Press release

Fiber Optic Cable Manufacturing Plant Cost Report 2026: Complete Investment Guide & Demand Analysis

The global telecommunications infrastructure industry is experiencing unprecedented growth driven by significant expansion of broadband infrastructure, rising investments in 5G networks, increasing deployment of data centers, and growing demand for high-speed communication across telecom, enterprise, and smart city projects. At the core of these developments lies the fastest data transmission medium-fiber optic cables. As digital transformation accelerates worldwide and connectivity becomes essential for economic development, cloud adoption, and emerging technologies, establishing a fiber optic cable manufacturing plant presents a strategically compelling business opportunity for telecommunications equipment suppliers and infrastructure investors seeking to capitalize on 5G rollout, data center expansion, FTTH deployment, and the global digital infrastructure boom.IMARC Group's report, "Fiber Optic Cable Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The fiber optic cable manufacturing plant project report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for a Sample Report: https://www.imarcgroup.com/fiber-optic-cable-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global fiber optic cable market demonstrates exceptional growth trajectory, valued at USD 7.21 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 15.91 Billion by 2034, exhibiting a remarkable CAGR of 9.2% from 2026-2034. This sustained expansion is driven by significant broadband infrastructure expansion, rising 5G network investments, increasing data center deployment, and growing high-speed communication demand.

Fiber optic cables are the fastest data transmission media, transmitting data through thin glass or plastic fibers as light pulses. These cables enable ultra-high-speed data transfer with minimal signal loss, making them the backbone of modern communication networks. A standard fiber optic cable contains core, cladding, protective coatings, strength members, and outer jacket specially designed for durability and signal integrity. Fiber optic cables are categorized by light propagation type and classified by distance and bandwidth requirements into single-mode and multi-mode variants. They are predominantly used in telecom, broadband internet, data centers, cable TV, military communication systems, and factory automation. Compared to metallic cables, fiber optics provide higher bandwidth, better security, immunity to electromagnetic interference, and longer service life, supporting digital infrastructure development as a foundational pillar.

The fiber optic cable sector grows continuously due to rapid digital transformation, 5G network establishment, and increasing data-intensive technology investments. According to the International Telecommunication Union (ITU), in 2025, 5G networks reached an estimated 55% of the global population, signaling strong progress in advanced mobile connectivity, though access remains uneven across regions. Accelerating 5G rollout directly boosts fiber optic cable demand, which forms the backbone of high-speed network infrastructure. Both governments and private telecom companies prioritize fiber deployment to deliver next-generation connectivity, smart infrastructure, and cloud computing ecosystems. Market momentum strengthens through increasing internet accessibility, video streaming demand, and sophisticated enterprise networking requirements.

Plant Capacity and Production Scale

The proposed fiber optic cable manufacturing facility is designed with an annual production capacity ranging between 50,000-100,000 fiber-km per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to serve diverse market segments-from telecommunications networks and data centers to FTTH connections, enterprise networking, and industrial communication systems-ensuring steady demand and consistent revenue streams across multiple end-use sectors serving digital infrastructure expansion.

Financial Viability and Profitability Analysis

The fiber optic cable manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal strong margins supported by stable demand and technological superiority:

• Gross Profit Margins: 30-40%

• Net Profit Margins: 12-18%

These margins reflect favorable manufacturing economics supported by essential digital infrastructure positioning, technological superiority over copper alternatives, strong long-term demand visibility from 5G and data center growth, and scalable manufacturing models. The project demonstrates excellent return on investment (ROI) potential, making it highly attractive for telecommunications equipment manufacturers and infrastructure investors seeking profitable growth in expanding connectivity markets with strong government support and private sector investments.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a fiber optic cable manufacturing plant reflects moderate-to-high raw material intensity:

• Raw Materials: 60-70% of total OpEx

• Utilities: 10-15% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, quality control, depreciation, and taxes

Optical fiber constitutes the primary cost driver at 60-70% of operating expenses. Additional inputs include HDPE (High-Density Polyethylene) and FRP (Fiber Reinforced Plastic) for protective layers and strength members. The utilities component reflects energy requirements for fiber drawing towers, coating systems, and optical testing equipment requiring controlled environments and precision operations essential for maintaining signal quality and manufacturing standards in telecommunications-grade cable production.

Buy Now: https://www.imarcgroup.com/checkout?id=11966&method=2175

Capital Investment Requirements

Setting up a fiber optic cable manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to telecommunications equipment markets, optical fiber suppliers, and robust infrastructure including reliable utilities, controlled environment capabilities, and waste management systems suitable for precision manufacturing operations.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for fiber optic cable production. Key machinery includes:

• Fiber drawing towers for optical fiber production

• Coating systems for protective layer application

• Buffering lines for fiber protection

• Stranding machines for cable assembly

• Jacketing lines for outer sheath application

• Optical testing equipment for quality assurance

Civil Works: Building construction, factory layout optimization, and infrastructure development designed for precision telecommunications manufacturing, ensuring controlled environments, efficient workflow from fiber drawing through final testing, and cleanroom capabilities where required.

Other Capital Costs: Pre-operative expenses, machinery installation costs, telecommunications certifications, quality control laboratory establishment, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Fiber optic cables find extensive applications across diverse telecommunications and industrial sectors:

Telecommunications Networks: Fiber optic cables transmit high-speed voice and data over large distances with minimal loss, ensuring network reliability and scalability for telecom infrastructure backbone applications.

Data Centers: High bandwidth and low latency characteristics enable simultaneous data transfer in and out of hyperscale and enterprise data centers, supporting cloud computing and digital services infrastructure.

FTTH and Broadband Infrastructure: Fiber cables form the backbone of last-mile connectivity, enabling high-speed internet access for residential and commercial users through fiber-to-the-home deployments.

Defense and Industrial Communication: Secure and interference-free transmission makes fiber optic cables suitable for mission-critical applications in defense systems and industrial automation requiring reliable data communications.

End-use sectors encompass telecommunications operators, data centers, infrastructure developers, and industrial users, all contributing to sustained demand across digital transformation initiatives.

Why Invest in Fiber Optic Cable Manufacturing?

Several compelling factors make fiber optic cable manufacturing an attractive investment opportunity:

Rapid Expansion of Digital Infrastructure: Ongoing investments in digital infrastructure including telecom, broadband, and smart city projects fuel continuous demand for fiber optic cables supporting global connectivity expansion.

Technological Superiority: Fiber optic cables are far superior to conventional copper wires in speed, bandwidth, and signal quality, making them the preferred choice for modern communication networks requiring high-performance data transmission.

Strong Long-Term Demand Visibility: Unstoppable market growth is guaranteed by increasing data consumption, cloud adoption, and 5G rollout, providing predictable revenue streams and sustainable business models for manufacturers.

Scalable Manufacturing Model: Production line expansion can be accomplished modularly to accommodate increasing volume demands and product diversification requirements, allowing flexible capacity scaling aligned with market growth.

Export Potential: Global demand for fiber optic cables provides manufacturers opportunities to serve international markets and optimize capacity utilization through export channels complementing domestic sales.

Manufacturing Process Excellence

The fiber optic cable manufacturing process involves several controlled stages ensuring product quality and performance:

• Preform Preparation: Optical fiber preform procurement or production for fiber drawing operations

• Fiber Drawing: High-temperature drawing of glass preforms into thin optical fibers

• Coating and Curing: Application of protective coatings and UV curing for fiber protection

• Buffering: Additional protective buffering layers for mechanical strength

• Stranding: Multiple fiber stranding into cable configurations

• Sheathing: Outer jacket application for environmental protection

• Testing and Quality Inspection: Comprehensive optical and mechanical testing for performance verification

• Final Packaging: Cable packaging for transportation and installation

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=11966&flag=C

Industry Leadership

The global fiber optic cable industry includes established telecommunications equipment manufacturers with extensive production capabilities. Key industry players include:

• Corning Inc.

• CommScope Holding Company Inc.

• Sumitomo Electric Industries Ltd.

• Prysmian Group

• Furukawa Electric

These companies serve diverse end-use sectors including telecommunications operators, data centers, infrastructure developers, and industrial users, demonstrating broad market applicability of fiber optic cable manufacturing.

Recent Industry Developments

July 2025: Prysmian announced investments in Relativity Networks, marking a strategic move toward next-generation fiber optic cable innovation. The initiative followed a March 2025 agreement covering production and global deployment of hollow-core optical fiber and cable, targeting ultra-low latency, AI acceleration, quantum networking, high-frequency trading, and sustainable, high-performance data center networks.

March 2025: Furukawa Electric Co., Ltd. introduced a unified global fiber optic cable business brand, Lightera, at the OFC Conference in San Francisco. The move combined the Fiber Cable Division (Japan), OFS Fitel, LLC (OFS), and Furukawa Electric LATAM S.A. (FEL), targeting AI, data centers, 5G/6G, utilities, medical, aerospace, defense, and sensing markets.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fiber Optic Cable Manufacturing Plant Cost Report 2026: Complete Investment Guide & Demand Analysis here

News-ID: 4375301 • Views: …

More Releases from IMARC Group

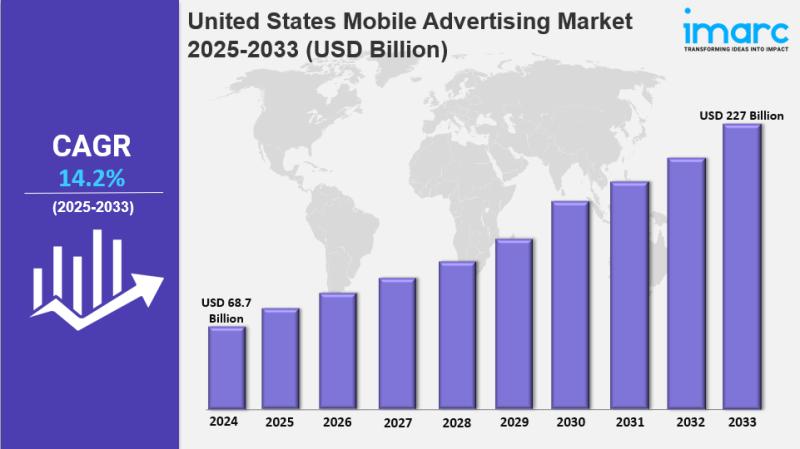

United States Mobile Advertising Market Size, Share And Growth Report 2033

IMARC Group has recently released a new research study titled "United States Mobile Advertising Market Report by Format Type (Search, Display, Video, Social Media, Websites, and Others), Industry Vertical (Retail and E-commerce, Media and Entertainment, Healthcare, BFSI, Education, Travel and Tourism, Automotive, and Others), and Region 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market…

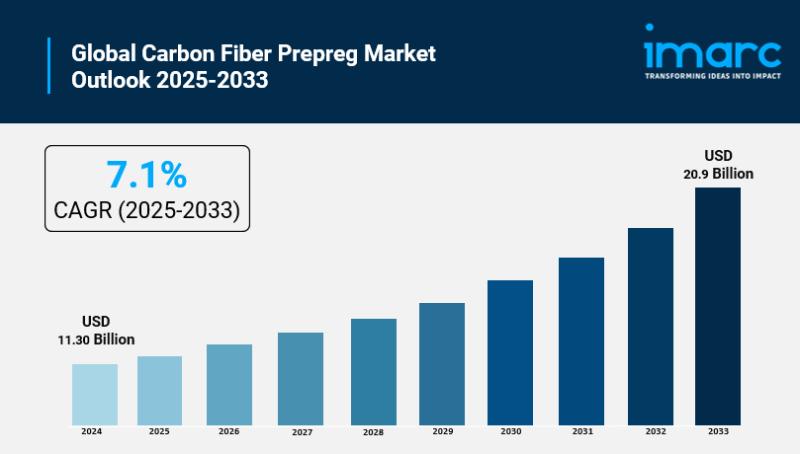

Carbon Fiber Prepreg Market Report, Industry Overview, Growth Rate and Forecast …

IMARC Group, a leading market research company, has recently released a report titled "Carbon Fiber Prepreg Market Size, Share, Trends and Forecast by Manufacturing Process, Resin Type, Resin, End Use Industry, and Region, 2025-2033". The study provides a detailed analysis of the industry, including the carbon fiber prepreg market report, size, and industry growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the…

Toys Manufacturing Plant Project Report 2026: Process Details, Market Outlook, a …

The global consumer goods industry is experiencing robust growth driven by increasing demand for educational toys, interactive playthings, and innovative entertainment solutions across all age groups. At the core of these developments lies a critical childhood development category-toys. As parents worldwide seek products enhancing cognitive development while providing entertainment, and as STEM education gains prominence alongside sustainability concerns, establishing a toys manufacturing plant presents a strategically compelling business opportunity for…

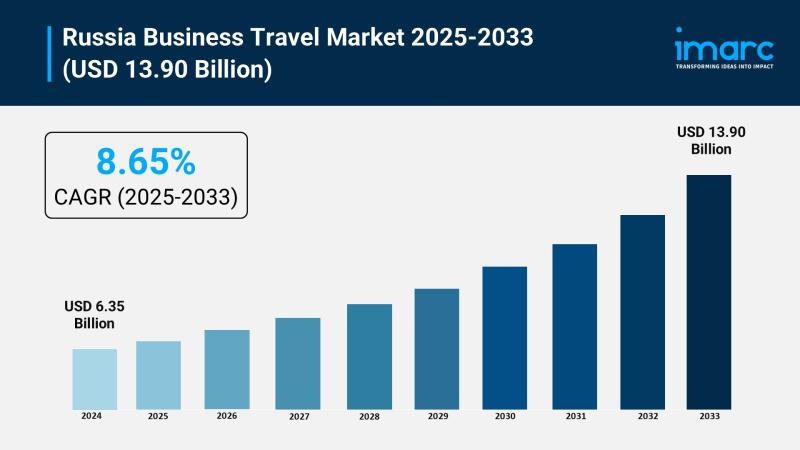

Russia Business Travel Market Set to Reach USD 13.90 Billion by 2033

Market Overview

The Russia business travel market was valued at USD 6.35 Billion in 2024. It is projected to reach USD 13.90 Billion by 2033, growing at a CAGR of 8.65% during the forecast period of 2025-2033. Growth is driven by expanding trade relations with Asia, rising domestic business activities, and infrastructure development, including improved transportation and flourishing domestic industries.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

Russia Business Travel Market…

More Releases for Fiber

Fiber Laser Market Forecast to 2028 COVID-19 Impact and Global Analysis By Type …

The fiber laser market was valued at US$ 2286.16 million in 2021 and is projected to reach US$ 4,765.43 million by 2028; it is expected to grow at a CAGR of 11.1% from 2021 to 2028.

Automotive production is constantly rising across the world, particularly in Asian and European countries, which is driving the demand for fiber lasers. Most automotive manufacturers are rapidly turning to fiber lasers to resolve their manufacturing…

Pea Fiber Market Inclinations Exhibit Growing Demand during the Period until 202 …

The new report on the pea fiber market provides estimations of the size of the global market and share and size of key regional markets during the historical period of 2014 – 2018. This highly favorable growth of the pea protein creates a highly conducive environment for the associated pea fiber market, which is expected to exhibit a promising CAGR of ~8% during the forecast period (2019-2029. The business intelligence…

Optical Fiber and Optical Fiber Cables Market

Optical Fibers and Optical Fiber Cables Market describes its growth, size, share, Forecast and trends to 2025

Optical Fibers and Optical Fiber Cables Market Production and Demand Analysis 2019 to 2025

Optical Fibers and Optical Fiber Cables Market 2019 Manufacturing Analysis and Development Forecast to 2025

Optical Fibers and Optical Fiber Cables Market 2019: Recent Study Including Growth Factors, Regional Drivers, Forecast 2025

Optical Fibers and Optical Fiber Cables Market Insights 2019, Global and…

Aramid Fiber Market (Para-Aramid Fiber, Meta-Aramid Fiber) by Type, Application …

The aramid fiber market (http://www.rnrmarketresearch.com/aramid-fiber-market-by-type-para-aramid-fiber-meta-aramid-fiber-and-application-security-protection-frictional-material-tire-rubber-reinforcement-optical-fiber-electrical-insulation-aeros-market-report.html) is projected to grow from USD 3.28 billion in 2018 to USD 5.78 billion by 2024, at a CAGR of 9.9%. The increasing demand for lightweight materials for automotive components owing to stringent environmental and emission regulations is expected to drive the market in the automotive industry. In addition, the demand for lightweight and flexible materials for body armor, firefighting equipment, bulletproof vests, helmets, and…

Fiber-optic couplers Market Segmentation By Type Y Fiber-optic Couplers, T Fiber …

Fiber-optic couplers market: Market Overview

Due to increasing reliance of organizations on IT, the demand for robust, agile and cost effective IT infrastructure is growing rapidly and supporting the Fiber-optic couplers market. The fabric-optic couplers market is expanding rapidly as the telecom services providers in this modern era are moving towards fiber based networking services. Increasing advancements in the telecom industry are one of the major factors driving the growth of…

Fiber Laser Market 2025 - Global Analysis and Forecasts by Type (Infrared Fiber …

The "Global Fiber Laser Market Analysis to 2025" is a specialized and in-depth study of the fiber laser industry with a focus on the global market trend. The report aims to provide an overview of global fiber laser market with detailed market segmentation by type, application and geography. The global fiber laser market is expected to witness high growth during the forecast period. The report provides key statistics on the…