Press release

Activated Alumina Balls Manufacturing Plant DPR 2026: CapEx/OpEx Analysis with Profitability Forecast

Activated alumina balls are highly porous, spherical aluminum oxide materials used primarily as adsorbents, desiccants, and catalysts in various industrial applications. Due to their high surface area, excellent thermal stability, and strong affinity for moisture and impurities, activated alumina balls are widely used in water treatment, air drying, oil and gas processing, chemical manufacturing, petrochemicals, and pharmaceutical industries.They play a critical role in applications such as fluoride removal from drinking water, drying of compressed air and gases, purification of hydrocarbons, sulfur removal, and as catalyst supports. With increasing demand for clean water, industrial gas purification, and efficient adsorption materials, the activated alumina balls market continues to expand steadily.

Setting up an activated alumina balls manufacturing plant involves processing aluminum hydroxide or alumina hydrate into porous spherical pellets through controlled forming, drying, calcination, and activation processes. Investment is required in granulation systems, rotary kilns or calciners, drying units, screening systems, and quality testing laboratories. A well-planned plant layout, skilled technical workforce, and compliance with environmental and safety standards are essential for successful operations.

Request for a Sample Report: https://www.imarcgroup.com/activated-alumina-balls-manufacturing-plant-project-report/requestsample

IMARC Group's report, titled "Activated Alumina Balls Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for establishing an activated alumina balls manufacturing unit. The report delivers a comprehensive industry overview along with micro-level insights into production processes, raw material requirements, utility consumption, infrastructure planning, machinery selection, manpower requirements, quality assurance, and regulatory compliance.

This comprehensive business plan outlines every critical step involved in setting up a successful activated alumina balls manufacturing plant-from raw material sourcing and process design to operational efficiency and financial feasibility. It offers valuable insights into plant setup costs, machinery investment, operating expenses, utilities, storage, packaging, and logistics planning.

Activated Alumina Balls Industry Outlook 2026:

The activated alumina balls industry is expected to witness steady growth, driven by rising demand for water purification solutions, industrial drying systems, and gas purification applications. Increasing environmental regulations, expansion of oil & gas infrastructure, and growing awareness of clean drinking water are further strengthening market prospects. Emerging economies offer strong opportunities due to rapid industrialization and infrastructure development.

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=13318&flag=C

Key Insights for Activated Alumina Balls Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Raw Material Preparation (Aluminum Hydroxide / Alumina Hydrate)

• Mixing and Granulation

• Ball Formation and Spheronization

• Drying

• Calcination / Activation

• Cooling

• Screening and Size Classification

• Quality Inspection and Testing

• Packaging and Storage

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout and Process Design

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Utility Requirements and Costs

• Quality Control and Testing Facilities

• Packaging and Warehousing Requirements

• Transportation and Logistics Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investment Requirements

• Operating and Maintenance Costs

• Expenditure Projections

• Revenue Forecasts

• Taxation and Depreciation

• Profit and Cash Flow Projections

• Financial Feasibility Analysis

Profitability Analysis:

• Total Revenue

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Buy Now:

https://www.imarcgroup.com/checkout?id=13318&method=2175

Key Cost Components of Setting Up an Activated Alumina Balls Manufacturing Plant:

• Raw Materials: Aluminum hydroxide, alumina hydrate, binders, and processing aids.

• Machinery & Equipment: Mixers, granulators, balling discs, dryers, rotary kilns or calciners, coolers, and screening machines.

• Infrastructure & Utilities: Factory buildings, electricity, fuel or gas for kilns, water supply, and dust control systems.

• Labor & Staffing: Chemical engineers, kiln operators, quality control technicians, maintenance staff, and administrative personnel.

• Technology & Automation: Automated granulation and calcination control systems, temperature monitoring units, and process optimization software.

• Quality Control & Testing: Surface area analysis, adsorption capacity testing, bulk density testing, and mechanical strength analysis.

• Packaging & Logistics: HDPE bags, jumbo bags, drums, labeling, and logistics handling.

• Environmental Compliance: Dust collection systems, emission control equipment, and regulatory approvals.

• Working Capital: Raw material procurement, inventory management, and daily operating expenses.

• Administrative & Overhead Costs: Licensing, insurance, utilities, and office operations.

Economic Trends Influencing Activated Alumina Balls Plant Setup Costs 2026:

• Fluctuations in alumina and energy prices

• Rising fuel and utility costs for calcination

• Growing demand from water treatment and oil & gas sectors

• Investment in energy-efficient kiln technologies

• Environmental and air emission compliance costs

• Skilled labor availability

• Transportation and logistics cost variations

• Inflation and financing cost pressures

• Export demand for adsorbent materials

• Sustainability and resource efficiency initiatives

Challenges and Considerations for Investors in Activated Alumina Balls Manufacturing Projects:

• Energy-intensive calcination and activation processes

• Maintaining consistent pore structure and adsorption capacity

• Raw material quality dependence

• Environmental compliance and dust management

• Competition from global adsorbent manufacturers

• Skilled manpower requirements

• Quality certification for water treatment applications

• Logistics and bulk handling challenges

• Price sensitivity in industrial markets

• Working capital management

Conclusion:

Investing in an activated alumina balls manufacturing plant offers a stable, technology-driven opportunity supported by growing demand from water treatment, industrial drying, and gas purification sectors. While the industry requires significant capital investment, energy-intensive processing, and strict quality control, efficient plant design, modern calcination technology, and strong compliance practices can ensure long-term profitability. With increasing focus on clean water, industrial efficiency, and environmental protection, activated alumina balls manufacturing remains a highly attractive sector for investors and entrepreneurs.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Activated Alumina Balls Manufacturing Plant DPR 2026: CapEx/OpEx Analysis with Profitability Forecast here

News-ID: 4374313 • Views: …

More Releases from IMARC Group

Food Processing Plant Report DPR 2026: Business Plan, Requirements and Cost Invo …

A food processing plant is an industrial facility where raw agricultural commodities such as fruits, vegetables, grains, meat, dairy, and seafood are transformed into value-added food products through cleaning, grading, processing, preservation, packaging, and storage. Food processing enhances shelf life, food safety, convenience, and nutritional availability, making it a critical pillar of modern food supply chains.

Food processing plants cater to a wide range of products, including packaged foods, ready-to-eat meals,…

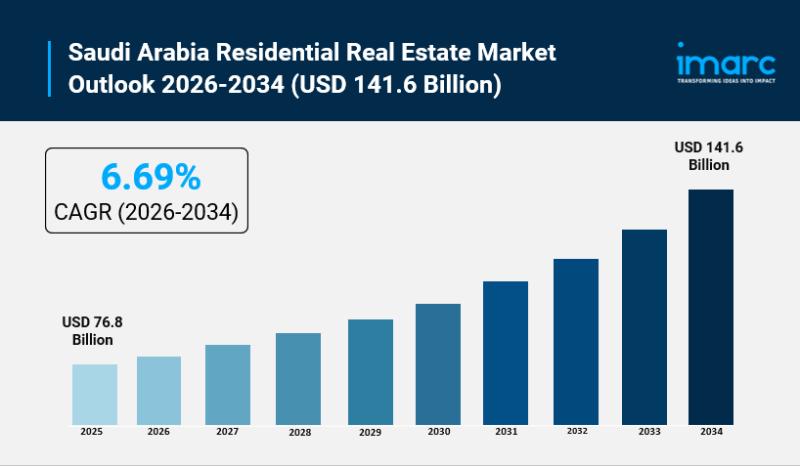

Saudi Arabia Residential Real Estate Market Size to Worth USD 141.6 Billion by 2 …

Saudi Arabia Residential Real Estate Market Overview

Market Size in 2025: USD 76.8 Billion

Market Forecast in 2034: USD 141.6 Billion

Market Growth Rate 2026-2034: 6.69%

According to IMARC Group's latest research publication, "Saudi Arabia Residential Real Estate Market Report by Type (Condominiums and Apartments, Villas and Landed Houses), and Region 2026-2034", the Saudi Arabia residential real estate market size reached USD 76.8 Billion in 2025. Looking forward, IMARC Group expects the market to…

Fuel Oil Prices See Strong Upside Momentum Across Key International Markets

Northeast Asia Fuel Oil Prices Movement January 2026:

Northeast Asia fuel oil prices in January 2026 were recorded at USD 0.84/kg, rising by 5.0% due to higher regional demand and limited supply. The fuel oil price trend showed upward momentum, while the fuel oil price index strengthened moderately. The fuel oil price chart reflected a clear price increase. The fuel oil price forecast suggests continued firmness in the short term.

Get the…

Citric Acid Production Plant (DPR) 2026: Industry Trends, CapEx/OpEx and Market …

The global citric acid manufacturing industry is experiencing steady growth driven by the rapidly expanding food and beverage sector and increasing demand for natural preservatives and acidulants. At the heart of this expansion lies a critical industrial ingredient-citric acid. As consumers worldwide increasingly seek clean-label products and manufacturers prioritize natural food additives over synthetic alternatives, establishing a citric acid production plant presents a strategically compelling business opportunity for entrepreneurs and…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…