Press release

Paper Plates Manufacturing Setup Report 2026: Plant Layout, Machinery, Raw Materials, and Financial Outlook

The global foodservice and catering industries are experiencing a transformative shift driven by rising environmental awareness, stringent restrictions on single-use plastics, and growing demand from quick-service restaurants and event management sectors. At the core of these developments lies a critical product category-paper plates. As consumers and businesses increasingly demand eco-friendly disposable tableware alternatives, establishing a paper plates manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and industrial investors seeking to capitalize on this rapidly expanding market driven by sustainability imperatives.IMARC Group's report, "Paper Plates Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The paper plates manufacturing plant setup cost report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for a Sample Report: https://www.imarcgroup.com/paper-plates-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global disposable tableware market demonstrates robust growth momentum driven by regulatory shifts away from plastic products and expanding foodservice operations. Paper-based plates are projected to dominate the disposable plates market, accounting for 48.5% of total consumption, reflecting strong market preference for biodegradable alternatives. This sustained expansion is driven by rising environmental awareness, growing restrictions on single-use plastics, increasing demand from foodservice outlets, and expanding use of disposable tableware in events, catering, and institutional dining facilities.

Paper plates are lightweight tableware products manufactured using paper pulp, kraft paper, or agricultural waste materials such as bagasse. Their biodegradable nature, cost-effective production process, and diverse application suitability make them the preferred choice for food services. Available in various forms, sizes, thicknesses, and coatings-including plain, laminated, compartmentalized, and grease-resistant variants-paper plates meet diverse requirements ranging from street food and takeaway meals to large-scale catering events. Their natural decay properties and recyclability position them as superior alternatives to plastic plates in regions enforcing strict sustainability regulations.

According to EU packaging waste data, in 2023, the EU produced approximately 79.7 million tons of packaging waste, with plastic representing 19.8%. Paper and cardboard together accounted for 40.4%, highlighting a clear shift toward fiber-based materials. This transition is accelerating adoption and market growth of paper plates in disposable foodservice applications, creating substantial long-term opportunities for manufacturing infrastructure investments.

Plant Capacity and Production Scale

The proposed paper plates manufacturing facility is designed with an annual production capacity ranging between 100-500 million pieces per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to serve diverse market segments-from foodservice and HoReCa operations to catering, institutional dining, and retail household consumption-ensuring steady demand and consistent revenue streams across multiple distribution channels.

Financial Viability and Profitability Analysis

The paper plates manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal attractive margins supported by high-volume repeat consumption patterns and stable market demand:

• Gross Profit Margins: 25-35%

• Net Profit Margins: 10-15%

These margins are supported by consistent demand across foodservice, catering, and institutional sectors, relatively simple manufacturing processes requiring limited skilled labor, and the critical nature of disposable tableware in hygiene-focused food service operations. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established industrial players looking to diversify into sustainable packaging products.

Buy Now: https://www.imarcgroup.com/checkout?id=19394&method=2175

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a paper plates manufacturing plant is characterized by high raw material intensity:

• Raw Materials: 70-80% of total OpEx

• Utilities: 10-15% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Paper rolls constitute the primary raw material input, representing the dominant cost component. The relatively low utilities proportion reflects the mechanically-intensive but energy-efficient nature of the forming and pressing operations. Establishing long-term contracts with reliable paper suppliers helps mitigate price volatility and ensures consistent material supply. The cost structure's high raw material dependency emphasizes the importance of supplier relationship management and strategic procurement practices for maintaining competitive pricing and operational profitability.

Capital Investment Requirements

Setting up a paper plates manufacturing plant requires capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to paper suppliers, target foodservice markets, and robust infrastructure including reliable transportation networks, utilities, and waste management systems. The site selection process must consider regulatory compliance requirements and adequate space for inventory management and future expansion.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for efficient production. Key machinery includes:

• Paper plate forming machines

• Hydraulic or pneumatic presses

• Drying systems

• Trimming units

• Packaging machines

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the manufacturing operation.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Paper plates find extensive applications across diverse commercial and institutional sectors, demonstrating their versatility and market importance:

Foodservice and HoReCa Sector: Paper plates support quick service operations by enabling hygienic food serving while reducing washing requirements and labor costs in restaurants, cafes, and fast-food establishments.

Catering and Event Management Industry: Disposable paper plates provide efficient solutions for food distribution, cost management, and simplified waste disposal at large-scale events including weddings, corporate functions, and social gatherings.

Institutional Dining Facilities: Schools, hospitals, colleges, and corporate canteens increasingly adopt paper plates for hygiene assurance and operational efficiency, eliminating washing infrastructure requirements and reducing water consumption.

Household and Retail Segment: Retail consumers choose paper plates for festivals, gatherings, and everyday use, valuing their affordability, convenience, and easy disposal characteristics.

End-use industries encompass foodservice operators, catering companies, institutional facilities, and retail distribution channels, all contributing to sustained high-volume consumption patterns.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=19394&flag=C

Why Invest in Paper Plates Manufacturing?

Several compelling factors make paper plates manufacturing an attractive investment opportunity:

Growing Shift Toward Eco-Friendly Products: Demand for environmentally friendly paper plates is accelerating due to regulatory bans on plastic disposables and rising consumer environmental consciousness. Government restrictions on single-use plastics create systematic market expansion for sustainable alternatives.

High Volume, Repeat Consumption: Paper plates are consumable products experiencing steady daily demand throughout foodservice, events, and institutional sectors. This consumption pattern ensures consistent sales volumes and predictable revenue streams.

Low Capital and Operating Complexity: The manufacturing process requires moderate investment compared to other industrial operations and involves relatively simple production workflows demanding limited skilled labor, reducing operational complexity and training requirements.

Scalable Business Model: Production capacity can be efficiently adjusted to match regional demand patterns or seasonal consumption fluctuations, providing operational flexibility for market-responsive capacity utilization.

Strong Institutional and Commercial Demand: Bulk purchases by caterers, restaurants, and institutional buyers guarantee consistent sales volumes and enable predictable production planning, reducing market uncertainty and supporting stable business operations.

Favorable Regulatory Environment: Increasing government restrictions on plastic tableware and supportive policies promoting biodegradable alternatives create a conducive regulatory framework for paper plates manufacturing investments.

Manufacturing Process Excellence

The paper plates manufacturing process involves several controlled stages ensuring product quality and operational efficiency:

• Preparation of Paper Pulp: Raw paper materials undergo preparation and quality verification to ensure feedstock consistency

• Sheet Forming or Blank Feeding: Paper sheets are cut to appropriate sizes or fed as pre-cut blanks into forming equipment

• Forming and Pressing of Plates: Paper blanks are shaped into plate configurations using hydraulic or pneumatic presses with precise molds

• Drying and Finishing: Formed plates undergo drying processes to remove moisture and achieve structural stability

• Quality Control: Finished plates are inspected for dimensional accuracy, structural integrity, and surface quality compliance

• Packaging: Inspected plates are stacked and packaged in protective materials for storage and distribution

Industry Leadership

The global paper plates industry is led by established manufacturers with extensive production capabilities and diverse market presence. Key industry players include:

• Vegware Ltd

• Genpak LLC

• Be Green Packaging LLC

• Duni Global

• Ckf Inc

These companies serve diverse end-use sectors including foodservice, catering, institutional, and retail segments, demonstrating the broad market applicability of paper plates manufacturing.

Recent Industry Developments

October 2025: KDP Impex unveiled a new line of stylish and sustainable paper plates and disposable tableware in Ghaziabad, India. The company announced that this new product line transitioned to 100% eco-friendly paper materials, marking a significant advancement in its product portfolio toward environmentally responsible disposable plates.

November 2025: Creationeers introduced the Perfect Plate, a next-generation solution for paper plates targeting the transformation of the disposable tableware industry. The product combines practicality, strong visual appeal, and eco-friendly design, aligning with evolving consumer preferences for sustainable, attractive, and functional paper plates across everyday dining and social occasions.

Browse Related Reports:

• Binding Wire Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/binding-wire-manufacturing-plant-project-report-2025-layout-machinery-raw-materials-and-financial-outlook

• Azodicarbonamide Production Plant Cost: https://industrytoday.co.uk/chemicals/azodicarbonamide-production-plant-cost-report-2025-capexopex-analysis-with-profitability-forecasts

• Veneer Production Plant Cost: https://industrytoday.co.uk/chemicals/veneer-production-plant-cost-report-2025-unit-setup-economics-and-financial-outlook

• Copper Sulphate Production Plant Cost: https://industrytoday.co.uk/chemicals/copper-sulphate-production-cost-report-2025-feasibility-study-plant-setup-and-profitability-insights

Conclusion

The paper plates manufacturing sector presents a strategically positioned investment opportunity at the intersection of environmental sustainability, regulatory transformation, and evolving consumer preferences. With strong regulatory support through plastic ban initiatives, accelerating demand across foodservice and institutional sectors, and favorable market dynamics driven by the global shift toward biodegradable alternatives, establishing a paper plates manufacturing plant offers significant potential for long-term business success and sustainable returns. The combination of moderate entry barriers, proven manufacturing technology, high-volume repeat consumption patterns, and expanding market opportunities across multiple distribution channels creates an attractive value proposition for serious industrial investors committed to sustainable product manufacturing and operational excellence in the rapidly growing eco-friendly packaging economy.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Paper Plates Manufacturing Setup Report 2026: Plant Layout, Machinery, Raw Materials, and Financial Outlook here

News-ID: 4366756 • Views: …

More Releases from IMARC Group

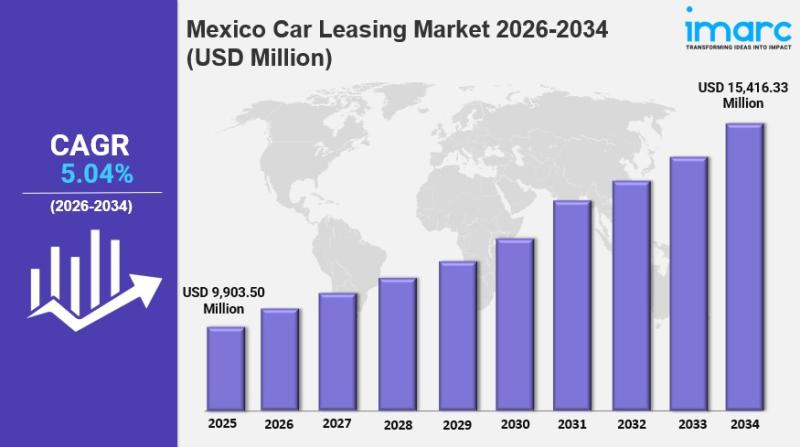

Mexico Car Leasing Market 2026 : Industry Size to Reach USD 15,416.33 Million by …

IMARC Group has recently released a new research study titled "Mexico Car Leasing Market Size, Share, Trends and Forecast by Type, Lease Type, Service Provider Type, Tenure, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico car leasing market size was valued at USD 9,903.50 Million in 2025 and is projected…

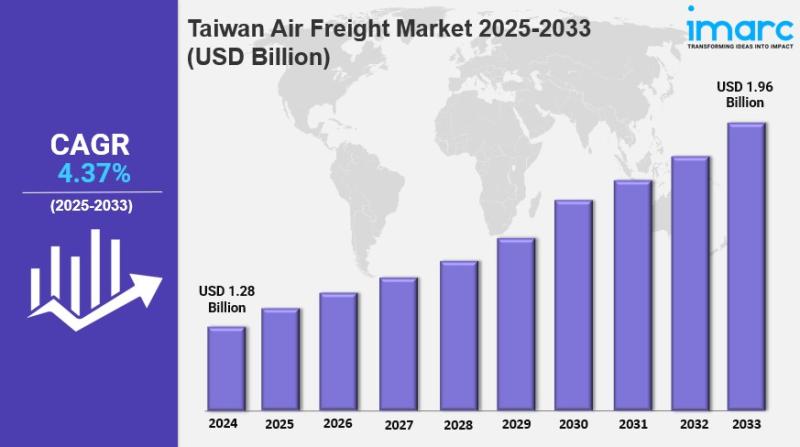

Taiwan Air Freight Market Size, Share, Industry Trends, Growth and Forecast to 2 …

IMARC Group has recently released a new research study titled "Taiwan Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End-User, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Taiwan air freight market size reached USD 1.28 Billion in 2024 and is projected to reach USD 1.96 Billion by…

Aluminum Foil Manufacturing Plant Cost Report 2026: CapEx/OpEx Analysis with Pro …

The global aluminum foil manufacturing industry is experiencing transformative growth driven by rising demand from food packaging and pharmaceutical sectors, growth in ready-to-eat and convenience foods, increasing use in insulation and construction applications, and expanding adoption in household and industrial packaging solutions. At the heart of this expansion lies a versatile, critical material-aluminum foil. As industries demand more reliable, protective, and high-performance packaging solutions, establishing an aluminum foil manufacturing plant…

MDF Board Manufacturing Plant Project Report 2026: Cost Structure, Production Pr …

The global construction and furniture manufacturing industries are experiencing a transformative shift driven by rapid urbanization, expansion of commercial real estate, and increasing demand for engineered wood products. At the core of these developments lies a critical building material-medium-density fiberboard (MDF). As industries demand more versatile, cost-effective, and eco-friendly wood alternatives, establishing an MDF board manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and industrial investors seeking to…

More Releases for Paper

Newsprint Paper Market | Alberta Newsprint, BO Paper Group, Daio Paper, Emami Pa …

Introduction:

The introduction to the report serves as a gateway into the comprehensive world of the newsprint paper market. As industries continue to evolve and adapt to changing consumer demands and technological advancements, understanding the market dynamics becomes paramount for industry stakeholders. The report takes on the responsibility of offering a profound and all-encompassing analysis of the newsprint paper market, catering to the needs of a diverse audience that includes manufacturers,…

Paraffin Paper Market to Witness Massive Growth by 2027 | Patty Paper, Dunn Pape …

A new research document released by HTF MI with title "Global Paraffin Paper Market SWOT analysis by Size, Status and Forecast 2022 to 2027" provides a complete assessment of Paraffin Paper Market. The study focuses on changing market dynamics, geopolitical and regulatory policies, key players Strategies to better analyse demand at risk across various product type. Some of the major and emerging players analysed in the study are Dunn Paper,…

Pulp and Paper Market Key Player Analysis By sappi, Lee & Man Paper, Nippon Pape …

Global Pulp and Paper Market Research Report 2018–2025 is a historical overview and in-depth study on the current & future market of the Pulp and Paper Industry. The report represents a basic overview of the market status, competitor segment with a basic introduction of key vendors, top regions, product types and end industries. This report gives a historical overview of the market trends, growth, revenue, capacity, cost structure, and…

Global Waste Paper Recycling Market Forecast 2019-2026 Miami Waste Paper, Dixie …

Market study on Global Waste Paper Recycling 2019 Research Report presents a professional and complete analysis of Global Waste Paper Recycling Market on the current market situation.

Report provides a general overview of the Waste Paper Recycling industry 2019 including definitions, classifications, Waste Paper Recycling market analysis, a wide range of applications and Waste Paper Recycling industry chain structure. The 2019's report on Waste Paper Recycling industry offers the global…

Book Paper Market Report 2018 Companies included Stora Enso, Oji Paper, Nippon P …

We have recently published this report and it is available for immediate purchase. For inquiry Email us on: jasonsmith@marketreportscompany.com *********

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025, etc. The report also provides…

Global Pulp and Paper Market 2018 Key Players: sappi, Lee & Man Paper, Nippon Pa …

Pulp and Paper Market:

WiseGuyReports.com adds “Pulp and Paper Market 2018 Global Analysis, Growth, Trends and Opportunities Research Report Forecasting 2025” reports tits database.

Executive Summary

Global Pulp and Paper Market valued approximately USD XX billion in 2017 is anticipated to grow with a healthy growth rate of more than XXX% over the forecast period 2017-2025. Pulp and paper producers produces and sells cellulose-based products, derived from wood. Packaging paper, graphic paper and…