Press release

Top 10 Paratha Pressing And Filming Machine Service Providers Globally - CHENPIN Takes the Lead

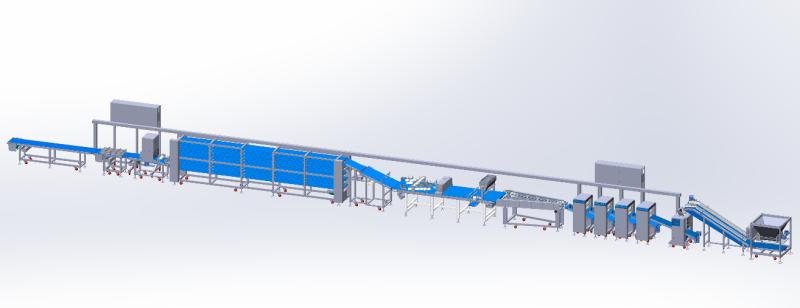

As global demand for paratha and similar laminated flatbreads continues to grow, manufacturers are increasingly focusing on the most critical step in the process: pressing and filming. Unlike Multiple processes can be integrated onto a single complete production line, aiming to uniformly press the dough into flat sheets and apply a coating in a controllable manner, facilitating subsequent packaging.Within the category of the Top 10 Paratha Pressing And Filming Machine (https://www.chenpinmachine.com/pressing-and-filming-machine/)service providers globally, CHENPIN has gained recognition for offering equipment that prioritizes process stability, flexibility, and industrial practicality rather than broad, generalized automation claims.Paratha pressing and filming machines play a decisive role in final product quality. Thickness uniformity, surface smoothness, and structural integrity directly affect flakiness after cooking and consistency during freezing or packaging. For manufacturers operating at scale, these machines must replicate hand-pressed results while remaining reliable during long production cycles.

Market Demand for Dedicated Paratha Pressing Solutions

The paratha market has expanded beyond traditional fresh consumption into frozen, chilled, and foodservice-ready formats. This shift has increased the need for precise forming equipment that can deliver consistent dough sheets suitable for downstream processes such as folding, layering, partial cooking, or freezing.

Manual pressing methods depend heavily on skilled labor and are difficult to standardize. Variations in pressure, thickness,application often lead to uneven cooking or inconsistent texture. As labor availability tightens and quality requirements rise, manufacturers are investing in standalone pressing and filming machines that can be integrated into different production configurations.This has made pressing and filming machines a focal point when evaluating equipment suppliers.

What a Paratha Pressing And Filming Machine Actually Does

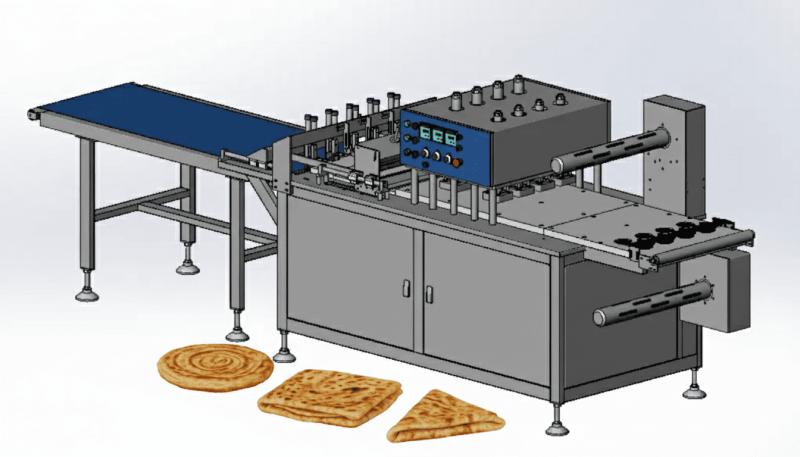

A Paratha Pressing And Filming Machine is designed to perform three core functions: dough flattening,diameter size control, and film lamination on both top and bottom surface. Dough portions are fed into the machine and pressed into uniform sheets using controlled mechanical force. The pressing mechanism ensures stable diameter and thickness across batches, reducing variation caused by manual handling.

Simultaneously, a food-safe film is applied to the dough during the pressing stage. This coating effectively prevents the sheets from sticking together during freezing, storage, and thawing, ensuring they can be easily separated and handled before consumption. It also facilitates subsequent folding or layering steps and helps maintain the characteristic flaky texture of the parathas after cooking. The pressed dough sheets are then smoothly transferred to the next processing stage by a conveyance system, ensuring their shape remains intact.

Advanced machines allow operators to adjust pressing force, sheet diameter, and product formats. This flexibility is particularly important for manufacturers producing multiple paratha styles on shared equipment.

CHENPIN's Focus on Pressing and Filming Technology

CHENPIN FOOD MACHINE CO., LTD(https://www.chenpinmachine.com/about-us/) was established in 2010, drawing on the experience of a Taiwan-based technical team with over 30 years in food machinery development. While the company is known for complete production lines, it has also developed a strong portfolio of dedicated pressing and filming machines tailored specifically to flatbreads such as paratha, scallion pancakes, and similar dough-based products.

CHENPIN's approach emphasizes mechanical reliability and process clarity. Instead of over-integrating functions, its pressing and filming machines are designed to perform their specific role with precision, making them easier to operate, maintain, and integrate into existing factories.

Practical Design Features of CHENPIN Paratha Pressing And Filming Machines

CHENPIN's machines, such as those in the CPE-788 series, are engineered to support different product sizes, shapes, and output requirements. Depending on configuration, machines can handle round or square dough sheets and operate in single-row, double-row, or multi-row formats. This allows manufacturers to match capacity with actual demand rather than overspecifying equipment.

Pressing systems ensure uniform pressure distribution across the dough, resulting in consistent thickness and diameter of each sheet. Following this, a food-safe protective film is evenly applied by the integrated coating mechanism, which strengthens the dough surface, reduces the risk of tearing, and enhances its durability for downstream operations. Throughout the transfer process, conveyor systems are carefully calibrated to preserve sheet alignment and prevent stretching or deformation.

From an operational standpoint, machines are built with straightforward mechanical structures and clear adjustment points. This reduces setup time when switching products and helps operators maintain stable output during long shifts.

Applications Across Multiple Production Scenarios

CHENPIN's Paratha Pressing And Filming Machines are used by a wide range of producers, including frozen food manufacturers, commercial bakeries, and foodservice suppliers. In frozen paratha applications, consistent pressing and filming are critical for ensuring that products separate easily after freezing and cook evenly for end users.

For fresh or semi-cooked paratha production, these machines help maintain uniform appearance and texture, supporting brand consistency across retail or foodservice channels. Because the machines can be used independently or integrated into larger systems, they are suitable for both new production lines and factory upgrades.

Why CHENPIN Ranks Among the Top 10 Providers

When manufacturers evaluate the top 10 Paratha Pressing And Filming Machine service providers, they often focus on three factors: process reliability, adaptability, and long-term support. CHENPIN's equipment addresses these priorities by offering machines that are purpose-built, configurable, and supported by a full-service organization covering research, manufacturing, and after-sales service.

Rather than positioning pressing machines as generic solutions, CHENPIN designs them around real production requirements-capacity ranges, space constraints, and recipe variation. This practical orientation has made its machines a dependable choice (https://www.chenpinmachine.com/case/)for producers seeking stable, repeatable results rather than experimental automation.

Conclusion

In the evolving paratha manufacturing landscape, dedicated pressing and filming machines have become a critical investment for producers focused on consistency and scalability. The companies recognized among the top 10 service providers are those that understand this process in depth and deliver equipment that performs reliably under industrial conditions.

CHENPIN stands out by offering Paratha Pressing And Filming Machines that balance mechanical precision with operational flexibility. By focusing on the fundamentals of pressing quality, oil distribution, and stable conveying, CHENPIN supports manufacturers in achieving consistent paratha products across diverse markets. More information about CHENPIN's pressing and filming machines and related food production equipment is available at https://www.chenpinmachine.com/.

CHENPIN FOOD MACHINE CO., LTD

No.61 Lane, Dongshe Road 129, Songjiang District, Shanghai,China

sales@chenpinsh.com

+86 021-57674550

"CHENPIN FOOD MACHINE CO., LTD was established in 2010. We build upon the technical expertise and spirit of the Taiwan province team who founded CHENPIN and already had been dedicated to the development and research of food equipment for more than 30 years before founding CHENPIN FOOD MACHINE CO., LTD.With the help of our hiahly skiled research and development team CHENPIN FOOD MACHINE CO., LTD obtained many patents in the area of automated food production machinery for dough, baking and lavered pastry dough products. Our company covers the whole value chain of producing automated food production machinery such as research and development,production,sales, marketing and after-sales services.

"Quality excellence" is the goal of CHENPIN.

"Innovation through Research and Development" is our spirit.

"Perfect service" is the attitude that CHENPIN strives for.

"Trust and long term relationships with our customers" is the business philosophy that CHENPIN follows."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Top 10 Paratha Pressing And Filming Machine Service Providers Globally - CHENPIN Takes the Lead here

News-ID: 4328519 • Views: …

More Releases from CHENPIN FOOD MACHINE CO., LTD

Is the Future Leading Company for Fully Automatic Lacha Paratha Making Machine f …

The global appetite for ethnic cuisine has reached an unprecedented peak, placing the humble lacha paratha at the center of a massive industrial transition. Traditionally, the production of this flaky, multi-layered Indian flatbread relied exclusively on the dexterity of skilled artisans who could stretch dough to near-transparency. However, as frozen food manufacturers strive for global expansion, they face a daunting challenge: maintaining handmade quality at an industrial scale while battling…

A Legacy of Excellence: How CHENPIN's Certified High Quality Food Machine Soluti …

The global food industry is witnessing a significant shift toward ethnic convenience foods, with frozen parotta and flatbreads leading the market expansion. As demand grows, commercial bakeries face the persistent challenge of maintaining traditional "handmade" quality while meeting massive production scales. High labor costs and the inconsistency of manual production often impede business growth and product reliability. To address these hurdles, CHENPIN Food Machine Co., Ltd offers a High Quality…

CHENPIN Unveils the Global Leading Automatic Tortilla Production Line: Redefinin …

In response to expanding global demand for automated flatbread and wrap-style products, the Global Leading Automatic Tortilla Production Line(https://www.chenpinmachine.com/tortilla-production-line-machine-cpe-950-product/) is setting new benchmarks in food manufacturing efficiency and consistency. This state-of-the-art solution integrates intelligent control systems,hot pressing, baking, and advanced cooling to, continuous production of tortillas, taco, lavash, and other flatbread formats with minimal manual intervention. At the forefront of these innovations stands CHENPIN FOOD MACHINE CO., LTD (CHENPIN)(https://www.chenpinmachine.com/about-us/), whose…

Process Deep Dive: How the Lacha paratha Making Machine Fully Automatic Company …

The global demand for consistent, high-quality layered flatbreads continues to grow, especially for products such as Lacha Paratha and Roti Canai . Within this context, the concept of a Fully Automatic Roti Canai Making Machine Fully Automatic Company(https://www.chenpinmachine.com/cpe-3000l-layered-lacha-paratha-production-line-machine-product/) reflects not only automation, but also the ability to industrialize traditional lamination techniques without sacrificing texture or structure.

Based on this direction, CHENPIN FOOD MACHINE CO., LTD(https://www.chenpinmachine.com/about-us/) has developed its Lacha Paratha Production…

More Releases for Pressing

Isostatic Pressing Market Poised for 8.75% CAGR Growth

The Isostatic Pressing Market is undergoing a significant transformation, with industry forecasts predicting rapid expansion and cutting-edge technological innovations by 2032. As businesses continue to embrace digital advancements and strategic shifts, the sector is set to experience unprecedented growth, driven by rising demand, market expansion, and evolving industry trends.

A recent in-depth market analysis sheds light on key factors propelling the Isostatic Pressing market forward, including increasing market share, dynamic segmentation,…

Innovations in Isostatic Pressing: Comprehensive Market Report 2024

"The Business Research Company recently released a comprehensive report on the Global Isostatic Pressing Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

Isostatic Pressing Market Continues to Grow Rapidly

The Isostatic Pressing Market 2024 Report makes available the current and future technical and financial analysis of the industry. It is one of the most comprehensive and important additions to the USD Analytics archive of market research studies. It offers detailed research and analysis of key aspects of the global Isostatic Pressing market. This global report explores the key factors affecting the growth of the dynamic Isostatic Pressing market, including…

Evaluating Isostatic Pressing Market 2024

The isostatic pressing market size has grown strongly in recent years. It will grow from $7.3 billion in 2023 to $7.85 billion in 2024 at a compound annual growth rate (CAGR) of 7.6%. The growth in the historic period can be attributed to growth in the aerospace industry, the increasing manufacturing production, the growing defense budgets and increasing automotive production.

The isostatic pressing market size is expected to see…

APAC Is Dominating Isostatic Pressing Market

The global isostatic pressing market is projected to be USD 13,568.1 million by 2030 growing at a CAGR of 7.0% during the forecast period. sectors including energy, aerospace, medical devices, automotive, and manufacturing regularly use isostatic pressing. In this regard, the requirement for such technology is significantly impacted by the growing requirement for contemporary materials and components with brilliant features, like homogeneity, high density, and mechanical strength.

Explore more about this…

APAC Is Dominating Isostatic Pressing Market

The global isostatic pressing market is projected to be USD 13,568.1 million by 2030 growing at a CAGR of 7.0% during the forecast period. sectors including energy, aerospace, medical devices, automotive, and manufacturing regularly use isostatic pressing. In this regard, the requirement for such technology is significantly impacted by the growing requirement for contemporary materials and components with brilliant features, like homogeneity, high density, and mechanical strength.

Explore more about this…