Press release

Black Liquor Screen Basket Material Selection: 304/316L/Duplex Steel for Different Pulping Processes

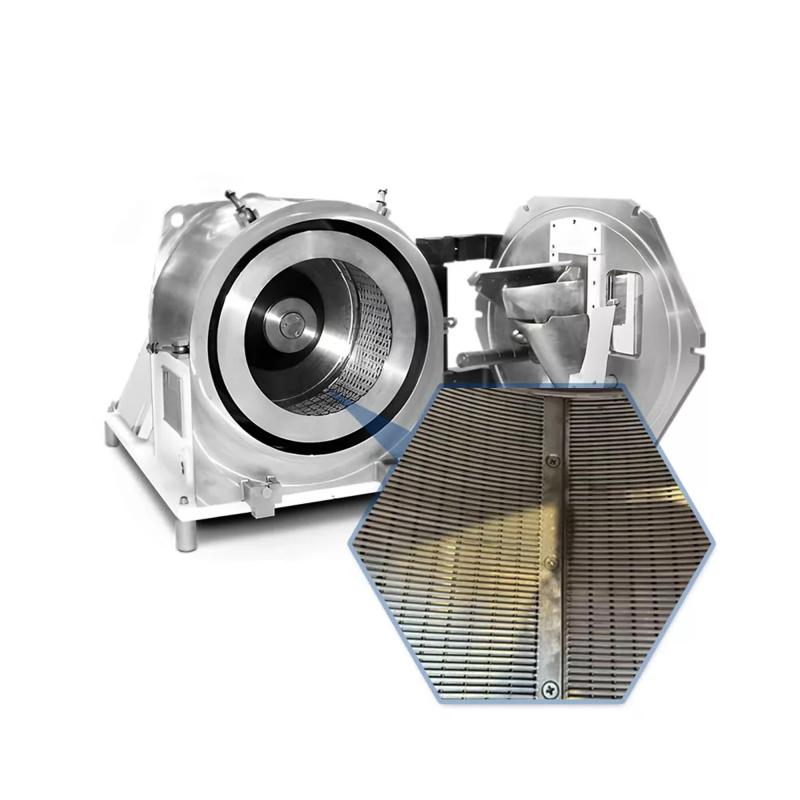

IntroductionSelecting the right material for black liquor screen baskets is the cornerstone of ensuring long service life, low maintenance costs and high screening efficiency in pulp mill black liquor treatment. The wrong material choice will lead to rapid wear, corrosion or deformation of the screen basket-especially for EB Drilled Screen Baskets, whose high-precision electron beam drilling holes rely on the original performance of the base material to exert screening advantages.

Black liquor contains alkali, sulfide, chloride and other corrosive media, and the pulp friction during screening will also cause abrasive damage to the screen basket. Combined with different pulping processes (kraft, mechanical, recycled paper, etc.), the composition and corrosivity of black liquor vary greatly. This article will detail the performance of 304/316L stainless steel and duplex steel, and match the most suitable material solutions for different pulping processes, especially for the material selection of high-precision EB Drilled Screen Baskets.

Key Material Performance Comparison for Black Liquor Screen Baskets

The three mainstream materials for industrial black liquor screen baskets (including EB Drilled Screen Baskets) are 304 stainless steel, 316L stainless steel and duplex steel. Their corrosion resistance, wear resistance and cost performance are quite different, and the matching scenarios are clear:

304 Stainless Steel:Good mechanical strength, easy processing, stable performance Resists mild alkali corrosion; general wear resistance Low Low-corrosivity black liquor system.

316L Stainless Steel: Molybdenum added, excellent pitting corrosion resistance Resists medium-high alkali/sulfide corrosion; better wear resistance than 304 Medium Medium-corrosivity black liquor, low sulfur pulping.

Duplex Steel (2205/2507): Dual-phase structure, high strength + high corrosion resistance,Resists high alkali/sulfur/chloride corrosion; excellent wear resistance High,High-corrosivity black liquor, heavy-duty screening.

Important Note for EB Drilled Screen Baskets: Electron beam drilling is a cold working process that does not damage the original metallographic structure of the base material. Unlike laser drilling, it will not cause thermal deformation or material performance degradation of the screen basket-this makes the EB Drilled Screen Basket can fully exert the corrosion and wear resistance of the selected base material, and the service life is 30%-50% longer than the ordinary processed screen basket of the same material.

Material Selection for EB Drilled Screen Baskets Based on Different Pulping Processes

The composition of black liquor is determined by the pulping process, which is the core basis for selecting the material of EB Drilled Screen Baskets. The following is the targeted material matching plan for the four most common pulping processes in the industry:

1. Kraft Pulping (Sulfate Pulping)

Black Liquor Characteristic: High alkali content, high sulfide concentration, strong corrosivity; serious pulp friction during screening.

Recommended Material: Duplex Steel (2205/2507) → EB Drilled Screen Baskets made of duplex steel can resist the high corrosion of sulfur-containing black liquor and the heavy wear of kraft pulp, which is the best choice for large-scale kraft pulp mills.

Alternative: 316L stainless steel (for small and medium-sized mills with low sulfur pulping and reduced production load).

2. Mechanical Pulping (MP/TMP)

Black Liquor Characteristic: Low alkali content, mild corrosivity; high fiber content, strong abrasive wear on screen basket.

Recommended Material: 304 Stainless Steel → EB Drilled Screen Baskets of 304 stainless steel have high cost performance, and the cold working of EB drilling maintains the mechanical strength of 304, which can effectively resist the abrasive wear of mechanical pulp.

3. Recycled Paper Pulping

Black Liquor Characteristic: Complex composition, containing chloride, ink residue and other impurities; local pitting corrosion is easy to occur on the screen basket.

Recommended Material: 316L Stainless Steel → The molybdenum element in 316L can effectively resist pitting corrosion caused by chloride, and the high-precision holes of EB Drilled Screen Baskets can avoid impurity blockage while ensuring screening efficiency.

4. Semi-Chemical Pulping

Black Liquor Characteristic: Moderate alkali content, low sulfide; balanced corrosion and wear.

Recommended Material: 316L Stainless Steel → A perfect balance of cost and performance, the EB Drilled Screen Baskets of this material can adapt to the medium load screening of semi-chemical pulping, and the service life is significantly longer than ordinary screen baskets.

Practical Material Selection Tips for EB Drilled Screen Baskets

Prioritize the corrosive medium content (sulfur, chloride, alkali concentration) of black liquor, not just the pulping process-test the black liquor components regularly and adjust the screen basket material in time.

For custom EB Drilled Screen Baskets, inform the supplier of the production load (screening capacity per hour) while providing the pulping process, and the supplier can optimize the material thickness and hole distribution design.

For pulp mills with mixed pulping processes, choose 316L stainless steel or duplex steel for EB Drilled Screen Baskets to ensure adaptability to different black liquor characteristics.

The surface coating (e.g., ceramic coating) can be matched on the basis of the base material, which further improves the wear resistance of the EB Drilled Screen Basket (suitable for heavy-duty screening scenarios).

Conclusion

The material selection of black liquor screen baskets is not a one-size-fits-all solution, and the EB Drilled Screen Basket, as a high-precision screening component, has higher requirements for the base material-only by matching the material with the pulping process and black liquor characteristics can the advantages of EB drilling's high precision, high consistency and long life be fully exerted.

Whether it is the low-cost 304 stainless steel, the balanced 316L stainless steel or the high-performance duplex steel, the rational selection can effectively reduce the replacement frequency of the screen basket, lower the maintenance cost of the pulp mill, and improve the overall efficiency of the black liquor treatment system.

https://www.johnsonslot.com/eb-drilled-screen-basket.html

E-mail: china@johnsonslot.com

Address: No.62,Lvcaicheng,Anping County,

Hebei Province,China

Hebei SLOT Filter Technology Co., Ltd. Global leader in industrial screening & separation solutions. With ISO 9001/SGS certifications and 15+ years of expertise, we engineer precision screening systems through proprietary wedge wire forming and polyurethane casting technologies.

SLOT's technology has been successfully applied in over 30 countries around the world and is widely used in numerous fields such as papermaking, petrochemicals, fine paper chemicals, energy and power, water treatment, automotive manufacturing, mining, food and beverage, and metal processing.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Black Liquor Screen Basket Material Selection: 304/316L/Duplex Steel for Different Pulping Processes here

News-ID: 4348862 • Views: …

More Releases from Hebei Slot Filter Technology Co.,Ltd.

Customized High-Frequency Screen Basket by Johnson Slot Boosts Service Life by 1 …

Johnson Slot, a professional manufacturer of industrial screening solutions, today announced a successful case study in which its customized high-frequency vibrating screen basket resolved severe wear issues for a major tin mining company in Southeast Asia. The client was processing highly abrasive and corrosive tin ore slurry, which caused rapid deterioration of standard screens. The tailored solution extended the screen basket's average service life from 60 days to 150 days,…

SLOT's Innovative Wedge Wire Screen Solution Sets New Benchmark for Water Effici …

A large farm in the North China Plain has long faced serious challenges with high sand content in well water and frequent screen clogging. When using traditional perforated screens, the system required 6-8 shutdowns for cleaning annually, significantly impacting irrigation stability and crop growth requirements. This issue not only increased maintenance costs but also directly threatened the farm's production efficiency.

SLOT Solution

Addressing this challenge, SLOT provided an innovative solution using 316L…

Centrifuge screen: Functions and Types

Centrifuge screens are one of the core components of a centrifuge. They directly determine the separation efficiency, processing capacity, and final product quality of the centrifuge.

1. Core Functions of Centrifuge Screens

*Filter Media: In a filter centrifuge, a screen serves as the filter medium. The screen is placed on the inner wall of the bowl. Under the action of centrifugal force, solid particles in the suspension are trapped on the screen…

More Releases for Screen

Best Screen Recorder for PC: A Comprehensive Guide to iTop Screen Recorder

Screen recording has become an essential tool for various tasks, including online teaching, gameplay recording, and business presentations. If you are looking for the best screen recorder for PC, iTop Screen Recorder is a reliable choice that offers advanced features with a user-friendly interface. This article will provide an in-depth review of iTop Screen Recorder, its features, benefits, and how to use it efficiently.

What is iTop Screen Recorder?

iTop Screen Recorder…

LED Cylindrical Screen Market

An LED cylindrical screen is a digital display shaped like a tube, offering a 360-degree viewing experience for impactful presentations and displays. The global LED cylindrical screen market is experiencing significant growth, driven by a multitude of compelling factors that underscore its versatility, innovation, and effectiveness in delivering impactful visual experiences. At the forefront of this growth is the increasing demand for immersive and interactive visual solutions across various industries.…

Solar Screen Market Is Expected To Grow Dramatically In The Future 2022-2029| So …

The latest release from WMR titled Solar Screen Market Research Report 2022-2029 contains all relevant information and Growth Factors. 𝐏𝐫𝐨𝐯𝐢𝐝𝐢𝐧𝐠 𝐢𝐭𝐬 𝐜𝐥𝐢𝐞𝐧𝐭𝐬 𝐰𝐢𝐭𝐡 𝐚𝐜𝐜𝐮𝐫𝐚𝐭𝐞 𝐝𝐚𝐭𝐚, 𝐢𝐭 𝐩𝐫𝐨𝐯𝐢𝐝𝐞𝐬 𝐭𝐡𝐞 𝐦𝐚𝐫𝐤𝐞𝐭 𝐨𝐮𝐭𝐥𝐨𝐨𝐤 𝐚𝐧𝐝 𝐡𝐞𝐥𝐩𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐦𝐚𝐤𝐢𝐧𝐠 𝐨𝐟 𝐜𝐫𝐮𝐜𝐢𝐚𝐥 𝐝𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬. The market is described in general terms, along with its definition, uses, advancements, and production technology. This market research study on Solar Screen keeps tabs on all emerging advancements and changes in…

Chanty's Screen Time Calculator

Chanty is delighted to announce the release of its all new and free Screen Time Calculator that does all the Math for you.

Chanty, one of the fastest growing team chat applications, has launched its new screen time calculator that lets you calculate your estimated screen time per week, month, year and even lifetime. All you have to do is enter the number of average hours you think you spend in…

Smart TV Global Market 2019 - Analysis By Screen Type, Screen Resolution, Screen …

Press Release – 25 Jan 2019

Research and Development News --

. .

Latest Update "Global Smart TV Market - Analysis By Screen Type, Screen Resolution, Screen Size, By Region, By Country (2018 Edition): Opportunities and Forecast (2013-2023)" with Industries Survey | Global Current Growth and Future.

' '

A comprehensive research report created through extensive primary research (inputs from industry experts, companies, stakeholders) and secondary research, the report aims to present the analysis…

Touch Screen Module

Global Touch Screen Module Market report provides a comprehensive study that takes account of the historical data, presents the current state, and anticipates the future. Additionally, it includes extremely useful information for new and growing company to mark themselves over the market. This report also contains important details such as End Users/Application, Trends in Future, Status and Outlook, production capacity, revenue, and Scope.

This report presents the worldwide Touch Screen Module…