Press release

Toothpaste Manufacturing Plant Cost 2026: End-to-End Project Report, Machinery Setup and Business Plan

The global toothpaste manufacturing industry represents a vital segment of the personal care and oral hygiene sector, characterized by consistent consumer demand, product innovation opportunities, and expanding market reach across retail, pharmaceutical, and institutional channels. As oral health awareness continues to rise globally and consumers increasingly prioritize specialized dental care formulations, the toothpaste manufacturing sector offers compelling investment opportunities for entrepreneurs and established businesses seeking to enter or expand within this essential consumer goods category. This comprehensive guide provides an authoritative exploration of the technical, financial, and strategic dimensions of establishing a toothpaste manufacturing plant, leveraging current market data and industry insights to support informed investment decision-making.Market Overview and Growth Potential

The toothpaste manufacturing sector is experiencing steady and sustained growth driven by powerful, interconnected market forces that reflect fundamental shifts in consumer health consciousness, purchasing behavior, and product preferences. The industry's expansion is propelled by several critical factors:

• Rising oral care awareness across demographic segments

• Increasing disposable incomes in emerging markets

• Growth of the retail pharmacy sector

• Expansion of e-commerce channels

• Growing consumer preference for specialized formulations

The global toothpaste market was valued at USD 22.3 Billion in 2025, establishing a substantial foundation for industry growth. According to comprehensive market analysis, the sector is projected to reach USD 29.7 Billion by 2034, exhibiting a steady CAGR of 3.26% from 2026 to 2034. This consistent growth trajectory reflects the essential nature of oral care products and the increasing consumer willingness to invest in premium, specialized formulations.

Consumer awareness regarding oral health has reached unprecedented levels, with research indicating that 92% of people recognized the link between oral health and overall wellness in 2024, while 89% believed good oral hygiene boosts confidence and social interaction. This heightened awareness is fundamentally transforming purchasing behaviors and driving sustained demand for quality toothpaste products across global markets.

Urbanization, rising incomes, and increasingly busy lifestyles are changing consumer habits toward preferring convenient, ready-to-use oral care products. The proliferation of dental clinics, pharmacies, supermarkets, and online platforms has significantly improved product accessibility, while professional dental recommendations for specific purposes like cavity prevention, whitening, and sensitivity management continue to drive category growth.

IMARC Group's report, "Toothpaste Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The toothpaste manufacturing plant cost report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Plant Capacity and Production Scale

The proposed toothpaste manufacturing facility is designed with strategic production capacity and operational flexibility as core principles. The annual production capacity ranges between 50,000 to 100,000 MT, enabling significant economies of scale while maintaining the agility necessary to respond to market dynamics and evolving consumer preferences.

This capacity range positions the plant to serve multiple market segments effectively:

• Retail Oral Care Sector: Consumer products for daily oral hygiene across mass market and premium segments

• Pharmaceutical and Healthcare Distribution: Professional-grade formulations recommended by dental practitioners

• Institutional Procurement: Bulk supply for hotels, schools, hospitals, and travel kit manufacturers

• Specialized Market Segments: Niche products targeting specific consumer needs

The production facility can manufacture diverse product variants to address varied consumer preferences and market opportunities:

• Herbal toothpaste formulations: Natural ingredient-based products

• Fluoride toothpaste: Cavity prevention and enamel strengthening

• Whitening toothpaste: Cosmetic enhancement formulations

• Sensitivity toothpaste: Specialized formulations for sensitive teeth

• Children's toothpaste: Age-appropriate formulations with appealing flavors

• Specialized variants: Charcoal-based, probiotic, and other innovative formulations

Request for a Sample Report: https://www.imarcgroup.com/toothpaste-manufacturing-plant-project-report/requestsample

Financial Viability and Profitability Analysis

The toothpaste manufacturing business demonstrates compelling financial fundamentals supported by consistent consumer demand, relatively stable raw material costs, and opportunities for product differentiation and premium pricing. The project offers healthy profitability potential with gross profit margins typically ranging between 25-35%, driven by efficient production processes, brand positioning, and value-added formulation capabilities.

Net profit margins are projected at 10-20%, reflecting operational efficiency achievable through optimized manufacturing processes, effective cost management, strategic brand development, and premium product positioning. These margin profiles compare favorably to many consumer goods categories and provide attractive returns while supporting competitive market pricing and marketing investments.

The financial projections developed for this project incorporate comprehensive analysis across all cost components and revenue streams. Capital investment modeling addresses land acquisition, site development, machinery procurement, utilities infrastructure, quality control laboratory setup, and working capital requirements. Operating cost analysis encompasses raw material expenses, utility consumption, packaging materials, labor costs, quality control and regulatory compliance, marketing and distribution expenses, and ongoing maintenance requirements.

These detailed financial models provide stakeholders with transparent visibility into project economics, including capital expenditure (CapEx) breakdowns, operating expenditure (OpEx) structures, income projections across product categories and market segments, expected return on investment (ROI), net present value (NPV) calculations, payback period analysis, and long-term profitability trajectories under various market scenarios.

Operating Cost Structure

Understanding the operating cost structure is fundamental to effective business planning and margin optimization in toothpaste manufacturing. The cost architecture reflects raw material diversity, formulation complexity, packaging requirements, and quality control imperatives.

In toothpaste manufacturing operations, raw materials account for approximately 50-60% of total operating expenses (OpEx), with calcium carbonate representing the predominant cost component as the primary abrasive ingredient.

Key Raw Materials Include:

• Calcium carbonate: Primary abrasive agent for cleaning teeth

• Flavoring agents: Mint, cinnamon, and other taste-enhancing ingredients

• Fluoride compounds: Active ingredients for cavity prevention

• Humectants: Moisture-retaining agents maintaining product consistency

• Binders: Ingredients providing proper texture and stability

• Surfactants: Foaming and cleaning agents

• Whitening agents: For specialty formulations

• Herbal extracts: For natural variant formulations

Utilities represent 10-15% of OpEx, covering electricity for mixing and homogenization equipment, water for formulation and cleaning operations, and climate control for maintaining product stability and quality during production and storage.

Additional operating costs encompass:

• Transportation for raw material delivery and finished product distribution

• Packaging materials (tubes, caps, cartons, labels) representing significant cost components

• Salaries and wages for production personnel, quality control staff, and administrative teams

• Depreciation on specialized manufacturing equipment

• Taxes and regulatory compliance costs

• Repairs, maintenance, and other operational expenses

Raw material procurement strategies must prioritize establishing reliable supplier relationships for critical ingredients, negotiating long-term contracts to stabilize costs, and maintaining quality standards across all formulation components.

Capital Investment Requirements

Establishing a toothpaste manufacturing plant requires comprehensive capital investment across multiple categories, reflecting the precision equipment, quality control infrastructure, and hygienic production environment essential for consumer safety and product quality.

Capital Expenditure Components:

• Land and Site Development Costs: Land registration, boundary development, site preparation

• Civil Works Costs: Building construction, storage facilities, quality control laboratories, administrative areas

• Machinery Costs: Largest portion of total capital expenditure

• Other Capital Costs: Utilities infrastructure, pre-operative expenses, initial working capital

Site Selection Considerations:

Strategic location selection must evaluate several critical factors:

• Easy access to key raw materials including calcium carbonate and flavoring agents

• Proximity to target markets to minimize distribution costs for temperature-sensitive finished products

• Robust infrastructure including reliable transportation networks, utilities access (particularly high-quality water supply), and waste management systems

• Compliance with local zoning laws and environmental regulations governing cosmetic and personal care product manufacturing

• Space for future expansion to accommodate capacity increases and new product line development

Essential Machinery Requirements:

High-quality, food-grade machinery tailored for toothpaste production represents the technical foundation:

• Mixers: For combining raw materials into homogeneous formulations

• Homogenizers: Ensuring uniform consistency and texture throughout the product

• Vacuum fillers: For air-free tube filling maintaining product integrity

• Tube filling and sealing machines: Automated systems for high-volume production

• Labeling systems: Automated application of product information and branding

• Quality inspection instruments: Testing equipment for consistency, safety, and performance verification

All machinery must comply with stringent personal care product manufacturing standards, feature hygienic design principles facilitating thorough cleaning, and incorporate precision control systems for consistent formulation accuracy. Equipment selection should prioritize automation capabilities to ensure production efficiency, minimize contamination risks, and maintain batch-to-batch consistency.

Civil works costs cover facility construction designed to meet good manufacturing practices (GMP) requirements, including controlled production environments, segregated storage areas for raw materials and finished goods, quality control laboratories, and administrative spaces. Other capital costs include utilities installation, regulatory licensing and approval expenses, initial working capital for inventory buildup, and contingency reserves.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=8695&flag=C

Manufacturing Process Overview

The toothpaste manufacturing process involves precise sequential operations designed to create consistent, safe, and effective oral care products:

Unit Operations Involved:

• Raw material weighing: Precise measurement of all formulation components

• Mixing and homogenization: Combining ingredients into uniform paste consistency

• Flavor and additive incorporation: Adding taste-enhancing and functional ingredients

• Quality inspection: Testing for consistency, safety, and performance specifications

• Filling: Transferring finished product into tubes using vacuum technology

• Packaging: Sealing tubes, applying caps, and placing in cartons

• Labeling: Applying product information, branding, and regulatory compliance details

Quality Assurance Criteria:

Comprehensive quality control systems must monitor formulation accuracy, ensure product purity and safety through microbiological testing, maintain stability during shelf life, verify performance characteristics (cleaning efficacy, foam generation, taste), and ensure full traceability across production batches.

Technical Tests:

Laboratory analysis includes viscosity measurement, pH testing, abrasion testing, fluoride content verification, microbial testing, stability testing under various storage conditions, and sensory evaluation to ensure consumer acceptability.

Major Applications and Market Segments

Toothpaste manufacturing serves multiple essential applications across diverse consumer and institutional categories:

Primary Applications:

• Daily Oral Hygiene: Fundamental cleaning and plaque removal for household consumers

• Whitening: Cosmetic enhancement for improved tooth appearance

• Cavity Prevention: Fluoride-based formulations protecting against tooth decay

• Gum Protection: Specialized formulations supporting periodontal health

• Specialized Treatments: Products addressing sensitive teeth and other specific oral health conditions

End-Use Industries:

• Oral Care and Personal Hygiene Sector: Consumer retail segment representing primary market

• Pharmaceutical and Retail Segments: Professional recommendations and pharmacy distribution

• Cosmetic Industry: Premium positioning for whitening and aesthetic enhancement

• Institutional Procurement: Bulk supply for dental clinics, hotels, hospitals, and travel industries

The diversity of applications and distribution channels creates natural demand stability and multiple revenue opportunities across consumer segments, price points, and geographic markets.

Buy Now: https://www.imarcgroup.com/checkout?id=8695&method=2175

Why Invest in Toothpaste Manufacturing?

Multiple strategic factors converge to make toothpaste manufacturing an attractive investment proposition:

✓ Rising Oral Care Awareness: Increasing consumer consciousness about oral hygiene fundamentals is driving sustained global demand growth for quality toothpaste products.

✓ Product Innovation and Differentiation: Manufacturers can produce diverse variants including herbal, whitening, fluoride-enriched, sensitivity-specific, and other specialized formulations to address varied consumer preferences and capture premium pricing opportunities.

✓ Expanding Retail and E-Commerce Channels: The proliferation of pharmacies, supermarkets, convenience stores, and online platforms has dramatically improved product accessibility and market penetration potential.

✓ Scalable Production: The capital-efficient nature of toothpaste manufacturing processes enables gradual capacity expansion with moderate incremental investment as market presence grows.

✓ Steady Demand and High Repeat Purchase: Oral care products generate very strong consumer loyalty and consistent repurchase patterns, guaranteeing continuous revenue flows and predictable cash generation.

✓ Essential Product Category: Toothpaste represents a non-discretionary personal care item with relatively stable demand characteristics across economic cycles.

✓ Premium Product Opportunities: Specialized formulations addressing specific needs (sensitivity, whitening, natural ingredients) command premium pricing and higher margins compared to basic variants.

Industry Leadership

The global toothpaste manufacturing industry features several established multinational leaders with extensive production capacities and diverse product portfolios:

Leading Toothpaste Manufacturers:

• Unilever PLC

• The Procter & Gamble Company

• GlaxoSmithKline PLC

• Colgate-Palmolive Co.

• Lion Corporation

These multinational corporations serve end-use sectors including retail, pharmaceutical, cosmetic, and institutional markets, providing broad spectrums of oral care solutions across multiple price points, formulations, and geographic regions. Their market presence demonstrates the scalability and profitability potential of professional toothpaste manufacturing operations while highlighting opportunities for new entrants to serve regional markets, niche segments, natural product categories, or specialized formulations addressing specific consumer needs.

Latest Industry Developments

The toothpaste sector continues to experience innovation and product development:

• January 2026: Hello introduced whipped toothpaste featuring a swirl-shaped, foaming formula that fights cavities, strengthens enamel, and freshens breath. The vegan formulation is free from artificial sweeteners, Flavors, dyes, SLS, parabens, and titanium dioxide, while avoiding animal testing.

• August 2025: Lion Corporation rolled out Dent Health Medicated Toothpaste DX Premium, featuring high concentrations of tranexamic acid and isopropyl methyl phenol. Formulated with Vitamin E to stimulate gum cells and repair tissue, the toothpaste includes more medicated ingredients than any other Dent Health variant, offering comprehensive care for periodontitis.

These developments underscore ongoing industry innovation, growing consumer demand for specialized formulations, and opportunities for product differentiation supporting market growth and premium positioning.

Conclusion

The toothpaste manufacturing sector presents a compelling investment opportunity characterized by strong market fundamentals, consistent consumer demand, attractive profit margins, and multiple product differentiation opportunities. The combination of increasing oral health consciousness expanding retail and e-commerce distribution channels, growing consumer preference for specialized formulations, and opportunities for brand development creates highly favorable conditions for both immediate profitability and sustained long-term business growth.

For entrepreneurs and businesses seeking to participate in the essential personal care products value chain, toothpaste manufacturing offers a proven pathway to creating value while meeting fundamental consumer needs for oral health and hygiene. The sector's consistent growth trajectory, coupled with the non-discretionary nature of oral care products and opportunities for premium positioning through innovation, ensures continued market relevance and attractive opportunities for well-planned and professionally executed manufacturing ventures delivering consistent quality, product innovation, and consumer value.

Browse Related Reports:

Fine Dining Restaurant Business Plan: https://industrytoday.co.uk/market-research-industry-today/fine-dining-restaurant-business-plan-2025-setup-costs-roi

Finishing School Business Plan: https://industrytoday.co.uk/market-research-industry-today/how-to-start-a-finishing-school-step-by-step-guide-2025

Organic Grocery Store Business Plan: https://industrytoday.co.uk/market-research-industry-today/how-to-write-an-organic-grocery-store-business-plan-2025

Skin and Hair Clinic Business Plan: https://industrytoday.co.uk/market-research-industry-today/step-by-step-guide-to-opening-a-skin-and-hair-clinic-in-2025

Gastroenterology Center Business Plan: https://industrytoday.co.uk/health_and_safety/how-to-attract-clients-to-your-gastroenterology-center-in-2025

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factoring Auditing

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Toothpaste Manufacturing Plant Cost 2026: End-to-End Project Report, Machinery Setup and Business Plan here

News-ID: 4368326 • Views: …

More Releases from IMARC Group

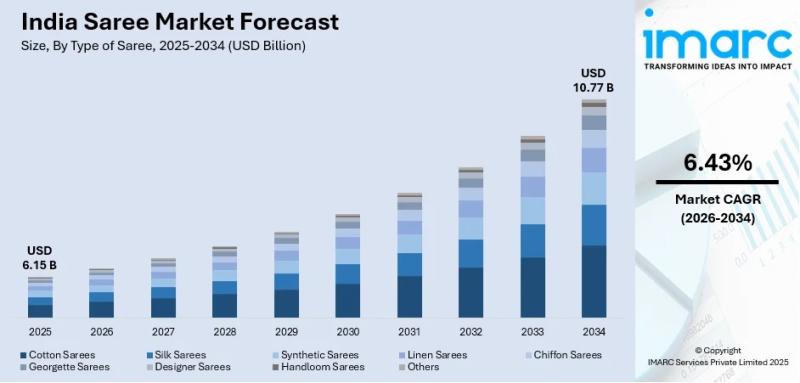

India Saree Market Size to Reach USD 10.77 Billion by 2034: Trends, Growth Facto …

The saree market size in india reached USD 6.15 Billion in 2025, according to the latest comprehensive industry analysis by IMARC Group. Evolving from a traditional cultural garment into a dynamic symbol of modern ethnic fashion, the market is projected to reach USD 10.77 Billion by 2034. This represents a steady compound annual growth rate (CAGR) of 6.43% during the forecast period (2026-2034).

What are the Key Growth Factors Driving the…

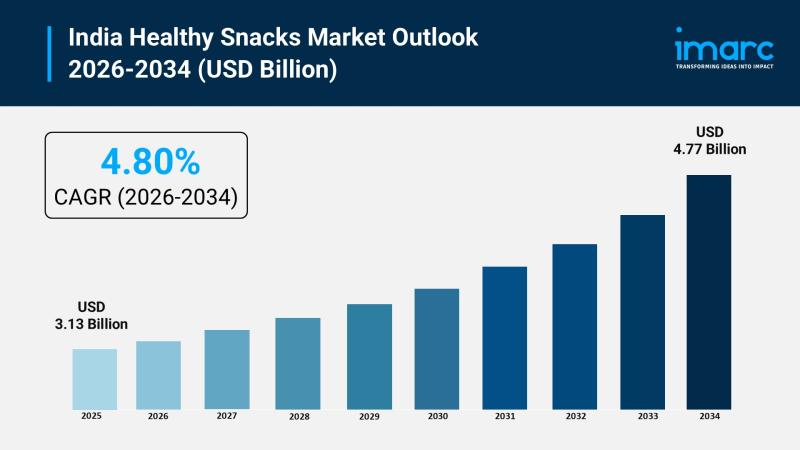

Healthy Snacks Market Size in India 2026-2034: Share, Trends, Industry Growth Dr …

Summary

The healthy snacks market size in india reached USD 3.13 Billion in 2025, according to the latest comprehensive industry analysis by IMARC Group. Driven by a dramatic shift toward preventive healthcare, rising disposable incomes, and the booming demand for clean-label, plant-based nutritional alternatives, the market is projected to reach USD 4.77 Billion by 2034. This represents a steady compound annual growth rate (CAGR) of 4.80% during the forecast period (2026-2034).

Download…

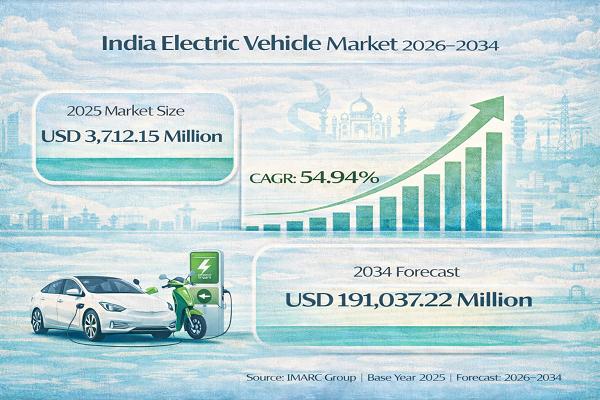

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

More Releases for Toothpaste

Toothpaste Manufacturing Plant Project Report 2025

Setting up a toothpaste manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Toothpaste Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a toothpaste manufacturing plant, covering…

Nobaton's Ampoule Toothpaste Sparks Worldwide Buzz

Image: https://www.globalnewslines.com/uploads/2025/05/8c3da6037aca9fbf469ae55c04ac7e84.jpgImage: https://www.globalnewslines.com/uploads/2025/05/7896c553fe2400daeaa3ca8506b253d7.jpg

Fremont, CA - Nobaton, a rising name in niche oral care, has introduced a category-defining innovation: the world's first ampoule-formulated toothpaste. Packaged in sealed, single-use capsules to preserve its active ingredients, the product has generated a wave of interest among both consumers and industry watchers. As demand grows, reports of long queues and fast sellouts have become increasingly common, turning this once-low-profile product into a global talking point.

Image:…

Toothpaste Tablets Market: A Comprehensive Overview

The global toothpaste tablets market was valued at approximately $68.60 million in 2023 and is projected to reach around $118.33 million by 2030, reflecting a compound annual growth rate (CAGR) of 8.2% from 2024 to 2030.

Toothpaste Tablets Market Overview

The toothpaste tablets market has been experiencing significant growth, driven by increasing environmental awareness and a shift towards sustainable oral care products. Consumers are seeking eco-friendly alternatives to traditional toothpaste,…

Toothpaste Market: Recent Discoveries and Innovations

The toothpaste market was valued at US$ 29,598.97 million in 2021 and is projected to reach US$ 40,766.21 million by 2028; it is expected to grow at a CAGR of 4.7% from 2021 to 2028. In terms of volume, the global demand for toothpaste is expected to reach over 19 billion units by 2028.

A toothpaste is derived from various components, the three main ones being abrasives, fluoride, and detergents. Toothpaste…

Zero Waste Toothpaste Tablets Market Growth Drivers, and Competitive Landscape | …

The Zero Waste Toothpaste Tablets Market Trends Overview 2024-2031:

A new Report by Worldwide Market Reports, titled "Zero Waste Toothpaste Tablets Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2031," offers a comprehensive analysis of the industry, which comprises insights on the Zero Waste Toothpaste Tablets market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures,…

Toothpaste Tablets Market to Witness Massive Growth by 2029 | Non Plastic Beach, …

The Latest research study released by HTF MI "Worldwide Toothpaste Tablets Market with 120+ pages of analysis on business Strategy taken up by key and emerging industry players and delivers know-how of the current market development, landscape, technologies, drivers, opportunities, market viewpoint, and status. Understanding the segments helps in identifying the importance of different factors that aid market growth. Some of the Major Companies covered in this Research are The…