws & Bolts Producer Fasto Showcasing At SAUDI BIG 5 here

News-ID: 4381098 • Views: …

More Releases from Fasto Industrial Co., Ltd.

Sustainability In Fastening: Fasto, A Top-Rated Stainless Steel Screws And Bolts …

High above the skyline of a burgeoning coastal metropolis, a specialized construction team secures the final panels of a massive aluminum façade. Exposed to the relentless salt spray of the ocean and the intense heat of the midday sun, every component of this multi-million dollar structure must withstand extreme environmental stress for decades. In such demanding scenarios, the integrity of the entire building rests on the smallest of components: the…

How To Identify A High Quality Bimetal Self Drilling Screws Supplier In China?

On a coastal construction site where the salt spray meets the structural skeleton of a new industrial complex, a critical failure often occurs: the sharp snap of a fastener head echoing against heavy-duty steel beams. While the high-salinity air demands the superior corrosion resistance of 304 or 316 stainless steel, the inherent softness of these alloys often causes them to buckle or shear when forced into thick structural framework. This…

Bimetal vs Carbon Steel: Insights From China Leading Bimetal Self Drilling Screw …

On a coastal construction site near the North Sea, a lead engineer inspects the structural integrity of a newly installed aluminum façade. The salty air and high humidity pose a constant threat of oxidation, a challenge where the choice of a single fastener determines the longevity of the entire building envelope. In such demanding environments, the selection between material types is not merely a matter of cost, but a critical…

China Leading Professional Multi-purpose Screws Producer Highlights From MESSE S …

The expansive halls of Messe Stuttgart serve as a premier destination for global industrial innovation, drawing thousands of engineering experts, international distributors, and construction professionals to witness the latest advancements in fastening technology. As one of the world's most influential trade fairs for the fastener and fixing industry, the event provides a critical barometer for market trends and technical excellence. Amidst the highly specialized displays of automotive and aerospace components,…

More Releases for Screws

Construction And Furniture Industries Fueling Structural Wood Screws Market Grow …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

Structural Wood Screws Market Size Growth Forecast: What to Expect by 2025?

The market size of the structural wood screws industry has seen consistent growth in the past few years. It's projected to expand from a value of $4.76 billion in 2024 to $5 billion in 2025, representing a…

What is the difference between drywall screws VS wood screws?

Sinsun Fasteners is a leading manufacturer of all kind of screws. We specialize in drywall screw [https://www.sinsunfastener.com/drywall-screw/]s and wood screws. Many customers are interested in understanding the differences between these widely used screws.

Today we will compare and explain the differences between them from the aspects of what they are, what they are used for, head shape, thread, tip, etc.

1. Comparison of main uses of plasterboard screws and wood screws

Comparison…

Orthopedic Screws Market Overview, Trends Analysis

"The new report published by The Business Research Company, titled ""Orthopedic Screws Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033"", delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the orthopedic screws market size has grown strongly in recent years. It will grow from $1.19 billion in…

Balls Screws Market Size 2024 to 2031.

Market Overview and Report Coverage

A ballscrew, also known as a ball bearing screw, is a mechanical device used to convert rotational motion into linear motion. They are commonly used in industrial machinery and automation equipment to provide precise and efficient linear motion.

The ballscrews market is expected to grow at a CAGR of 5.94% during the forecasted period. The market is driven by the increasing demand for automation and…

Unlocking Prosperity: Orthopedic Screws Market Insights

Growth Market Reports, a prominent Market research firm, has recently released a comprehensive report on the 𝐎𝐫𝐭𝐡𝐨𝐩𝐞𝐝𝐢𝐜 𝐒𝐜𝐫𝐞𝐰𝐬 𝐌𝐚𝐫𝐤𝐞𝐭. This report offers a complete overview of the key aspects of the market, providing a robust assessment of the current Market situation and its anticipated scope. The report spans the forecast period from 2024 to 2032.

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐎𝐫𝐭𝐡𝐨𝐩𝐞𝐝𝐢𝐜 𝐒𝐜𝐫𝐞𝐰𝐬 𝐌𝐚𝐫𝐤𝐞𝐭 𝐬𝐢𝐳𝐞 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐔𝐒𝐃 𝟏.𝟐𝟎 𝐁𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬…

Self-Drilling Screws from Challenge Europe

The concept of self-drilling screws came out of the need for speed and the realisation that by putting a cutting face on the end of a power driven screw it could cut its own hole and immediately generate a female thread, so saving a considerable amount of time. In the case of self-drilling Tek type screws, with integral sealing washer, this time saving is increased, together with the added functional…