Press release

Chlor-Alkali Production Plant Cost (DPR)2026: Industry Trends, CapEx/OpEx and Market Growth

The chlor-alkali industry is a cornerstone of the global chemical sector, supplying essential industrial chemicals such as chlorine, caustic soda (sodium hydroxide), and hydrogen. These products are widely used across water treatment, pulp and paper, textiles, soaps and detergents, alumina refining, pharmaceuticals, plastics, and chemical manufacturing. Due to their indispensable applications and steady industrial demand, understanding the chlor-alkali production plant cost is critical for investors planning long-term chemical manufacturing projects.Chlor-alkali production is primarily based on the electrolysis of brine using membrane cell, diaphragm cell, or mercury cell technology. Among these, membrane cell technology is increasingly preferred due to its higher energy efficiency, lower environmental impact, and compliance with global sustainability standards.

Setting Up a Chlor-Alkali Production Plant

Establishing a chlor-alkali production plant involves multiple technical and financial considerations. The process begins with brine preparation, followed by electrolysis, chlorine handling and liquefaction, caustic soda concentration, hydrogen recovery, storage, and packaging. Each of these stages requires specialized equipment and strict safety controls.

The chlor-alkali production plant cost is influenced by plant capacity, technology selection, power availability, raw material sourcing, and compliance with environmental and safety regulations. Since electricity accounts for a major portion of operating expenses, access to reliable and cost-effective power is a decisive factor in project feasibility.

Request for a Sample Report: https://www.imarcgroup.com/chlor-alkali-manufacturing-plant-project-report/requestsample

IMARC Group's report titled "Chlor-Alkali Production Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a detailed roadmap for setting up a chlor-alkali manufacturing facility. The report delivers macro-level industry insights along with micro-level project details covering process flow, utilities, machinery, manpower, infrastructure, and financial modeling.

Chlor-Alkali Industry Outlook 2026

The global chlor-alkali industry is projected to witness steady growth through 2026, supported by rising demand from water treatment facilities, PVC manufacturing, alumina production, and the expanding chemical processing sector. Increasing investments in infrastructure, sanitation, and industrial manufacturing across emerging economies are further strengthening market prospects.

Additionally, stricter environmental regulations are accelerating the transition toward membrane cell technology, impacting both capital investment and the overall chlor-alkali production plant cost. Energy optimization, automation, and digital process control systems are also improving operational efficiency and profitability.

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=23602&flag=C

Key Insights for Chlor-Alkali Production Plant Setup

Detailed Process Flow:

Product Overview

Brine Preparation and Purification

Electrolysis Process

Chlorine Drying and Liquefaction

Caustic Soda Concentration

Hydrogen Handling and Storage

Quality Control and Safety Measures

Project Details, Requirements, and Costs Involved:

Land Selection and Site Development

Plant Layout and Safety Zoning

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging and Storage Requirements

Transportation and Logistics

Utility Requirements (Power, Water, Steam)

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis

Project Economics:

Capital Investment Breakdown

Operating Cost Structure

Energy and Utility Expenses

Maintenance and Consumables

Revenue Projections

Taxation and Depreciation

Profit and Cash Flow Analysis

Profitability Analysis:

Total Revenue

Total Operating Expenditure

Gross Profit and Margin

Net Profit and Margin

Break-Even Analysis

A well-planned project with energy-efficient technology can significantly optimize the chlor-alkali production plant cost and improve long-term returns.

Buy Now: https://www.imarcgroup.com/checkout?id=23602&method=2175

Key Cost Components of Setting Up a Chlor-Alkali Production Plant

Raw Materials: Salt (brine), water, chemicals for purification

Machinery & Equipment: Electrolyzers, rectifiers, brine treatment units, evaporators, compressors, chlorine liquefaction systems

Infrastructure & Utilities: Plant buildings, power substations, cooling systems, water treatment facilities

Power Consumption: Major contributor to operating expenses

Labor & Staffing: Engineers, electrochemical specialists, operators, safety personnel

Technology & Automation: Advanced control systems for efficiency and safety

Quality Control & Testing: Chemical analysis and monitoring equipment

Environmental Compliance: Effluent treatment, emission control, and hazardous material handling

Working Capital: Inventory, utilities, and operational liquidity

Administrative & Overheads: Licensing, insurance, and management costs

Economic Trends Influencing Chlor-Alkali Production Plant Cost 2026

Rising electricity tariffs

Shift toward membrane cell technology

Stringent environmental and safety regulations

Volatility in industrial demand cycles

Increased automation and digitalization

Growth in downstream chemical applications

Infrastructure development in emerging markets

Inflation and capital equipment pricing

Emphasis on sustainable chemical manufacturing

Challenges and Considerations for Investors

High initial capital requirement

Dependence on low-cost power supply

Strict environmental and safety compliance

Handling and storage of hazardous chemicals

Price volatility of end products

Operational complexity and skilled manpower dependency

Market competition and regional regulations

Despite these challenges, strategic planning and technology selection can help manage the chlor-alkali production plant cost effectively and ensure sustainable profitability.

Conclusion

Investing in a chlor-alkali manufacturing facility offers strong long-term potential driven by consistent industrial demand and expanding downstream applications. However, careful evaluation of technology, energy sourcing, regulatory compliance, and financial planning is essential. With modern membrane cell technology, efficient power management, and strong safety systems, investors can successfully optimize the chlor-alkali production plant cost and achieve competitive advantages in the global chemical market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Chlor-Alkali Production Plant Cost (DPR)2026: Industry Trends, CapEx/OpEx and Market Growth here

News-ID: 4373405 • Views: …

More Releases from IMACR Group

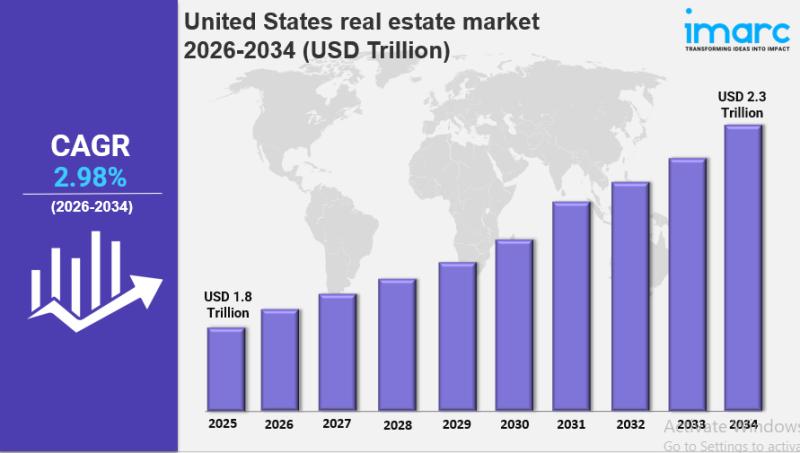

United States Real Estate Market Size Share, Industry Overview, Latest Trends an …

IMARC Group has recently released a new research study titled "United States Real Estate Market Size, Share, Trends and Forecast by Property, Business, Mode, and Region, 2026-2034, offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Real Estate Market Size Overview

The United States real estate market size was valued at USD 1.8 Trillion in 2025.…

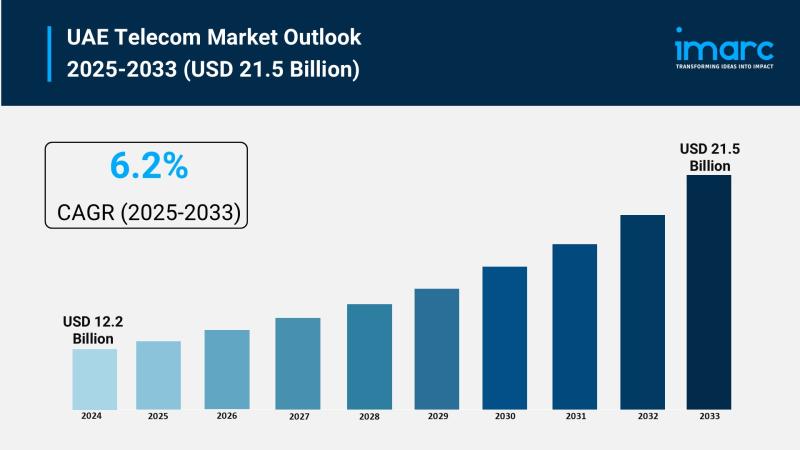

UAE Telecom Market Size is Expected to Reach USD 21.5 Billion By 2033 | CAGR: 6. …

UAE Telecom Market Overview

Market Size in 2024: USD 12.2 Billion

Market Size in 2033: USD 21.5 Billion

Market Growth Rate 2025-2033: 6.2%

According to IMARC Group's latest research publication, "UAE Telecom Market Size, Share, Trends and Forecast by Components, Material Used, End User, and Region, 2025-2033", the UAE telecom market size reached USD 12.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 21.5 Billion by 2033, exhibiting a…

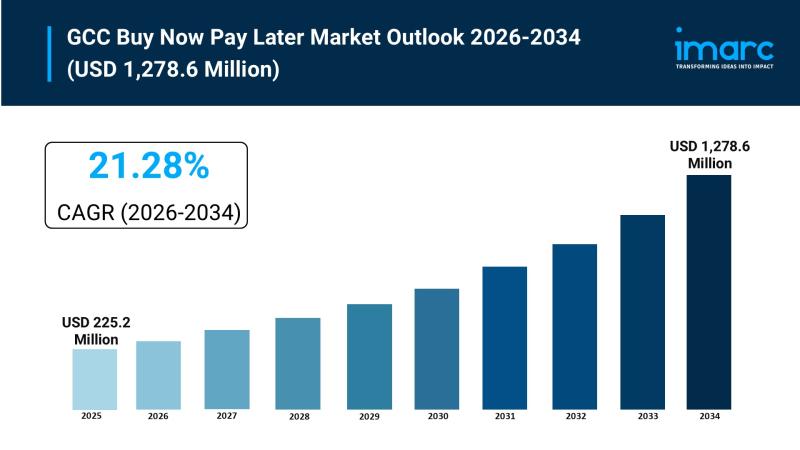

GCC Buy Now Pay Later Market Size to Hit USD 1,278.6 Million by 2034 | With a 21 …

GCC Buy Now Pay Later Market Overview

Market Size in 2025: USD 225.2 Million

Market Size in 2034: USD 1,278.6 Million

Market Growth Rate 2026-2034: 21.28%

According to IMARC Group's latest research publication, "GCC Buy Now Pay Later Market Report by Channel (Online, Point of Sale (POS)), Organization Size (Large Enterprises, Small and Medium Enterprises), End Use (Consumer Electronics, Fashion and Garment, Healthcare, Leisure and Entertainment, Retail, and Others), Purchase (Small Ticket Items (Up…

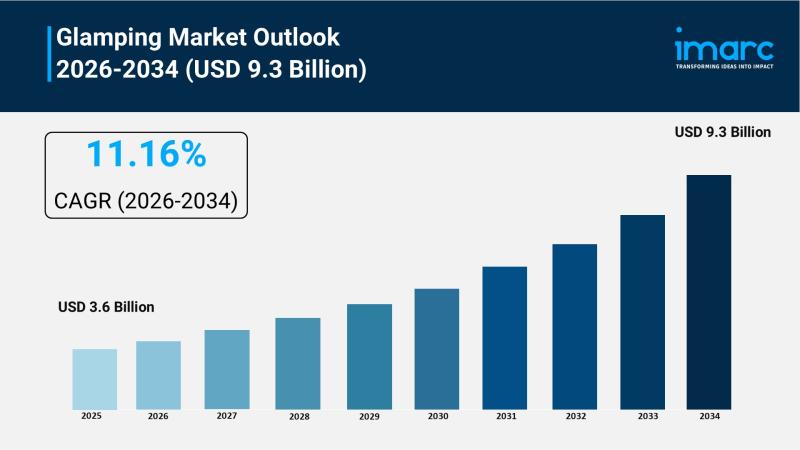

Glamping Market Size Worth USD 9.3 Billion, Globally, by 2034 at a CAGR of 11.16 …

Market Overview:

According to IMARC Group's latest research publication, "Glamping Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", TThe global glamping market size was valued at USD 3.6 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 9.3 Billion by 2034, exhibiting a CAGR of 11.16% during 2026-2034.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts.…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…