Press release

What are the challenges in CNC turning of stainless steel parts?

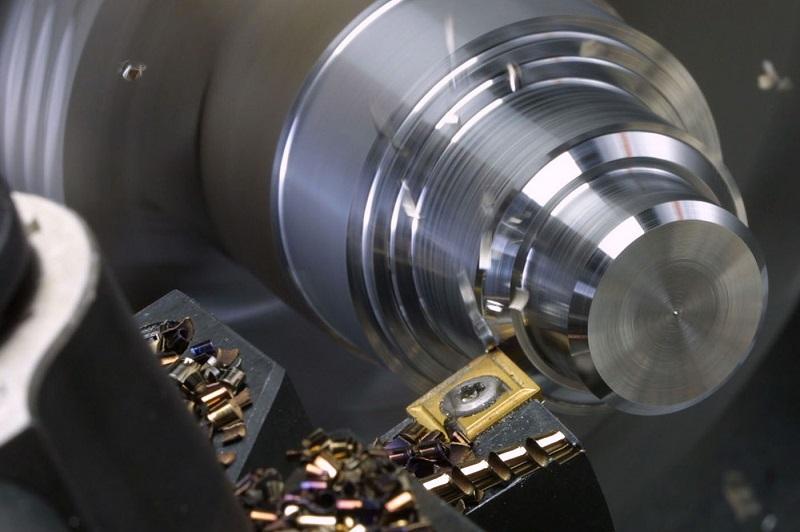

Precision CNC turning [https://www.dgsxltd.com/custom-metal-parts-cnc-turning-services/] is typically used for machining rotary parts that can be securely clamped on a lathe. CNC lathes are characterized by high rigidity, precision manufacturing, and accurate tool setting. They allow for straightforward and precise manual or automatic tool compensation, enabling the machining of parts with stringent lathe accuracy requirements. Moreover, the tool movement in numerically controlled turning is achieved through high-precision interpolation and servo drive systems. When machining arcs or other curved surfaces, this method produces shapes that more closely conform to the geometric requirements of the design drawings compared to copy lathes.Stainless steel, which contains 16%-18% chromium, is often referred to as acid-resistant or corrosion-resistant stainless steel. It offers good corrosion resistance in atmospheric or mildly corrosive environments and maintains high strength at elevated temperatures (>450 degrees C). Known for its excellent corrosion resistance, formability, adaptability, and strong toughness across a wide temperature range, stainless steel is widely used in heavy industry, light industry, and everyday products.

When CNC machining [https://www.dgsxltd.com/cnc-machining/] stainless steel parts, the goals are speed, accuracy, and precision. However, challenges are often encountered during the process. Below, we analyze the key difficulties that may arise in the CNC turning of stainless steel components.

Image: https://ecdn6.globalso.com/upload/p/2590/image_other/2026-01/cnc-machining-services-7.jpgImage: https://ecdn6.globalso.com/upload/p/2590/image_other/2026-01/turning-machining-3.jpg

1.High Thermal Strength and ToughnessThe high thermal strength and toughness of stainless steel make it difficult to achieve high-speed cutting, which directly impacts CNC machining. This is a major challenge in the CNC cutting of stainless steel. While austenitic and martensitic stainless steels do not exhibit high hardness or tensile strength-comparable to that of No. 40 carbon steel-their elongation, reduction of area, and impact value are significantly higher. For example, the elongation of 1Cr18Ni9Ti is as high as 210% of that of No. 40 steel. This results in difficulties in chip breaking during high-speed CNC cutting [https://www.dgsxltd.com/non-standard-cnc-machining-services-for-outdoor-product-parts/], along with substantial energy consumption due to cutting deformation.

2.Work Hardening and AdhesivenessStainless steel is prone to work hardening and chip adhesion, with poor thermal conductivity further complicating the cutting process. During high-speed CNC turning, stainless steel tends to undergo work hardening. The extrusion of the workpiece material by the tool tip causes deformation in the cutting zone, leading to intragranular slip, lattice distortion, and microstructural densification. This can increase the cutting hardness by 2-3 times, with the hardened layer sometimes reaching hundreds of micrometers in depth. Additionally, the strong adhesion and poor thermal conductivity of stainless steel chips contribute to built-up edge formation on the tool tip and cutting edge, exacerbating vibration during machining and accelerating tool wear.

3.Thread Machining IssuesCommon problems include poor surface roughness of threads and severe tool wear. During CNC threading of stainless steel, typical issues such as poor thread surface finish, fish-scale-like patterns, and tool biting often occur. These are primarily attributed to an excessively small relief angle on both sides of the threading tool, which increases friction with the thread surface and deteriorates machining quality. Moreover, tool wear cannot be overlooked, as it alters the rake and relief angles, leading to increased cutting force, vibration, and degradation of the machined surface.

4.Tool and Machine Tool FactorsInsufficient rigidity and poor machine tool accuracy cause vibration, negatively affecting machining quality. The rigidity of the machine tool and tooling system is also critical. Problems such as insecure clamping of the threading tool, excessive tool overhang, inadequate rigidity of the tool holder, and poor machine tool accuracy can induce vibration, thereby compromising thread surface quality. Therefore, during operation, it is essential to ensure the stability of the machine tool, tool, and workpiece, and to carefully adjust the tool tip height to avoid tool biting.

Image: https://ecdn6.globalso.com/upload/p/2590/image_other/2026-01/cnc-turning-services-3.jpg

Although precision CNC machining [https://www.dgsxltd.com/custom-metal-cnc-machining-bicycle-components/] of stainless steel offers an impressive balance of beneficial properties, it does come with certain challenges. Austenitic stainless steels are particularly prone to work hardening during machining, which can increase their hardness. If the machinist is unfamiliar with stainless steel processing, this can accelerate tool wear and negatively impact the quality of the finished product.

Furthermore, stainless steel generally has relatively low thermal conductivity, leading to heat buildup in the cutting zone. Without adequate cooling and proper cutting parameters, temperatures can rise high enough to cause sensitization of the stainless steel. Depending on the intended application of the stainless steel part, this may result in issues such as intergranular corrosion and stress corrosion cracking.

Despite these challenges, experienced machinists can reliably produce high quality stainless steel CNC parts [https://www.dgsxltd.com/non-standard-cnc-turning-cnc-milling-titanium-alloy-parts/] as long as suitable tools and equipment are used, along with well-optimized machining practices.

Media Contact

Company Name: Dongguan SX Technology Co.,Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=what-are-the-challenges-in-cnc-turning-of-stainless-steel-parts]

Country: China

Website: https://www.dgsxltd.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release What are the challenges in CNC turning of stainless steel parts? here

News-ID: 4379015 • Views: …

More Releases from ABNewswire

Invest in The Wardrobe Foundation: These 3 Boots Are Built to Last

(Email: nate@qlcodex.com Phone/WhatsApp/Wechat: +86 13880425105 Website: www.qlcodex.com)

Trends come and go, but what truly stays in our closets are those timeless, always-reliable pieces. This winter, Q.L. CODEX wants to talk about the few pairs of boots that can walk with you for five, ten years, or even longer. They're not just shoes; they're part of your signature style.

1. The Western Boot [https://www.qlcodex.com/boots/]: Your 3-in-1 Style Chameleon

This boot holds the free spirit…

How to Understand Investment Casting? Industry Trends and Best Practices

Investment casting [https://www.dgsxltd.com/investment-casting/], a sophisticated process that transforms wax patterns into precise metal components, can be classified into three main types based on the shell material used: silica sol casting, sodium silicate (water glass) casting, and composite casting. Also known as the "lost wax casting [https://www.dgsxltd.com/comprehensive-range-of-metal-casting-services/]" process, this method involves multiple steps-including wax pattern creation, shell building, dewaxing, metal pouring, and post-casting treatment-to produce parts with exceptional dimensional accuracy and…

What are the advantages of aluminum alloy in precision CNC machining?

In the field of precision CNC machining [https://www.dgsxltd.com/custom-metal-cnc-machining-bicycle-components/], material selection directly influences processing efficiency and product quality. Aluminum alloy stands out in CNC machining due to its unique combination of properties, making it one of the preferred materials across various industries such as aerospace, consumer electronics, and automotive manufacturing-rightly earning it the title of the "Lightweight Artisan" of modern manufacturing. As a high-precision forming technology, CNC machining of aluminum alloy…

Which types of parts are suitable for CNC turning?

CNC turning [https://www.dgsxltd.com/non-standard-cnc-machining-services-for-outdoor-product-parts/] is one of the indispensable and critical CNC machining [https://www.dgsxltd.com/cnc-machining/] methods in modern manufacturing. It enables automated processing through numerical control technology, allowing for the efficient and precise machining of a wide range of complex parts. Compared with conventional turning machining, CNC turning offers higher production efficiency and greater machining accuracy, making it suitable for processing various types of components.

CNC turning is carried out using a CNC…

More Releases for CNC

XTJ CNC Elevates Custom CNC Machining for Highly Precise Industrial Applications

Carmel, IN 46032, United States, 28th Jan 2026 - XTJ CNC, a prominent provider of custom CNC machining servicesa prominent provider of custom CNC machining services, has announced significant advancements in its capabilities to better serve industries requiring high-precision components. With a focus on custom CNC machining, the company is reinforcing its reputation as a trusted partner in the aerospace, automotive, and electronics sectors. These advancements reflect XTJ CNC's commitment…

Benefits of CNC Machining for Custom Robotic Projects - Tuofa CNC Machining

Robotics is evolving quickly, and higher-performance robots demand stronger mechanical consistency. As DOF increases, joint stacks and mounting interfaces must align accurately to preserve smooth, repeatable motion. CNC machining delivers custom parts with controlled dimensions and reliable quality, reducing fit issues during assembly. It also shortens prototype cycles and supports small-batch production, helping robotics teams convert designs into dependable hardware.

Robotics is getting smarter and smarter. Better perception, smarter control loops,…

CNC Controller Market Report 2024 - CNC Controller Market Trends, Opportunities …

"The Business Research Company recently released a comprehensive report on the Global CNC Controller Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

CNC Controller Global Market to Generate $3.84 Billion By 2028, Registering at a …

"The new report published by The Business Research Company, titled CNC Controller Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033, delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the cnc controller market size has grown strongly in recent years. It will grow from $2.82 billion…

Silver CNC Now Offers CNC Rotary Tables for CNC Machining Centers

Silver CNC is now offering a new line of CNC rotary tables that are perfect for use with CNC machining centers. The rotary tables are available in three different sizes, and each one is made from high-quality cast iron to ensure durability and precision. With a built-in indexing system, the rotary tables make it easy to position your workpiece exactly where you need it. Plus, they're backed by a full…

Trending 2020: CNC Machine (CNC Machine Tools) Market Booming Worldwide

Prophecy Market Insights recently presented CNC Machine (CNC Machine Tools) market report which provides reliable and sincere insights related to the various segments and sub-segments of the market. The market study throws light on the various factors that are projected to impact the overall dynamics of the CNC Machine (CNC Machine Tools) market over the forecast period (2019-2029).

The CNC Machine (CNC Machine Tools) research study contains 100+ market data Tables,…