Press release

Coconut Shell Powder Manufacturing Plant Setup - 2026, Business Plan, Investment & Growth Opportunities

The global push toward sustainable manufacturing, circular economy principles, and eco-friendly industrial materials is rapidly reshaping how industries source raw materials and develop value-added products. At the forefront of this green transformation stands coconut shell powder-a finely milled, renewable material derived from dried coconut shells, a by-product of the coconut processing industry that would otherwise constitute agricultural waste. Renowned for its exceptional hardness, low moisture content, and high carbon composition, coconut shell powder serves as a remarkably versatile raw material across activated carbon production, industrial abrasives and polishing, rubber and plastics manufacturing, incense and mosquito coil production, and eco-friendly composite materials. A joint report by Circle Economy and the International Labour Organization (ILO) reveals that approximately 121-142 million people worldwide work in sectors supporting the circular economy, including repair, recycling, second-hand trade, and waste management, accounting for roughly 5-5.8% of global employment-underscoring the enormous economic scale and expanding opportunity within sustainable material conversion. As industries increasingly shift toward biodegradable and renewable inputs, environmental awareness intensifies, water purification demands grow, and circular economy initiatives accelerate globally, establishing a coconut shell powder manufacturing plant represents a strategically compelling investment opportunity for agricultural processors, green material manufacturers, and sustainability-focused investors seeking to capitalize on rising demand across activated carbon, abrasives, rubber and plastics, incense, and composite material sectors.Request for a Sample Report: https://www.imarcgroup.com/coconut-shell-powder-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global coconut shell powder market demonstrates strong and accelerating growth fundamentals driven by sustainability trends and diverse industrial applications. Valued at USD 361.92 Million in 2025, the market is projected by IMARC Group to reach USD 723.48 Million by 2034, exhibiting an impressive CAGR of 8.0% from 2026 to 2034-effectively doubling in value over the forecast period. This robust expansion is primarily driven by rising demand for natural and sustainable raw materials across industries, increasing use in industrial polishing and abrasive applications, growing adoption in activated carbon production for water purification and air filtration, and expanding utilization in eco-friendly filler and composite materials.

Coconut shell powder is a finely milled material derived from dried coconut shells, a by-product of the coconut processing industry. The shells undergo a carefully controlled multi-step process including cleaning, drying, crushing, and grinding to produce powders with varying mesh sizes precisely tailored to specific application requirements. Renowned for its exceptional hardness providing superior abrasive performance, low moisture content ensuring dimensional stability and consistent processing characteristics, and high carbon composition making it an ideal precursor for activated carbon production, coconut shell powder serves as a remarkably versatile raw material across diverse industries. It is extensively used in the production of activated carbon for water treatment and air purification, industrial abrasives and polishing compounds for surface finishing, and as fillers in resins, rubber, and composite materials improving mechanical properties. Additionally, it finds important applications in mosquito coil and agarbatti incense production where its binding strength and controlled burning properties deliver consistent performance. Being inherently renewable and biodegradable, coconut shell powder provides a sustainable and environmentally friendly alternative to synthetic fillers and mineral-based materials, aligning perfectly with global sustainability objectives and green manufacturing initiatives.

The coconut shell powder market is witnessing steady growth driven by multiple converging sustainability and industrial application trends. Rising demand for activated carbon in water purification addressing contamination challenges, air filtration improving indoor environmental quality, and industrial applications requiring high-performance adsorption media represents a significant and growing market segment. Industries are increasingly preferring eco-friendly abrasives for polishing, cleaning, and surface finishing applications over synthetic alternatives, further accelerating powder consumption. Natural fillers derived from coconut shell powder are gaining significant popularity in rubber, plastics, and composite materials manufacturing due to their ability to enhance mechanical strength, reduce material costs, and provide sustainable alternatives to petroleum-derived synthetic fillers. Heightened environmental awareness and circular economy initiatives are encouraging the utilization of coconut shell waste, transforming agricultural by-products into valuable industrial raw materials. Expansion in mosquito coil and incense production across tropical regions also supports consistent market demand. Ongoing innovations in activated carbon technologies, growth in industrial and environmental remediation applications, and increasing adoption of renewable and biodegradable materials across manufacturing sectors are collectively strengthening the long-term market outlook for coconut shell powder.

Plant Capacity and Production Scale

The proposed coconut shell powder manufacturing facility is designed with an annual production capacity ranging between 2,000-5,000 MT, enabling economies of scale in procurement, processing, and distribution while maintaining operational flexibility to accommodate diverse mesh size specifications and product grade requirements. This strategically calibrated capacity positions manufacturers to effectively serve activated carbon producers requiring consistent high-carbon-content powder, abrasives and polishing companies demanding precisely graded particle sizes, rubber and plastics manufacturers seeking natural filler materials, incense and mosquito coil producers requiring powder with appropriate binding and combustion properties, and composite material developers utilizing biodegradable fillers-ensuring steady production utilization across multiple high-value application segments with capacity expansion possible through moderate incremental investment.

Financial Viability and Profitability Analysis

The coconut shell powder manufacturing business demonstrates healthy profitability potential under normal operating conditions and stable coconut shell pricing environments. The financial projections reveal attractive investment economics:

Gross Profit Margins: 30-40%

Net Profit Margins: 12-18%

These attractive margins are supported by low raw material costs as coconut shells are widely available and affordable in coconut-producing regions as agricultural by-products, value-added conversion transforming waste material into high-specification industrial products commanding premium pricing across multiple application segments, stable and growing demand from activated carbon, abrasives, rubber and plastics, and incense industries ensuring consistent revenue streams, a scalable production model enabling capacity expansion with moderate incremental investment as market demand grows, and strong alignment with global sustainability trends creating expanding market opportunities. The project demonstrates compelling return on investment potential backed by proven crushing and grinding technologies, well-established quality standards for various mesh size specifications, growing environmental awareness driving preference for natural and biodegradable materials, expanding activated carbon market requirements for water purification and air filtration, circular economy initiatives encouraging waste-to-value conversion, and proximity advantages in coconut-growing regions providing cost-effective feedstock access-making it an attractive proposition for agricultural processors, green material manufacturers, and sustainability-focused investors seeking participation in high-growth renewable material markets.

Buy Now: https://www.imarcgroup.com/checkout?id=8533&method=2175

Operating Cost Structure

Understanding the operating expenditure structure is critical for effective financial planning and sustainable profitability. The cost structure for a coconut shell powder manufacturing plant is characterized by:

Raw Materials: 50-60% of total OpEx

Utilities: 20-25% of OpEx

Raw materials constitute the primary portion of operating costs, with dried coconut shells serving as the essential feedstock and principal cost driver. Coconut shells sourced from coconut processing facilities, oil mills, or agricultural collectors provide the base material requiring crushing, grinding, and pulverization. The significant advantage of coconut shell powder manufacturing lies in the low and stable cost of this feedstock-coconut shells are abundant by-products in coconut-producing regions including India, Indonesia, Philippines, and Sri Lanka, often available at minimal cost or even as waste material from coconut oil and coconut milk processing operations. Establishing reliable supply relationships with coconut processing facilities, developing collection networks from agricultural regions, implementing effective procurement strategies to ensure consistent shell quality and moisture content, and securing long-term supply agreements are essential for maintaining production continuity and managing the relatively modest raw material cost component of this manufacturing operation.

Utility costs, representing 20-25% of operating expenses reflecting the energy-intensive nature of crushing, grinding, and pulverization processes, encompass electricity for crushers, hammer mills, pulverizers, vibrating screens, and dust collection systems that constitute the core processing equipment. Additional utility requirements include thermal energy for drying coconut shells to achieve appropriate moisture content before processing, and compressed air for pneumatic conveying and dust management systems essential for workplace safety and product quality. Additional operational expenses include skilled labor for machine operation, quality control, and packaging, maintenance programs ensuring equipment reliability and consistent particle size output, quality control testing validating mesh size distribution, carbon content, moisture levels, and application-specific performance characteristics, transportation costs for inbound coconut shell collection and outbound finished product distribution to diverse industrial customers, packaging materials including bags and containers protecting powder from moisture absorption, equipment depreciation on grinding and crushing machinery, applicable taxes, and environmental compliance costs including dust emission management and workplace safety protocols. Implementing energy-efficient grinding systems, optimizing crushing and grinding sequences to minimize energy consumption per unit produced, developing comprehensive dust collection and suppression systems, and maintaining rigorous quality management systems ensuring first-pass product conformance across diverse mesh size specifications significantly reduce costs while meeting the exacting requirements of activated carbon, abrasives, rubber, and composite material customers.

Capital Investment Requirements

Establishing a coconut shell powder manufacturing plant requires capital investment strategically distributed across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to coconut processing facilities or major coconut-growing agricultural regions ensuring reliable, cost-effective feedstock supply and minimizing shell collection transportation costs. The site must provide convenient access to target industrial customers including activated carbon producers, abrasives manufacturers, rubber and plastics companies, and incense producers. Essential infrastructure includes reliable transportation networks, dependable electrical power supply for processing equipment, adequate water supply for washing operations, and dust management systems meeting environmental and workplace safety standards.

Machinery and Equipment: The largest portion of capital expenditure is allocated to specialized crushing and grinding equipment. Key machinery includes:

• Crushers: Primary size reduction equipment breaking down whole coconut shells into coarse fragments suitable for subsequent grinding and pulverization stages

• Hammer Mills: High-speed impact grinding machines reducing crushed shell fragments to intermediate powder sizes through repeated hammer impacts

• Pulverizers: Precision grinding equipment achieving the fine particle sizes and specific mesh grades required for activated carbon precursor and abrasive applications

• Vibrating Screens: Precision classification equipment separating finished powder into specific mesh size grades tailored to diverse application requirements

• Dust Collection Systems: Essential safety and environmental equipment capturing airborne powder particles during grinding and handling operations protecting workers and preventing emissions

• Packing Machines: Automated weighing and packaging equipment filling bags or containers with finished powder products for storage and distribution

Civil Works: Manufacturing facilities including processing halls with adequate dust suppression and ventilation systems, raw material storage areas for coconut shell inventory with moisture protection, finished product warehousing maintaining appropriate storage conditions, quality control laboratories equipped with mesh analysis equipment, moisture analyzers, and carbon content testing instruments, and comprehensive utility infrastructure including electrical systems, drying facilities, and dust management infrastructure ensuring workplace safety and environmental compliance.

Other Capital Costs: Pre-operative expenses including feasibility studies, detailed process engineering design, machinery installation and commissioning, operator training on crushing and grinding operations, environmental permits and workplace safety approvals, initial working capital covering coconut shell inventory and packaging materials, and contingency provisions for process optimization and capacity adjustments during plant establishment and initial ramp-up supporting market entry.

Major Applications and Market Segments

Coconut shell powder finds extensive and diverse applications across industrial sectors demonstrating its versatility and growing importance in sustainable manufacturing:

Activated Carbon Manufacturing: Coconut shell powder serves as a key raw material for activated carbon production due to its high carbon content, providing superior porosity and adsorption capacity when activated-critical for water purification addressing contamination, air filtration improving environmental quality, and industrial adsorption applications.

Abrasives and Polishing Industry: Used in surface finishing, cleaning, and polishing applications as an eco-friendly alternative to synthetic mineral abrasives, providing effective material removal and surface preparation across automotive, furniture, and industrial components manufacturing.

Rubber and Plastics Industry: Acts as a natural, biodegradable filler material in rubber compounds and plastic formulations, improving mechanical strength, reducing material costs, enhancing processing characteristics, and providing sustainable alternatives to petroleum-derived synthetic fillers.

Incense and Mosquito Coil Manufacturing: Provides essential binding strength, controlled combustion properties, and appropriate particle characteristics for manufacturing mosquito coils delivering consistent insect repellent performance and incense sticks producing steady fragrance release.

End-use industries spanning the activated carbon industry, abrasives and polishing, rubber and plastics, incense and agarbatti manufacturing, and composite material producers all contribute to sustained and diversified demand providing revenue stability and creating multiple growth pathways for coconut shell powder manufacturers aligned with global sustainability objectives and circular economy principles.

Why Invest in Coconut Shell Powder Manufacturing?

Several compelling strategic factors make coconut shell powder manufacturing an attractive and viable investment:

Utilization of Agro-Waste: Coconut shells are converted from agricultural waste into high-value industrial products, creating economic value from by-products while supporting circular economy principles and reducing environmental waste disposal concerns.

Rising Demand for Natural Materials: Industries globally are shifting toward biodegradable and renewable inputs driven by environmental regulations, consumer preferences for sustainable products, and corporate sustainability commitments-creating expanding market opportunities.

Strong Industrial Applications: Continuous and growing demand from activated carbon production for water and air purification, abrasives for surface finishing, and filler markets for rubber and plastics ensures diversified revenue streams across multiple industrial sectors.

Low Raw Material Cost: Coconut shells are widely available and affordable in coconut-producing regions as agricultural by-products, often available at minimal cost from coconut oil mills and processing facilities, providing a significant cost advantage in feedstock procurement.

Scalable Production Model: Capacity expansion is achievable with moderate incremental investment in additional crushing and grinding equipment, enabling manufacturers to grow production in line with increasing market demand without requiring entirely new facility construction.

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=8533&flag=C

Industry Leadership

The global coconut shell powder manufacturing industry includes established companies with production capabilities and diverse application portfolios serving industrial customers. Key industry players include:

• Viet Delta

• Shree Balajee Magnesite

• Premium

• SREE AGRO PRODUCTS

• Sudar Bio Fuels

These companies serve end-use sectors including activated carbon production, abrasives and polishing, rubber and plastics manufacturing, incense and agarbatti production, and composite material development, demonstrating the broad market applicability and commercial viability of coconut shell powder manufacturing across diverse sustainable industrial applications.

Recent Industry Developments

November 2025: Haycarb PLC launched coconut shell granular activated carbon for PFAS-contaminated water treatment, offering high microporosity, exceptional durability, and treatment efficiency. NSF-certified and Prop 65 compliant, the product supports sustainable water treatment solutions, reduces carbon footprint compared to alternatives, and allows regeneration and reuse-ideal for municipal, industrial, and commercial water purification applications ensuring longer lifespan and cost-effective PFAS removal.

February 2025: Jaipur-based startup Cancrie produced nanocarbon from coconut shell waste to enhance battery efficiency and lifespan. Currently serving lead-acid batteries including electric rickshaws and solar applications, Cancrie plans a 10X production expansion supported by USD 1.5 Million funding and global market ambitions-demonstrating the emerging high-technology applications emerging from coconut shell-derived materials beyond traditional industrial uses.

Conclusion

The coconut shell powder manufacturing sector presents a strategically positioned investment opportunity at the intersection of sustainable manufacturing, circular economy principles, and diversified industrial applications. With attractive profit margins of 30-40% gross profit and 12-18% net profit, strong and diversified demand across activated carbon, abrasives, rubber and plastics, incense, and composite material sectors, favorable market growth projections with 8.0% CAGR reaching USD 723.48 Million by 2034-effectively doubling market value over the forecast period-low-cost and abundantly available agricultural waste feedstock, and proven manufacturing technologies, establishing a coconut shell powder manufacturing plant offers significant potential for sustainable business success and attractive long-term returns. The combination of agro-waste utilization converting by-products into value-added products, rising global demand for natural and biodegradable materials, strong industrial applications across multiple sectors, low and stable raw material costs in coconut-producing regions, scalable production model enabling growth with moderate investment, circular economy alignment creating expanding opportunities, and emerging high-technology applications in activated carbon for water purification and advanced materials creates a compelling value proposition for agricultural processors, green material manufacturers, and sustainability-focused investors committed to quality manufacturing excellence and long-term participation in renewable industrial material markets.

About IMARC Group

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Coconut Shell Powder Manufacturing Plant Setup - 2026, Business Plan, Investment & Growth Opportunities here

News-ID: 4375087 • Views: …

More Releases from IMARC Group

The State of Europe Fintech Market: Industry Dynamics and Key Performance Indica …

Market Overview

The Europe fintech market size was valued at USD 113.42 Billion in 2025 and is projected to reach USD 461.57 Billion by 2034. It is expected to grow at a compound annual growth rate (CAGR) of 16.88% during the forecast period from 2026 to 2034. This growth is driven by increased adoption of digital technology, government support for fintech growth, and consumer acceptance of innovative financial services. The market…

Automotive Adaptive Front Lighting System Market to Grow at a CAGR of 7.16% duri …

Market Overview

The global Automotive adaptive front lighting system market size reached USD 2.4 Billion in 2025., with expectations to grow to USD 4.5 Billion by 2034 at a CAGR of 7.16% during 2026-2034. This increase is mainly attributed to the demand for better visibility during nighttime driving, supportive government regulations, and technological advancements such as LED and laser lighting.

Study Assumption Years

• Base Year: 2025

• Historical Year/Period: 2020-2025

• Forecast Year/Period: 2026-2034

Market Key Takeaways

• Current Market…

Instant Coffee Powder Manufacturing Plant Cost 2026: Raw Materials Requirement a …

The global instant coffee powder manufacturing industry stands as a dynamic component of modern beverage production systems worldwide, positioned at the intersection of convenience food trends, evolving consumer lifestyles, and coffee culture expansion. As a soluble coffee product created by dehydrating brewed coffee extract into powder or granule form, instant coffee represents a technological innovation delivering rapid preparation, extended shelf life, and consistent quality-transforming coffee consumption patterns across diverse demographics…

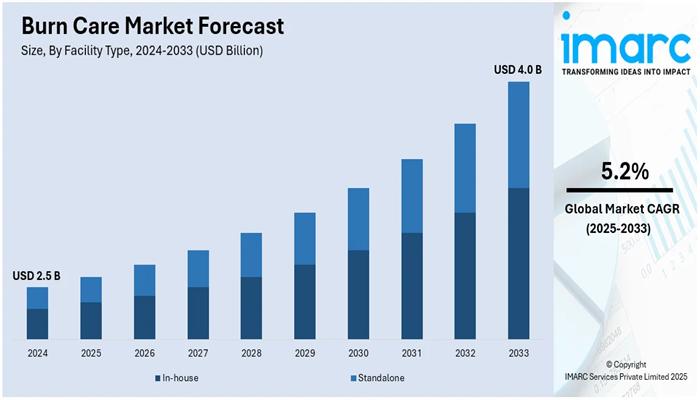

Global Burn Care Market Report by Facility Type, Treatment Type, Burn Severity, …

Market Overview

The global Burn Care Market was valued at USD 2.5 Billion in 2024 and is projected to reach USD 4.0 Billion by 2033, growing at a CAGR of 5.2% between 2025 and 2033.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

Market Key Takeaways

• Current Market Size: USD 2.5 Billion (2024)

• CAGR: 5.2% (2025-2033)

• Forecast Period: 2025-2033

• The market is driven by increasing prevalence of burn injuries globally.

• Rising awareness and demand for advanced…

More Releases for Coconut

Coconut Flour Market Future Business Opportunities 2025-2032 | Celebes Coconut C …

According to a new report by Coherent Market Insights, titled "Coconut Flour Market Size 2025, provides insightful information about regional and international markets that are anticipated to expand between 2025 and 2032. This thorough study looks at the competitive landscape, value chain analysis, major market segments, geographical trends, and changing market dynamics. It also offers a thorough analysis of the forces and limitations influencing the market. As a vital resource…

Coconut Products Market Forecast to 2027 - COVID-19 Impact and Global Analysis b …

An exhaustive evaluation of restrains included in Coconut Products Market report portrays dissimilarity to drivers and hence, gives room for tactical planning. Characteristics that overshadow market progress are as essential as they can be understood to advance different bends for getting hold of lucrative scenarios that.

Coconuts are highly nutritious as they are high on fibers; vitamins C, E, B1, B3, B5, and B6; and minerals such as sodium, iron, calcium,…

Coconut Market Size, Share & Trends Analysis Report By Product (Coconut Water, C …

The global Coconut market was valued at 12960 million in 2020 and is projected to reach US$ 16990 million by 2027, at a CAGR of 7.0% during the forecast period.

Coconut Market Overview

This market research report addresses great insights into the market and consumer data and their interpretation through various figures and graphs. The coconut market is estimated to be worth over billions by 2025. This growth is mainly due to…

Current research: Coconut Milk Market Exceptional Business Performance | The Coc …

Report Ocean recently published a new report on the Global Coconut Milk Market. The study has an in-depth analysis of the forecast period from 2021-2025. The report reveals a comprehensive picture of the Coconut Milk Market situation, taking into consideration all major trends, market dynamics, and competitive factors. Additionally, the report contains key statistics concerning the Coconut Milk Market situation of the leading key players, key market trends, and potential…

Coconut Cream Market 2019 Analysis By Top Manufacturers Celebes Coconut Corporat …

A new business intelligence report released by Up Market Research on “Global Coconut Cream Market”. Report provides a comprehensive market analysis with future prospects to 2026. Report focuses on the major drivers and restraints providing analysis of the market share, segmentation, revenue forecasts and geographic regions of the market.

Get Sample Copy Of This Report @

https://www.upmarketresearch.com/home/requested_sample/109904

The report contains 112 pages which highly exhibit on current market analysis scenario, upcoming as…

Global Coconut Cream Market 2018 Key Players: Celebes Coconut Corporation, Conne …

Coconut Cream Market:

WiseGuyReports.com adds “Coconut Cream Market 2018 Global Analysis, Growth, Trends and Opportunities Research Report Forecasting 2023” reports tits database.

Executive Summary

Geographically, this report is segmented into several key Regions, with production, consumption, revenue (million USD), market share and growth rate of Coconut Cream in these regions, from 2012 to 2023 (forecast), covering

North America (United States, Canada and Mexico)

Europe (Germany, France, UK, Russia and Italy)

Asia-Pacific (China, Japan, Korea, India and…