Press release

Lead Acid Battery Manufacturing Plant: Complete DPR with Process Flow, Machinery & Profitability

Lead acid batteries are among the most widely used energy storage solutions globally, finding extensive applications across automotive, industrial, telecom, power backup, renewable energy storage, UPS systems, and railway sectors. Due to their reliability, recyclability, and cost-effectiveness, lead acid batteries continue to dominate the global battery market despite the emergence of advanced battery technologies. As a result, understanding the lead acid battery manufacturing plant cost is critical for investors planning to enter this resilient and demand-driven industry.Setting up a lead acid battery manufacturing plant involves sourcing high-purity lead, lead alloys, sulfuric acid, separators, containers, and additives, along with installing advanced grid casting, plate pasting, curing, formation, assembly, and finishing systems. The project requires substantial capital investment in specialized machinery, pollution control systems, safety infrastructure, quality testing laboratories, and skilled technical manpower. Efficient process design, automation, recycling integration, and strict compliance with environmental regulations play a vital role in optimizing operational efficiency and long-term profitability.

Request for a Sample Report: https://www.imarcgroup.com/lead-acid-battery-manufacturing-plant-project-report/requestsample

IMARC Group's report titled "Lead Acid Battery Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for establishing a lead acid battery manufacturing unit. The report delivers a comprehensive market overview and micro-level insights, including production processes, raw material sourcing, machinery requirements, utilities, infrastructure, manpower, packaging, transportation, and detailed financial analysis related to the lead acid battery manufacturing plant cost.

This in-depth business plan covers every critical stage of setting up a manufacturing facility-from understanding global and regional market dynamics to navigating operational, regulatory, and financial challenges. It provides actionable intelligence on plant layout planning, machinery selection, operating costs, raw material procurement strategies, utilities management, storage, logistics, and waste handling.

Lead Acid Battery Industry Outlook 2026

The lead acid battery industry is expected to witness steady growth in 2026, driven by rising automotive production, expansion of telecom infrastructure, increasing demand for data centers, and growing adoption of renewable energy systems requiring reliable energy storage. Government initiatives supporting electric mobility, grid stabilization, and battery recycling are further strengthening market prospects. Technological advancements in battery design, enhanced charge cycles, and energy efficiency improvements are also positively influencing the overall lead acid battery manufacturing plant cost and return on investment.

Speak to Analyst for Customized Report : https://www.imarcgroup.com/request?type=report&id=8557&flag=C

Key Insights for Lead Acid Battery Manufacturing Plant Setup

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Parameters

• Technical Tests and Performance Standards

Project Details, Requirements, and Costs Involved:

• Land, Location, and Site Development

• Plant Layout and Safety Design

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation and Logistics Requirements

• Utility Requirements (Power, Water, Air)

• Manpower Requirements and Wage Structure

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis

Project Economics:

• Capital Investments

• Operating and Maintenance Costs

• Expenditure Forecast

• Revenue Projections

• Depreciation and Tax Structure

• Profit and Cash Flow Analysis

Profitability Analysis

• Total Revenue

• Total Operational Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Buy Now: https://www.imarcgroup.com/checkout?id=8557&method=2175

Key Cost Components of Setting Up a Lead Acid Battery Manufacturing Plant

• Raw Materials: Lead ingots, lead oxide, sulfuric acid, separators, additives, containers, terminals, and electrolytes.

• Machinery & Equipment: Grid casting machines, oxide mills, pasting machines, curing chambers, formation tanks, assembly lines, and charging systems.

• Infrastructure & Utilities: Manufacturing sheds, acid storage tanks, power supply systems, compressed air units, and effluent treatment plants.

• Labor & Staffing: Engineers, chemists, technicians, machine operators, quality inspectors, and administrative staff.

• Technology & Automation: Automated plate processing, formation control systems, and battery testing units.

• Quality Control & Testing: Equipment for capacity testing, charge-discharge cycles, vibration testing, and safety compliance.

• Packaging & Distribution: Battery containers, labeling, pallets, warehousing, and logistics.

• Environmental Compliance: Lead recovery units, air pollution control systems, acid neutralization, and hazardous waste management.

• Working Capital: Raw material inventory, operational expenses, and short-term liquidity needs.

• Administrative & Overhead Costs: Licensing, insurance, utilities, compliance, and management expenses.

Economic Trends Influencing Lead Acid Battery Manufacturing Plant Cost 2026

• Volatility in lead and sulfuric acid prices

• Rising energy and utility costs

• Increased adoption of automated manufacturing systems

• Stricter environmental and recycling regulations

• Skilled labor demand and wage inflation

• Growth in battery recycling integration

• Transportation and supply chain cost fluctuations

• Inflation and interest rate trends

• Sustainability and circular economy initiatives

• Competitive pricing pressure from domestic and global players

Challenges and Considerations for Investors

• High initial capital investment

• Dependence on lead price stability

• Strict environmental and safety regulations

• Hazardous material handling risks

• Energy-intensive manufacturing process

• Skilled manpower requirements

• Waste and effluent management obligations

• Market competition from alternative battery technologies

• Regulatory changes affecting battery disposal and recycling

• Demand cyclicality in automotive and industrial sectors

Conclusion

Investing in a lead acid battery manufacturing plant offers long-term growth potential supported by stable demand, strong recyclability advantages, and widespread industrial applications. However, careful planning around capital investment, raw material sourcing, environmental compliance, and energy efficiency is essential. With advanced technology adoption, effective quality control, recycling integration, and strategic cost management, manufacturers can optimize the lead acid battery manufacturing plant cost and achieve sustainable profitability in a competitive global market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Lead Acid Battery Manufacturing Plant: Complete DPR with Process Flow, Machinery & Profitability here

News-ID: 4373455 • Views: …

More Releases from IMARC Group

Netherlands Online Travel Market Projected to Reach USD 13,903.47 Million by 203 …

Market Overview

The Netherlands online travel market reached a size of USD 5,954.64 Million in 2025. It is projected to grow and reach USD 13,903.47 Million by 2034, based on a forecast period from 2026 to 2034 with a growth rate of 9.88%. Growth is driven by rising digital adoption, user-friendly mobile booking platforms, and a shift towards customized travel planning. Increasing popularity among younger consumers and enhanced digital infrastructure further…

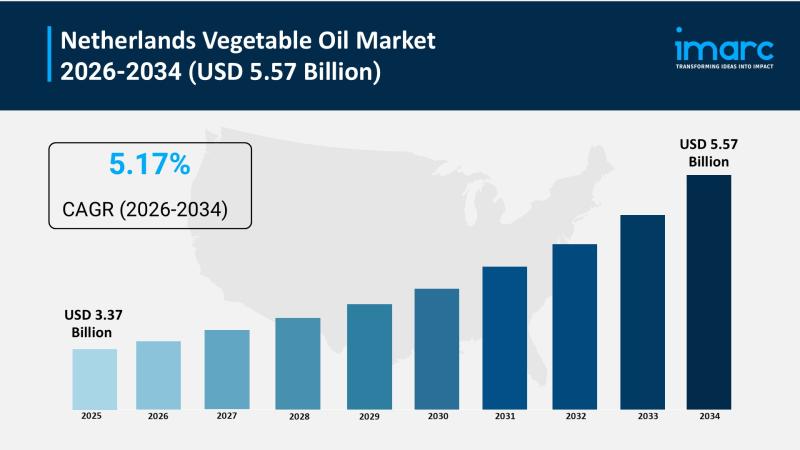

Netherlands Vegetable Oil Market is Expected to Reach USD 5.57 Billion by 2026-2 …

Market Overview

The Netherlands Vegetable Oil Market reached a size of USD 3.37 Billion in 2025, driven by the country's strategic role as a processing and re-export hub for vegetable oils serving EU and global supply chains. The market is projected to grow to USD 5.57 Billion by 2034, supported by rising domestic demand for health-conscious and sustainable oils. Circular economy policies and certified sourcing further enhance market growth. This report…

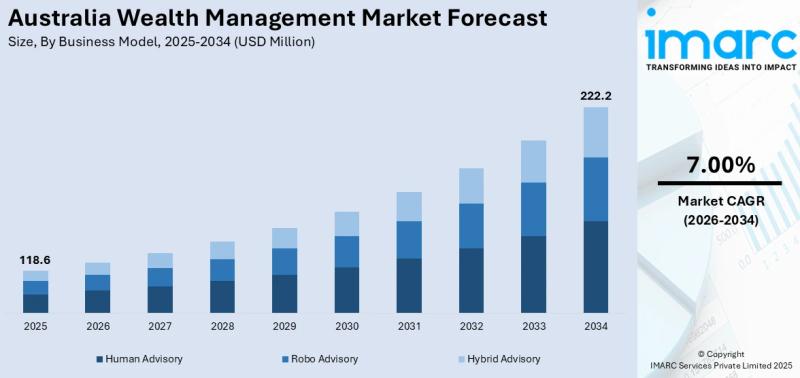

Australia Wealth Management Market Projected to Reach USD 222.2 Million by 2034

Market Overview

The Australia wealth management market size was valued at USD 118.6 Million in 2025 and is projected to reach USD 222.2 Million by 2034, reflecting significant market growth. The forecast period for this growth spans from 2026 to 2034 with a Compound Annual Growth Rate (CAGR) of 7.00%. Key growth drivers include rising high-net-worth individuals, regulatory reforms, and rapid digital transformation. For comprehensive details, visit the Australia Wealth Management…

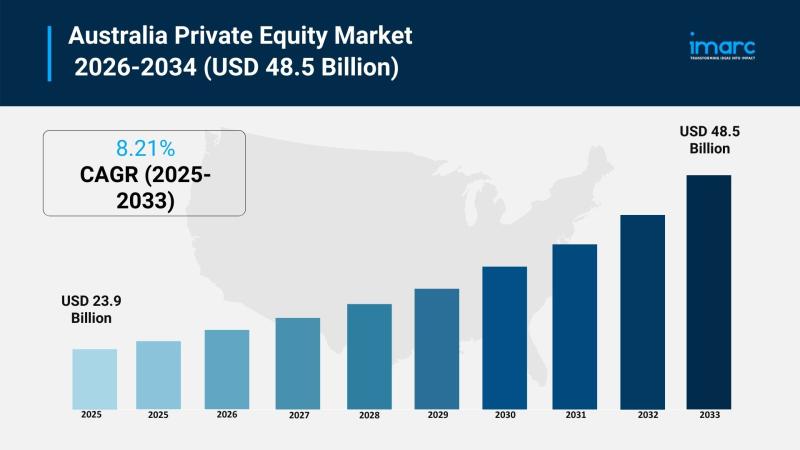

Australia Private Equity Market Projected to Reach USD 48.5 Billion by 2034

Market Overview

The Australia private equity market size reached USD 23.9 billion in 2025 and is forecast to grow to USD 48.5 billion by 2034. The market is expected to expand during 2026-2034 at a CAGR of 8.21%. Growth is driven by demand across fund types including buyout, venture capital, infrastructure, and real estate, with investors focusing on technology, fintech, healthcare, and renewable energy sectors. Australia's strong economic stability and regulatory…

More Releases for Lead

Lead Fluorides as Currency: Exploring the Global Lead Fluoride Market

Los Angeles, United States - In this comprehensive research study, we delve into the intricate details of the global Lead Fluoride market, providing a thorough analysis of its critical aspects. The report illuminates the anticipated growth of the global Lead Fluoride market during the forecast period, supported by SWOT analysis and Porter's Five Forces analysis. This illumination includes an in-depth exploration of the market's strengths, weaknesses, and the various players…

Digital Services for Lead Generation | Local Lead Generation Websites | Lead Gen …

Lead Generation consists of attracting and renovating target audiences that have shown interest in your product or services. The objective is to guide prospects through the purchaser’s journey to the end of the sales funnel. Content is one of the leading tools B2B marketers utilize to create leads. This may comprise of social media posts, blog posts, coupons and live events. You utilize the forms to capture leads that employ…

Digital Services for Lead Generation, Local Lead Generation Websites

Businesses these days are reliant on lead generation to advertise their service before the consumers to get more business and endure in bullish market. The Lead generation service is an unceasing effort to attract and change the target audience’s mind towards the business offering. It is an act of completely compelling the consumer to purchase the business services. It will boost brand image and outcome in good sales for the…

Digital Services for Lead Generation, Lead Generation Platforms: Ken Research

The Lead generation is the practice of gaining fresh leads for your business. It is cultivating the interest of a person in your product or service so much that they distribute you with their contact specifics. It is the start of the technique which leads to a prospective customer turning into a purchaser. And then perchance buying from your business. Your business should then be nurturing such leads that you…

Global Lead Acid Batteries Market | Global Lead Acid Batteries Industry | Lead A …

Lead acid battery refers to the oldest type of rechargeable battery with its use spanning across various industries. It has the advantage of supplying the high surge current, as the cells have great power to weight ratio. High power to weight ratio & low cost makes these batteries attractive for its use in the automotive sector. These batteries comprises of plates, cell, container, separators, and battery terminals. It is extensively…

Local Lead Generation Websites | Best Companies for Online Lead Generation | Lea …

The Lead Generation is a foremost marketing procedure that comprise finding people who would be interested in purchasing your product and/or services. It comprises collecting contact details of the interested impending buyers/consumers in exchange for something that is of worth to them - for e.g educational, collateral, research content or a free trial of a product. This is a foremost activity to build a sales pipeline. The Lead Generation is…