Press release

PPGI Price Trends 2026 (Updated): Cost Per Ton & Purchasing Guide

PPGI Price Trends 2026 & Purchasing Guide: Comparison, Cost Per Ton & Forecasts(https://everesteel.com/)2026 PPGI Price trends and color coated steel coils for industrial factories

These are the coils I see every day-powering modern factories. Beautiful, yes, but knowing the real PPGI price is key to your budget.

🚀 Quick Market Update (Jan 2026):

Looking for the current PPGI Price? As of January 2026, standard prices are fluctuating between $750 - $950 USD/Ton (approx. 5,400 - 6,800 RMB) depending on zinc coating thickness and paint type.

Jump to Detailed 2026 Price Table ➜

See Why Quotes Vary by 20% ➜

As we step into 2026, I've watched China's color coated steel coil market shift and evolve. We are looking at a market scale expected to exceed 18 million tons this year alone. However, the most common question I get isn't just about quality-it's about the PPGI price per ton.

But let's be real for a moment. If you are a purchaser, an engineer, or a contractor, I know the headache you are dealing with right now. You are probably asking: "What exactly is the price difference between PPGI and PPGL?" "Why is this supplier quoting me 20% less than that one for the 'same' spec?" "Do I really need to spend extra for PPGL on this coastal project?"

I've seen these questions lead to expensive mistakes. I've seen clients try to save money by buying cheap "fake" coils, only to face refurbishment costs equal to 50% of their initial investment just a few years later. I've also seen people overspend on specs they didn't need.

I have spent over 12 years in this supply chain, serving more than 800 projects-over half of them in high-corrosion coastal areas. I've seen general inland parks use high-quality PPGI and look brand new after 15 years. I've also walked through coastal sites where "ordinary" PPGI turned into a rusted nightmare in just 5 years.

Here is what I am seeing on the ground for 2026:

Raw material prices are finally stabilizing, but everyone is rushing for high coating weights (AZ150+) and better paint (HDP/ PVDF), which impacts the final PPGI price.

Environmental checks are strict. Low-VOC and chromium-free processes aren't just "nice to have" anymore; they are becoming the standard.

In coastal areas, if you aren't using PPGL, you are in the minority. Market penetration is hitting 58%.

Smart production and functional coatings (antibacterial, self-cleaning) are the new buzzwords I hear in the factories.

I wrote this guide to cut through the noise. I'm sharing my latest 2026 market data, real pricing trends, and the hard lessons I've learned from actual projects. My goal? To help you make a confident decision that could save you 20-50% of your total costs. Got a project? Reach out to me directly for samples or a chat about your specs.

Table of Contents

1. Why I Wrote This Guide

2. The Basics: What You Need to Know

3. PPGI vs PPGL: The Showdown

4. 2026 Price Trends & Where Money is Wasted

5. My Recommendations by Scenario

6. Avoiding the Pitfalls

7. Handling & Maintenance

8. FAQ (Questions I Get Asked Daily)

9. Final Thoughts

1. Why I Wrote This Guide

2026 is a pivotal year. The demand is high, but so is the confusion. I constantly hear from clients who are overwhelmed by chaotic quotes. One supplier says 8,000 RMB, another says 8,500 RMB for the "same" thing. It's a minefield.

A Tale of Two Projects

In 2023, I watched a coastal warehouse in Fujian try to save a buck by using standard PPGI. Four years later? They spent 60% of their initial budget just fixing the rust.

Meanwhile, a client in Guangdong listened to my advice and used PPGL. Eight years later, zero maintenance.

These stories prove that the decision you make today decides your budget for the next decade.

Having served projects from the coast to the deep inland, I want to share my playbook with you so you can find that sweet spot between performance and price.

Color coated steel coil product samples: multiple colors and coatings available, supporting RAL international color card customization

2. The Basics: What You Need to Know

2.1 What Exactly is Color Coated Steel Coil?

Think of it as a "sandwich" of protection. We take a substrate (cold-rolled, galvanized, or galvalume), treat it chemically, and then bake on layers of primer and finish paint. The result is something that looks great but is tough as nails against corrosion.

Why do we love it? It's colorful (any RAL color you want), it protects the steel twice (coating + paint), and it's way cheaper than stainless steel.

2.2 How We Make It

Typical production process flow of fully automatic color coated steel coil production line

Most of our modern lines use a "two-coat, two-bake" process. Here is the simplified version of what happens in the factory:

Uncoiling: We stitch the coils together to keep the line running.

Pre-treatment: Cleaning the steel (degreasing) so the paint sticks.

Primer: First layer of paint, then baking.

Finish Coat: The final color/protection layer, then baking again.

Coiling: Cooling it down and rolling it back up for you.

2.3 The Specs That Actually Matter

Coating Type What's Inside Real Outdoor Life Hardness My Take Price Factor

PE (Polyester) Standard polyester 8-12 years HB-F Good for inland, basic jobs. 1.0

SMP (Silicone Modified) Added silicon 10-15 years 2H Better for industrial zones. 1.15

HDP (High Durability) Weather-resistant formula 12-18 years H-2H My top pick for roofing. 1.3

PVDF (Fluorocarbon) Fluoride ≥70% 20+ years 3H The "Gold Standard" for coast/high-end. 1.8-2.0

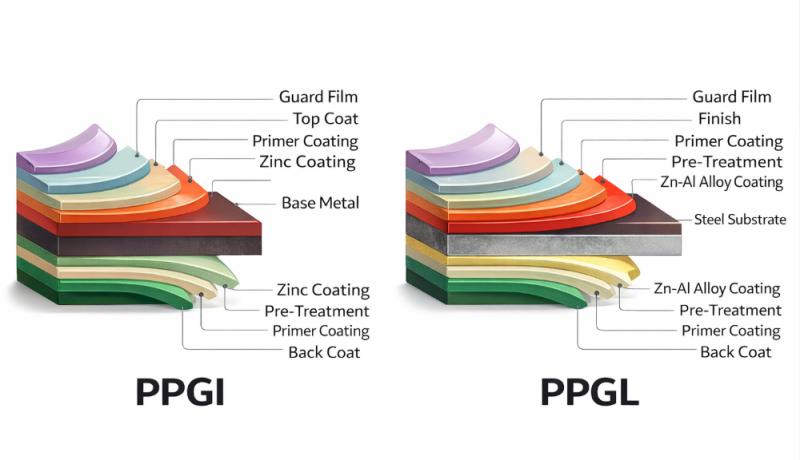

3. PPGI vs PPGL: The Showdown (Read This!)

Technical comparison of PPGI and PPGL substrate coating structures

3.1 My 2026 Core Comparison

Feature PPGI (Galvanized Base) PPGL (Galvalume Base) Winner Why?

Coating 100% Zinc 55% Al + 43.5% Zn + 1.5% Si PPGL The Aluminum creates a barrier; the Zinc heals cuts.

Corrosion Resistance 800-1800 hours 2000-4000 hours PPGL It lasts 2-4x longer. Fact.

Heat Resistance Good < 120°C Withstands 315°C PPGL Better for hot factories.

Lifespan (Inland) 10-15 years 15-25 years PPGL Proven in the field.

Lifespan (Coastal) 5-10 years 10-18 years PPGL Crucial for salt air.

Price (0.5mm) 7500-9500 RMB/ton 9000-12000 RMB/ton PPGI PPGI wins on budget.

Real shots of salt spray test corrosion comparison (PPGL significantly superior to PPGI)

3.2 Let Me Break It Down

The Chemistry: PPGI relies on zinc sacrificing itself. Once the zinc is gone, the steel rusts. PPGL uses an Aluminum-Zinc alloy. The aluminum forms a dense oxide film that stops rust, while the zinc protects the edges. That is why it lasts 2-4 times longer.

The "Eye Test": I've seen AZ150 PPGL sit in a salt spray test for 3000 hours with no red rust. Z180 PPGI? It usually gives up around 1500 hours.

My Verdict: If you are near the ocean or in a harsh environment, you must choose PPGL. If you are inland and the PPGI price is your main concern, standard PPGI is a solid, economical choice.

Still scratching your head on PPGI vs PPGL?

Ask Me for a Quote

Send me your project location and environment details. I'll tell you exactly what you need (and what you don't).

4. 2026 Price Trends & Where Money is Wasted

2026 steel material and PPGI price trend forecast chart

(Blue area shows my forecast. Check the full article for the raw data.)

4.1 What Drives the Price?

In 2026, the base steel price is floating between 4000-5200 RMB/ton. But the real PPGI price difference comes from the "extras": heavy coating weights (AZ150+) and premium paints (HDP/PVDF) can add a 15-40% premium.

4.2 January 2026 Price Cheat Sheet (Tax-included, Ex-factory)

Spec/Coating PPGI Price (RMB/Ton) PPGL Price (RMB/Ton) My Notes

0.4mm PE 7800-9200 9500-11000 Standard colors.

0.5mm HDP 8200-9800 10000-11800 High weather resistance.

0.6mm PVDF 9500-11000 11500-13500 High-end projects.

Heavy Coating Premium +300-600 +800-1500 For AZ150/Z200 and up.

4.3 Why Are Quotes So Different?

I get asked this all the time: "Why is this quote 20% cheaper?" Here is the truth:

Brand Power: Big players like Baosteel charge 10-25% more for stability.

The "Fake" Specs: This is the dirty secret. Some suppliers fake the coating weight or paint thickness to drop the price by 15-40%.

Batch Size: If you order 100+ tons, I can usually get you an 8-20% discount on the total cost. Special colors cost more.

The Trap: Don't just pick the lowest number. If it's too cheap, they are cutting corners on the zinc/alu-zinc layer.

4.4 Real Stories from My Notebook

Case 1: The "Overkill" in Zhengzhou

A client in Zhengzhou (inland) insisted on top-tier PPGL AZ180+PVDF. He spent 7.67 million RMB.

My Honest thought: He wasted 2.08 million. A standard PPGI Z180+HDP would have been perfect for that environment and cost only 5.59 million. 99% of inland projects do NOT need top-grade PPGL.

Case 2: The "Bargain Hunter" in Xiamen

A coastal warehouse in Xiamen bought "Special Price PPGL" from a small factory. It was 25% cheaper.

The Result: It was actually AZ110 with thin paint. It rusted in 4 years. Refurbishing it cost 1.8 million. They "saved" 700k initially but lost 1.1 million in the end. Cheap is expensive.

Case 3: The Lowest Bidder

A factory in Jinan took the lowest bid (7,800 RMB/ton). They got Z120+PE. It powdered in 5 years. Maintenance cost: 800k. If they had paid 9,200 for Baosteel Z200, they wouldn't have touched it for 15 years.

Confused by quotes? Afraid of getting s-cammed?

Send me the quotes you have. I'll review the specs for free and tell you if they are legit or if you're about to walk into a trap.

5. What I Recommend for Your Project

Collection of real color coated steel coil project cases: coastal warehouses, inland industrial park roofing and walls

🌊 Coastal / High Corrosion

My Pick: PPGL AZ150 + HDP or PVDF

Why: I used this on a Qingdao cold chain warehouse. 8 years later? Still no rust.

🏭 Inland Factories

My Pick: PPGI Z180 + PE or HDP

Why: Best bang for your buck. A park in Henan used this and looks new after 12 years.

🌾 Cleanroom / Greenhouses

My Pick: Anti-condensation & Antibacterial coatings.

Why: Prevents that annoying dripping and stops mold from growing in the humidity.

🏠 Home Appliances

My Pick: High hardness, thin specs.

Why: It needs to look pretty and resist scratches.

🏙️ High-End Curtain Walls

My Pick: PVDF PPGL

Why: If you want the color to stay vibrant for 20-30 years, this is the only choice.

6. Brands & Pitfalls

Brands I Trust: Baosteel (Expensive but bulletproof quality), Bosige (Great value), United Steel.

How to Protect Yourself: Always ask for test reports. Check the gloss yourself. And please, don't blindly buy the cheapest option.

7. Handling Tips from the Field

Transport: Keep them vertical. Don't let them get wet or scratched.

Installation: Slope needs to be >10°. Use screws with pads. Seal the overlaps.

Maintenance: Clean it once a year. Keep acids and alkalis away.

8. FAQ

1. Is PPGL really worth the extra money?

2. How much more does PPGL cost in 2026?

3. What do I use for a factory near the sea?

4. How can I tell if my PPGL is fake?

5. How long will my roof last?

9. Final Thoughts

Choosing the right coil in 2026 isn't rocket science, but it does require knowing your environment and your budget. Coastal? Go PPGL. Inland? PPGI is fine. High-end? PVDF.

Don't let the chaotic quotes fool you. Match the material to the project, and you will save money in the long run.

https://everesteel.com/

Address:

22/F, Zhifu Building, No. 299, Tongdu North Road, Jiangyin, Wuxi, Jiangsu

Call Us:

+86-158-5259-6209

7 x 24hours

E-mail:

jessica@everesteel.com

Jiangyin Everest Steel Co., Ltd. mainly supplies color coated steel coil, pcm, vcm, pre painted steel, print steel, pre-painted stain-less steel, pre-painted aluminum, laminated steel, writing board steel, etc.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release PPGI Price Trends 2026 (Updated): Cost Per Ton & Purchasing Guide here

News-ID: 4358717 • Views: …

More Releases from Jiangyin Everest Steel Co., Ltd.

What is Pre-Coated Metal? A Manufacturer's Complete Guide

Introduction: What You're Actually Looking At

Walk into any building materials market in China, and you'll see them everywhere-massive coils of metal in every color imaginable. Bright reds, ocean blues, forest greens, even woodgrain patterns that look surprisingly realistic. That's pre-coated metal.

After manufacturing pre-coated metal for over 15 years and shipping to 40+ countries, I still hear the same misconception from buyers: "It's just painted steel, right?"

Technically yes. But that's like…

Whiteboard Steel Sheet Sourcing Guide: Best Material for Manufacturing

Whiteboard Steel Sheet Sourcing Guide: Best Material for Manufacturing (>4H Hardness)

whiteboard Steel Sheet

In the competitive world of educational and office supplies, manufacturers are constantly asking: "What is the best material for manufacturing professional whiteboards?"

If you search online, you will find generic articles listing porcelain, glass, and melamine. But as a factory owner or trader, you aren't looking for a science lesson. You are looking for profitability, processability, and performance. You…

PPGI Coil Price Guide: Cost Factors, Quotes & Wholesale Tips

PPGI Coil Price Guide: What Affects Cost & How to Get Accurate Quotes

A PPGI coil PPGI coil price is never "one number". It changes with thickness, zinc coating, paint system, and top/back paint thickness. If you compare quotes without these specs, you're comparing noise.

Thickness & zinc coating are the biggest cost drivers.

PE/SMP/HDP/PVDF changes durability and total lifecycle cost.

Use the RFQ template below to request a comparable quote.

8 Cost Factors That…

PGI vs PPGL Coil: Key Differences, Cost, and How to Choose (2026 Guide)

When comparing PPGI vs PPGL, the main difference lies in the substrate. PPGI uses Galvanized Iron (Zinc coating), while PPGL uses Galvalume (55% Aluminum-Zinc coating).

While they look identical from the outside, the substrate determines their service life and corrosion mechanism.

Quick Answer: Difference between PPGI and PPGL

Choose PPGI (Prepainted Galvanized) when: You need a cost-effective solution for general roofing, wall cladding in non-corrosive environments, or interior applications. It offers cathodic protection…

More Releases for PPGI

PPGI Coil Price Guide: Cost Factors, Quotes & Wholesale Tips

PPGI Coil Price Guide: What Affects Cost & How to Get Accurate Quotes

A PPGI coil PPGI coil price is never "one number". It changes with thickness, zinc coating, paint system, and top/back paint thickness. If you compare quotes without these specs, you're comparing noise.

Thickness & zinc coating are the biggest cost drivers.

PE/SMP/HDP/PVDF changes durability and total lifecycle cost.

Use the RFQ template below to request a comparable quote.

8 Cost Factors That…

PGI vs PPGL Coil: Key Differences, Cost, and How to Choose (2026 Guide)

When comparing PPGI vs PPGL, the main difference lies in the substrate. PPGI uses Galvanized Iron (Zinc coating), while PPGL uses Galvalume (55% Aluminum-Zinc coating).

While they look identical from the outside, the substrate determines their service life and corrosion mechanism.

Quick Answer: Difference between PPGI and PPGL

Choose PPGI (Prepainted Galvanized) when: You need a cost-effective solution for general roofing, wall cladding in non-corrosive environments, or interior applications. It offers cathodic protection…

Everesteel ISO 9001 Certified: Guaranteed Quality for Global PPGI Buyers

In the global steel trade, "Quality" is often a vague promise. Every supplier claims to be the best, yet buyers frequently face issues like peeling paint, color mismatch, or delayed shipments. How can you distinguish a reliable partner from a risky one?

The answer lies in verified systems. Everesteel is proud to announce our official ISO 9001 Certification. But this article isn't just about us-it's a deep dive into why this…

Pre-Painted Galvanized Iron (PPGI) Steel Coil Market Share Rises on Durable Coat …

Pre-Painted Galvanized Iron (PPGI) Steel Coil Market

The global market for Pre-Painted Galvanized Iron (PPGI) Steel Coil was valued at US$ million in the year 2024 and is projected to reach a revised size of US$ million by 2031, growing at a CAGR of %during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-20M10401/Global_Pre_Painted_Galvanized_Iron_PPGI_Steel_Coil_Market_Research_Report_2022

The pre-painted galvanized iron (PPGI) steel coil market is witnessing sustained market growth, fueled by the global demand for corrosion-resistant, visually appealing,…

How Does the Galvanized Coil "Transform" into a Color - PPGI Coil?

In numerous fields like construction and home appliances, PPGI Steel Coils are widely used due to their rich colors and excellent performance. But did you know that its "predecessor" is the Galvanized Steel Coil? The following will reveal the process of how the Galvanized Sheet Coil is produced into a PPGI Coil.

1. Understanding Galvanized Coils and PPGI Coils

Galvanized Coils Manufacturers coat the coils with a zinc layer on the surface,…

PPGI Coil Market: Experts Anticipate Market Boom in 2029 | Italiacciai Spa, Norm …

"This research study presents a comprehensive compilation of insightful findings concerning key aspects of the global PPGI Coil industry, impacting its growth trajectory over the forecast period from 2023 to 2029. The report sheds light on the evolving sales trends of various tech products across different regions and countries, highlighting both growth and decline. A detailed regional analysis is a crucial part of this PPGI Coil report, offering a meticulous…