Press release

A Complete Guide to Choosing the Right PVC Tarpaulin from Linyang, a Leading China Manufacturer

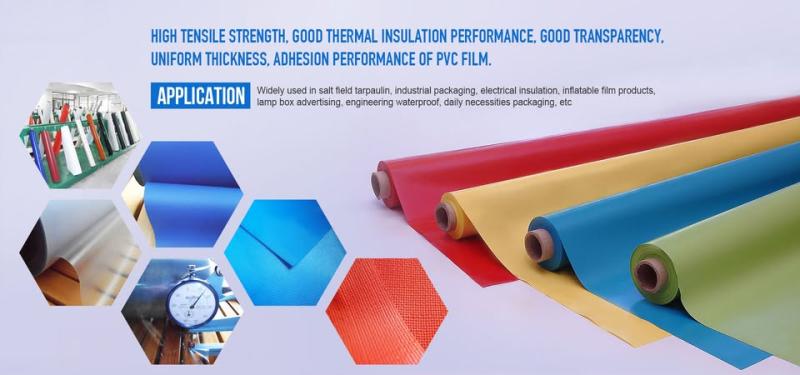

With countless PVC tarpaulin options flooding the market, how do buyers identify the right specifications for their specific applications? For businesses seeking reliable guidance, Zhongshan Linyang Plastic Co., Ltd., a Leading China PVC Tarpaulin Manufacturer (https://www.linyangplastics.com/pvc-tarpaulin/) with 25 years of expertise, offers comprehensive insights into selecting tarpaulin materials that balance performance requirements with practical considerations. Understanding key specifications-from denier ratings to GSM weight-ensures your investment delivers the durability, weather resistance, and longevity your application demands.Understanding PVC Tarpaulin Specifications: The Technical Foundation

PVC tarpaulin selection begins with comprehending fundamental specifications that determine material performance. Three primary measurements define tarpaulin characteristics: denier (D), weave density, and weight measured in grams per square meter (GSM). These specifications work together to determine strength, durability, and suitability for specific applications.

Denier refers to the thickness and weight of yarns used in the base fabric-specifically, 9,000 meters of yarn weighing 500 grams equals 500D. Higher denier numbers indicate thicker, stronger yarns capable of greater tensile strength and tear resistance. Common denier specifications range from 500D for lighter applications to 1500D for demanding industrial uses.

Weave density, expressed as threads per inch in both directions (e.g., 20×20, 18×18), indicates how tightly polyester yarns are woven together. Premium weave densities like 30×30 or 32×30 provide superior strength compared to standard 18×18 or 20×20 weaves. Tighter weaves offer better tear resistance and dimensional stability, particularly important for applications involving mechanical stress or wind loads.

GSM weight measurement encompasses both the base fabric and PVC coating layers. PVC tarpaulins can range from 400GSM for light-duty covers to over 2600 GSM for ultra-heavy-duty industrial applications. However, weight alone doesn't guarantee quality-the distribution between base fabric strength and coating thickness significantly impacts performance.

Application-Specific Selection: Matching Specifications to Usage Scenarios

Transportation and Logistics Coverage

For transportation applications like truck covers hauling construction materials, gravel, steel beams, or heavy machinery, thicker PVC tarpaulin with greater denier count provides necessary abrasion resistance and impact tolerance. As a Global Leading Pvc Tarpaulin Supplier (https://www.linyangplastics.com/zhongshan-linyang-plastic-co-ltd.html), Linyang recommends 1000D×1000D base fabrics with 20×20 weave density and weights ranging from 650GSM to 900GSM for curtain-side trucks and flatbed cargo protection.

These specifications ensure tarpaulins withstand constant handling, strap friction, and exposure to rough cargo surfaces without premature tearing or puncturing. Reinforced edges and grommets-features Linyang incorporates into its transportation-grade tarpaulins-provide secure fastening points that maintain integrity despite wind loads during highway transit.

Agriculture and Outdoor Equipment Protection

Agricultural applications require balancing durability with practical handling considerations. For hay storage, equipment covers, and temporary grain storage, 500D to 1000D specifications with weights between 450GSM and 650GSM provide adequate weather protection while remaining manageable for frequent deployment and repositioning.

UV stabilization becomes critical for agricultural tarpaulins experiencing extended outdoor exposure. PVC tarpaulin with added UV stabilizers demonstrates better color fastness and extended outdoor lifespan. Linyang's agricultural-grade tarpaulins incorporate UV inhibitors that maintain material integrity for multiple growing seasons, even under intense solar radiation common in agricultural regions worldwide.

Construction Site and Industrial Applications

Construction environments demand materials resisting tearing, puncturing, and abrasion when exposed to scaffolding, debris, and harsh handling conditions. China Best Cover Tarpaulin Factory specifications for construction typically feature 1000D base fabrics with 18×18 to 20×20 weave densities and weights from 610GSM to 900GSM.

Fire retardancy requirements vary by region and application. Linyang offers flame-retardant formulations meeting international standards including B1, B2, M1, M2, and NFPA701, ensuring compliance with construction site safety regulations. Chemical resistance properties protect materials from exposure to concrete, solvents, and other construction substances that might degrade unprotected tarpaulins.

Tent Structures and Temporary Shelters

For tent applications, specifications balance durability requirements with portability considerations-500D to 1000D base fabrics with weights from 550GSM to 850GSM provide adequate structural integrity while maintaining reasonable weight for transport and setup. Blackout properties in heavier weights (750GSM and above) offer light blocking for specialized tent applications.

Membrane structures requiring larger spans demand higher specifications. Architectural membranes and large tents utilize 1500D base fabrics with Panama weave (32×30 or 30×30 density) and weights ranging from 750GSM to 1250GSM to withstand structural loads and environmental stresses.

China TOP Impermeable Tarpaulin Manufacturer: Linyang's Technical Advantages

Wide-Format Production Capabilities

Linyang's specialized calendering and laminating unit produces tarpaulins up to 6.5 meters wide-a dimension critical for applications requiring seamless coverage. Wide-format production eliminates weak seams where joined sections might fail, particularly important for large truck covers, agricultural greenhouses, and industrial enclosures. This technical capability positions Linyang among few manufacturers capable of delivering true wide-format materials without compromise.

Customization Options Supporting Diverse Requirements

Understanding that applications vary dramatically, Linyang offers extensive customization including width specifications from 1.6 meters to 6.6 meters, weight ranges from 400 GSM to 1700GSM, base fabric options (500D, 840D, 1000D, 1500D), color selection via RAL and PANTONE systems, flame retardant certifications, environmental compliance (3P, 6P, REACH, heavy metal-free), and surface treatments like PVDF or acrylic coatings.

This customization flexibility ensures customers receive materials precisely matching their specifications rather than compromising with standard options inadequate for particular applications. For projects with unique requirements-specialized colors for branding, specific flame ratings for safety compliance, or enhanced UV protection for extreme climates-Linyang's technical team works directly with customers to develop appropriate formulations.

Quality Control Throughout Manufacturing

Operating six advanced PVC calendering production lines from its 33,333 square meter facility in Zhongshan City, Guangdong Province, Linyang maintains strict quality protocols ensuring consistency across production runs. Computer monitoring systems track temperature, pressure, and material flow continuously during calendering, automatically adjusting parameters to maintain specifications.

Each production batch undergoes testing for thickness uniformity, tensile strength, tear resistance, dimensional stability, and coating adhesion. This systematic approach ensures materials consistently meet stated specifications-reliability particularly important for customers ordering large quantities for major projects where material inconsistency would create significant complications.

Key Selection Criteria: Making Informed Purchasing Decisions

Evaluate Total Cost of Ownership

While initial price per square meter influences purchasing decisions, total cost of ownership provides more accurate value assessment. High-quality tarps may cost more upfront but save significantly through fewer replacements and reduced failure-related losses. A tarpaulin lasting five years versus two effectively reduces material consumption by 60%-a compelling economic advantage beyond purchase price alone.

Calculate replacement frequency based on material specifications and application demands. For commercial operations where tarpaulin failure causes cargo damage, project delays, or safety incidents, premium materials with proven durability justify higher initial investment through reduced risk and operational continuity.

Consider Environmental Conditions

Environmental factors including UV intensity, saltwater exposure, temperature swings, and mechanical loads like frequent folding, wind flapping, and abrasion significantly impact material longevity. Applications in coastal environments require enhanced corrosion resistance for grommets and reinforcements. Desert climates demand maximum UV stabilization. Cold climate operations need materials maintaining flexibility at low temperatures.

Linyang's export experience spanning over 60 countries provides practical knowledge about which specifications perform optimally in diverse environments. This field-tested expertise helps customers select materials appropriate for their specific operational conditions rather than generic recommendations potentially inadequate for particular challenges.

Verify Manufacturer Credentials and Track Record

Selecting reputable manufacturers with established quality systems reduces risk of receiving substandard materials. Linyang's 25-year operational history, ISO9001 and ISO14001 certifications, and annual output exceeding 60 million US dollars demonstrate manufacturing stability and quality commitment. Long-term suppliers provide consistent product quality, technical support, and reliable delivery schedules-attributes essential for businesses depending on predictable material supply.

Request material samples for evaluation before large orders. Physical inspection allows assessment of coating quality, material flexibility, edge reinforcement, and overall construction quality that specifications alone cannot fully convey. Sample evaluation also enables application testing under actual usage conditions, verifying theoretical specifications translate into practical performance.

Beyond Specifications: Value-Added Considerations

Technical Support and Application Guidance

Experienced manufacturers like Linyang provide application guidance helping customers optimize material selection. This technical support addresses questions about appropriate specifications for specific uses, installation best practices, maintenance recommendations, and troubleshooting for performance issues. Access to knowledgeable technical resources prevents costly specification mistakes and supports successful material deployment.

Environmental Responsibility and Sustainability

Modern procurement increasingly considers environmental factors alongside technical performance. Linyang's environmental-friendly formulations, production waste reduction strategies, and energy-efficient manufacturing demonstrate commitment to sustainability valued by environmentally conscious buyers. Materials incorporating recycled content where specifications permit, combined with extended service life reducing replacement frequency, align with circular economy principles increasingly important in global supply chains.

Comprehensive Product Range

Suppliers offering diverse product portfolios enable customers to source multiple material types from single vendors, simplifying procurement and ensuring consistency across related applications. Beyond PVC tarpaulin, Linyang produces transparent films, embossed films, inflatable films, and other functional polymer materials, providing comprehensive solutions for businesses requiring varied plastic products.

For businesses seeking reliable PVC tarpaulin solutions backed by manufacturing expertise and proven international performance, detailed technical specifications and product information are available at https://www.linyangplastics.com/

Selecting the right PVC tarpaulin requires understanding how technical specifications-denier, weave density, and GSM weight-translate into real-world performance across diverse applications. By matching specifications to usage scenarios, evaluating total cost of ownership, considering environmental conditions, and partnering with reputable manufacturers like Zhongshan Linyang Plastic Co., Ltd., businesses ensure their tarpaulin investments deliver the durability, reliability, and longevity their operations demand. With 25 years of manufacturing experience, comprehensive customization capabilities, and proven quality systems, Linyang provides the technical expertise and product range supporting informed selection decisions that balance performance requirements with practical considerations.

Company Address :

No.22, Yixian Road, Torch Development Zone, Zhongshan City, Zhongshan, Guangdong, China

lydzl@tsaiyang.com

Zhongshan Linyang Plastic Co., Ltd. was established in Zhongshan City, Guangdong Province in April 2002 and has been in operation for 25 years. It is a wholly foreign-owned enterprise with a registered capital of 4 million US dollars.

The total area of the company is 33333 square meters (33 hectares). The company currently has over 150 employees and an annual output value of over 60 million US dollars.

Since its establishment in 2002, we have always adhered to our original intention, practical and innovative concepts, and continuously provided customers with higher quality products. Therefore, we have a good reputation both domestically and internationally, and more and more customers understand and trust us.

For 25 years, with its keen market insight, outstanding technical strength, and robust business strategy, it has become a leading enterprise in the field of functional polymer materials. Our products are exported to more than 60 countries and regions around the world, occupying an important position in the domestic and international PVC film and PVC Tarpaulin field.

Zhongshan Linyang Plastic Co., Ltd. since its inception, specializing in the production of a wide range of plastic products, including soft super Clear film, normal transparent film, color film, environmental friendly film, inflatable film, flocking film, laminating film, stationery film, used in inflatable, table cloth, decoration, stationery, , printing, laminating, packaging, handbags, etc.

In addition, we also specialized in the production of colorful PVC Tarpaulin products, can be used in advertising, tents, agriculture, inflatable toys, pools, irrigation and other industries.

At present, the company has six advanced PVC calendering production lines, and one calendering and laminating unit that can produce 6.6m wide PVC Tarpaulin with a monthly output of 2500T.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release A Complete Guide to Choosing the Right PVC Tarpaulin from Linyang, a Leading China Manufacturer here

News-ID: 4361432 • Views: …

More Releases from Zhongshan Linyang Plastic Co., Ltd.

Why Linyang, China's Best Cover Tarpaulin Factory, Leads in Durability, Innovati …

What elevates a China's Best Cover Tarpaulin Factory (https://www.linyangplastics.com/pvc-tarpaulin/) above competitors in a market where durability claims are common but performance varies dramatically? Zhongshan Linyang Plastic Co., Ltd. has distinguished itself through three interconnected pillars: engineering materials that withstand extreme conditions for years rather than months, pioneering innovations that solve real-world application challenges, and environmental practices that reduce impact without compromising performance. This comprehensive approach transforms tarpaulin manufacturing from commodity…

A Buyer's Guide to Sourcing From Linyang, One of China's Best Cover Tarpaulin Fa …

How can international buyers navigate China's vast manufacturing landscape to identify suppliers delivering consistent quality, reliable delivery, and genuine certifications? For businesses seeking cover tarpaulins, Zhongshan Linyang Plastic Co., Ltd. exemplifies what to look for in China's Best Cover Tarpaulin Factories (https://www.linyangplastics.com/pvc-tarpaulin/) with ISO Certifications. This guide addresses due diligence, quality verification, and strategic considerations for successful sourcing-lessons from Linyang's 25-year track record serving customers across more than 60 countries.

The…

Behind the Technology: Linyang's Path to Being China Top PVC Film Supplier

What transforms a regional manufacturer into a China Top PVC Film Supplier (https://www.linyangplastics.com/products.html) recognized across more than 60 countries? For Zhongshan Linyang Plastic Co., Ltd., the answer lies not in overnight success but in 25 years of methodical technology advancement, strategic capacity building, and unwavering focus on product innovation. This journey-from a startup facility in 2002 to a manufacturing powerhouse generating over 60 million US dollars annually-reveals how technological mastery…

China TOP PVC Fabric Manufacturer Partners with China National Light Industry Co …

What drives a China TOP PVC Fabric Manufacturer (https://www.linyangplastics.com/products.html) to pursue industry-leading partnerships that elevate manufacturing standards? For Zhongshan Linyang Plastic Co., Ltd., the answer lies in strategic collaboration with the China National Light Industry Council (CNLIC), a comprehensive industry organization bridging government policy with enterprise development. This partnership reinforces Linyang's commitment to quality enhancement while positioning the company at the forefront of China's evolving functional polymer materials sector.

Understanding the…

More Releases for PVC

PVC Coated Fabrics Market Accelerates at 5.3% CAGR as Transportation, Infrastruc …

The PVC coated fabrics market reached USD million in 2022 and is projected to witness lucrative growth by reaching up to USD million by 2031. The market is growing at a CAGR of 5.3% from 2024 to 2031.

Market growth is fueled by surging demand for durable, waterproof materials in transportation, marine, and construction sectors, alongside rising infrastructure projects and automotive upholstery needs. Key drivers include advancements in eco-friendly PVC formulations…

PVC Foam Profiles Market Outlook 2034: Global Valuation to Reach USD 4.8 Billion …

The global PVC foam profiles market was valued at US$ 2.9 Bn in 2023. As industries continue to adopt lightweight, moisture-resistant, and dimensionally stable materials, PVC foam profiles are witnessing growing integration into construction, automotive, marine, and furniture manufacturing applications. According to current projections, the market is set to expand at a CAGR of 4.2% from 2024 to 2034, ultimately reaching US$ 4.8 Bn by 2034. This sustained growth reflects…

The Growing PVC Window Market

New York, US, - [01-December- 2025] - The PVC window market is experiencing significant growth, driven by increasing demand for energy-efficient and sustainable building materials. As consumers and builders alike prioritize durability, cost-effectiveness, and environmental impact, PVC (polyvinyl chloride) windows have emerged as a preferred choice in residential and commercial construction. This press release provides an overview of the current state of the PVC window market, key trends, and future…

New PVC External Lubricant Improves Performance

Shandong HTX New Material Co., Ltd. is a newly established company that has already made a significant impact in the industry. Since its inception in March 2021, the company has been focused on producing high-quality PVC External Lubricant [https://www.htxchem.com/lubricant-manufacture-price-product/] and other related products. HTX is a comprehensive enterprise that not only specializes in PVC processing aids but also involves itself in research and development, production, and sales.

The product range offered…

PVC Pipes Market to See Major Growth by 2026 | Bow Plastics, Royal PVC, Tulsi Ex …

Latest released the research study on Global PVC Pipes Market, offers a detailed overview of the factors influencing the global business scope. PVC Pipes Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the PVC Pipes

The study covers emerging player’s data, including: competitive…

Global Polyvinyl Chloride (PVC) Market 2017 -

Worldwide Polyvinyl Chloride (PVC) 2017 Research Report presents a professional and complete analysis of Global Polyvinyl Chloride (PVC) Market on the current situation.

In the first part, the report provides a general overview of the Polyvinyl Chloride (PVC) industry 2017 including definitions, classifications, Polyvinyl Chloride (PVC) market analysis, a wide range of applications and Polyvinyl Chloride (PVC) industry chain structure. The 2017's report on Polyvinyl Chloride (PVC) industry offers the global…