Press release

Glue Laminated Timber Manufacturing Plant Setup - 2026, Industry Trends, and ROI Analysis

The global construction industry is undergoing a fundamental transformation driven by the need for sustainable, high-performance building materials. At the forefront of this engineered wood revolution stands glue laminated timber-commonly referred to as glulam-a composite wood material produced by bonding several layers of lumber using structural adhesives to create large, strong structural members exceeding the capabilities of conventional timber. Glulam has redefined timber construction, enabling architects and engineers to design structures featuring long spans, curved forms, and complex frameworks combining exceptional structural performance with aesthetic appeal. Renowned for its superior strength, outstanding dimensional stability, and remarkable design versatility, glue laminated timber serves as the preferred material for beams, columns, arches, trusses, and roofing systems across residential, commercial, infrastructure, and specialty construction. Rising urbanization, expanding infrastructure development, growing adoption of green building practices, and government policies promoting low-carbon construction and carbon sequestration in wood products are collectively driving sustained demand-establishing a glue laminated timber manufacturing plant as a strategically compelling investment opportunity.Request for a Sample Report: https://www.imarcgroup.com/glue-laminated-timber-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global glue laminated timber market demonstrates steady growth underpinned by enduring demand from construction and infrastructure sectors. Valued at USD 4.39 Billion in 2025, the market is projected to reach USD 5.35 Billion by 2034, exhibiting a CAGR of 2.2% from 2026 to 2034. This consistent expansion reflects the deepening integration of engineered wood into mainstream construction, driven by increasing construction activities, expanding use in modular structures, and rising demand for sustainable solutions across residential, commercial, and industrial projects.

The manufacturing process transforms timber into high-performance structural material through lumber grading, finger jointing, adhesive application, high-pressure lamination pressing, controlled adhesive curing, and precision finishing. Key advantages include significantly enhanced strength, superior dimensional stability, and design versatility enabling long spans and curved structures. Government policies promoting low-carbon construction, carbon sequestration, and renewable materials, combined with advancements in adhesive systems improving moisture resistance and fire performance, are strengthening the long-term market outlook.

Plant Capacity and Production Scale

The proposed facility is designed with an annual production capacity ranging between 20,000-50,000 cubic meters, enabling economies of scale in procurement, adhesive application, pressing, and distribution while maintaining operational flexibility for diverse product specifications. This positions manufacturers to serve construction contractors, infrastructure developers, residential builders, and specialty structure developers, with expansion achievable through moderate incremental investment.

Financial Viability and Profitability Analysis

The glue laminated timber business demonstrates healthy profitability under stable operating conditions:

Gross Profit Margins: 25-35%

Net Profit Margins: 10-15%

These margins are supported by significant value addition transforming commodity timber into premium engineered structural products, stable demand across residential, commercial, and infrastructure segments, alignment with green building trends, moderate entry barriers favoring manufacturers with technical expertise, and local supply chain advantages. The project offers compelling return on investment backed by proven lamination technologies, growing engineered wood adoption, supportive government policies, and strong carbon sequestration alignment.

Operating Cost Structure

The operating expenditure structure is characterized by:

Raw Materials: 70-80% of total OpEx

Utilities: 10-15% of OpEx

Raw materials are the dominant cost, with timber and structural adhesives as essential feedstocks. High-quality lumber from sustainably managed sources must meet exacting specifications for moisture content, straightness, and structural grade. Structural adhesives-primarily melamine-urea-formaldehyde or polyurethane systems-directly affect durability and moisture resistance. Utility costs encompass energy for drying kilns, lamination presses, and adhesive curing. Additional expenses include skilled labor, equipment maintenance, quality testing, transportation, packaging, and environmental compliance.

Buy Now: https://www.imarcgroup.com/checkout?id=8602&method=2175

Capital Investment Requirements

Establishing a plant requires strategic capital allocation across key categories:

Land and Site Development: Strategic location proximate to timber supply and construction markets minimizes transportation costs. The site requires reliable power, space for lumber storage, drying kilns, production lines, warehousing, and future expansion.

Machinery and Equipment: The largest capital allocation covers specialized lamination equipment:

• High-Quality Presses: Large-format hydraulic or pneumatic presses applying controlled pressure and heat during adhesive curing, ensuring consistent bond strength across finished products

• Planers: Precision machinery dimensioning lumber to exact thickness before lamination and finishing glulam to precise tolerances after pressing

• Laminating Systems: Automated adhesive application and layer assembly ensuring uniform glue line coverage critical for structural performance

• Drying Kilns: Climate-controlled chambers reducing lumber moisture to precise levels for optimal adhesive bonding and dimensional stability

• Finishing Machines: Post-production equipment performing surface treatment, profiling, length cutting, and quality finishing

Civil Works and Other Costs: Large-span production halls, drying infrastructure, quality laboratories, and product storage. Pre-operative costs include engineering design, commissioning, training, permits, working capital, and contingency provisions.

Major Applications and Market Segments

Construction: Structural beams, arches, trusses, and frameworks in commercial and residential buildings providing long-span solutions with superior load-bearing capacity.

Infrastructure: Bridges, terminals, and public buildings where engineered wood offers durability, flexibility, and environmental advantages.

Commercial and Residential: Roofs, columns, and long-span systems enabling open floor plans and dramatic architectural spaces.

Specialty Structures: Sports halls, auditoriums, and modular assemblies requiring exceptional span capability and structural performance.

Why Invest in Glue Laminated Timber Manufacturing?

Structural and Sustainable Solution: Glulam provides strong, durable, eco-friendly alternatives to steel and conventional timber, aligning with green building and carbon sequestration objectives.

Moderate Entry Barriers: Capital requirements and adhesive technology expertise create competitive advantages favoring established manufacturers.

Alignment with Construction Mega-trends: Growth in sustainable housing, modular construction, and infrastructure drives consistent glulam demand.

Policy and Government Support: Housing programs, green building incentives, and infrastructure policies actively encourage engineered wood adoption.

Local Supply Chain Advantage: Regional production ensures steady timber supply, reduces transportation costs, and provides dependable domestic alternatives.

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=8602&flag=C

Industry Leadership

Leading manufacturers in the global glue laminated timber industry include companies with extensive production capacities and diverse application portfolios. Key players include:

• Boise Cascade Company

• Canfor Corporation

• Stora Enso Oyj

• Binderholz GmbH

• Boral Limited

• Setra Group AB

• Pfeifer Group

• KLH Massivholz GmbH

• Schilliger Holz AG

• Eugen Decker Holzindustrie KG

• Zublin Timber GmbH

• Nordic Structures

• Weyerhaeuser Company

• Structurlam Mass Timber Corporation

• Mayr-Melnhof Holz Holding AG

• Hasslacher Norica Timber GmbH

These companies serve construction, infrastructure, sports facilities, and residential and commercial buildings, demonstrating the commercial maturity and broad applicability of the engineered wood sector.

Recent Industry Developments

September 2025: Element5 announced a USD 107 Million expansion of mass timber manufacturing in St. Thomas, Ontario, supported by Invest Ontario. The new facility features a fully automated glulam production line doubling capacity, strengthening sustainable building material supply and demonstrating industry confidence in engineered wood demand.

February 2025: Henkel introduced the Loctite HB XE adhesive line-a next-generation timber construction solution combining sustainability with advanced fire resistance for cross-laminated and glue laminated timber, meeting increasingly stringent fire safety regulations across Europe.

Conclusion

The glue laminated timber manufacturing sector presents a strategically compelling investment at the intersection of sustainable construction and engineered wood innovation. With margins of 25-35% gross profit and 10-15% net profit, a market expanding from USD 4.39 Billion to USD 5.35 Billion by 2034, broad application diversity, significant value-added conversion of timber into premium structural products, supportive policies, and strong carbon sequestration alignment, a glue laminated timber plant offers compelling long-term returns. Moderate entry barriers, alignment with construction mega-trends, local supply advantages, and continuous adhesive innovation create an enduring value proposition for timber processors and investors committed to the high-growth engineered wood construction sector.

About IMARC Group

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Glue Laminated Timber Manufacturing Plant Setup - 2026, Industry Trends, and ROI Analysis here

News-ID: 4375195 • Views: …

More Releases from IMARC Group

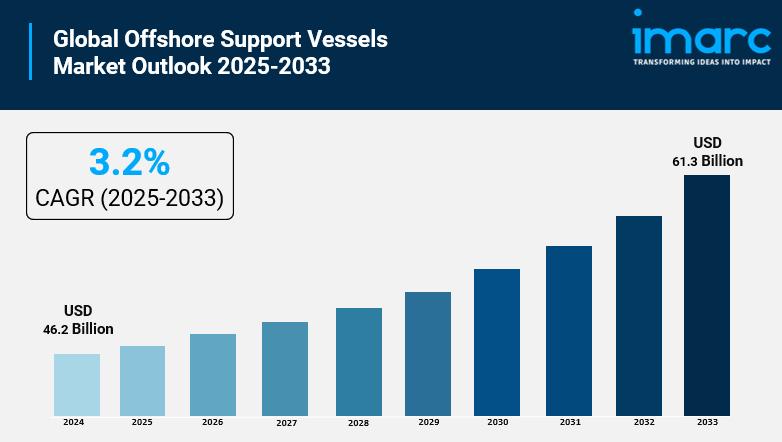

Offshore Support Vessels Market to Reach USD 61.3 Billion by 2033, Driven by Inc …

The global offshore support vessels market size was valued at USD 46.2 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 61.3 Billion by 2033, exhibiting a CAGR of 3.2% during 2025-2033. Asia Pacific currently dominates the market, holding a market share of over 25% in 2024.

Rising Offshore Exploration and Production Activities Driving Demand

The OSV market is rebounding alongside a new wave of exploration and production…

Germany Higher Education Market Size, Share & Growth Forecast 2025-2033: Compreh …

Market Overview

The Germany higher education market reached a size of USD 1.27 Billion in 2024 and is projected to grow to USD 6.28 Billion by 2033, with a CAGR of 19.40% during the forecast period of 2025-2033. Driven by strong government funding, increasing international student enrollment, and the digital transformation in education, Germany accounted for 4.2% of the global higher education market in 2023. The sector also sees growing adoption…

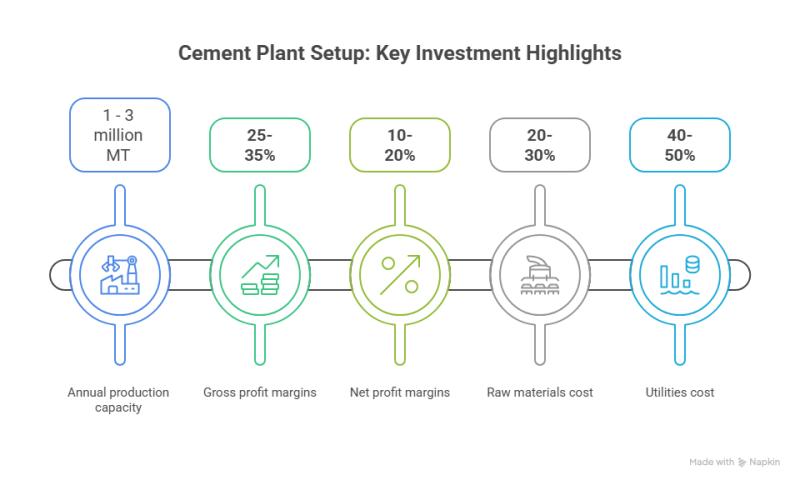

Cement Manufacturing Plant DPR - 2026: CapEx/OpEx Analysis with Profitability Fo …

Cement Manufacturing Plant Project Report 2026: A Comprehensive Investment Guide:

The global cement manufacturing industry stands as one of the largest and most indispensable segments of heavy industry, underpinning virtually every facet of physical infrastructure across the planet. Driven by rapid urbanisation, record-scale government infrastructure programmes, housing demand in emerging economies, and the continuous need to repair and upgrade ageing built environments, the cement sector is experiencing sustained volume growth coupled…

Latin America Online Grocery Market Size, Share & Growth Projections 2025-2033: …

Market Overview

The Latin America online grocery market was valued at USD 3.8 Billion in 2024 and is projected to reach USD 10.1 Billion by 2033, growing at a CAGR of 10.95% during the forecast period from 2025 to 2033. The growth is driven by increasing internet penetration, changing consumer lifestyles, urbanization, competitive pricing, the impact of the COVID-19 pandemic, and expanding logistics infrastructure. Online grocery shopping offers convenience and contactless…

More Releases for Timber

American Pole & Timber Announcing Custom Timber Trusses for Large-Scale Commerci …

Image: https://www.getnews.info/wp-content/uploads/2024/10/1728426751.jpeg

We work hard to make sure our trusses exceed the expectations of every client, whether it's for a custom home, a stadium, or an office building.

Known for impressive craftsmanship and durable timber structures, the company is now expanding its offerings to meet the needs of stadiums, schools, public visitor centers, and other major commercial buildings.

Houston, TX - American Pole & Timber, a leader in custom wood product manufacturing, is…

American Pole & Timber Elevates Luxury Home Design with Turnkey Timber Truss Sol …

Image: https://www.getnews.info/wp-content/uploads/2024/09/1727459717.jpg

"Luxury homes are defined by their attention to detail, and timber trusses add an unmatched level of craftsmanship and natural beauty to these spaces." - Eric Lincoln, Sr VP Sales at American Pole & Timber

American Pole & Timber is proud to offer its turnkey timber truss solutions tailored to meet the needs of high-end residential projects.

Sep 27, 2024 - Houston, TX - As the demand for distinctive and…

American Pole & Timber Offers Complete Turnkey Timber Trusses - From Design to I …

Image: https://www.getnews.info/wp-content/uploads/2024/09/1726210590.jpeg

We understand that timber trusses are more than just structural elements - they are attention-commanding conversation pieces.

American Pole & Timber, a trusted leader in timber products and custom structural wood components, is proud to offer a complete turnkey solution for timber trusses - from initial concept design through to on-site installation.

Sep 13, 2024 - Houston, TX - American Pole & Timber, a trusted leader in timber products and…

Timber Products or Modified Timber Market Share, Growth Opportunities 2023

The global timber products or modified timber market size was valued at USD 612.3 billion in 2021 and is poised to grow at a significant CAGR of 6.8% during the forecast period 2023-29. Timber products or modified timber market refers to the market for wood products that have been modified through chemical, thermal, or other treatments to enhance their properties such as durability, strength, and resistance to decay or fire.…

Timber Frames Market Growing Popularity Emerging Trends 2028 - Bensonwood, Persi …

Worldwide Timber Frames Market Analysis to 2028 is a specialized and in-depth study of the Timber Frames Industry with a focus on the global market trend. The report aims to provide an overview of global Timber Frames Market with detailed market segmentation by product/application and geography. The global Timber Frames Market is expected to witness high growth during the forecast period. The report provides key statistics on the Market status…

Global Glue-Laminated Timber Market 2017 - Forest Timber Engineering Ltd, Boise …

The Glue-Laminated Timber Market 2017 examines the performance of the Glue-Laminated Timber market, enclosing an in-depth judgment of the Glue-Laminated Timber market state and the competitive landscape globally. This report analyzes the potential of Glue-Laminated Timber market in the present as well as the future prospects from various angles in detail.

The Global Glue-Laminated Timber Market 2017 report includes Glue-Laminated Timber industry volume, market Share, market Trends, Glue-Laminated Timber Growth aspects,…