Press release

Junction Box Manufacturing Plant Cost 2026: Setup Details, Capital Investments, and Business Plan

The global electrical infrastructure industry is experiencing robust growth driven by increasing demand for electrical safety and connectivity solutions across construction, energy, automotive, and telecommunications sectors. At the core of these developments lies a critical electrical component-junction boxes. As industries worldwide prioritize safe electrification, reliable power delivery, grid modernization, renewable energy installations, and electric vehicle infrastructure, establishing a junction box manufacturing plant presents a strategically compelling business opportunity for electrical component manufacturers and infrastructure suppliers seeking to capitalize on megatrend alignment with EVs, renewable energy, automation, and expanding electrical safety requirements across industrial and commercial applications.IMARC Group's report, "Junction Box Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The junction box manufacturing plant project report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for a Sample Report: https://www.imarcgroup.com/junction-box-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global junction box market demonstrates strong growth trajectory, valued at USD 4.77 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 8.14 Billion by 2034, exhibiting a robust CAGR of 6.1% from 2026-2034. This sustained expansion is driven by increasing demand for electrical safety and connectivity solutions across construction, energy, automotive, and telecommunications industries.

Junction boxes are electrical containers or housings designed to shield connections, switches, and circuit boards in electrical systems. These protective enclosures safely contain wiring, junctions, and electrical connectors while shielding them from external factors including dust, moisture, and physical damage. Junction boxes are manufactured from various materials-plastic, metal, and fiberglass-selected based on intended application and environmental suitability requirements.

The junction box market is driven by construction activity expansion, increasing renewable energy investments, and rising industrial automation. According to India's Ministry of New and Renewable Energy, the country added a record 44.5 GW renewable energy capacity in 2025. Demand for safe, reliable electrical enclosures in power systems, industrial machinery, and telecommunications infrastructure grows due to heightened safety concerns and stricter regulatory standards. As cities expand and the global push for energy-efficient sustainable buildings continues, junction box requirements in electrical wiring systems are rising.

Additionally, the automotive industry's complex electrical wiring needs and growing electric vehicle adoption contribute to junction box demand. Furthermore, increasing smart grid deployment and connected device proliferation drive higher demand for junction boxes in communication and data networks.

Plant Capacity and Production Scale

The proposed junction box manufacturing facility is designed with an annual production capacity ranging between 5-10 million units per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to serve diverse market segments-from electrical installations and construction projects to industrial automation systems, telecommunications infrastructure, and renewable energy applications-ensuring steady demand and consistent revenue streams across multiple end-use sectors serving electrification and industrial expansion trends.

Financial Viability and Profitability Analysis

The junction box manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal strong margins supported by stable demand and value-added applications:

• Gross Profit Margins: 30-40%

• Net Profit Margins: 12-18%

These margins reflect favorable manufacturing economics supported by essential electrical infrastructure positioning, OEM certification requirements creating barriers to entry, growing renewable energy and EV megatrends, and increasing emphasis on electrical safety standards. The project demonstrates excellent return on investment (ROI) potential, making it highly attractive for electrical component manufacturers and infrastructure equipment suppliers seeking profitable growth in expanding electrification markets.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a junction box manufacturing plant reflects moderate raw material intensity with balanced input costs:

• Raw Materials: 65-75% of total OpEx

• Utilities: 10-15% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, quality control, depreciation, and taxes

Metal components constitute the primary cost driver. Additional inputs include plastic granules (PC/ABS), terminals, seals, and screws essential for producing electrical enclosures meeting safety standards. The utilities component reflects energy requirements for stamping, welding, and powder coating operations. The balanced cost structure provides reasonable flexibility for price management while maintaining quality standards essential for electrical safety applications and regulatory compliance across diverse industrial and commercial markets.

Buy Now: https://www.imarcgroup.com/checkout?id=12076&method=2175

Capital Investment Requirements

Setting up a junction box manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to metal and plastic component suppliers, target industrial markets, and robust infrastructure including reliable transportation, utilities, and waste management systems suitable for metal fabrication and coating operations.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for junction box production. Key machinery includes:

• Sheet metal shears for material cutting

• Punch presses for hole creation

• Bending brakes for forming operations

• Welding stations for assembly

• Powder coating lines for surface finishing

• Assembly jigs and quality testing units

• Packaging systems for finished products

Civil Works: Building construction, factory layout optimization, and infrastructure development designed for metal fabrication operations, ensuring efficient workflow from material processing through final assembly and quality testing.

Other Capital Costs: Pre-operative expenses, machinery installation costs, safety certifications, quality control laboratory establishment, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Junction boxes find extensive applications across diverse electrical and industrial sectors:

Electrical Installations: Housing and protecting wire connections in residential, commercial, and industrial electrical systems, ensuring safe operation and regulatory compliance across building infrastructure.

Industrial Systems: Enclosures for control wiring, automation equipment, and machinery connections in manufacturing facilities, providing robust protection for critical industrial electrical components.

Construction: Junction boxes for lighting, power distribution, and building infrastructure applications, supporting safe electrical installations in new construction and renovation projects.

Telecommunication: Protection and organization of data, signal, and communication cable connections, ensuring reliable network infrastructure for telecommunications and data center operations.

End-use sectors encompass electrical installations, construction projects, industrial automation, telecommunications infrastructure, and renewable energy systems, all contributing to sustained demand across electrification expansion.

Why Invest in Junction Box Manufacturing?

Several compelling factors make junction box manufacturing an attractive investment opportunity:

Essential Electrical Infrastructure Component: Junction boxes are critical for protecting, organizing, and distributing electrical connections across residential, commercial, industrial, automotive, and rail systems, making them foundational elements for safe electrification, reliable power delivery, and industrial operations.

Moderate but Strategic Entry Barriers: While capital requirements are lower than high-tech electronics, consistent quality, precise enclosure design, adherence to safety standards, and OEM certifications create meaningful barriers favoring experienced manufacturers who ensure reliability and standardized pricing.

Megatrend Alignment: Rapid growth in electric vehicles, renewable energy installations, automation, and data center infrastructure drives steady demand for robust, flexible, and vibration-resistant junction boxes. Industries such as EVs and renewable energy experience double-digit global expansion rates.

Policy and Infrastructure Support: Government initiatives in grid modernization, rail electrification, renewable energy projects, EV charging networks, and domestic manufacturing incentives (e.g., Make in India, PLI schemes for electronics and automotive components) indirectly stimulate demand for high-quality junction boxes.

Localization and Supply Chain Reliability: OEMs and EPC contractors increasingly prefer local, dependable suppliers to reduce lead times, mitigate material price volatility, and maintain consistent availability, creating opportunities for regional manufacturers with efficient sourcing and operations.

Manufacturing Process Excellence

The junction box manufacturing process involves several controlled stages ensuring product quality and safety compliance:

• Stamping: Metal sheets are stamped into required shapes and sizes using precision dies

• Bending: Stamped components are bent to create enclosure forms and mounting features

• Welding: Components are welded together to form complete junction box structures

• Powder Coating: Surface finishing applied for corrosion resistance and aesthetic appeal

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=12076&flag=C

Industry Leadership

The global junction box industry includes established electrical equipment manufacturers with extensive production capabilities. Key industry players include:

• ABB Group

• Schneider Electric

• Rittal

• Eaton Corporation

• Legrand

These companies serve diverse end-use sectors including electrical installations, construction, industrial automation, telecommunications, and renewable energy, demonstrating broad market applicability of junction box manufacturing.

Recent Industry Developments

January 2026: ABB announced signing an agreement to acquire Netcontrol, a provider of electrical grid automation solutions for power utilities and critical infrastructure operators, strengthening ABB's position in electrical infrastructure and expanding junction box application opportunities in grid modernization projects.

Browse Related Reports:

• Hydrobromic Acid Production Plant Cost: https://industrytoday.co.uk/chemicals/hydrobromic-acid-production-plant-cost-report-2025-setup-economics-and-financial-outlook

• Cigarette Filter Tube Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/cigarette-filter-tube-manufacturing-plant-cost-2025-unit-setup-machinery-and-raw-materials

• Cinnamon Powder Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/cinnamon-powder-manufacturing-plant-cost-2025-setup-details-capital-investments-and-business-plan

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Junction Box Manufacturing Plant Cost 2026: Setup Details, Capital Investments, and Business Plan here

News-ID: 4373144 • Views: …

More Releases from IMARC Group

Urea Phosphate Manufacturing Plant Cost 2026: Business Plan, Setup Requirements …

The global urea phosphate manufacturing industry is witnessing robust growth driven by the rapidly expanding agriculture sector and increasing demand for high-efficiency fertilizers. At the heart of this expansion lies a critical specialty fertilizer-urea phosphate. As agricultural regions transition toward precision irrigation systems and controlled nutrient delivery methods, establishing a urea phosphate manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and agro-chemical investors seeking to capitalize on this…

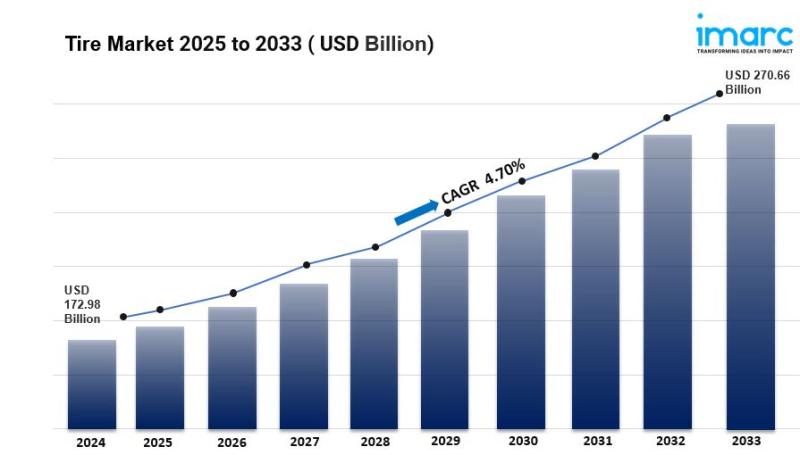

Tire Market Size to Surpass USD 270.66 Billion by 2033 | At CAGR 4.70%

IMARC Group, a leading market research company, has recently released a report titled "Tire Market Size, Share, Trends and Forecast by Design, End-Use, Vehicle Type, Distribution Channel, Season, and Region, 2025-2033." The study provides a detailed analysis of the industry, including the tire market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Market Overview

The global tire market…

Establish a Magnet Manufacturing Plant: Investment Cost, Production Process & RO …

Magnets are essential functional materials that generate magnetic fields and are widely used in electric motors, generators, transformers, consumer electronics, medical devices, automotive systems, renewable energy equipment, and industrial machinery. Depending on composition and application, magnets are classified into permanent magnets (ferrite, neodymium, samarium cobalt, alnico) and electromagnetic components. With rapid electrification, automation, and renewable energy expansion, magnets have become critical components across modern industries.

Growing demand from electric vehicles (EVs),…

Global Prawn Market Size, Share, Forecast & Species-Wise Analysis Report 2025-20 …

The global prawn market is on a steady growth trajectory, valued at 8.6 million tons in 2024, with projections to reach 11.1 million tons by 2033, growing at a CAGR of 2.76%. This expansion is fueled by rising global seafood demand, increasing health-conscious eating habits, and the integration of prawns into diverse cuisines worldwide. Technological innovations in sustainable aquaculture, supportive international trade policies, and the rising use of prawns in…

More Releases for Junction

Dual Junction Circulators Market Efficient Circulation in Dual Junction Systems …

The Report on "Dual Junction Circulators Market" provides Key Benefits, Market Overview, Regional Analysis, Market Segmentation, Future Trends Upto 2030 by Infinitybusinessinsights.com. The report will assist reader with better understanding and decision making.

The Dual Junction Circulators Market is experiencing growth as dual junction circulators play a crucial role in RF (radio frequency) and microwave applications, providing signal isolation and directionality. These circulators find applications in various industries, including telecommunications, aerospace,…

Gastroesophageal Junction Adenocarcinoma Therapeutics Market - Revolutionizing C …

Newark, New Castle, USA: The "Gastroesophageal Junction Adenocarcinoma Therapeutics Market" provides a value chain analysis of revenue for the anticipated period from 2023 to 2031. The report will include a full and comprehensive analysis of the business operations of all market leaders in this industry, as well as their in-depth market research, historical market development, and information about their market competitors.

Gastroesophageal Junction Adenocarcinoma Therapeutics Market: https://www.growthplusreports.com/report/gastroesophageal-junction-adenocarcinoma-therapeutics-market/8809

This latest report researches the…

Global Super Junction MOSFET Market Size & Trends

According to a new market research report published by Global Market Estimates, the Global Super Junction MOSFET Market is projected to grow from USD 3.1 billion in 2022 to USD 8.7 billion in 2027 at a CAGR of 16.3% from 2022 to 2027.

The major drivers of the super junction MOSFET market are the large demand for these transistors in the electronics industry for the fabrication of high-voltage electronic components, growing…

Podiatry First Bondi Junction

Podiatry First is recognised as the leading and most progressive Podiatry clinic in the Eastern Suburbs. Established in 2002, Podiatry First has grown to become one of the most respected and busiest clinics in the area.

Podiatry First Bondi Junction

Suite 1801, 101 Grafton Street, Westfield Tower 2, Bondi Junction NSW 2022

Podiatry First is recognised as the leading and most progressive Podiatry clinic in the Eastern Suburbs. Established in 2002, Podiatry First…

Terminal and Junction Boxes Market Report 2018: Segmentation by Type (Plastic Te …

Global Terminal and Junction Boxes market research report provides company profile for Ningbo GZX PV Technology CO.,LTD., Schneider Electric, FIBOX, Cortem Group, Ningbo ChuangYuan PV Technology Co., Ltd, RENHESOLAR, Eaton, Zhejiang Zhonghuan Sunter, PV Technology Co. Ltd, ABB, Rittal and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of…

New M8x1-passive junction boxes from ESCHA

Halver, 23 April 2015 – In November 2014, the connector- and housing specialist ESCHA presented its new M8x1-passive junction-generation at the SPS IPC Drives in Nuremberg. The I/O-junctions are particularly distinguished for their compact housing style as well as their flexible mounting options. Various versions will be available as of May 2015.

The new M8x1-passive junction-generation from ESCHA consists of 4-way-, 8-way- und 10-way-junctions with pluggable M8x1-connections as well as 4-way-…