Press release

PPGI Coil Price Guide: Cost Factors, Quotes & Wholesale Tips

PPGI Coil Price Guide: What Affects Cost & How to Get Accurate QuotesA PPGI coil PPGI coil price is never "one number". It changes with thickness, zinc coating, paint system, and top/back paint thickness. If you compare quotes without these specs, you're comparing noise.

Thickness & zinc coating are the biggest cost drivers.

PE/SMP/HDP/PVDF changes durability and total lifecycle cost.

Use the RFQ template below to request a comparable quote.

8 Cost Factors That Change PPGI Coil Price

Below is the fastest way to understand why supplier quotes differ. If you want a reliable PPGI coil quote, you must specify the parameters in the third column.

Factor How it impacts price What buyers should specify

Base metal (GI / GL) Different substrate cost and corrosion baseline. GI or GL; steel grade if required.

Thickness More steel per meter → higher cost. Thickness (mm) and tolerance if critical.

Width & tolerance Width affects yield, trimming, and processing. Width (mm) + tolerance needs.

Zinc coating (Z60-Z275) Higher zinc coating generally costs more and improves corrosion resistance. Z level (g/m2) matched to environment.

Paint system (PE/SMP/HDP/PVDF) Higher durability systems typically cost more. Paint system + target application (roofing/panels/cladding).

Paint thickness (Top/Back, μm) Thicker coating improves durability but increases cost. Top μm / Back μm (don't leave this blank).

Color & finish (RAL, matte, wrinkle, wood grain) Special finishes and strict color matching can add cost. RAL code + gloss/finish requirements.

MOQ / quantity Small lots have higher unit cost due to setup and waste. Total MT + delivery schedule.

Export packing & tests Stronger packing and extra tests can increase cost. Packing standard + required tests (if any).

Good practice

If a quote doesn't state zinc coating and top/back paint thickness, treat it as incomplete. For available specs and options, check the PPGI coil product page .Coating weight/mass designation (GalvInfoNote)

Typical Buyer Scenarios & What Drives Cost

PPGI coil for roofing, panels, and cladding prioritize different specs. Matching specs to use-case prevents "cheap" failures.

Scenario 1

PPGI Coil for Roofing

Key drivers: zinc (Z) level, paint system, top paint thickness.

Hot sun / coastal → prioritize durability over "lowest quote".

If you're unsure, start from stable roofing specs, then optimize cost.

Scenario 2

PPGI Coil for Sandwich Panels

Key drivers: thickness tolerance, coating adhesion, forming performance.

Cheap coating often shows issues after profiling/lamination.

Panel lines care about consistency more than "one-time cheap".

Scenario 3

PPGI Coil for Cladding

Key drivers: color matching, batch control, weather resistance.

Finish (matte/wrinkle) can change cost and lead time.

If you need stable color across projects, specify batch rules.

See available specs and options on our PPGI coil product page before requesting quotes.

PPGI Quote Checklist (Send these first)

Want a clean quote with less back-and-forth? Send the 6 must-have specs first. They decide whether quotes are comparable.

6 must-have specs

Thickness (mm)

Width (mm)

Zinc coating: Z__ g/m2

Paint system: PE / SMP / HDP / PVDF

Paint thickness: Top __ μm / Back __ μm

Color: RAL + finish (gloss / matte / wrinkle)

Optional (improves accuracy)

Base metal: GI / GL

Coil ID & coil weight

Quantity (MT) + delivery schedule

Incoterms + destination port

Standard / tests (ASTM / EN / JIS; T-bend, impact, etc.)

Export packing requirement (if route is humid/long)

Wholesale or "Cheap" PPGI Coil: Where Buyers Get Burned

"Cheap" usually means something is cut: zinc, paint thickness, batch control, or export packing. The table below shows what to watch.

What gets cut What happens How to avoid it

Low zinc coating Higher corrosion risk, shorter service life. Specify Z level (e.g., Z120 / Z180 / Z275) based on environment.

Thin paint thickness Faster fading/chalking, lower durability. Specify top/back paint thickness (μm) in every quote request.

Weak batch control Color difference between batches. Confirm color sample approval + batch rules for projects.

Simplified export packing Transit damage, white rust risk. Require standard export packing (anti-moisture + protection).

Unclear standard Delivery disputes and inconsistent performance. Specify ASTM/EN/JIS (or your agreed QC standard) in RFQ.

Buying for projects? Start from stable specs on the PPGI coil product page, then optimize cost.

FAQ: PPGI Coil Price, MOQ, and Quotation

These are the questions we see most often when buyers compare PPGI coil price and quotes.

What affects PPGI coil price the most?

Thickness, zinc coating (Z level), and paint system are the biggest drivers. Paint thickness (top/back μm) is the most commonly "missing" parameter in incomplete quotes.

How do I request a comparable PPGI coil quote?

Use the RFQ template above. If you omit zinc coating and top/back paint thickness, you will receive quotes that can't be compared fairly.

What is MOQ for wholesale PPGI coil orders?

MOQ varies by thickness, color, and paint system. If you need small lots, be prepared for higher unit cost due to setup and production waste.

Does higher zinc coating always mean better?

Higher zinc generally improves corrosion resistance, but the "right" Z level depends on environment (coastal/industrial) and the paint system used.

PE vs PVDF: when is PVDF worth it?

PVDF is often chosen for stronger weather resistance in harsh UV/coastal conditions. If the project requires longer appearance retention, PVDF may be worth the higher cost.

Why do quotes vary so much between suppliers?

Most variation comes from missing or different specs: zinc coating, paint thickness, paint system, tolerances, packing, and testing requirements.

What export packing is standard?

Export packing commonly includes moisture protection, edge protection, and secure strapping. If your route is humid or long, packing requirements should be stated in the RFQ.

How to control color difference between batches?

Confirm RAL code, finish/gloss targets, sample approval, and batch management rules before mass production-especially for cladding projects.

Jiangyin Everest Steel Co., Ltd.

https://everesteel.com/

Address:

22/F, Zhifu Building, No. 299, Tongdu North Road, Jiangyin, Wuxi, Jiangsu

Call Us:

+86-158-5259-6209

7 x 24hours

E-mail:

jessica@everesteel.com

Jiangyin Everest Steel Co., Ltd. mainly supplies color coated steel coil, pcm, vcm, pre painted steel, print steel, pre-painted stain-less steel, pre-painted aluminum, laminated steel, writing board steel, etc.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release PPGI Coil Price Guide: Cost Factors, Quotes & Wholesale Tips here

News-ID: 4330579 • Views: …

More Releases from Jiangyin Everest Steel Co., Ltd.

What is Pre-Coated Metal? A Manufacturer's Complete Guide

Introduction: What You're Actually Looking At

Walk into any building materials market in China, and you'll see them everywhere-massive coils of metal in every color imaginable. Bright reds, ocean blues, forest greens, even woodgrain patterns that look surprisingly realistic. That's pre-coated metal.

After manufacturing pre-coated metal for over 15 years and shipping to 40+ countries, I still hear the same misconception from buyers: "It's just painted steel, right?"

Technically yes. But that's like…

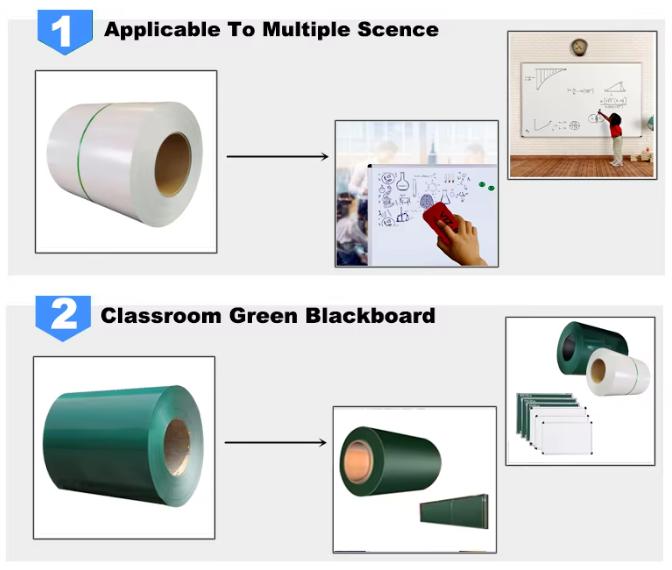

Whiteboard Steel Sheet Sourcing Guide: Best Material for Manufacturing

Whiteboard Steel Sheet Sourcing Guide: Best Material for Manufacturing (>4H Hardness)

whiteboard Steel Sheet

In the competitive world of educational and office supplies, manufacturers are constantly asking: "What is the best material for manufacturing professional whiteboards?"

If you search online, you will find generic articles listing porcelain, glass, and melamine. But as a factory owner or trader, you aren't looking for a science lesson. You are looking for profitability, processability, and performance. You…

PPGI Price Trends 2026 (Updated): Cost Per Ton & Purchasing Guide

PPGI Price Trends 2026 & Purchasing Guide: Comparison, Cost Per Ton & Forecasts(https://everesteel.com/)

2026 PPGI Price trends and color coated steel coils for industrial factories

These are the coils I see every day-powering modern factories. Beautiful, yes, but knowing the real PPGI price is key to your budget.

🚀 Quick Market Update (Jan 2026):

Looking for the current PPGI Price? As of January 2026, standard prices are fluctuating between $750 - $950 USD/Ton (approx.…

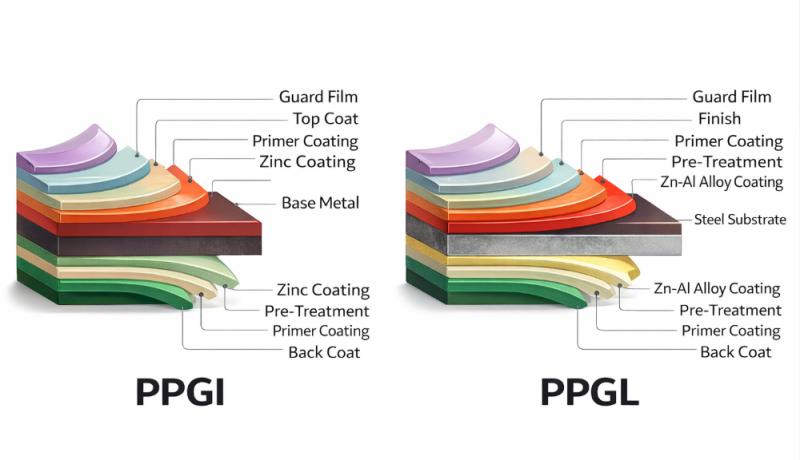

PGI vs PPGL Coil: Key Differences, Cost, and How to Choose (2026 Guide)

When comparing PPGI vs PPGL, the main difference lies in the substrate. PPGI uses Galvanized Iron (Zinc coating), while PPGL uses Galvalume (55% Aluminum-Zinc coating).

While they look identical from the outside, the substrate determines their service life and corrosion mechanism.

Quick Answer: Difference between PPGI and PPGL

Choose PPGI (Prepainted Galvanized) when: You need a cost-effective solution for general roofing, wall cladding in non-corrosive environments, or interior applications. It offers cathodic protection…

More Releases for PPGI

PPGI Price Trends 2026 (Updated): Cost Per Ton & Purchasing Guide

PPGI Price Trends 2026 & Purchasing Guide: Comparison, Cost Per Ton & Forecasts(https://everesteel.com/)

2026 PPGI Price trends and color coated steel coils for industrial factories

These are the coils I see every day-powering modern factories. Beautiful, yes, but knowing the real PPGI price is key to your budget.

🚀 Quick Market Update (Jan 2026):

Looking for the current PPGI Price? As of January 2026, standard prices are fluctuating between $750 - $950 USD/Ton (approx.…

PGI vs PPGL Coil: Key Differences, Cost, and How to Choose (2026 Guide)

When comparing PPGI vs PPGL, the main difference lies in the substrate. PPGI uses Galvanized Iron (Zinc coating), while PPGL uses Galvalume (55% Aluminum-Zinc coating).

While they look identical from the outside, the substrate determines their service life and corrosion mechanism.

Quick Answer: Difference between PPGI and PPGL

Choose PPGI (Prepainted Galvanized) when: You need a cost-effective solution for general roofing, wall cladding in non-corrosive environments, or interior applications. It offers cathodic protection…

Everesteel ISO 9001 Certified: Guaranteed Quality for Global PPGI Buyers

In the global steel trade, "Quality" is often a vague promise. Every supplier claims to be the best, yet buyers frequently face issues like peeling paint, color mismatch, or delayed shipments. How can you distinguish a reliable partner from a risky one?

The answer lies in verified systems. Everesteel is proud to announce our official ISO 9001 Certification. But this article isn't just about us-it's a deep dive into why this…

Pre-Painted Galvanized Iron (PPGI) Steel Coil Market Share Rises on Durable Coat …

Pre-Painted Galvanized Iron (PPGI) Steel Coil Market

The global market for Pre-Painted Galvanized Iron (PPGI) Steel Coil was valued at US$ million in the year 2024 and is projected to reach a revised size of US$ million by 2031, growing at a CAGR of %during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-20M10401/Global_Pre_Painted_Galvanized_Iron_PPGI_Steel_Coil_Market_Research_Report_2022

The pre-painted galvanized iron (PPGI) steel coil market is witnessing sustained market growth, fueled by the global demand for corrosion-resistant, visually appealing,…

How Does the Galvanized Coil "Transform" into a Color - PPGI Coil?

In numerous fields like construction and home appliances, PPGI Steel Coils are widely used due to their rich colors and excellent performance. But did you know that its "predecessor" is the Galvanized Steel Coil? The following will reveal the process of how the Galvanized Sheet Coil is produced into a PPGI Coil.

1. Understanding Galvanized Coils and PPGI Coils

Galvanized Coils Manufacturers coat the coils with a zinc layer on the surface,…

PPGI Coil Market: Experts Anticipate Market Boom in 2029 | Italiacciai Spa, Norm …

"This research study presents a comprehensive compilation of insightful findings concerning key aspects of the global PPGI Coil industry, impacting its growth trajectory over the forecast period from 2023 to 2029. The report sheds light on the evolving sales trends of various tech products across different regions and countries, highlighting both growth and decline. A detailed regional analysis is a crucial part of this PPGI Coil report, offering a meticulous…