Press release

High Performance Polymer Market Outlook Rising Demand Driving USD 47.25 Billion Opportunity

High Performance Polymer Market size was valued at USD 31.98 Billion in 2024 and the total High Performance Polymer revenue is expected to grow at a CAGR of 5% from 2025 to 2032, reaching nearly USD 47.25 Billion.Market Overview:

The High Performance Polymer (HPP) market represents a critical segment of advanced materials engineered to deliver exceptional mechanical strength, thermal stability, chemical resistance, and long-term durability under extreme conditions. These polymers, including PEEK, PPS, fluoropolymers, polyimides, and liquid crystal polymers, are increasingly replacing metals and conventional plastics across demanding applications. Industries such as aerospace, automotive, electronics, medical devices, energy, and industrial manufacturing rely on HPPs to achieve weight reduction, design flexibility, corrosion resistance, and improved lifecycle performance. The market is characterized by high entry barriers due to complex manufacturing processes, stringent quality standards, and significant R&D investments. Innovation plays a central role, with manufacturers focusing on material customization, enhanced processing techniques, and application-specific grades. As sustainability and efficiency become strategic priorities, high performance polymers are emerging as essential materials that enable next-generation engineering solutions across global value chains.

Request a sample copy of the report to see what's inside: https://www.maximizemarketresearch.com/request-sample/104467/

Key Market Trends for 2026:

By 2026, the High Performance Polymer market is expected to witness strong trends centered on lightweighting, miniaturization, and multifunctional material design. One major trend is the growing adoption of HPPs in electric vehicles, where thermal management, electrical insulation, and reduced component weight are critical. Another key trend is the expansion of HPP use in semiconductor manufacturing and advanced electronics, driven by demand for high-purity, heat-resistant, and chemically stable materials. Additive manufacturing using high performance polymers is also gaining momentum, enabling rapid prototyping and complex geometries previously difficult to achieve. Sustainability-focused trends include the development of recyclable, bio-based, and low-emission polymer grades without compromising performance. Additionally, increased collaboration between polymer manufacturers and end-use industries is shaping customized solutions, accelerating innovation cycles, and expanding the application scope of high performance polymers across emerging technologies.

Market Dynamics: What's Driving Growth:

The growth dynamics of the High Performance Polymer market are shaped by technological advancement, evolving industrial requirements, and material substitution trends. Industries are increasingly shifting from metals and traditional engineering plastics toward high performance polymers to improve efficiency, reduce maintenance costs, and enhance design flexibility. Rapid innovation in aerospace and defense applications demands materials capable of withstanding extreme temperatures, pressure, and chemical exposure, directly supporting market expansion. In healthcare, the rise of minimally invasive procedures and implantable devices is boosting demand for biocompatible and sterilization-resistant polymers. Additionally, digitalization and automation across manufacturing sectors are increasing the need for precision components made from stable and high-strength polymer materials. Supply chain localization and investments in advanced polymer processing facilities are further strengthening market momentum, while continuous research into improved performance characteristics sustains long-term growth potential.

Need Reliable Market Data? Save 30% This New Year: https://www.maximizemarketresearch.com/market-report/global-high-performance-polymer-market/104467/

High Performance Polymer Key Market Drivers and Major Challenges

Key drivers of the High Performance Polymer market include rising demand for high-strength, lightweight materials, increasing performance requirements in critical applications, and rapid growth in advanced manufacturing technologies. Regulatory pressure to improve fuel efficiency and reduce emissions is accelerating polymer adoption in transportation sectors. However, the market also faces notable challenges that influence adoption rates. High material and processing costs remain a significant barrier, particularly for price-sensitive industries and emerging markets. Limited awareness of long-term cost benefits can slow replacement of conventional materials. Additionally, complex fabrication techniques and the need for specialized equipment restrict widespread usage. Supply constraints for raw materials and dependency on advanced production infrastructure further add to market complexity. Overcoming these challenges requires continuous innovation, cost optimization, and stronger collaboration across the value chain to unlock broader commercial opportunities.

Market Segmentation:

by Type

Fluoropolymers

High Performance Polyamides

Liquid Crystal Polymers

Polyimides

Sulfone Polymers

by Application

Automotive

Medical

Industrial

Electrical & Electronics

High Performance Polymer Market, Key Players are:

1. DuPont

2. 3M

3. Solvay

4. Resirene

5. MC Polymers

6. Celanese

7. Arkema

8. Chevron Phillips

9. Victrex

10. Sabic Global technologies

11. Arkema

12. BASF SE

13. Celanese Corporation

14. DAIKIN INDUSTRIES, Ltd.

15. E. I. Dupont De Nemours and Company

16. Evonik Industries AG

17. Saudi Basic Industries Corporation (SABIC)

18. Solvay S.A.

19. Sumitomo Chemical Co., Ltd.

FAQs:

What are high performance polymers?

They are advanced polymers engineered to deliver exceptional strength, heat resistance, and chemical stability in extreme conditions.

Which industries use high performance polymers the most?

Aerospace, automotive, electronics, medical devices, energy, and industrial manufacturing are the primary users.

What are the main benefits of high performance polymers?

They offer lightweight design, high durability, corrosion resistance, and long service life.

Are high performance polymers environmentally friendly?

Sustainability is improving through recyclable, bio-based, and low-emission polymer developments.

What limits the adoption of high performance polymers?

High material costs and complex processing requirements are the main barriers.

What is the future outlook for the high performance polymer market?

The market is expected to grow steadily due to rising demand from advanced and high-performance applications.

Related Reports:

Global Colorimeter Market https://www.maximizemarketresearch.com/market-report/global-colorimeter-market/119427/

Belt Sander Market https://www.maximizemarketresearch.com/market-report/belt-sander-market/216221/

Global Industrial Food Cutting Machines Market https://www.maximizemarketresearch.com/market-report/global-industrial-food-cutting-machines-market/101805/

Xenon Flash Lamp Market https://www.maximizemarketresearch.com/market-report/xenon-flash-lamp-market/187926/

Coil Winding Machines Market https://www.maximizemarketresearch.com/market-report/coil-winding-machines-market/75560/

Contact Maximize Market Research:

3rd Floor, Navale IT Park, Phase 2

Pune Banglore Highway, Narhe,

Pune, Maharashtra 411041, India

sales@maximizemarketresearch.com

+91 96071 95908, +91 9607365656

Maximize Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology and communication, cars and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release High Performance Polymer Market Outlook Rising Demand Driving USD 47.25 Billion Opportunity here

News-ID: 4352703 • Views: …

More Releases from MAXIMIZE MARKET RESEARCH PVT. LTD.

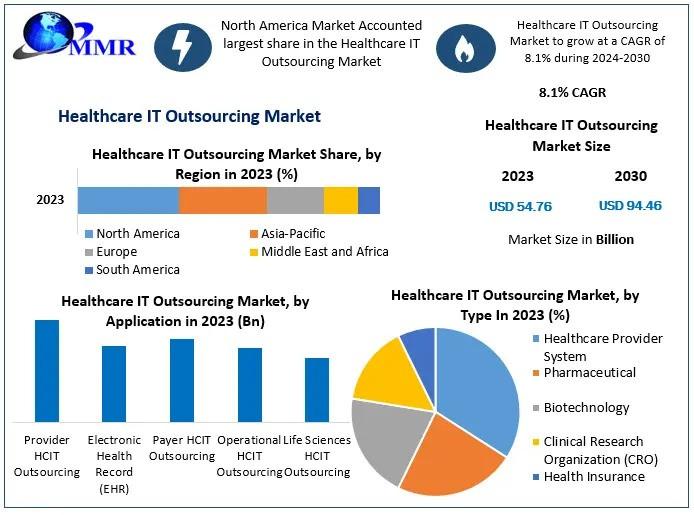

Healthcare IT Outsourcing Market Insights: Projected Growth from US$ 54.76 Billi …

Healthcare IT outsourcing Market was valued ~US$ 54.76 Bn in 2023 and is expected to reach ~US$ 94.46 Bn by 2030, at CAGR of 8.10% during forecast period of 2024 to 2030.

Healthcare IT outsourcing market Overview:

The healthcare IT outsourcing market is experiencing significant growth as healthcare organizations increasingly seek efficient and cost-effective solutions to manage their IT infrastructure and data systems. Outsourcing IT services, such as electronic health records (EHR)…

Premium Cosmetics Market Insights: Projected Growth at 6.82% CAGR, Reaching US$ …

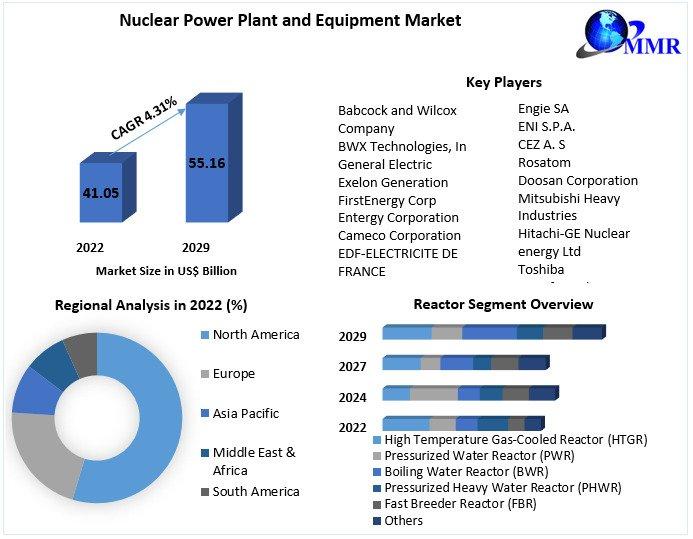

Nuclear Power Plant and Equipment Market was valued at US$ 43.36 Bn. in 2023 and the total Premium Cosmetics revenue is expected to grow at 6.82 % from 2024 to 2030, reaching nearly US$ 68.29 Bn.

Nuclear Power Plant and Equipment Market Overview:

The nuclear power plant and equipment market plays a pivotal role in the global energy sector, providing a significant share of the world's electricity. As countries work towards reducing…

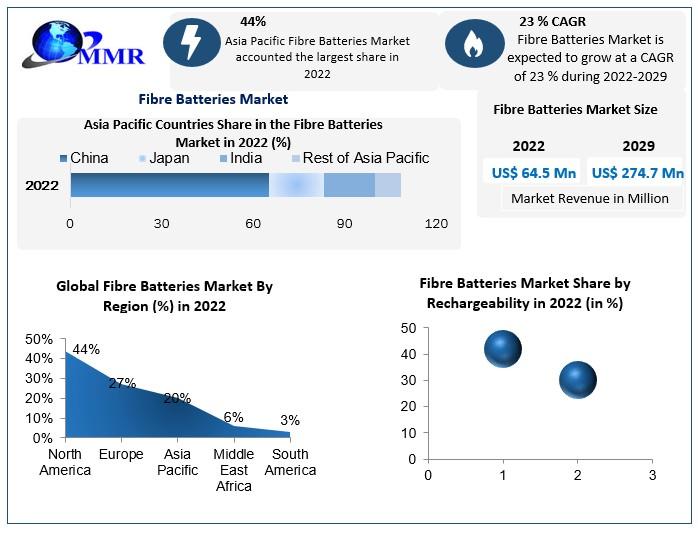

Fibre Batteries Market Expected to Grow at a 23% CAGR, Reaching USD 274.7 Millio …

Fibre Batteries Market size was valued at USD 64.5 Mn. in 2022 and the total Fibre Batteries revenue is expected to grow by 23 % from 2022 to 2029, reaching nearly USD 274.7 Mn.

Fibre Batteries Market Overview:

The fibre batteries market is witnessing remarkable growth as the demand for lightweight, flexible, and efficient energy storage solutions continues to rise. Fibre batteries, which integrate energy storage capabilities into flexible materials like carbon…

Wood Truss Market Analysis: Strengthening the Future of Residential and Commerci …

Wood Truss Market Set for Robust Growth, Projected to Reach USD 1.60 Billion by 2032

The global wood truss market is poised for steady growth, with market size valued at USD 1.07 Billion in 2024 and expected to expand at a CAGR of 5.2% from 2025 to 2032, reaching nearly USD 1.60 Billion. The market's growth is driven by rising demand for sustainable construction practices, cost-effective building solutions, and structural design…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…