Press release

Global Polyolefin Polystyrene Foam Market is projected to reach a market size of USD 239.05 million by the end of 2030.

According to the report published by Virtue Market Research in Global Polyolefin Polystyrene Foam Market was valued at USD 184.31 million and is projected to reach a market size of USD 239.05 million by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 4.43%.Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/polyolefin-polystyrene-foam-market/request-sample

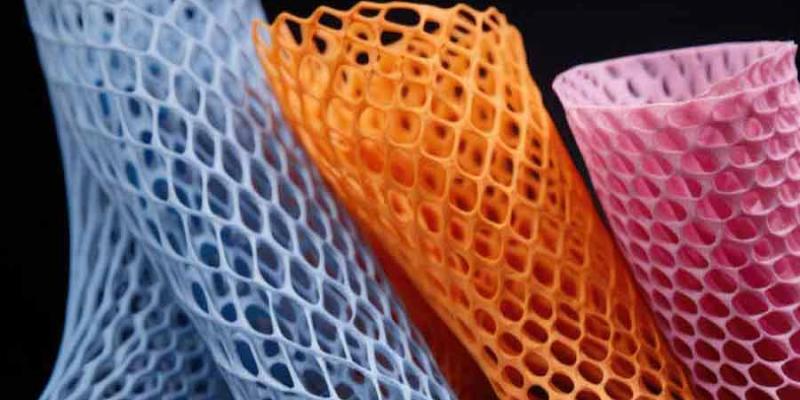

The Polyolefin Polystyrene Foam Market has been gradually transforming into a cornerstone of lightweight material innovation, serving diverse sectors like packaging, construction, automotive, and consumer goods. These foams are valued for their low density, heat insulation, and strong cushioning properties. Over the years, industries have increasingly leaned toward materials that balance performance, sustainability, and cost efficiency - and polyolefin and polystyrene foams have risen to meet this demand.

A long-term force driving this market has been the steady expansion of the packaging and construction industries. Urbanization continues to shape new patterns of consumption and infrastructure development. As people around the world build more homes, offices, and public spaces, the need for insulation materials that conserve energy and reduce costs has become essential. Polyolefin and polystyrene foams provide exactly that - excellent insulation, moisture resistance, and durability. Moreover, industries now look for materials that can sustain performance under extreme conditions without adding extra weight. These foams offer a perfect balance, leading manufacturers to adopt them not just for cost savings, but also for performance reliability over time. This gradual shift toward lightweight and energy-efficient materials has kept the market expanding, even amid shifting global economic trends.

However, the outbreak of COVID-19 brought temporary disruptions. The lockdowns in 2020 and 2021 halted manufacturing, slowed logistics, and created uncertainty in supply chains. Many factories dealing with foam production faced raw material shortages and transport delays. The demand from the construction and automotive industries also weakened during that period. Yet, one surprising development occurred - a rise in packaging demand. With online shopping and home deliveries becoming the norm, packaging requirements surged. Foam packaging materials became vital to protect goods during transport, giving the market a partial cushion against broader industrial slowdowns. As economies reopened, the rebound in manufacturing and infrastructure projects reignited the need for foam-based solutions, helping the industry recover faster than expected.

In the short term, the growing focus on thermal efficiency has been acting as a powerful market driver. Governments in many countries are tightening energy conservation standards for buildings, and this has opened up significant space for insulation materials like polyolefin and polystyrene foam. These foams trap air effectively, maintaining interior temperatures and lowering heating or cooling energy use. For industries seeking compliance with energy codes or certification systems, using such materials becomes a straightforward way to meet sustainability goals while cutting long-term costs. This factor has made foam materials more attractive, especially in new construction and retrofitting projects.

Alongside this, an emerging opportunity lies in the development of eco-friendly foam formulations. Traditional foams, especially polystyrene-based, have faced criticism for their environmental footprint and disposal challenges. This has encouraged several companies to innovate with recyclable and bio-based foam materials. Research is ongoing to design foams that maintain high insulation and cushioning capabilities while also being easier to recycle. This opportunity could redefine the industry's future, especially as governments and corporations increase their sustainability commitments.

A notable trend in the Polyolefin Polystyrene Foam Market today is the blending of advanced manufacturing technology with material science. The integration of extrusion and molding techniques, coupled with automation and real-time process control, has enhanced foam uniformity and performance. Producers are experimenting with hybrid foam structures that combine the flexibility of polyolefin with the rigidity of polystyrene to deliver multi-functional materials suitable for demanding applications. Additionally, digital tools for production monitoring and predictive quality control are helping manufacturers optimize costs while improving consistency. This shift toward technology-driven manufacturing is making foam production faster, cleaner, and more efficient than ever before.

Segmentation Analysis:

By Foam Type: Polyethylene (PE) Foam, Polypropylene (PP) Foam, Ethylene Vinyl Acetate (EVA) Foam

In the Polyolefin Polystyrene Foam Market, each foam type serves a distinct purpose shaped by material flexibility, durability, and performance. Polyethylene (PE) foam is the largest segment due to its wide use in packaging, construction insulation, and sports equipment padding. Its light weight, moisture resistance, and strong cushioning properties make it a favorite choice across industries that value protection and reliability. This foam's ability to resist vibration and pressure damage keeps it in constant demand for shipping and insulation applications. On the other hand, Polypropylene (PP) foam is the fastest growing during the forecast period because of its impressive heat resistance, structural strength, and recyclability.

Industries such as automotive and electronics are rapidly adopting PP foam for lightweight components and protective casing. Ethylene Vinyl Acetate (EVA) foam, known for its flexibility and shock absorption, continues to play a steady supporting role in footwear and soft padding materials. With growing emphasis on recyclable and performance-driven foams, these materials are being fine-tuned to deliver not just function but also eco-conscious advantages, reflecting how industries are blending strength, comfort, and sustainability in new design strategies.

By End-User Industry: Automotive, Construction, Packaging, Footwear, Bedding and Furniture, Other End-User Industries

The Polyolefin Polystyrene Foam Market serves a range of end-user industries, each seeking efficiency and performance from foam-based materials. Among these, the largest segment is Packaging, driven by the ongoing boom in e-commerce, logistics, and safe transport needs. Companies prefer these foams for their strong shock absorption and insulation properties, protecting fragile goods and electronics during transit.

The versatility of both polyolefin and polystyrene foams ensures goods arrive intact, even under long-distance shipping conditions. The fastest growing end-user segment is Automotive, as manufacturers increasingly rely on lightweight foam materials to improve fuel efficiency and passenger comfort. These foams are used in seats, bumpers, headliners, and noise-reducing panels, supporting the industry's sustainability goals while maintaining safety and design quality. Construction follows closely, leveraging foam for insulation, sealing, and soundproofing, while the footwear and furniture industries continue integrating foams for comfort, support, and design flexibility. Each of these industries demonstrates how material science is aligning with real-world performance needs, where durability, comfort, and environmental benefits converge to redefine product standards across consumer and industrial landscapes.

By Application: Thermal Insulation, Impact Protection, Soundproofing, Buoyancy, Cushioning, Other Applications

Across the Polyolefin Polystyrene Foam Market, applications reveal how versatile these materials truly are. The largest application segment is Thermal Insulation, primarily fueled by energy-efficient building trends and the need to maintain temperature stability in both residential and commercial spaces. These foams help reduce heating and cooling costs while resisting moisture and heat flow, making them ideal for walls, roofs, and refrigeration units.

The fastest growing application is Impact Protection, which has found increasing adoption in packaging, automotive interiors, and consumer electronics. As global shipping and electronic device usage continue to expand, the demand for shock-absorbing foam materials is rising sharply. Soundproofing also plays an important role, with foams being used in studios, vehicles, and offices to reduce unwanted noise. Buoyancy applications in marine products and cushioning in footwear and bedding further expand the market's functional diversity. Manufacturers are now experimenting with advanced foam structures that combine different cell densities, allowing one product to serve multiple functions, from insulation to vibration control, in a single application layer. This adaptive use highlights how innovation is reshaping traditional material capabilities.

Read More @ https://virtuemarketresearch.com/report/polyolefin-polystyrene-foam-market

Regional Analysis:

In regional distribution, the Polyolefin Polystyrene Foam Market demonstrates diverse growth patterns shaped by economic development, industrial maturity, and sustainability awareness. The largest regional market is Asia-Pacific, driven by strong construction growth, rapid urbanization, and the booming packaging sector across countries like China, India, and Japan. The region's expanding manufacturing base and infrastructure projects have amplified the use of foam for insulation and packaging applications. Moreover, local producers benefit from low-cost raw materials and easy access to large consumer markets.

Meanwhile, the fastest growing region during the forecast period is North America, where industries are embracing eco-friendly foam solutions and energy-efficient building practices. Regulatory pushes toward sustainability and recycling are encouraging innovation in foam manufacturing, particularly in automotive and construction applications. Europe continues to show consistent growth, supported by its strong automotive and furniture industries, while South America and the Middle East & Africa remain emerging markets focusing on cost-effective and adaptable foam materials. Each region reflects unique market dynamics, blending environmental awareness with industrial modernization to expand the global footprint of polyolefin and polystyrene foams.

Latest Industry Developments:

• Adoption of circular and bio-based feedstocks is shaping raw material strategies: The market is moving toward circularity as manufacturers prioritize recycled polyolefins and bio-derived foam formulations to reduce lifecycle emissions and ease end-of-life handling. Demand from regulators and large buyers for recyclable packaging and lower-carbon building materials pushes product lines toward higher recycled content, certified bio-alternatives, and designs that simplify separation and reprocessing. This trend encourages partnerships with recyclers, pilot programs for chemically recycled feedstocks, and R&D into bio-resins that mimic foam performance while shrinking raw-material footprints, reshaping procurement and product roadmaps across the sector.

• Digital and automated production techniques are being scaled to raise quality and cut cost: Process digitalization, predictive control, and factory automation are increasingly deployed to tighten cell-structure control, reduce , and accelerate cycle times for foam extrusion and molding. Real-time sensors and analytics enable stable blowing agent dosing, uniform density, and faster changeovers for smaller production runs, which supports customization without large cost penalties. These investments also improve traceability required for recycled content claims and reduce energy use through optimized heating and cooling profiles. The cumulative effect is a manufacturing footprint that is more flexible, resilient to supply shocks, and capable of meeting tighter performance tolerances demanded by advanced applications.

• Application-led lightweighting and multifunctional foams are expanding use cases across mobility and construction: End markets are forcing material evolution as automotive and building sectors seek lower mass, combined thermal and acoustic performance, and integrated crash protection. Manufacturers respond by engineering hybrid cell architectures, gradient-density panels, and foam composites that deliver simultaneous buoyancy, insulation, and impact energy management. Product development centers on modular, form-tailored components that cut vehicle weight and improve building envelope efficiency while preserving crashworthiness and comfort. This application focus accelerates adoption in clean-mobility platforms and retrofitting projects, creating demand for design-for-manufacture approaches and cross-sector testing protocols.

customize the Full Report Based on Your Requirements @ https://virtuemarketresearch.com/report/polyolefin-polystyrene-foam-market/customization

contact Us:

Virtue Market Research

Kumar Plaza, #103, SRPF Rd, Ramtekadi, Pune, Maharashtra 411013, India

About Us:

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Polyolefin Polystyrene Foam Market is projected to reach a market size of USD 239.05 million by the end of 2030. here

News-ID: 4352672 • Views: …

More Releases from Virtue Market Research

The Global Vodka Seltzer Market is projected to reach a market size of USD 16.22 …

The Vodka Seltzer Market was valued at USD 9.4 billion in 2024 and is projected to reach a market size of USD 16.21 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 8.1%.

Request Sample @ https://virtuemarketresearch.com/report/vodka-seltzer-market/request-sample

The vodka seltzer market has grown from a niche beverage choice into a mainstream favorite, supported by shifting consumer lifestyles and evolving…

The Global Telehealth Services Market and is projected to reach a market size of …

The Global Telehealth Services Market was valued at USD 126.1 billion and is projected to reach a market size of USD 302.49 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 15.7%.

Request Sample @ https://virtuemarketresearch.com/report/telehealth-services-market/request-sample

The perennial shift towards patient-centric healthcare has been a pivotal long-term market driver for telehealth services. Over the years, the industry has witnessed…

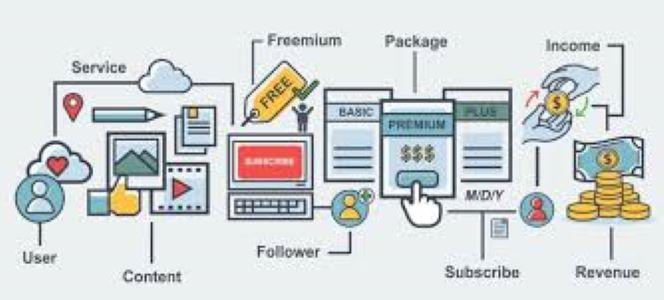

The Subscription Box/Subscription E-Commerce Market is projected to reach a mark …

The Subscription Box/Subscription E-Commerce Market is valued at USD 47.19 billion in 2024 and is projected to reach a market size of USD 97.73 billion by the end of 2030. Over the outlook period of 2025-2030, the market is anticipated to grow at a CAGR of 12.9%.

Request Sample @ https://virtuemarketresearch.com/report/subscription-e-commerce-market/request-sample

The subscription e-commerce market has grown into one of the most dynamic parts of the digital economy. It began as a…

The Global Aramid Fibre Reinforced Polymer Composites Market is projected to rea …

According to the report published by Virtue Market Research in Aramid Fibre Reinforced Polymer Composites Market was valued at USD 5.55 billion and is projected to reach a market size of USD 8.57 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 7.5%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/aramid-fibre-reinforced-polymer-composites-market/request-sample

The Aramid Fibre Reinforced Polymer Composites…

More Releases for Foam

Foam Concentrate Market: High-growth Regions to Expand Geographic Footprint | Ch …

"This research study presents a comprehensive compilation of insightful findings concerning key aspects of the global Foam Concentrate industry, impacting its growth trajectory over the forecast period from 2023 to 2029. The report sheds light on the evolving sales trends of various tech products across different regions and countries, highlighting both growth and decline. A detailed regional analysis is a crucial part of this Foam Concentrate report, offering a meticulous…

Packaging Foams Market Report with Forecast 2020-2025 | Top Key Players: BASF, A …

Global Packaging Foams market would thus note a steady growth over the forecast period of 2020 - 2025. The robust CAGR (Compound Annual Rate Growth) will chart an upward growth curve and create lucrative growth opportunities in the global Packaging Foams market. In, turn, this will lead to improvement in market worth.

Request a PDF sample of this report: https://www.adroitmarketresearch.com/contacts/request-sample/1415

Global Packaging Foams Market: Notable Development

Global Packaging Foams market is set to…

Technical Foam Services Develops Innovative New Scaffold Foam

Northamptonshire, United Kingdom (8th February, 2013) - Technical Foam Services Ltd, a leading independent engineer-based manufacturer and foam producer, announces the creation of a new scaffold foam.

Technical Foam Services Ltd and their strategic construction partner have been working in unison to develop the Closed Cell PE Scaffold Foam, which uses high density polyethylene foam to offer protection against work equipment damage to decorated surfaces. The scaffold foam also uses a…

Technical Foam Services Creates Foam Inserts for Rak Ceramics

Northamptonshire, United Kingdom (18th February, 2013) - Technical Foam Services Ltd, a leading independent engineering-based manufacturer and foam producer, earlier this month secured a contract with leading ceramic tile design and manufacturer Rak Ceramics.

Rak Ceramics specialises in offering a range of high-quality ceramic tiles, distributing their products to DIY retailers and kitchen designers nationwide.

Sales representatives from the company were becoming increasingly concerned with the loss and damage of these tiles…

Technical Foam Services Manufactures Cancer Prevention Foam

Northamptonshire, United Kingdom (17 June, 2011) - Technical Foam Services, a leading independent engineering-based manufacturer and foam producer, is proud to have been part of an exciting new development in the world of cancer prevention.

A far cheaper and more patient-friendly method has been developed by the UK Medical Research Council, which involves the use of a reticulated foam sponge encapsulated within a pill. Once the pill is swallowed, it dissolves…

Technical Foam Services Expand Range of Foam Insert Fabrics

Northamptonshire, United Kingdom (19th May, 2011) – Technical Foam Services, a leading independent engineering-biased manufacturer and foam producer, has expanded their range of fabrics to be used with foam inserts.

Technical Foam Services have long been recognised as the UK’s leading supplier of foam inserts, producing them for a wide variety of applications, such as large suitcase inserts suitable for holding ceramics and glassware through to small inserts used…