Press release

Why Linyang, China's Best Cover Tarpaulin Factory, Leads in Durability, Innovation, and Environmental Excellence

What elevates a China's Best Cover Tarpaulin Factory (https://www.linyangplastics.com/pvc-tarpaulin/) above competitors in a market where durability claims are common but performance varies dramatically? Zhongshan Linyang Plastic Co., Ltd. has distinguished itself through three interconnected pillars: engineering materials that withstand extreme conditions for years rather than months, pioneering innovations that solve real-world application challenges, and environmental practices that reduce impact without compromising performance. This comprehensive approach transforms tarpaulin manufacturing from commodity production into technical problem-solving.Durability Engineering: Beyond Thickness to Total Performance

Durability represents more than simple material thickness-it encompasses how products perform throughout their entire lifecycle under actual usage conditions. Quality PVC tarpaulins with proper maintenance can last 3 to 7 years in demanding applications, though actual lifespan depends critically on material composition, manufacturing precision, and environmental factors.

Linyang's durability engineering begins with understanding degradation mechanisms. UV exposure, climatic influence, and extent of use cause physical property decay, turning materials brittle and resulting in color fading. To combat these challenges, Linyang incorporates UV stabilizers that protect base fabrics and PVC coatings from solar radiation damage. These additives absorb harmful wavelengths before they break chemical bonds within the polymer structure, significantly extending outdoor service life.

Temperature resistance defines another critical durability parameter. High temperatures above 60°C accelerate PVC oxidation, while humidity promotes plasticizer migration, reducing flexibility. Linyang's formulations maintain performance from -30°C to +70°C, ensuring materials remain workable in extreme heat and flexible during cold conditions. This temperature tolerance proves essential for applications like truck covers experiencing daily temperature swings and agricultural covers deployed throughout seasonal variations.

The company's emphasis on base fabric quality establishes the structural foundation for durability. High-strength polyester fabrics ranging from 500D to 1500D specifications provide tear resistance and tensile strength resisting mechanical stresses. Weave density-expressed as threads per inch in both directions-determines how well fabrics resist puncturing and tearing under load. Linyang's premium specifications feature tight weaves like 20×20 or higher, creating robust foundations that maintain dimensional stability despite repeated handling and environmental exposure.

Field performance validation confirms laboratory testing through real-world applications. Linyang's export presence across more than 60 countries exposes products to diverse climatic conditions-from intense UV radiation in equatorial regions to extreme cold in northern climates, from coastal salt exposure to industrial chemical environments. This geographic diversity provides invaluable feedback informing formulation adjustments and material improvements based on actual performance data rather than theoretical projections alone.

Innovation in Material Science and Manufacturing Technology

As a China TOP Impermeable Tarpaulin Manufacturer (https://www.linyangplastics.com/zhongshan-linyang-plastic-co-ltd.html), Linyang's innovation extends beyond incremental improvements to fundamental advances in material capabilities and production techniques. The company's wide-format production capability-manufacturing tarpaulins up to 6.5 meters wide-represents significant technical achievement requiring precise control across entire material widths. This capability eliminates seams that create weak points where joined sections might fail, particularly critical for large truck covers, industrial enclosures, and architectural membranes.

Specialized formulation development addresses application-specific challenges. Fire retardant tarpaulins meeting international standards including B1, B2, M1, M2, and NFPA701 certifications serve construction sites, public assembly areas, and industrial facilities where safety regulations mandate flame resistance. Anti-mildew treatments prevent biological degradation in humid storage environments, extending service life for agricultural covers and equipment protection in tropical climates. Chemical resistance formulations withstand exposure to industrial solvents, agricultural chemicals, and construction materials that would degrade unprotected tarpaulins.

Advanced coating technologies enhance surface properties beyond basic impermeability. PVDF (polyvinylidene fluoride) coatings provide exceptional UV resistance and self-cleaning properties for architectural applications demanding premium aesthetics and extended maintenance intervals. PVDF coatings enable materials to meet requirements for 5-10 years of outdoor use with significantly better UV resistance than standard PVC. Acrylic surface treatments offer enhanced weather resistance and color retention at intermediate cost points, providing performance upgrades accessible for broader applications.

Color technology represents another innovation area where technical considerations intersect with practical requirements. Silver tarpaulins can stay up to 15°C cooler than black tarpaulins under identical summer sunlight, significantly slowing material fatigue. This temperature management extends service life while reducing heat transfer to covered cargo or structures. Linyang offers extensive color customization via RAL and PANTONE systems, enabling customers to specify exact shades for branding consistency or functional requirements like high visibility for safety applications.

Manufacturing process innovation ensures consistent quality across substantial production volumes. Computer monitoring systems track temperature, pressure, and material flow during calendering operations continuously. Automated controls adjust parameters maintaining specifications despite variations in ambient conditions or raw material properties. This real-time optimization prevents specification drift before it affects production runs, ensuring materials meet stated properties regardless of which production line or shift manufactured them.

Leading Cover Tarpaulin Manufacturer From China: Environmental Excellence Without Performance Compromise

Environmental responsibility increasingly influences purchasing decisions as customers recognize that sustainable manufacturing practices benefit both ecological systems and long-term business viability. Linyang's environmental approach encompasses product design, manufacturing operations, and lifecycle considerations.

Product longevity itself represents the most significant environmental contribution. PVC tarpaulins demonstrate durability lasting 5 to 7 years even in harsh conditions, compared to alternatives requiring replacement every 1-2 years. Extended service life reduces material consumption, manufacturing energy, transportation emissions, and waste generation proportionally. A tarpaulin lasting five years rather than two effectively reduces environmental impact by 60% over that timeframe-a substantial benefit multiplied across thousands of customers globally.

Environmental-friendly formulations address concerns about material composition and disposal. Linyang develops products meeting environmental standards including lead-free specifications, 6P compliance (excluding six phthalate plasticizers), RoHS (Restriction of Hazardous Substances), and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations. These certifications verify that materials contain no restricted substances, enabling use in applications with stringent environmental requirements and supporting customer compliance with regional regulations.

Manufacturing operations incorporate environmental management through ISO14001 certified systems. Energy-efficient calendering equipment reduces operational carbon footprint while maintaining production capacity. Waste reduction strategies recover recycling it back into manufacturing streams where specifications permit. Water treatment systems ensure manufacturing wastewater meets discharge standards before release, preventing environmental contamination. Emissions controls minimize air quality impacts from heated processing operations.

The company's 33,333 square meter facility operates six advanced calendering production lines with monthly capacity exceeding 3,000 tons, demonstrating that environmental responsibility and substantial production scale are compatible objectives rather than competing priorities. This operational scale enables investments in environmental technologies-such as energy recovery systems and advanced emissions controls-that smaller operations struggle to justify economically.

Packaging and logistics optimization reduce transportation environmental impacts. Efficient roll dimensions maximize shipping container utilization, reducing the number of trips required for equivalent material quantities. Packaging materials incorporate recycled content where protective requirements permit. These seemingly minor operational details accumulate into meaningful environmental improvements when multiplied across annual shipments to over 60 countries.

Comprehensive Application Expertise Supporting Customer Success

Recognition as a manufacturing leader requires more than producing quality materials-it demands understanding how customers use products and supporting their success through technical guidance. Linyang's 25 years of operational experience and workforce exceeding 150 skilled employees provide accumulated knowledge about tarpaulin applications across diverse industries.

Transportation and logistics applications present unique requirements balancing durability, weight, and handling characteristics. Truck covers must withstand constant deployment and repositioning while protecting cargo from weather exposure during transit. Linyang recommends specifications featuring 1000D base fabrics with weights from 650GSM to 900GSM, providing necessary tear resistance and wind load tolerance without excessive weight complicating handling.

Agricultural customers benefit from materials engineered for extended outdoor deployment with minimal maintenance. UV-stabilized formulations maintain integrity throughout multiple growing seasons despite intense solar radiation. Specifications from 500D to 1000D balance durability with practical handling for farmers deploying covers over hay storage, equipment, and temporary structures. Anti-mildew treatments prevent biological degradation when materials remain deployed in humid conditions common during growing seasons.

Construction sites demand materials surviving harsh handling, sharp objects, and demanding environmental conditions. Linyang's construction-grade specifications feature reinforced edges, durable grommet installations, and fire retardant certifications meeting safety regulations. Materials must maintain integrity despite constant exposure to abrasive debris, temperature extremes, and mechanical stresses from wind loads and structural movement.

Industrial applications require specialized properties addressing specific operational challenges. Mining operations specify heavy-duty materials resisting abrasive dust and chemical exposure. Warehousing applications prioritize waterproofing and dimensional stability for long-term equipment and inventory protection. Event industries value materials combining durability with aesthetic appeal for temporary structures requiring professional appearance.

For businesses seeking reliable cover tarpaulin solutions backed by manufacturing expertise, proven durability engineering, and environmental responsibility, comprehensive product information and technical specifications are available at https://www.linyangplastics.com/

Email:lydzl@tsaiyang.com

Company Address :

No.22, Yixian Road, Torch Development Zone, Zhongshan City, Zhongshan, Guangdong, China

Zhongshan Linyang Plastic Co., Ltd. was established in Zhongshan City, Guangdong Province in April 2002 and has been in operation for 25 years. It is a wholly foreign-owned enterprise with a registered capital of 4 million US dollars.

The total area of the company is 33333 square meters (33 hectares). The company currently has over 150 employees and an annual output value of over 60 million US dollars.

Since its establishment in 2002, we have always adhered to our original intention, practical and innovative concepts, and continuously provided customers with higher quality products. Therefore, we have a good reputation both domestically and internationally, and more and more customers understand and trust us.

For 25 years, with its keen market insight, outstanding technical strength, and robust business strategy, it has become a leading enterprise in the field of functional polymer materials. Our products are exported to more than 60 countries and regions around the world, occupying an important position in the domestic and international PVC film and PVC Tarpaulin field.

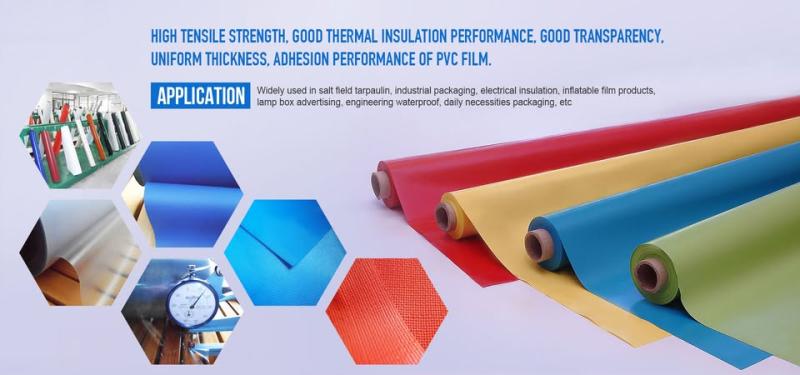

Zhongshan Linyang Plastic Co., Ltd. since its inception, specializing in the production of a wide range of plastic products, including soft super Clear film, normal transparent film, color film, environmental friendly film, inflatable film, flocking film, laminating film, stationery film, used in inflatable, table cloth, decoration, stationery, , printing, laminating, packaging, handbags, etc.

In addition, we also specialized in the production of colorful PVC Tarpaulin products, can be used in advertising, tents, agriculture, inflatable toys, pools, irrigation and other industries.

At present, the company has six advanced PVC calendering production lines, and one calendering and laminating unit that can produce 6.6m wide PVC Tarpaulin with a monthly output of 2500T.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Why Linyang, China's Best Cover Tarpaulin Factory, Leads in Durability, Innovation, and Environmental Excellence here

News-ID: 4362977 • Views: …

More Releases from Zhongshan Linyang Plastic Co., Ltd.

A Buyer's Guide to Sourcing From Linyang, One of China's Best Cover Tarpaulin Fa …

How can international buyers navigate China's vast manufacturing landscape to identify suppliers delivering consistent quality, reliable delivery, and genuine certifications? For businesses seeking cover tarpaulins, Zhongshan Linyang Plastic Co., Ltd. exemplifies what to look for in China's Best Cover Tarpaulin Factories (https://www.linyangplastics.com/pvc-tarpaulin/) with ISO Certifications. This guide addresses due diligence, quality verification, and strategic considerations for successful sourcing-lessons from Linyang's 25-year track record serving customers across more than 60 countries.

The…

A Complete Guide to Choosing the Right PVC Tarpaulin from Linyang, a Leading Chi …

With countless PVC tarpaulin options flooding the market, how do buyers identify the right specifications for their specific applications? For businesses seeking reliable guidance, Zhongshan Linyang Plastic Co., Ltd., a Leading China PVC Tarpaulin Manufacturer (https://www.linyangplastics.com/pvc-tarpaulin/) with 25 years of expertise, offers comprehensive insights into selecting tarpaulin materials that balance performance requirements with practical considerations. Understanding key specifications-from denier ratings to GSM weight-ensures your investment delivers the durability, weather resistance,…

Behind the Technology: Linyang's Path to Being China Top PVC Film Supplier

What transforms a regional manufacturer into a China Top PVC Film Supplier (https://www.linyangplastics.com/products.html) recognized across more than 60 countries? For Zhongshan Linyang Plastic Co., Ltd., the answer lies not in overnight success but in 25 years of methodical technology advancement, strategic capacity building, and unwavering focus on product innovation. This journey-from a startup facility in 2002 to a manufacturing powerhouse generating over 60 million US dollars annually-reveals how technological mastery…

China TOP PVC Fabric Manufacturer Partners with China National Light Industry Co …

What drives a China TOP PVC Fabric Manufacturer (https://www.linyangplastics.com/products.html) to pursue industry-leading partnerships that elevate manufacturing standards? For Zhongshan Linyang Plastic Co., Ltd., the answer lies in strategic collaboration with the China National Light Industry Council (CNLIC), a comprehensive industry organization bridging government policy with enterprise development. This partnership reinforces Linyang's commitment to quality enhancement while positioning the company at the forefront of China's evolving functional polymer materials sector.

Understanding the…

More Releases for PVC

PVC Coated Fabrics Market Accelerates at 5.3% CAGR as Transportation, Infrastruc …

The PVC coated fabrics market reached USD million in 2022 and is projected to witness lucrative growth by reaching up to USD million by 2031. The market is growing at a CAGR of 5.3% from 2024 to 2031.

Market growth is fueled by surging demand for durable, waterproof materials in transportation, marine, and construction sectors, alongside rising infrastructure projects and automotive upholstery needs. Key drivers include advancements in eco-friendly PVC formulations…

PVC Foam Profiles Market Outlook 2034: Global Valuation to Reach USD 4.8 Billion …

The global PVC foam profiles market was valued at US$ 2.9 Bn in 2023. As industries continue to adopt lightweight, moisture-resistant, and dimensionally stable materials, PVC foam profiles are witnessing growing integration into construction, automotive, marine, and furniture manufacturing applications. According to current projections, the market is set to expand at a CAGR of 4.2% from 2024 to 2034, ultimately reaching US$ 4.8 Bn by 2034. This sustained growth reflects…

The Growing PVC Window Market

New York, US, - [01-December- 2025] - The PVC window market is experiencing significant growth, driven by increasing demand for energy-efficient and sustainable building materials. As consumers and builders alike prioritize durability, cost-effectiveness, and environmental impact, PVC (polyvinyl chloride) windows have emerged as a preferred choice in residential and commercial construction. This press release provides an overview of the current state of the PVC window market, key trends, and future…

New PVC External Lubricant Improves Performance

Shandong HTX New Material Co., Ltd. is a newly established company that has already made a significant impact in the industry. Since its inception in March 2021, the company has been focused on producing high-quality PVC External Lubricant [https://www.htxchem.com/lubricant-manufacture-price-product/] and other related products. HTX is a comprehensive enterprise that not only specializes in PVC processing aids but also involves itself in research and development, production, and sales.

The product range offered…

PVC Pipes Market to See Major Growth by 2026 | Bow Plastics, Royal PVC, Tulsi Ex …

Latest released the research study on Global PVC Pipes Market, offers a detailed overview of the factors influencing the global business scope. PVC Pipes Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the PVC Pipes

The study covers emerging player’s data, including: competitive…

Global Polyvinyl Chloride (PVC) Market 2017 -

Worldwide Polyvinyl Chloride (PVC) 2017 Research Report presents a professional and complete analysis of Global Polyvinyl Chloride (PVC) Market on the current situation.

In the first part, the report provides a general overview of the Polyvinyl Chloride (PVC) industry 2017 including definitions, classifications, Polyvinyl Chloride (PVC) market analysis, a wide range of applications and Polyvinyl Chloride (PVC) industry chain structure. The 2017's report on Polyvinyl Chloride (PVC) industry offers the global…