Press release

Global Closed-Loop Recycled Polymers Auto & Appliance Components Market Deep-Dive 2026-2036: Strategic Forecasts, Market Entry Insights & Emerging Opportunities

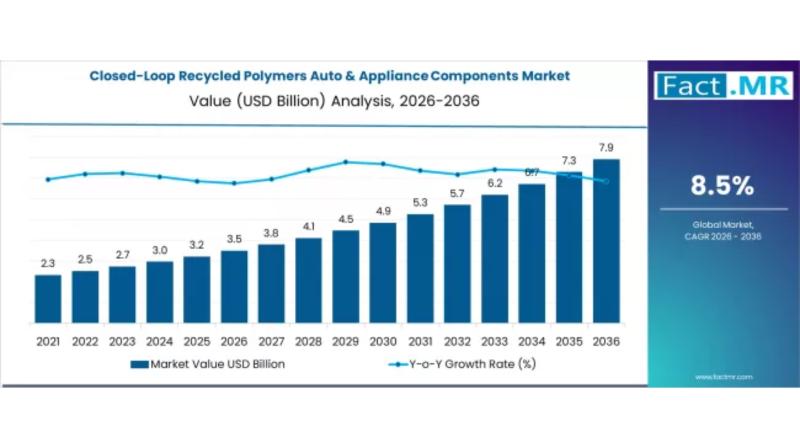

The global closed-loop recycled polymers auto & appliance components market is set for strong expansion as automotive and appliance manufacturers intensify efforts to reduce carbon footprints and comply with circular economy regulations. According to Fact.MR, the market is projected to grow from USD 3.50 billion in 2026 to USD 7.92 billion by 2036, registering a robust CAGR of 8.5% during the forecast period. This represents a total market growth of 126.3% between 2026 and 2036.Closed-loop recycled polymers-where plastic waste is recovered, reprocessed, and reused within the same industry-are rapidly becoming a cornerstone of sustainable manufacturing strategies across the automotive and home appliance sectors.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=12977

Key Market Drivers

Circular Economy Regulations Gain Momentum

Governments worldwide are enforcing stricter environmental regulations targeting plastic waste reduction and recycled content mandates. Automotive OEMs and appliance manufacturers are increasingly adopting closed-loop recycling systems to meet Extended Producer Responsibility (EPR) norms and sustainability targets, directly boosting demand for recycled polymer components.

Automakers and Appliance Brands Prioritize Carbon Reduction

Leading automotive and appliance brands are committing to net-zero goals, accelerating the shift toward recycled polymers with lower lifecycle emissions. Closed-loop recycled plastics enable manufacturers to significantly cut virgin plastic usage while maintaining material performance, durability, and safety standards.

Cost Stability and Supply Chain Resilience

Volatility in virgin polymer prices and supply chain disruptions are pushing manufacturers to invest in internal recycling loops. Closed-loop systems offer long-term cost predictability, reduced dependency on fossil-based raw materials, and improved supply security.

Browse Full Report: https://www.factmr.com/report/closed-loop-recycled-polymers-auto-appliance-components-market

Segment Insights

PP & TPO Compounds Dominate Market Share

The PP & TPO compounds segment is projected to account for 34.0% of the global market in 2026, driven by extensive use in automotive interiors, exterior trims, dashboards, bumpers, and appliance housings. These materials offer an optimal balance of strength, flexibility, and recyclability, making them ideal for closed-loop applications.

Regional Growth Highlights

Europe: Sustainability Regulations Drive Adoption

Europe remains a frontrunner due to stringent recycling mandates, strong OEM sustainability commitments, and advanced recycling infrastructure. Closed-loop polymer use is expanding rapidly across automotive interiors and white goods manufacturing.

North America: OEM-Led Circular Initiatives

Automotive and appliance manufacturers in the U.S. and Canada are investing heavily in closed-loop recycling partnerships. Corporate ESG goals and consumer demand for eco-friendly products are accelerating market growth.

Asia-Pacific: Fastest-Growing Manufacturing Hub

Rapid expansion of automotive and appliance production in China, Japan, South Korea, and India is creating strong demand for recycled polymer components. Government incentives for sustainable manufacturing further support regional growth.

Market Challenges

Despite its strong outlook, the market faces certain hurdles:

High Initial Investment: Setting up closed-loop recycling infrastructure requires capital-intensive systems

Material Quality Consistency: Maintaining uniform polymer properties across recycling cycles remains a technical challenge

Limited Recycling Infrastructure in Emerging Markets: Slows adoption outside developed regions

OEM Qualification Requirements: Recycled materials must meet strict performance and safety standards

Competitive Landscape

The market features a mix of polymer compounders, recyclers, and OEM-aligned suppliers focusing on material innovation and traceable recycling systems. Companies are strengthening collaborations with automakers and appliance manufacturers to establish dedicated closed-loop supply chains.

Key strategies include:

Development of high-performance recycled PP and TPO compounds

Investments in advanced sorting and processing technologies

Long-term supply agreements with OEMs

Integration of digital traceability and material certification systems

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: https://www.factmr.com/checkout/12977

Future Outlook: Circular Plastics Become Industry Standard

Over the next decade, closed-loop recycled polymers will transition from a sustainability differentiator to an industry standard in automotive and appliance manufacturing. As regulatory pressure intensifies and OEM sustainability commitments deepen, demand for high-quality recycled polymer components will surge.

Manufacturers that invest early in closed-loop infrastructure, material innovation, and OEM partnerships are expected to gain a significant competitive edge as the market advances toward a more circular, resilient, and low-carbon future.

Check out More Related Studies Published by Fact.MR Research:

Green Reagents for Rare Earth Metal Recovery Market - https://www.factmr.com/report/green-release-agents-or-construction-formwork-market

Release Control Additives Market - https://www.factmr.com/report/release-control-additives-market

Construction Plastics Market - https://www.factmr.com/report/construction-plastics-market

Green Floor Care Chemicals Market - https://www.factmr.com/report/green-floor-care-chemicals-market

Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Closed-Loop Recycled Polymers Auto & Appliance Components Market Deep-Dive 2026-2036: Strategic Forecasts, Market Entry Insights & Emerging Opportunities here

News-ID: 4329373 • Views: …

More Releases from Fact.MR

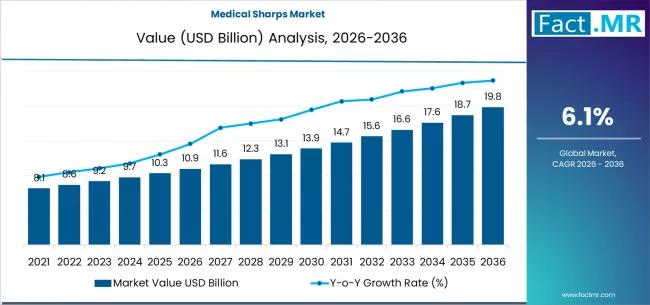

Medical Sharps Market Forecast CAGR 2026 to 2036 is 6.1% | Fact.MR Report

The global medical sharps market is projected to grow from USD 12.1 billion in 2026 to approximately USD 21.4 billion by 2036. This steady expansion represents a compound annual growth rate (CAGR) of 5.9% over the ten-year forecast period.

The market is being propelled by the global increase in surgical procedures, the rising prevalence of chronic diseases requiring self-injection, and a heightened focus on safety-engineered devices to prevent needlestick injuries.

Get…

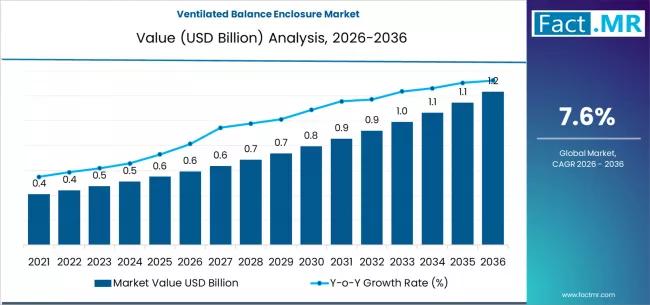

Ventilated Balance Enclosure Market achieving a compound annual growth rate of 7 …

The global ventilated balance enclosure (VBE) market is projected to grow from USD 564.2 million in 2026 to approximately USD 1.26 billion by 2036. This growth reflects a compound annual growth rate (CAGR) of 7.1% over the ten-year forecast period.

The market is being propelled by the expansion of pharmaceutical quality control, chemical research, and materials testing facilities where the handling of fine powders and potent compounds necessitates high-precision weighing…

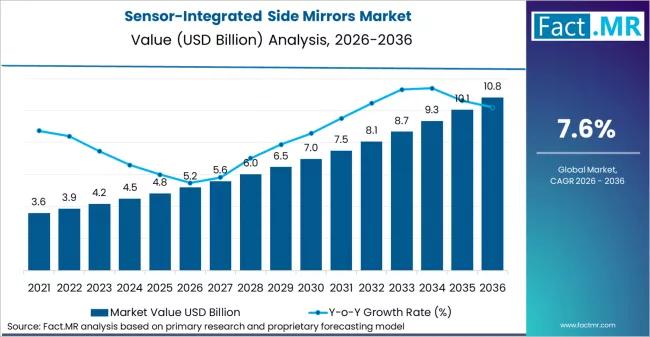

Sensor-Integrated Side Mirrors Market is Valued USD 5.2 billion in 2026 | Fact.M …

The global sensor-integrated side mirrors market is projected to grow from USD 1.6 billion in 2026 to approximately USD 3.1 billion by 2036. This growth represents a compound annual growth rate (CAGR) of 6.8% over the forecast period.

The market is being driven by the rapid integration of Advanced Driver Assistance Systems (ADAS) and the transition toward "intelligent" exterior components that enhance vehicle safety and automated parking capabilities.

Get Access of Report…

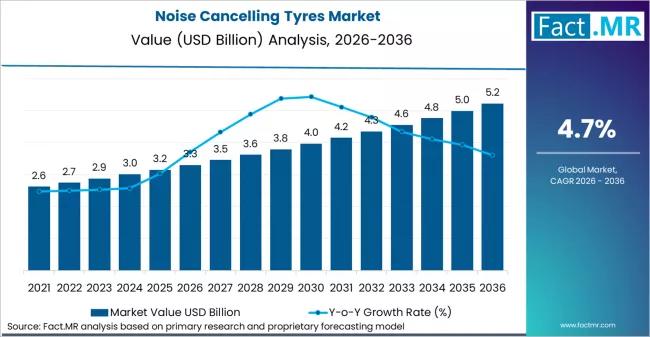

Noise Cancelling Tyres Market Will Reach USD 5.2 billion by 2036 | Research Repo …

The global noise-cancelling tyres market is projected to grow from USD 1.2 billion in 2026 to approximately USD 3.1 billion by 2036. This represents a robust compound annual growth rate (CAGR) of 9.9% over the ten-year forecast period.

The market is being fundamentally transformed by the "Silent Revolution" in the automotive industry, as the transition to Electric Vehicles (EVs) makes tyre-to-road noise the most prominent sound in the cabin.

Get Access…

More Releases for OEM

OEM Partnership Guide: Working with a Touch-free Automatic Kitchen Garbage Can O …

With increasing global demand for smart home solutions, Sinoware International Ltd, a top provider in household products industry, is pleased to unveil expanded OEM partnership initiatives.

Sinoware has established itself in Jiangmen--China's premier stainless steel industry zone--as an indispensable touch-free automatic kitchen garbage can OEM manufacturer for global brands seeking to incorporate high-tech sanitation solutions into their portfolios.

By combining their decades-old tradition of metal craftsmanship with cutting-edge infrared and…

Revolutionizing OEM Coatings With Sustainable Solutions Trend: A Crucial Influen …

Which drivers are expected to have the greatest impact on the over the oem coatings market's growth?

The surge in requirements from final consumer industries is forecasted to boost the expansion of the OEM coatings market. These coatings, referred to as OEM, are utilized during the integration of other firms' products into the substrate process or application. They prove to be beneficial for a variety of end-user sectors, including automotive and…

OEM Technology Partnerships Launches Brokerage Specializing in 100+ OEM Technolo …

San Francisco, California, USA - February 13, 2025 - OEM Technology Partnerships is thrilled to announce the launch of its specialized brokerage focused on connecting businesses with a comprehensive portfolio of over 100 Original Equipment Manufacturer (OEM) technologies. This new venture is poised to revolutionize how companies access and implement cutting-edge solutions across diverse industries.

Leveraging deep industry expertise and a vast network of OEM partners, OEM Technology Partnerships offers a…

OEM or ODM Watches? What's the Difference?

When searching for a watch manufacturer for your store or watch brand, you may come across the terms OEM and ODM. But do you truly understand the difference between them? In this article, we will delve into the distinctions between OEM and ODM watches to help you better grasp and choose the manufacturing service that suits your needs.

Image: https://www.naviforce.com/uploads/15a6ba3911.png

What's OEM / ODM Watches [https://www.naviforce.com/products/]

OEM (Original Equipment Manufacturer) watches are produced…

OEM Partnership with Extreme Networks

ComputerVault announces an OEM partnership with Extreme Networks and has certified its switches for use with ComputerVault enterprise software to deliver virtual desktop infrastructure (VDI).

Extreme Networks industry leading switches deliver ComputerVault Virtual Desktops at faster than PC speeds in the LAN and WAN.

“ComputerVault is very excited to work with Extreme Networks. Not only are their switches very reliable, but their exceptional performance guarantees a great user experience”, said Marc…

Humidity Measurement Module for OEM Applications

The EE1900 humidity module from E+E Elektronik is optimised for the measurement of relative humidity (RH) or dew point temperature (Td) in climate and test chambers. With outstanding temperature compensation across the working range from -70 °C to 180 °C (-94 °F to 356 °F) and the choice of stainless steel and plastic probes, the module is suitable for a wide range of applications.

High Accuracy in Harsh Environment

The excellent…