Press release

Garlic Powder Manufacturing Plant: Investment, Process, and Industry Outlook 2026

Garlic powder is a widely used dehydrated food ingredient known for its strong flavor, long shelf life, and convenience. It is extensively used across food processing, spice blends, ready-to-eat meals, sauces, seasonings, pharmaceuticals, nutraceuticals, and animal feed applications. Due to rising demand for processed and convenience foods, the garlic powder industry continues to expand steadily, making it an attractive opportunity for investors and food manufacturers.Understanding the garlic powder manufacturing plant cost is essential for entrepreneurs planning to enter this segment. Costs vary depending on production capacity, automation level, raw material sourcing, energy usage, and compliance with food safety standards. With efficient processing technology and quality control, garlic powder manufacturing can offer stable margins and export potential.

Overview of Garlic Powder Manufacturing

Garlic powder is produced by dehydrating fresh garlic cloves and grinding them into a fine powder. The manufacturing process focuses on preserving flavor, aroma, and nutritional properties while ensuring microbial safety and uniform particle size. Setting up a garlic powder processing facility requires investment in washing, peeling, slicing, drying, grinding, sieving, and packaging systems, along with utilities and skilled manpower.

Request for a Sample Report: https://www.imarcgroup.com/garlic-powder-manufacturing-plant-project-report/requestsample

IMARC Group's report titled "Garlic Powder Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive roadmap for establishing a garlic powder manufacturing facility. The report delivers micro-level insights into processing steps, equipment selection, infrastructure planning, cost estimation, and financial performance.

This detailed business plan helps stakeholders evaluate the garlic powder manufacturing plant cost by covering capital investment, operating expenses, profitability, and long-term market viability.

Garlic Powder Industry Outlook 2026

The global garlic powder market is expected to witness steady growth through 2026, supported by increasing demand for natural flavoring agents, clean-label ingredients, and shelf-stable food products. Growth in quick-service restaurants, packaged food consumption, and export-oriented spice processing is strengthening market prospects. Additionally, rising awareness of garlic's health benefits is driving demand from pharmaceutical and nutraceutical sectors.

Technological advancements in dehydration and grinding processes are improving yield, color retention, and flavor consistency, positively impacting overall plant efficiency and profitability.

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7428&flag=C

Key Insights for Garlic Powder Manufacturing Plant Setup

Detailed Process Flow:

• Product Overview

• Garlic Cleaning and Sorting

• Peeling and Slicing

• Dehydration / Drying

• Grinding and Sieving

• Quality Control and Testing

• Packaging and Storage

Project Details, Requirements, and Costs Involved:

• Land, Location, and Site Development

• Plant Layout and Material Flow

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Evaluating these elements is critical for accurately estimating the garlic powder manufacturing plant cost and ensuring operational efficiency.

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Careful cost control, raw material planning, and energy optimization significantly improve project returns.

Buy Now: https://www.imarcgroup.com/checkout?id=7428&method=2175

Key Cost Components of Setting Up a Garlic Powder Manufacturing Plant

• Raw Materials: Fresh garlic bulbs, food-grade additives, and processing aids

• Machinery & Equipment: Washing units, peeling machines, slicers, dryers, pulverizers, sieves, and packaging machines

• Infrastructure & Utilities: Processing halls, cold storage, power supply, water systems, and waste handling units

• Labor & Staffing: Plant managers, machine operators, quality controllers, maintenance staff, and administrative personnel

• Technology & Automation: Automated drying, grinding, and packaging lines for consistent quality

• Quality Control & Testing: Moisture, microbial, color, and particle size testing equipment

• Packaging & Branding: Bulk and retail packaging materials, labeling, and warehousing

• Environmental Compliance: Wastewater treatment, solid waste disposal, and hygiene standards

• Working Capital: Raw material procurement, inventory, and daily operations

• Administrative & Overhead Costs: Licensing, insurance, utilities, and office expenses

All these factors directly influence the overall garlic powder manufacturing plant cost.

Economic Trends Influencing Garlic Powder Manufacturing Plant Cost 2026

• Seasonal fluctuations in garlic prices

• Rising energy and fuel costs

• Increasing adoption of energy-efficient dryers

• Food safety and hygiene regulations

• Labor availability and wage trends

• Export demand and logistics costs

• Inflation and financing rates

• Sustainability initiatives in food processing

• Competition from low-cost producers

• Technological innovation in dehydration

Challenges and Considerations for Investors

• Dependence on seasonal garlic supply

• Price volatility of raw materials

• High energy consumption during drying

• Maintaining consistent product quality

• Compliance with food safety standards

• Storage and shelf-life management

• Skilled workforce requirements

• Market competition and pricing pressure

• Export regulations and certifications

• Capital recovery period

Addressing these challenges through efficient planning and technology adoption is essential for long-term success and profitability.

Conclusion

Investing in a garlic powder manufacturing facility offers strong growth potential driven by rising demand for processed foods, seasonings, and health-oriented ingredients. While the garlic powder manufacturing plant cost involves significant investment in drying and processing equipment, strategic planning, energy efficiency, and quality control can deliver attractive returns. With increasing domestic and export demand, modern garlic powder manufacturing plants are well-positioned for sustainable growth in the global food ingredients market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Garlic Powder Manufacturing Plant: Investment, Process, and Industry Outlook 2026 here

News-ID: 4374395 • Views: …

More Releases from IMACR Group

Chlor-Alkali Production Plant Cost (DPR)2026: Industry Trends, CapEx/OpEx and Ma …

The chlor-alkali industry is a cornerstone of the global chemical sector, supplying essential industrial chemicals such as chlorine, caustic soda (sodium hydroxide), and hydrogen. These products are widely used across water treatment, pulp and paper, textiles, soaps and detergents, alumina refining, pharmaceuticals, plastics, and chemical manufacturing. Due to their indispensable applications and steady industrial demand, understanding the chlor-alkali production plant cost is critical for investors planning long-term chemical manufacturing projects.

Chlor-alkali…

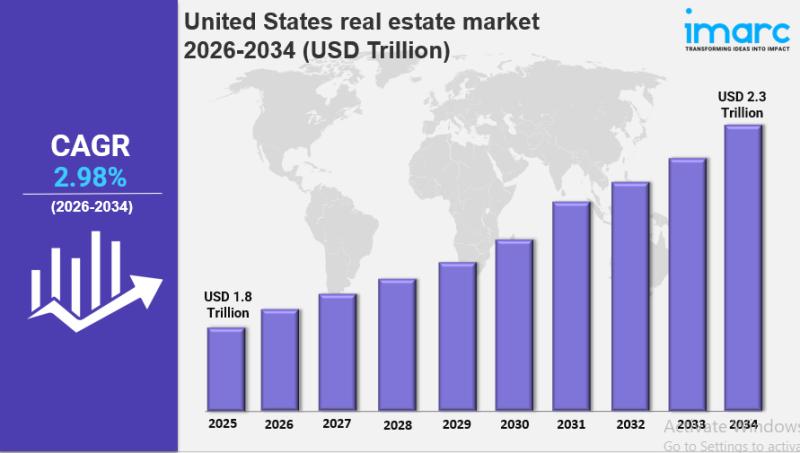

United States Real Estate Market Size Share, Industry Overview, Latest Trends an …

IMARC Group has recently released a new research study titled "United States Real Estate Market Size, Share, Trends and Forecast by Property, Business, Mode, and Region, 2026-2034, offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Real Estate Market Size Overview

The United States real estate market size was valued at USD 1.8 Trillion in 2025.…

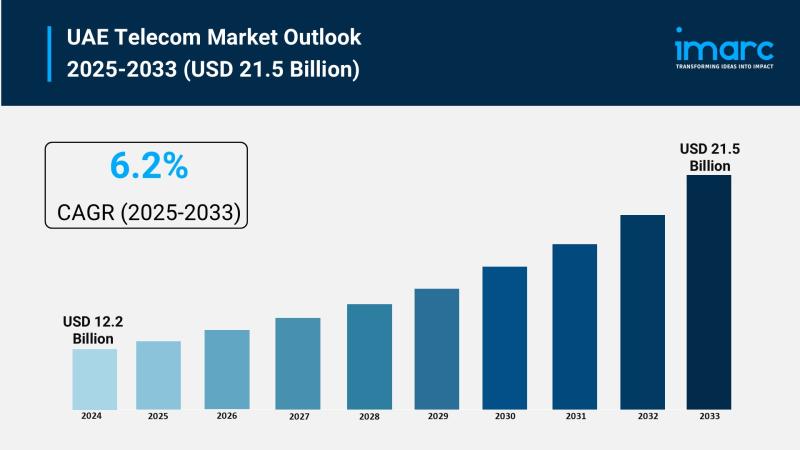

UAE Telecom Market Size is Expected to Reach USD 21.5 Billion By 2033 | CAGR: 6. …

UAE Telecom Market Overview

Market Size in 2024: USD 12.2 Billion

Market Size in 2033: USD 21.5 Billion

Market Growth Rate 2025-2033: 6.2%

According to IMARC Group's latest research publication, "UAE Telecom Market Size, Share, Trends and Forecast by Components, Material Used, End User, and Region, 2025-2033", the UAE telecom market size reached USD 12.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 21.5 Billion by 2033, exhibiting a…

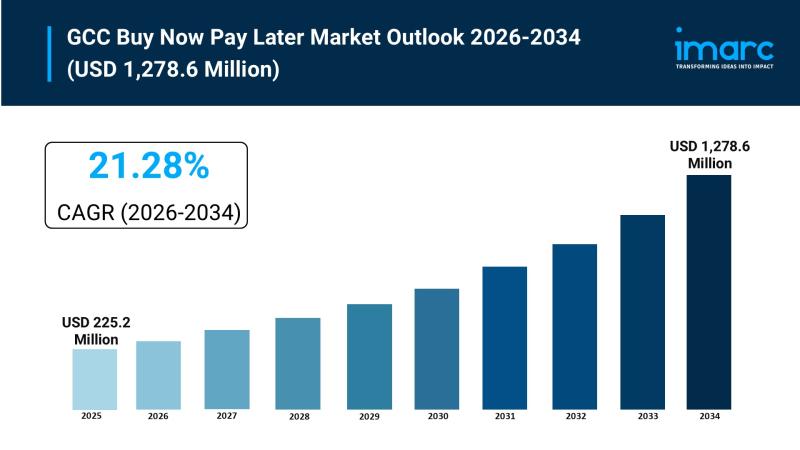

GCC Buy Now Pay Later Market Size to Hit USD 1,278.6 Million by 2034 | With a 21 …

GCC Buy Now Pay Later Market Overview

Market Size in 2025: USD 225.2 Million

Market Size in 2034: USD 1,278.6 Million

Market Growth Rate 2026-2034: 21.28%

According to IMARC Group's latest research publication, "GCC Buy Now Pay Later Market Report by Channel (Online, Point of Sale (POS)), Organization Size (Large Enterprises, Small and Medium Enterprises), End Use (Consumer Electronics, Fashion and Garment, Healthcare, Leisure and Entertainment, Retail, and Others), Purchase (Small Ticket Items (Up…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…