Press release

Process Deep Dive: How the Lacha paratha Making Machine Fully Automatic Company Achieves Perfect Layering

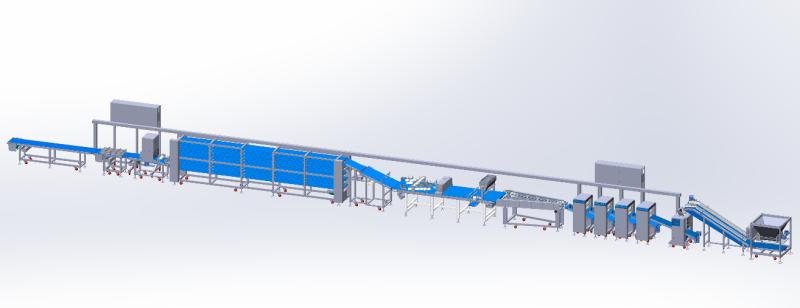

The global demand for consistent, high-quality layered flatbreads continues to grow, especially for products such as Lacha Paratha and Roti Canai . Within this context, the concept of a Fully Automatic Roti Canai Making Machine Fully Automatic Company(https://www.chenpinmachine.com/cpe-3000l-layered-lacha-paratha-production-line-machine-product/) reflects not only automation, but also the ability to industrialize traditional lamination techniques without sacrificing texture or structure.Based on this direction, CHENPIN FOOD MACHINE CO., LTD(https://www.chenpinmachine.com/about-us/) has developed its Lacha Paratha Production Line Machine as a core solution for scalable, fully automatic layered flatbread production.

From Handcrafted Technique to Industrial Precision: The Evolution of Lacha Paratha Production

Traditionally, Lacha Paratha relies on repeated stretching, oiling, rolling, and relaxing to create its rich, flaky layers. Yet manual methods depend heavily on artisan skill and lack the consistency needed for large-scale output.

CHENPIN meets this challenge by translating each handcrafted step into a controlled mechanical process-building layers progressively rather than forcing them together. Instead of compressing multiple actions into one, the production line breaks down lamination into distinct, sequenced stages:

Dough chunker → Continuous sheeting → Sheet stretching → Auto oil-bushing → Sheet dividing→Auto rolling → Relaxing&Conveying →Cutting→Rolling&Forming → Pressing & filming→ Quick freezing → Packaging

This integrated flow ensures gentle, continuous handling. Dough is sheeted under balanced tension to maintain gluten integrity; oil is applied evenly to enable clean layer separation; and scheduled relaxing phases allow stress to dissipate before further shaping.

By mirroring the logic of traditional craft with mechanical accuracy, CHENPIN's production line achieves uniform thickness, well-defined layers, and consistent quality-batch after batch. The process honors the art of hand-made paratha while delivering repeatable results, higher efficiency, and long-term production stability.

Lacha Paratha Production Line Machine: Capacity and Customization

To translate these advanced process flows into scalable commercial output, CHENPIN's Lacha Paratha Production Line Machine is available in different configurations to match production scale.

The CPE-3368 model supports capacities of 7,500-10,000 pieces per hour, making it suitable for large-scale frozen food and industrial bakery operations. Meanwhile, the CPE-3268 model, with capacities of 5,000-7,000 pieces per hour, serves medium-scale manufacturers seeking high consistency with lower footprint requirements.

Beyond standard capacity, the production line is designed for customization. Dough weight, product diameter, layer count, and relaxing structure can be adjusted according to recipe requirements. This flexibility allows manufacturers to preserve brand-specific texture profiles while maintaining stable output. To ensure continuous operation, the Lacha Paratha Production Line Machine is designed to work in coordination with CHENPIN's CP-788 series paratha pressing and filming machines. This integration enables uninterrupted transfer from pressing to film covering, reducing manual handling and preventing layer deformation.

Dough Preparation and Relaxing Control

The success of such high-speed output depends heavily on the microscopic management of the raw material. Layer integrity begins with controlled dough conditioning. In the Lacha Paratha Production Line Machine, dough is processed to achieve consistent elasticity before lamination. Multi-stage relaxing conveyors allow the dough sheet to release internal stress gradually, which is critical for preventing shrinkage and layer breakage during folding.

For example, the CPE-3368 configuration integrates extended relaxing sections of up to 6 meters with 7-9 relaxing layers, supporting stable lamination at high speed. This controlled relaxation ensures that each subsequent folding action forms clean, continuous layers rather than compressed sheets.

The defining feature of Lacha Paratha lies in its layered structure. CHENPIN replicates traditional hand-folding through synchronized rolling and folding modules that apply consistent stretching ratios across the dough sheet. Instead of aggressive compression, the system balances tension and extension, allowing oil-separated layers to form naturally. This process enables the production line to maintain uniform thickness, rich layering, and elastic texture across every piece.

Automation and System Synergy

Powering these intricate mechanical movements is a high degree of automation. Advanced control systems monitor and coordinate each stage of production, from dough conveying to pressing synchronization. Operators can manage key parameters through centralized interfaces, simplifying operation while reducing labor dependency.

At the same time, CHENPIN emphasizes customization(https://www.chenpinmachine.com/case/). Production lines can be tailored to specific requirements related to paratha diameter, weight, capacity, and recipe composition. Optional functions, such as automatic scallion sprinkling, can be incorporated to expand product variety and meet regional flavor preferences. This modular customization strategy allows manufacturers to scale and diversify without replacing core equipment.

Why CHENPIN Represents a Future-Leading Approach

Ultimately, CHENPIN's competitive strength lies not in a single machine, but in its process-oriented engineering philosophy. Instead of treating each unit as an isolated function, CHENPIN designs production lines as coordinated systems that reflect real dough behavior at every stage. By analyzing gluten development, oil absorption, sheet tension, and relaxation response, the equipment is engineered to work with the dough rather than against it.

This process-driven approach enables precise control over lamination dynamics. Stretching, oiling, rolling, and relaxing are executed progressively, which reduces internal stress and improves layer stability. As a result, the production line maintains consistent performance even at high operating speeds, without sacrificing flakiness or structural clarity.

Moreover, CHENPIN emphasizes equipment coordination and timing accuracy across the entire line. Conveying speed, roller pressure, and relaxing duration are synchronized through centralized control logic, allowing each process to support the next. This coordination minimizes deformation, lowers flotsam rates, and enhances repeatability during extended production cycles.

Conclusion

As global demand for layered flatbreads continues to expand, manufacturers increasingly require solutions that combine automation with craftsmanship-level quality. CHENPIN's Lacha Paratha Production Line Machine demonstrates how advanced process design and mechanical precision can preserve traditional characteristics while enabling industrial scalability.

Through controlled sheeting, precise oiling and rolling, structured relaxing, and seamless automation, CHENPIN provides a future-ready foundation for reliable and high-quality flatbread production.

For more information about CHENPIN's Lacha Paratha Production Line Machine and automated flatbread solutions, please visit: https://www.chenpinmachine.com/.

CHENPIN FOOD MACHINE CO., LTD

No.61 Lane, Dongshe Road 129, Songjiang District, Shanghai,China

sales@chenpinsh.com

+86 021-57674551

CHENPIN FOOD MACHINE CO., LTD was established in 2010. We build upon the technical expertise and spirit of the Taiwan province team who founded CHENPIN and already had been dedicated to the development and research of food equipment for more than 30 years before founding CHENPIN FOOD MACHINE CO., LTD.With the help of our hiahly skiled research and development team CHENPIN FOOD MACHINE CO., LTD obtained many patents in the area of automated food production machinery for dough, baking and lavered pastry dough products. Our company covers the whole value chain of producing automated food production machinery such as research and development,production,sales, marketing and after-sales services.

"Quality excellence" is the goal of CHENPIN.

"Innovation through Research and Development" is our spirit.

"Perfect service" is the attitude that CHENPIN strives for.

"Trust and long term relationships with our customers" is the business philosophy that CHENPIN follows.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Process Deep Dive: How the Lacha paratha Making Machine Fully Automatic Company Achieves Perfect Layering here

News-ID: 4372258 • Views: …

More Releases from CHENPIN FOOD MACHINE CO., LTD

Is the Future Leading Company for Fully Automatic Lacha Paratha Making Machine f …

The global appetite for ethnic cuisine has reached an unprecedented peak, placing the humble lacha paratha at the center of a massive industrial transition. Traditionally, the production of this flaky, multi-layered Indian flatbread relied exclusively on the dexterity of skilled artisans who could stretch dough to near-transparency. However, as frozen food manufacturers strive for global expansion, they face a daunting challenge: maintaining handmade quality at an industrial scale while battling…

A Legacy of Excellence: How CHENPIN's Certified High Quality Food Machine Soluti …

The global food industry is witnessing a significant shift toward ethnic convenience foods, with frozen parotta and flatbreads leading the market expansion. As demand grows, commercial bakeries face the persistent challenge of maintaining traditional "handmade" quality while meeting massive production scales. High labor costs and the inconsistency of manual production often impede business growth and product reliability. To address these hurdles, CHENPIN Food Machine Co., Ltd offers a High Quality…

CHENPIN Unveils the Global Leading Automatic Tortilla Production Line: Redefinin …

In response to expanding global demand for automated flatbread and wrap-style products, the Global Leading Automatic Tortilla Production Line(https://www.chenpinmachine.com/tortilla-production-line-machine-cpe-950-product/) is setting new benchmarks in food manufacturing efficiency and consistency. This state-of-the-art solution integrates intelligent control systems,hot pressing, baking, and advanced cooling to, continuous production of tortillas, taco, lavash, and other flatbread formats with minimal manual intervention. At the forefront of these innovations stands CHENPIN FOOD MACHINE CO., LTD (CHENPIN)(https://www.chenpinmachine.com/about-us/), whose…

The Most Reliable Automatic Pizza Production Line Factory, CHENPIN, Delivers Sca …

As global consumption of pizza continues to expand across retail, foodservice, and frozen food channels, manufacturers face increasing pressure to scale output while maintaining consistency and process stability. In this context, the Best Automatic Pizza Production Line Factory is no longer defined solely by nominal capacity. Instead, it is evaluated by how effectively automation integrates with dough behavior, product consistency, and long-term operational reliability. An Automatic Pizza Production Line(https://www.chenpinmachine.com/automatic-pizza-production-line-product/) …

More Releases for Lacha

Is the Future Leading Company for Fully Automatic Lacha Paratha Making Machine f …

The global appetite for ethnic cuisine has reached an unprecedented peak, placing the humble lacha paratha at the center of a massive industrial transition. Traditionally, the production of this flaky, multi-layered Indian flatbread relied exclusively on the dexterity of skilled artisans who could stretch dough to near-transparency. However, as frozen food manufacturers strive for global expansion, they face a daunting challenge: maintaining handmade quality at an industrial scale while battling…

A Legacy of Excellence: How CHENPIN's Certified High Quality Food Machine Soluti …

The global food industry is witnessing a significant shift toward ethnic convenience foods, with frozen parotta and flatbreads leading the market expansion. As demand grows, commercial bakeries face the persistent challenge of maintaining traditional "handmade" quality while meeting massive production scales. High labor costs and the inconsistency of manual production often impede business growth and product reliability. To address these hurdles, CHENPIN Food Machine Co., Ltd offers a High Quality…

India Frozen Paratha Market, Size, Share, Growth | Forecast (2023-2028) | Renub …

India Frozen Paratha Market will develop at a CAGR of 19.33 Percent from 2022-2030. The frozen paratha Industry continues to be challenged by numerous misconceptions regarding frozen meals and the procedure in India. Initially, the Indian frozen food market was most effectively constrained to primary frozen veggies like peas and French fries. With the increasing numbers of nuclear families, the demand for frozen paratha products has been reawakened in…

BITSAA Chennai Rocks BITSian Day Celebrations with Unforgettable Music Nite

Proud to be BITSians who are alumni of Institution of Eminence in India today BITS Pilani firmly believe that music can bond irrespective of who you are, what you are and where you are. It’s a source of entertainment as well as platform to put across past, present but also future messages. Music is undoubtedly a factor that binds the world together irrespective of the cultural diversities and is the…

Bindaas BITSians Enthral BITS Pilani Alumni Association BITSAA Ahmedabad Chapter

It has always been said that music which is indeed the food of soul is also the language of feeling and of passion, as words are the language of reason. Music has a profound impact on our mind and bodies as it is fun, relaxing, motivating and energizing

The aim of the BITSAA Ahmedabad Chapter is to stay connected with all the BITSian Alumni from Ahmedabad & nearby cities (Baroda,…

BITSync 2016 The first pan-American BITSian Conference indeed a Stellar Constell …

BITS Pilani Alumni Association Silicon Valley Chapter BITSAA SV brought together a whole range of dreamers performers and achievers around the world to discuss Industry trends, Entrepreneurship, building Indo American companies and much more.

Every BITSian in Silicon Valley takes pride in acknowledging the fact that a successful entrepreneur needs to acquire Information Skills, Problem Solving Skills, Decision Making Skills, Communication Skills apart from Ability for Time, Stress as well as…