Press release

Unlocking Value in Self-Crosslinking Polymers: Market Trends, Cost Insights, and Regional Opportunities

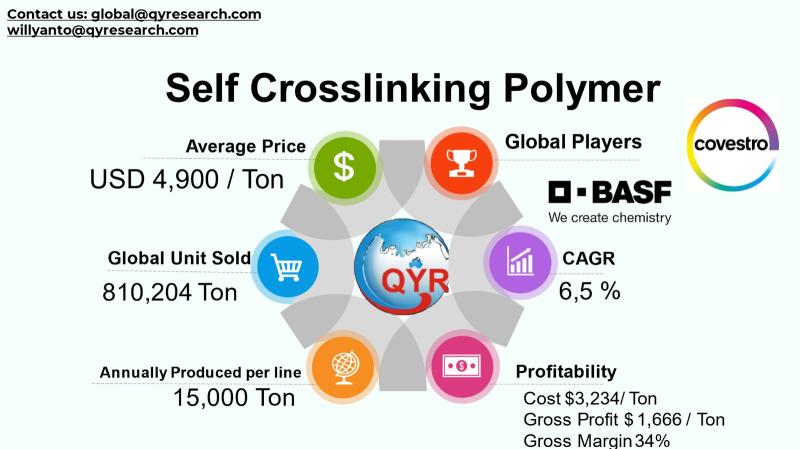

The global Self-Crosslinking Polymer industry encompasses a specialized segment of advanced polymers designed to form internal covalent bonds without external catalysts during curing, enhancing mechanical strength, chemical resistance, and durability. These polymers are widely applied across automotive coatings, industrial adhesives, protective finishes, construction materials, and performance coatings where high performance and environmental compliance are critical. With increasingly stringent regulations on solvent emissions and rising demand for high-durability materials, self-crosslinking polymers are gaining traction in applications requiring enhanced adhesion, longevity, and resilience under diverse operating conditions. Unlike conventional polymer systems that require external crosslinking agents or initiators, self-crosslinking polymers simplify processing and offer improved environmental and performance profiles, making them attractive across mature and emerging markets worldwide.In 2024, the global Self-Crosslinking Polymer market size amounted to USD 3,970 million with a growing compound annual growth rate at 6,5% through 2031, reaching market size USD 6,169 million by 2031. With an average selling price at USD 4,900 per ton, reflecting the total of 810,204 ton sold in 2024. The factory gross margin is at 34%, implies to a factory gross profit of USD 1,666 per ton and cost of goods sold is USD 3,234 per ton. The COGS breakdown is raw materials, energy, utilities, labor, overhead, quality/packaging. A single line full machine capacity production is around 15,000 ton per line per year. Downstream demand is concentrated in coatings & paints, adhesives/sealants, construction materials and automotive components.

Latest Trends and Technological Developments

In 2025, significant advancements in hybrid waterborne self-crosslinking polyurethane dispersions were highlighted as driving trends, where new formulations enhance mechanical properties and environmental compliance, meeting regulatory pressures for low VOC emissions in coatings and adhesives (September 2025). Innovations in high-performance waterborne systems are enabling expanded use in textiles, automotive finishes, and industrial sealants with improved durability and sustainability. These developments reflect industry shifts toward eco-friendly polymer technologies and digital process optimization to increase production efficiency and reduce waste.

Archer Daniels Midland (ADM), a global food ingredients producer, purchases VINNEX® 8888 for use in biodegradable composite materials at a contract price in the range of USD 4,500 - 5,500 per metric ton. In a specific industrial application, Fritzmeier GmbH, a leading manufacturer of tractor cabins and vehicle bodies, utilizes VINNEX® technology to produce lightweight, natural-fiber-reinforced composite components. The polymer acts as a binding agent for materials like flax and hemp, with the formulation for a major cabin production run consuming several tons of the product, representing a material cost of approximately USD 50,000 per project lot.

Lubrizol's CARBOSET® self-crosslinking acrylic polymers are widely specified. A buyer like PPG Industries procures CARBOSET® GA-1694 for high-performance overprint varnishes at a price of roughly USD 3.80 per kilogram. This product is then applied by WestRock Company at its corrugated packaging facilities. The polymer is used as a coating to provide exceptional scuff and chemical resistance to premium shipping boxes for electronics. A single coating line at a large WestRock plant can apply this formulation to thousands of square meters daily, with an annual consumption valued at over USD 200,000.

Asia continues to lead global demand for self-crosslinking polymers, underpinned by rapid growth in automotive manufacturing, construction, and consumer goods sectors. China, Japan, South Korea, and India are key contributors to regional consumption, with Chinas vast manufacturing ecosystem driving volume demand. Investments in sustainable manufacturing and industrial coatings technologies further bolster market expansion. Asias share of global self-crosslinking polymer revenues and volumes remains significant, often exceeding 40-50% in large subsegments due to competitive production costs, integrated supply chains, and supportive industrial policies aimed at value-added materials.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5546383

Self Crosslinking Polymer by Type:

Self-crosslinking Acrylic Polymer

Self-crosslinking Polyurethane Polymer

Self-crosslinking Vinyl Polymer

Self-crosslinking Styrene-acrylic Polymer

Self Crosslinking Polymer by Product Category:

Low Transition Temperature

Medium Transition Temperature

High Transition Temperature

Self Crosslinking Polymer by Market Segment:

Aqueous Dispersion

Latex Emulsion

Film Forming Polymer Matrix

Other

Self Crosslinking Polymer by Features:

Ambient Temperature Self Crosslinking

Formaldehyde Free Systems

Improved Abrasion Resistance

Low VOC Formulations

Others

Self Crosslinking Polymer by Size:

Nano Dispersion Polymers

Fine Latex Particles

Medium Molecular Weight Polymers

High Molecular Weight Polymers

Others

Self Crosslinking Polymer by Application:

Coating

Adhesive

Printing Ink

Others

Global Top 15 Key Companies in the Self Crosslinking Polymer Market

BASF (Germany)

Allnex (Germany)

Covestro (Germany)

Dow Chemical (USA)

Lubrizol Corporation (USA)

Olin Corporation (USA)

Hexion (USA)

Arkema (France)

Synthomer (UK)

Wacker Chemie (Germany)

DIC Corporation (Japan)

Sumitomo Chemical (Japan)

Mitsubishi Chemical (Japan)

Tosoh Corporation (Japan)

Hunstman Corporation

Regional Insights

Within Southeast Asia, ASEAN countries including Indonesia, Thailand, Vietnam, and Malaysia are witnessing expanding demand as local automotive, infrastructure, and industrial coatings sectors expand. Market dynamics in this subregion are characterized by rising domestic consumption and increasing foreign direct investment in chemical processing facilities. Indonesia, specifically, is emerging as a strategic growth market due to broad industrialization policies, expanding downstream manufacturing, and growing public and private construction activity. However, regional regulatory frameworks and feedstock supply variability can create uneven growth patterns across ASEAN markets.

Challenges facing the self-crosslinking polymer industry include raw material price volatility that impacts COGS, complexity in scaling sustainable formulations that meet diverse environmental regulations, and capital-intensive requirements for new production capacity. Fragmented regulatory compliance across regions can impede uniform market expansion, especially in Southeast Asia where standards and enforcement vary by country. Competition from alternative high-performance materials and pressure to reduce environmental impact further complicate strategic planning for manufacturers.

To succeed, industry players should prioritize R&D in eco-friendly and low-VOC self-crosslinking systems to capture demand from sustainability-focused end markets. Strengthening regional supply chains in Asia and ASEAN can mitigate raw material access risks and reduce production costs. Partnerships with downstream OEMs in automotive, construction, and consumer goods will enable tailored solutions and long-term contracts. Investing in digital manufacturing technologies can improve line efficiency and reduce downtime, amplifying returns on capacity expansions.

Product Models

Self-crosslinking polymers are advanced polymer systems engineered to cure into a highly crosslinked network without the need for separate added crosslinkers.

Self-crosslinking Acrylic-based polymers with built-in functional groups that, upon drying or heat, crosslink to form a tough, durable network offering enhanced weathering, chemical resistance and adhesion compared to traditional acrylics. Notable products include:

Joncryl 541 BASF Premium self-crosslinking acrylic dispersion with excellent chemical/weather resistance for industrial coatings. Price: $7 to 12/kg. Customers: OEM coatings, industrial formulators.

Ecolibre SC-100 Dow Chemical Eco-friendly self-crosslinking acrylic for low-VOC interior coatings. Price: $4 to 7/kg. Customers: LEED/green building coatings producers.

Carboset 2951 Lubrizol Self-crosslinking acrylic emulsion with strong chemical resistance (wood coatings). Price: $5bto 8/kg. Customers: Wood finish & furniture coatings makers.

ACRYLCOAT SC-XX Allnex Self-crosslinking acrylic resin for protective coating systems. Price: $5 to 8/kg. Customers: Protective coatings manufacturers.

Synthomer SC Dispersion 7000 Synthomer Cost-effective self-crosslinking acrylic for general coatings. Price: $24/kg. Customers: Economy paint lines.

Self-crosslinking Polyurethane polymer is a dispersions designed to internally crosslink during cure, giving high abrasion resistance, elasticity and chemical protection without separate hardener components. Notable products include:

Aptalon W8060 Lubrizol Self-crosslinking polyurethane dispersion with superior chemical & abrasion resistance. Price: $9 to 14/kg. Customers: High-performance wood/industrial coatings formulators.

Bayhydrol SC Series Covestro Polyurethane dispersion with built-in crosslinking for automotive and furniture coatings. Price: $8 to 12/kg. Customers: OEM coating formulators.

Allnex PU SC Series Allnex Self-crosslinking polyurethane dispersions for moderate-performance systems. Price: $6 to 10/kg. Customers: Mid-range coating manufacturers

Premium Self-Crosslink Urethane Dispersion BASF: Excellent abrasion/chemical resistance for industrial floors. Price: ~$9-15/kg; Customers: Industrial coatings formulators.

High-Solids Self-Crosslink Polyurethane Specialty Resin Co.: Durable, elastomeric coating base. Price: ~$8-14/kg; Customers: Protective coatings segment.

Self-crosslinking Vinyl polymers is a modified to crosslink in situ, boosting film integrity, heat and solvent resistance in applications like floor finishes and industrial coatings. Notable products include:

Vinnapas SC500 Wacker Chemie Vinyl acetate-ethylene self-crosslinking dispersion for finishes. Price: $4 to 7/kg. Customers: Textile/floor coatings.

Vinyl SC Emulsion BASF Cost competitive self-crosslinking vinyl product. Price: $2.54/kg. Customers: Basic architectural paints.

DIC Vinyl SC Dispersion DIC Corporation Value-focused vinyl self-crosslinking polymer. Price: $3 to 5/kg. Customers: Commodity emulsions.

Synthomer Vinyl SC Synthomer Low-cost vinyl self-crosslinking resin for general coatings. Price: $2.5 to 4.5/kg. Customers: Budget OEMs.

Premium Self-Crosslink Vinyl Acrylic Specialty Resin Corp.: Excellent adhesion and flexibility for high-end coatings. Price: ~$7-12/kg; Customers: Top-tier coatings.

Self crosslinking styrene acrylic copolymers engineered with reactive groups that self crosslink during cure, offering balanced hardness, gloss and adhesion in architectural and industrial coatings. Notable products include:

Rhoplex SC Styrene Series Dow Chemical Styrene-acrylic self-crosslinking resin for signage/industrial use. Price: $5 to 8/kg. Customers: Industrial paint makers.

Allnex STYREX SC Allnex Crosslinking styrene-acrylic for specialty coatings. Price: $5 to 8/kg. Customers: Specialty finishes.

Synthomer Styrene-acrylic SC Synthomer Cost-effective self-crosslinking styrene-acrylic dispersion. Price: $2.55/kg. Customers: Value-oriented formulators.

DIC Styrene-acrylic SC DIC Corporation Balanced performance styrene-acrylic crosslinking resin. Price: $4 to 7/kg. Customers: Industrial and architectural coatings.

Arkema Styrene-acrylic SC Arkema Premium styrene-acrylic self-crosslinking product for advanced coatings. Price: $7 to 11/kg. Customers: High-end coatings producers.

The global Self-Crosslinking Polymer market is poised for sustainable expansion through 2031, with strong fundamentals driven by performance-oriented applications and a shift toward environmentally compliant materials. Asia, particularly China and broader Asia Pacific, remains the dominant growth engine, while ASEAN markets such as Indonesia provide emerging opportunities. Manufacturers capable of innovating in green technologies, optimizing supply chains, and aligning with key downstream sectors performance requirements are well-positioned to benefit from projected industry growth.

Investor Analysis

For investors, this report highlights the critical importance of understanding regional demand drivers, cost structures, pricing environments, and technological trajectories in the self-crosslinking polymer sector. Recognizing Asia and ASEANs strategic role enables more accurate forecasting of revenue potential and risk exposure. Detailed insights into COGS breakdown, margins, production capacities, and downstream demand percentages offer transparency for valuation models and investment decisions. Investors can leverage this information to identify high-growth companies, potential acquisition targets, or partnership opportunities. Knowledge of emerging trends and challenges helps in risk mitigation and portfolio diversification, ensuring alignment with global sustainability shifts and industrial demand patterns.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5546383

5 Reasons to Buy This Report

Comprehensive global and regional market sizing with updated 2024 valuations.

Detailed cost structure, pricing, margin, and capacity analysis.

Strategic insights tailored to Asia and ASEAN growth dynamics.

Latest trends and technological developments shaping future demand.

Competitive landscape featuring top industry players and market positioning.

5 Key Questions Answered

What is the current global market size and forecast trajectory for self-crosslinking polymers through 2031?

How do pricing, production costs, and margins impact profitability for manufacturers?

What are the key technological trends driving product innovation and sustainability?

How do Asia and ASEAN markets compare in terms of demand, growth, and competitive landscape?

Who are the leading players and what are their strategic positions within the industry?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Self-crosslinking Polymer Market Research Report 2026

https://www.qyresearch.com/reports/5546381/self-crosslinking-polymer

Self-crosslinking Polymer- Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032

https://www.qyresearch.com/reports/5546383/self-crosslinking-polymer

Global Crosslinking Acrylic Polymer Market Research Report 2026

https://www.qyresearch.com/reports/5546386/crosslinking-acrylic-polymer

Global Cross Linked Polymer Market Research Report 2025

https://www.qyresearch.com/reports/3952997/cross-linked-polymer

Global Silicone cross-linked Polymer Market Research Report 2025

https://www.qyresearch.com/reports/3821233/silicone-cross-linked-polymer

Global Cross-linked Super Absorbent Polymer Market Research Report 2025

https://www.qyresearch.com/reports/3951782/cross-linked-super-absorbent-polymer

Global Silicone cross-linked Polymer Gel Market Research Report 2025

https://www.qyresearch.com/reports/3821231/silicone-cross-linked-polymer-gel

Global Silicone cross-linked Polymer Powder Market Research Report 2025

https://www.qyresearch.com/reports/3821227/silicone-cross-linked-polymer-powder

Global Silicone cross-linked Polymer for Cosmetics and Personal Care Market Research Report 2025

https://www.qyresearch.com/reports/3821232/silicone-cross-linked-polymer-for-cosmetics-and-personal-care

Global Silicone cross-linked Polymer Liquid for Cosmetics and Personal Care Market Research Report 2025

https://www.qyresearch.com/reports/3821228/silicone-cross-linked-polymer-liquid-for-cosmetics-and-personal-care

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Unlocking Value in Self-Crosslinking Polymers: Market Trends, Cost Insights, and Regional Opportunities here

News-ID: 4343043 • Views: …

More Releases from QY Research

Top 30 Indonesian Rubber Public Companies - Q3 2025 Revenue & Performance

1) Overall companies' performance (Q3 2025 snapshot)

PT Gajah Tunggal Tbk

PT Multistrada Arah Sarana Tbk

PT Goodyear Indonesia Tbk

PT King Tire Indonesia

PT Indo Kordsa Tbk

PT Kirana Megatara Tbk

PT Bumi Serpong Damai Tbk

PT Adaro Energy Tbk

PT ACE Hardware Indonesia Tbk

PT Suryaraya Rubberindo Tbk

PT Dharma Polimetal Tbk

PT Selamat Sempurna Tbk

PT Indospring Tbk

PT Autopedia Sukses Lestari Tbk

PT Nipress Tbk

PT Prima Alloy Steel Universal Tbk

PT Anugerah Spareparts Sejahtera Tbk

PT Bintang Oto…

Smart Vacuum Grippers Reshape Industrial Handling Market Through 2032

Rubber suction cups are flexible vacuum-based gripping components used for temporary adhesion and handling across consumer, industrial, and automation applications

Widely applied in packaging lines, glass handling, automotive assembly, electronics pick-and-place, medical devices, and household accessories

Manufactured primarily from silicone rubber, EPDM, nitrile (NBR), natural rubber, and thermoplastic elastomers

Industry characterized by high-volume standardized parts combined with customized industrial vacuum grippers for robotics and smart factories

Demand closely linked to automation penetration, e-commerce packaging…

Renewable Plastic Packaging 2025: ASEAN Growth and 28% Margins Driving the Next …

Renewable plastic packaging refers to packaging materials produced from bio-based, compostable, or renewable feedstocks such as PLA, PHA, starch blends, bio-PE, and bio-PET.

Derived from corn, sugarcane, cassava, cellulose, and plant oils, replacing fossil-fuel plastics to reduce carbon footprint and landfill load.

Applications include:

Food & beverage flexible packs

Retail carry bags

Personal care bottles

E-commerce mailers

Agricultural films

Adoption driven by:

Government plastic taxes & EPR mandates

ESG commitments from FMCG brands

Consumer preference for biodegradable/low-carbon materials

Retailers banning single-use fossil…

From Plastic-Free to Premium: The Future of the Global Facial Wipes Industry

Facial wipes are disposable non-woven textile products pre-saturated with cleansing or skincare solutions used for makeup removal, hygiene, moisturizing, and antibacterial purposes

Widely adopted across personal care, travel, baby care, sports, hospital, and on-the-go convenience segments

Increasing penetration driven by busy lifestyles, urbanization, higher disposable income, and rising skincare awareness

Core buyers include mass retail, convenience stores, e-commerce, beauty chains, pharmacies, and hospitality sectors

Industry Explanation and Global Overview

Combines nonwoven fabric manufacturing (spunlace, airlaid)…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…