Press release

How to Understand Investment Casting? Industry Trends and Best Practices

Investment casting [https://www.dgsxltd.com/investment-casting/], a sophisticated process that transforms wax patterns into precise metal components, can be classified into three main types based on the shell material used: silica sol casting, sodium silicate (water glass) casting, and composite casting. Also known as the "lost wax casting [https://www.dgsxltd.com/comprehensive-range-of-metal-casting-services/]" process, this method involves multiple steps-including wax pattern creation, shell building, dewaxing, metal pouring, and post-casting treatment-to produce parts with exceptional dimensional accuracy and superior surface finish.The core principle lies in applying successive layers of refractory material onto the wax pattern. Once hardened and dried, the wax is melted out to form a hollow ceramic shell. This shell is then fired and prepared for pouring molten metal, resulting in highly detailed and precise castings.

Now, let's explore the complete workflow of investment casting in detail.

Image: https://ecdn6.globalso.com/upload/p/2590/image_other/2026-01/stainless-steel-casting-2.jpgImage: https://ecdn6.globalso.com/upload/p/2590/image_other/2026-01/metal-casting-company-3.jpg

1. Process and Key Steps

Investment casting is a method used to obtain high-precision metal casting [https://www.dgsxltd.com/custom-precision-casting-service-for-marine-and-offshore-engineering/] parts through processes such as wax pattern creation, shell molding, dewaxing, pouring, and post-processing. This process requires not only skilled craftsmanship but also modern equipment and technology to ensure the high quality of investment castings.

2. Importance of Wax Pattern Production

In investment casting, wax patterns play a crucial role. They must accurately shape the cavity within the refractory shell while maintaining high dimensional precision and excellent surface finish to ensure the final quality of the castings. Additionally, the design and production of wax patterns should facilitate subsequent shell-making processes, thereby improving overall production efficiency.

3. Shell Making and Dewaxing

In investment casting, the wax pattern undergoes coating, sand stuccoing, and hardening to form a thin shell of 1-2 mm. However, to ensure sufficient shell strength, multiple coating cycles-typically six to seven layers or more-are required for different wax pattern shapes and structures. This results in a refractory shell with a final thickness exceeding 10 mm.

Next, to remove the wax pattern and form the casting cavity, a dewaxing process is performed. We employ steam dewaxing, which melts the wax and allows it to drain smoothly through the downward-facing sprue. The recovered wax is recycled for reuse, making the process both environmentally friendly and economical.

4. Pouring and Post-Processing

Before metal pouring, the shell must be placed in a sintering furnace and fired at temperatures above 950 degrees C for approximately two hours. This step removes moisture, residual wax, and other impurities from the shell, enhancing its strength and ensuring cavity cleanliness.

After removal from the sintering furnace, the shell is immediately poured with molten metal at high temperatures (typically around 1050 degrees C). At this stage, the slower cooling rate and relatively high fluidity of the molten metal within the shell enable precise replication of the cavity shape, thereby improving casting accuracy.

After pouring and cooling, the castings undergo a series of post-processing steps to meet customer requirements for appearance and performance. These steps include shell removal, shot blasting, gate cutting, grinding, weld repair, passivation, and heat treatment. Through multiple inspections, defective castings are identified and repaired to ensure the final product quality.

Image: https://ecdn6.globalso.com/upload/p/2590/image_other/2026-01/metal-casting-services.png

After gaining a comprehensive understanding of the investment casting process, it is crucial to recognize the common defects that may arise during production and how to mitigate or prevent them. Defects in investment castings can be categorized into surface and internal flaws, as well as dimensional and roughness deviations. Surface and internal defects include issues such as incomplete filling, cold shuts, shrinkage porosity, gas pores, slag inclusions, hot tearing, and cold cracking, while dimensional and roughness deviations are primarily manifested as elongation and deformation of the castings.

The occurrence of these defects is influenced by multiple factors, such as the pouring temperature of the molten alloy, the sintering temperature and preparation process of the ceramic shell, and the design of the gating system and casting structure. To address different types of defects, it is essential to analyze their specific causes and implement corresponding preventive and corrective measures. For example, to mitigate incomplete filling, it may be necessary to increase the pouring temperature and shell temperature to ensure adequate fluidity of the molten metal. Alternatively, adjustments can be made to the wall thickness of the casting or the design of the gating system. Other measures include thorough sintering of the shell to improve its permeability, controlling the pouring speed, and ensuring sufficient molten metal volume. Through these targeted approaches, defects in precision casting components [https://www.dgsxltd.com/custom-non-standard-metal-precision-casting-components/] can be effectively reduced or eliminated, thereby enhancing product quality.

Media Contact

Company Name: Dongguan SX Technology Co.,Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=how-to-understand-investment-casting]

Country: China

Website: https://www.dgsxltd.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Understand Investment Casting? Industry Trends and Best Practices here

News-ID: 4379017 • Views: …

More Releases from ABNewswire

Invest in The Wardrobe Foundation: These 3 Boots Are Built to Last

(Email: nate@qlcodex.com Phone/WhatsApp/Wechat: +86 13880425105 Website: www.qlcodex.com)

Trends come and go, but what truly stays in our closets are those timeless, always-reliable pieces. This winter, Q.L. CODEX wants to talk about the few pairs of boots that can walk with you for five, ten years, or even longer. They're not just shoes; they're part of your signature style.

1. The Western Boot [https://www.qlcodex.com/boots/]: Your 3-in-1 Style Chameleon

This boot holds the free spirit…

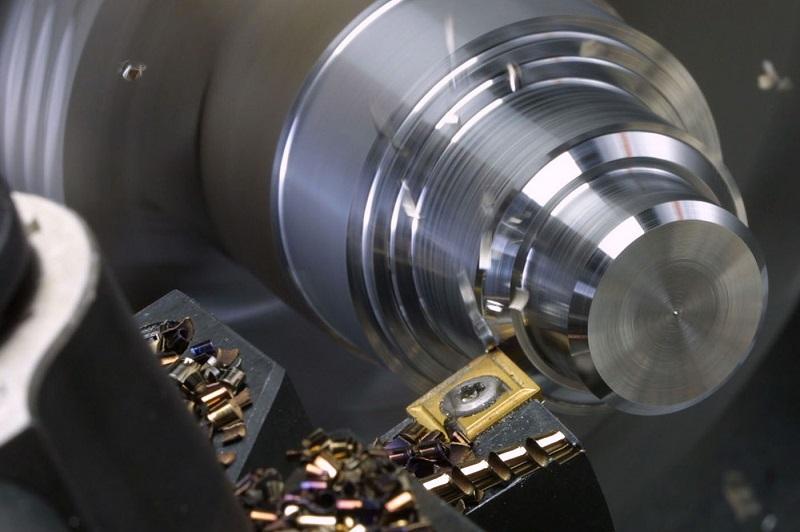

What are the challenges in CNC turning of stainless steel parts?

Precision CNC turning [https://www.dgsxltd.com/custom-metal-parts-cnc-turning-services/] is typically used for machining rotary parts that can be securely clamped on a lathe. CNC lathes are characterized by high rigidity, precision manufacturing, and accurate tool setting. They allow for straightforward and precise manual or automatic tool compensation, enabling the machining of parts with stringent lathe accuracy requirements. Moreover, the tool movement in numerically controlled turning is achieved through high-precision interpolation and servo drive systems.…

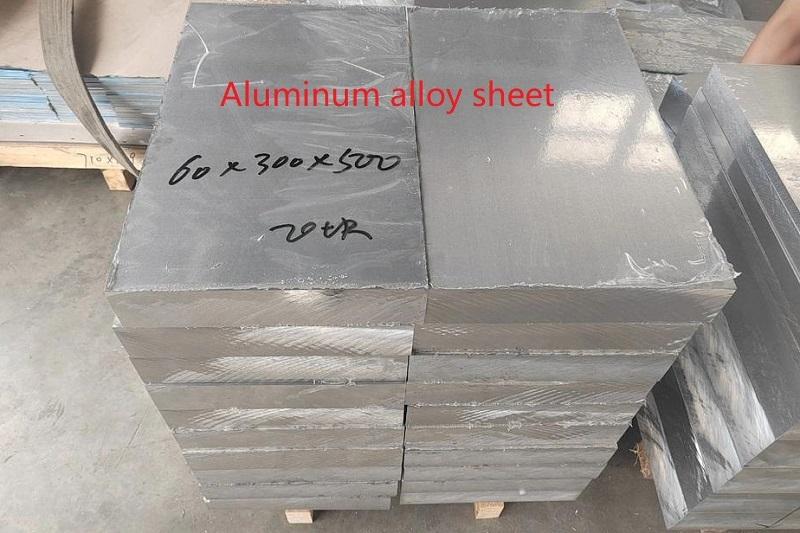

What are the advantages of aluminum alloy in precision CNC machining?

In the field of precision CNC machining [https://www.dgsxltd.com/custom-metal-cnc-machining-bicycle-components/], material selection directly influences processing efficiency and product quality. Aluminum alloy stands out in CNC machining due to its unique combination of properties, making it one of the preferred materials across various industries such as aerospace, consumer electronics, and automotive manufacturing-rightly earning it the title of the "Lightweight Artisan" of modern manufacturing. As a high-precision forming technology, CNC machining of aluminum alloy…

Which types of parts are suitable for CNC turning?

CNC turning [https://www.dgsxltd.com/non-standard-cnc-machining-services-for-outdoor-product-parts/] is one of the indispensable and critical CNC machining [https://www.dgsxltd.com/cnc-machining/] methods in modern manufacturing. It enables automated processing through numerical control technology, allowing for the efficient and precise machining of a wide range of complex parts. Compared with conventional turning machining, CNC turning offers higher production efficiency and greater machining accuracy, making it suitable for processing various types of components.

CNC turning is carried out using a CNC…

More Releases for Investment

ST Investment Co., Ltd: Pioneering the Global Investment Trend

Since its establishment in 2017 in the United Kingdom, ST Investment Co., Ltd has rapidly emerged as a shining star in the global investment sector. Through its diversified business portfolio and exceptional financial services, the company provides a comprehensive wealth growth platform for clients worldwide. Its services span key sectors such as artificial intelligence-based smart contracts, private equity, gold investments, and wealth management, all aimed at delivering stable and diverse…

Lakshmishree Investment: Common Investment Mistakes When Markets Are High

One big mistake many investors make is taking too much risk because they fear missing out.

Stock markets around the world are on fire! From the bustling streets of Wall Street to the vibrant Bombay Stock Exchange (BSE), markets are scaling new highs, leaving many investors excited and bewildered. While this bull run is thrilling, it can also be confusing. Should you jump in and buy more? Hold on tight…

private equity international,private equity investment, equity firm,private inve …

Private equity firms are investment companies that specialize in acquiring and managing private companies. These firms typically provide capital to mature companies that have a proven track record of revenue and earnings, but that may be underperforming or undervalued. Private equity firms typically hold their investments for several years and then exit through a sale or an initial public offering (IPO).

http://gdzaojiazixun.cn/

China private investment consulting

E-mail:nolan@pandacuads.com

The private equity process begins with the…

China Investment Bank, China Investment Consultant, China Investment Corporation …

Pandacu is a company that specializes in cross-border investment in China. The company was founded in china and has since grown to become one of the leading cross-border investment firms in China. Pandacu offers a wide range of services to its clients, including investment advisory, market research, due diligence, and post-investment support.

http://pandacuads.com/

Investment banking consultant

Email:nolan@pandacuads.com

Cross-border investment in China can be a complex and challenging process, as the country has a unique…

Trident Steels - Investment Casting, Stainless Steel Investment Casting, Steel I …

With decades of experience in this industry, we have become the preferred partner for global companies who look for high-end metal casting manufacturing from India. Our investment casting company in India offers best-in-class quality products and services to our customers. We are a customer-centric company and invest in our people, processes, and technology to provide high-quality products every time. This has helped us to become the preferred partner for companies…

Investment Management Market Growth Improvement Highly Witness | NWQ Investment …

Investment management is designed to help investors or owners to recognize, manage, and communicate the performance and risks of assets and related investments. As an alternative to spending time pursuing data and manually creating reports, fund managers, owners, and operators can focus on maximizing performance.

Investment Management market size is expected to grow at a compound annual growth rate of xx% for the forecast period of 2021 to 2028.

Market IntelliX report…