Press release

Almond Processing Plant DPR - 2026: Investment Cost, Market Growth and Machinery

The global almond processing industry is witnessing robust growth driven by the rapidly expanding health and wellness, plant-based food, and confectionery sectors and increasing demand for nutritious, versatile, and high-value nut products. At the heart of this expansion lies a critical food processing segment-almond processing. As consumers worldwide transition toward healthier snacking habits and plant-based dietary alternatives, establishing an almond processing plant presents a strategically compelling business opportunity for entrepreneurs and food processing investors seeking to capitalize on this growing and essential market.Market Overview and Growth Potential

The global almond market demonstrates a strong growth trajectory, valued at 1.70 Million Tons in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach 2.28 Million Tons by 2034, exhibiting a robust CAGR of 3.3% from 2026-2034. This sustained expansion is driven by rising consumption of nuts as healthy snacks, growing demand in confectionery and bakery products, expanding use in dairy alternatives such as almond milk, and increasing adoption of plant-based diets.

Almonds are the edible seeds that come from the fruit of the almond tree (Prunus dulcis), which belongs to the Rosaceae family. Almonds are considered drupes or stone fruits because of the hard shell that surrounds the kernel, which is the part that people consume and is packed with nutrients. Having a very mild, slightly sweet taste and an extremely crunchy texture, almonds are eaten either raw or roasted, and they are also used to prepare many products like almond flour, almond butter, almond milk, and almond oil. They have an excellent nutritional profile and are known for being a good source of healthy monounsaturated fats, plant-based proteins, dietary fibers, vitamins (especially vitamin E and B-complex), minerals (like magnesium, calcium, and potassium), and antioxidants.

The global almond market is experiencing strong growth driven by increasing consumer awareness of healthy snacking and nutritious diets, as almonds are valued for their protein, healthy fats, vitamins, and antioxidants. According to an industry report, 56% of consumers enjoy a healthy snack at least once daily, compared to 49% for indulgent snacks. The rising incorporation of almonds into bakery, confectionery, and snack products further fuels market demand, while the growing popularity of plant-based and dairy-alternative products, such as almond milk and almond-based yogurts, is expanding the market scope significantly.

Plant Capacity and Production Scale

The proposed almond processing facility is designed with an annual production capacity ranging between 10,000-20,000 MT per Year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from household consumption and commercial bakery products to almond milk and dairy substitutes, confectionery production, snack foods, and cosmetic-grade almond oil-ensuring steady demand and consistent revenue streams across multiple product categories.

Request for a Sample Report: https://www.imarcgroup.com/almond-processing-plant-project-report/requestsample

Financial Viability and Profitability Analysis

The almond processing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

Gross Profit Margins: 20-30%

Net Profit Margins: 8-12%

These margins are supported by stable demand across food processing, confectionery, bakery, dairy alternative, and nutraceutical sectors, value-added nut processing positioning, and the critical nature of processed almonds in healthy snacking and plant-based food applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established food processors looking to diversify their product portfolio in the nut processing segment.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for an almond processing plant is primarily driven by:

Raw Materials: 80-85% of total OpEx

Utilities: 5-10% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with raw almonds in shells being the primary input material. Establishing long-term contracts with reliable almond growers and suppliers helps mitigate price volatility and ensures consistent raw material supply, which is critical given that raw almond procurement represents the most significant cost factor in almond processing operations.

Capital Investment Requirements

Setting up an almond processing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to almond-growing regions and raw almond suppliers. Proximity to target food processing and retail markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws, food safety regulations, and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized processing equipment essential for production. Key machinery includes:

• Cleaners and washing systems for removing dirt, debris, and foreign matter from raw almonds before processing

• Shellers and cracking machines for mechanically removing hard shells to extract almond kernels with minimal damage

• Blanchers and steam processing equipment for removing thin brown skin from almond kernels to produce blanched almonds

• Roasters and thermal processing units for roasting almonds at controlled temperatures to develop desired flavor and texture

• Grinders and milling equipment for producing almond flour, almond butter, and finely ground almond products

• Oil extraction systems using cold-pressing or solvent extraction methods for producing cosmetic and culinary-grade almond oil

• Conveyors and material handling systems for efficient movement of almonds through different processing stages

• Packaging machines for automated weighing, filling, sealing, and labeling of finished almond products in retail and bulk packaging

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and maintain the highest food hygiene standards throughout the production process. The layout should be optimized with separate areas for raw almond storage, cleaning and shelling zone, blanching section, roasting unit, grinding and milling area, oil extraction facility, quality control laboratory, finished goods warehouse, utility block, waste management area, and administrative block.

Other Capital Costs: Pre-operative expenses, machinery installation costs, food safety and regulatory compliance certifications including HACCP and FDA approvals, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=9398&flag=C

Major Applications and Market Segments

Processed almond products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Food Processing Industry: Almonds and almond-derived products are essential ingredients for bakery, confectionery, and snack production, adding nutritional value, texture, and premium positioning to finished food products.

Dairy Alternatives: Almond milk and almond-based dairy substitutes are growing rapidly among health-conscious consumers, lactose-intolerant individuals, and those following plant-based or vegan dietary preferences worldwide.

Retail and Household Consumption: Raw, roasted, blanched, and sliced almonds are widely used as convenient healthy snacks and versatile cooking ingredients in household kitchens and commercial food preparation.

Almond Oil Production: Almond oil is extensively used in edible applications for cooking and dressing, as well as in cosmetic and pharmaceutical formulations for skincare, haircare, and therapeutic massage products.

Why Invest in Almond Processing?

Several compelling factors make almond processing an attractive investment opportunity:

Rising Health Awareness: Almonds are recognized as nutrient-dense superfoods supporting heart health, brain function, and overall wellness, driving sustained consumer demand across developed and emerging markets globally.

Growing Demand in Confectionery and Bakery: Almonds are critical ingredients in premium chocolates, pastries, artisan breads, and snack foods, where they add nutritional value, texture, and premium brand positioning.

Expanding Plant-Based Diets: Almond milk, almond butter, and other almond-based products cater to the rapidly growing vegan, lactose-intolerant, and health-conscious consumer populations seeking dairy and animal product alternatives.

Product Diversification Opportunities: Multiple value-added products can be developed from almond processing, including blanched almonds, almond flour, almond butter, and cosmetic-grade almond oil, enabling manufacturers to target diverse market segments.

Scalable Production Model: Processing units can expand capacity gradually based on market demand, raw material availability, and capital availability, supporting sustainable and financially prudent business growth strategies.

Global Trade and Export Opportunities: Processed almonds and almond products have strong international demand, particularly in Asian, Middle Eastern, and European markets, creating significant export revenue potential for efficient processors.

Premium Product Positioning: Almonds command premium pricing compared to other nuts due to their superior nutritional profile, culinary versatility, and strong consumer brand associations with health and quality.

Manufacturing Process Excellence

The almond processing procedure involves several precision-controlled stages:

• Cleaning: Raw almonds in shells are thoroughly cleaned using washing systems and air classifiers to remove dirt, debris, stones, and foreign matter before further processing

• Grading: Cleaned almonds are sorted and graded by size, weight, and quality using mechanical screens and optical sorting equipment to ensure uniform processing and consistent product quality

• Shelling: Graded almonds are mechanically cracked and shells are separated from kernels using specialized shelling machines and air separation systems

• Blanching: Shelled almond kernels are treated with steam or hot water to loosen and remove the thin brown skin, producing smooth blanched almonds for premium applications

• Roasting: Blanched or natural almonds are roasted in controlled-temperature ovens to develop desired flavor, color, and crunchiness for different product specifications

• Slicing or Grinding: Processed almonds are sliced, slivered, diced, or ground into almond flour or almond butter depending on final product requirements and market demand

• Almond Oil Extraction: Selected almond kernels undergo cold-pressing or solvent extraction processes to produce high-quality edible and cosmetic-grade almond oil with maximum nutrient retention

• Quality Inspection and Packaging: Finished almond products undergo comprehensive quality testing for moisture, size, color, flavor, and contamination, followed by automated packaging in retail or bulk formats for distribution

Buy Now:

https://www.imarcgroup.com/checkout?id=9398&method=2175

Industry Leadership

The global almond processing industry is led by established food processors and nut companies with extensive production capabilities and diverse product portfolios. Key industry players include:

• Blue Diamond Growers

• Wonderful Pistachios & Almonds

• Panoche Creek Packing

• Spycher Brothers

• Select Harvest

• Mariani Nut Company

• Waterford Nut Co.

These companies serve diverse end-use sectors including the food processing industry, confectionery and bakery sector, dairy alternatives, nutraceuticals, health and wellness segment, and retail grocery distribution, demonstrating the broad market applicability of processed almond products.

Recent Industry Developments

September 2025: EAT and the Almond Board of California formed a strategic partnership to promote sustainable, healthy diets and responsible almond production. Launched at the Stockholm Food Forum 2025, the collaboration aims to scale nutritious, environmentally friendly food systems, advance agricultural innovation, and support global health and planetary sustainability goals.

February 2025: Blue Diamond Almonds partnered with Mike's Hot Honey to launch Hot Honey Almonds, a sweet and spicy snack combining honey and chili flavors with almonds. Available online and in select Walmart stores, the collaboration highlights both brands' focus on bold, innovative flavors, offering a versatile on-the-go snack or culinary topping.

Conclusion

The almond processing sector presents a strategically positioned investment opportunity at the intersection of health and wellness, plant-based nutrition, and premium food processing. With favorable profit margins ranging from 20-30% gross profit and 8-12% net profit, strong market drivers including rising health consciousness, expanding plant-based dietary trends, growing confectionery and bakery demand, and increasing adoption of almond-based dairy alternatives, establishing an almond processing plant offers significant potential for long-term business success and sustainable returns. The combination of essential nutritional applications, critical role in healthy snacking and plant-based foods, expanding product innovation opportunities across flour, butter, milk, and oil segments, and strong export potential to international markets creates an attractive value proposition for serious food processing investors committed to quality manufacturing and operational excellence.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. IMARC Group provides a comprehensive suite of market entry and expansion services, including market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Almond Processing Plant DPR - 2026: Investment Cost, Market Growth and Machinery here

News-ID: 4377306 • Views: …

More Releases from IMARC Group

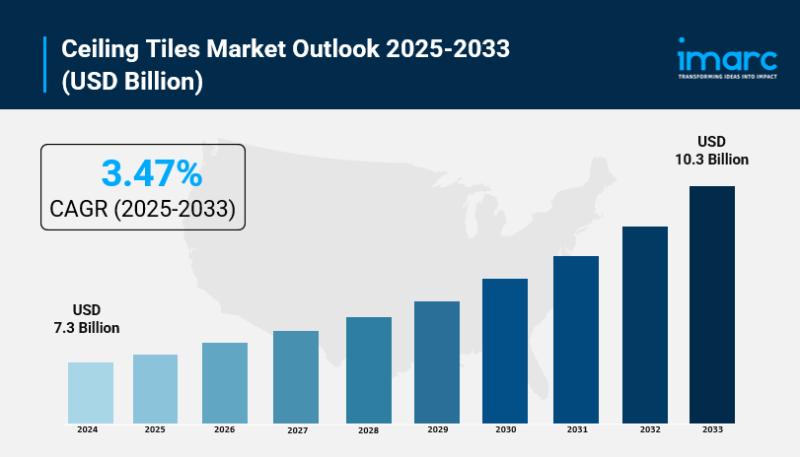

Ceiling Tiles Market is Expected to Grow USD 16.3 Billion by 2033 | At CAGR 3.77 …

IMARC Group, a leading market research company, has recently released a report titled "Ceiling tiles Market Size, Share, Trends and Forecast by Product, Material, Distribution Channel, Pricing, End-User, and Region, 2025-2033." The study provides a detailed analysis of the industry, including the Ceiling tiles market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Ceiling Tiles Market Overview

The…

India Hospital Market Overview: Size, Industry Expansion & Growth Potential 2026 …

India Hospital Market Report Introduction:

According to IMARC Group's report titled "India Hospital Market Size, Share, Growth & Forecast 2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

How Big is the India Hospital Industry?

The India hospital market size was valued at USD 193.42 Billion in 2025 and is projected to reach USD 364.55 Billion by 2034, growing at a compound annual growth…

Gelato Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

The global gelato industry is experiencing robust growth driven by rising consumer preference for premium frozen desserts, growth in foodservice outlets such as cafes and ice cream parlors, expansion of retail channels, and increasing awareness of artisanal and high-quality frozen treats. As urbanization accelerates, disposable incomes rise, and consumers shift toward premium frozen dessert options with natural ingredients and innovative flavors, establishing a gelato manufacturing plant presents a strategically compelling…

Biodiesel Manufacturing Plant DPR 2026: Investment Cost, Market Growth & ROI

The global biodiesel manufacturing industry is witnessing robust growth driven by the rapidly expanding renewable energy sector and increasing demand for sustainable transportation fuels. At the heart of this expansion lies a critical clean fuel solution-biodiesel. As transportation sectors transition toward low-carbon alternatives and controlled emissions reduction methods, establishing a biodiesel manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and renewable energy investors seeking to capitalize on this…

More Releases for Almond

Almond Drink Market Beyond the Nut: Exploring the Growth Potential of the Almond …

Almond Drink Market to reach over USD 8.23 billion by the year 2031 - Exclusive Report by InsightAce Analytic

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Almond Drink Market Size, Share & Trends Analysis Report By Type (Sweetened And Unsweetened), Application (Food Service Industry, Household) And Distribution Channel (E-Commerce, Retail, Supermarket/Hypermarket, And Others. )- Market Outlook And Industry Analysis 2031"

The global almond drink…

Almond Flavored Powder Market Rich and Nutty Almond Flavor Enhancements for Vari …

Global Almond Flavored Powder Market Overview:

The Almond Flavored Powder market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Almond Flavored Powder market has experienced significant growth, driven by factors such as increasing consumer demand, technological advancements, and globalization. This growth…

Numerous Nutritional Benefits Offered by Almond and Almond Ingredients Driving t …

The Almond Ingredients Market size is estimated to be valued at USD 10.2 billion in 2020. It is projected to reach USD 16.9 billion by 2025, recording a CAGR of 10.5% in terms of value. Numerous nutritional benefits offered by almond and almond ingredients, a rapid increase in almond-based product launches by key players in the food & beverage market, growing inclination of consumers toward plant-based and gluten-free products, and…

Almond Oils, Almond Oils Manufacturer, Almond Oils Supplier - Ozone Naturals

Ozone Naturals is one of the largest supplier of Almond Oil in India. In our sophisticated (SCFE) processing facilities, it is extracted from almond's nut to ensure its quality. Almond Oil has been known for its infinite number of health benefits including its famous skin and beauty benefits. The reason why almond oil is so good for health lies in its composition. Being a rich source of various vitamins and…

Almond Oils, Almond Oils Manufacturer, Almond Oils Supplier - Ozone Naturals

Ozone Naturals is one of the largest supplier of Almond Oil in India. In our sophisticated (SCFE) processing facilities, it is extracted from fresh almonds to ensure its quality. Almond Oil has been known for its infinite number of health benefits including its famous skin and beauty benefits. The reason why almond oil is so good for health lies in its composition. Being a rich source of various vitamins and…

Global Almond Drinks Market 2017 - Fuerst Day Lawson, The Pressery, Luz Almond, …

Almond Drinks market research report provides the newest industry data and industry future trends, allowing you to identify the products and end users driving Revenue growth and profitability also lists the leading competitors and provides the insights strategic industry Analysis of the key factors influencing the market.

This report studies Almond Drinks in Global market, especially in North America, China, Europe, Southeast Asia, Japan and India, with production, revenue, consumption,…