Press release

Global Polymers Market Deep-Dive 2026-2036: Strategic Forecasts, Market Entry Insights & Emerging Opportunities

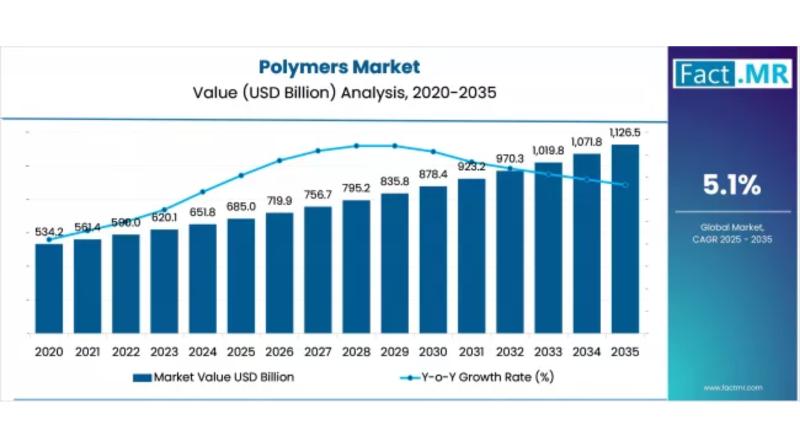

The global polymers market is set for sustained expansion, driven by rising demand across packaging, automotive, construction, electronics, and healthcare industries.According to a comprehensive analysis by Fact.MR, the market is projected to grow from USD 685.0 billion in 2025 to approximately USD 1,126.5 billion by 2035, reflecting an absolute increase of USD 440.0 billion over the forecast period. This represents a total growth of 64.2%, with the market expected to expand at a CAGR of 5.1% between 2025 and 2035.

Polymers-ranging from commodity plastics to high-performance and specialty polymers-form the backbone of modern industrial and consumer applications. Their versatility, durability, lightweight properties, and cost efficiency continue to drive widespread adoption across end-use sectors worldwide.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=11202

Key Market Drivers

Rising Demand from Packaging Industry

Packaging remains the largest end-use segment for polymers, fueled by rapid urbanization, e-commerce growth, and increasing consumption of packaged food and beverages. Flexible and rigid plastic packaging solutions made from polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) offer superior durability, barrier protection, and cost efficiency, making them indispensable to global supply chains.

Expanding Automotive and Transportation Applications

The automotive industry continues to shift toward lightweight materials to improve fuel efficiency and reduce emissions. Polymers are increasingly replacing metals in interior components, under-the-hood applications, and electric vehicle (EV) parts. High-performance polymers enhance design flexibility while supporting sustainability and performance optimization.

Growth in Construction and Infrastructure Development

Polymers play a critical role in construction through applications such as pipes, insulation, flooring, roofing, and sealants. Rapid infrastructure development in emerging economies, coupled with the need for corrosion-resistant and long-lasting materials, is strengthening polymer consumption in residential, commercial, and industrial construction.

Advancements in Specialty and High-Performance Polymers

Innovation in polymer science is driving the development of high-performance materials with enhanced thermal stability, chemical resistance, and mechanical strength. These polymers are gaining traction in aerospace, electronics, medical devices, and renewable energy applications.

Browse Full Report: https://www.factmr.com/report/polymers-market

Regional Growth Highlights

Asia-Pacific: Market Leader with Strong Manufacturing Base

Asia-Pacific dominates the global polymers market, supported by large-scale manufacturing in China, India, Japan, and Southeast Asia. Rapid industrialization, expanding consumer goods production, and strong automotive and electronics sectors continue to fuel regional demand.

North America: Innovation and Sustainability Drive Growth

The U.S. and Canada remain key markets due to advanced manufacturing capabilities and strong R&D investments. Increasing focus on recyclable, bio-based, and circular polymers is reshaping product development across packaging and industrial applications.

Europe: Regulatory Push toward Sustainable Polymers

European markets are witnessing a shift toward eco-friendly and recyclable polymers, driven by stringent environmental regulations and sustainability targets. Demand for biodegradable plastics and recycled polymer content is rising across packaging and consumer goods sectors.

Middle East & Africa and Latin America: Emerging Opportunities

Growing construction activity, infrastructure development, and expanding consumer markets are creating new growth avenues for polymer producers in these regions.

Market Segmentation Insights

By Product Type

Commodity Polymers - Including PE, PP, PVC, and PET, widely used in packaging and construction

• Engineering Polymers - Used in automotive, electronics, and industrial machinery

• High-Performance & Specialty Polymers - Applied in aerospace, medical, and advanced electronics

By End Use

Packaging - Food, beverage, and consumer goods

• Automotive & Transportation - Lightweight structural and interior components

• Building & Construction - Pipes, insulation, coatings, and profiles

• Electrical & Electronics - Insulation, connectors, and housings

• Healthcare & Medical Devices - Sterile and biocompatible applications

Market Challenges

Despite steady growth, the polymers market faces several challenges:

• Environmental Concerns and Plastic Waste Management

• Volatility in Raw Material Prices

• Stringent Regulatory Frameworks on Single-Use Plastics

• Need for Scalable Recycling and Circular Economy Solutions

Competitive Landscape

The global polymers market is highly competitive, with major players focusing on capacity expansions, sustainable material innovation, and strategic partnerships. Companies are investing heavily in recycled polymers, bio-based alternatives, and advanced manufacturing technologies to align with evolving regulatory and consumer expectations.

Key Industry Participants Include:

• BASF SE

• Dow Inc.

• SABIC

• LyondellBasell Industries

• ExxonMobil Chemical

• Covestro AG

• Arkema

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: https://www.factmr.com/checkout/11202

Future Outlook: Toward Sustainable and High-Performance Polymer Solutions

Over the next decade, the polymers market will increasingly shift toward sustainability-driven innovation, including recyclable, bio-based, and low-carbon polymer solutions. As industries balance performance requirements with environmental responsibility, polymers will remain essential to global manufacturing and infrastructure development.

Manufacturers that prioritize circular economy strategies, advanced material science, and regional production resilience are expected to gain a competitive edge as the global polymers market advances toward USD 1.1 trillion by 2035.

Check out More Related Studies Published by Fact.MR Research:

Cast Elastomer Market - https://www.factmr.com/report/cast-elastomers-market

Polymers Market - https://www.factmr.com/report/polymers-market

Cold Cast Elastomers Market - https://www.factmr.com/report/2918/cold-cast-elastomers-market

Polymer Blends & Alloys Market - https://www.factmr.com/report/polymer-blends-and-alloys-market

Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Polymers Market Deep-Dive 2026-2036: Strategic Forecasts, Market Entry Insights & Emerging Opportunities here

News-ID: 4324464 • Views: …

More Releases from Fact.MR

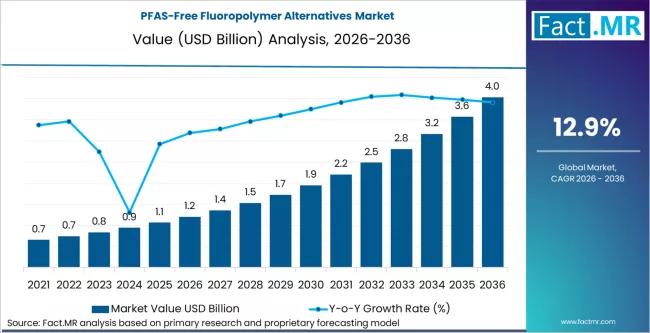

PFAS-Free Fluoropolymer Alternatives Market projects a CAGR of 12.9% by 2036

The global PFAS-free fluoropolymer alternatives market is projected to grow from USD 1.25 billion in 2026 to approximately USD 3.12 billion by 2036. This reflects a rapid compound annual growth rate (CAGR) of 9.6% over the ten-year forecast period.

The market is being aggressively driven by a global regulatory crackdown on "forever chemicals" (PFAS), forcing major industries to find non-fluorinated substitutes for coatings, membranes, and high-performance plastics.

Get Access of Report…

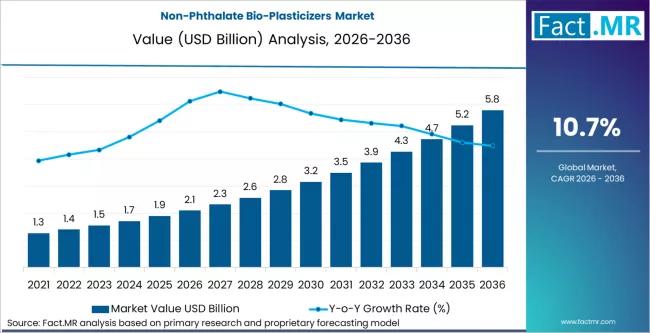

Non-Phthalate Bio-Plasticizers Market is Expected to Reach USD 5.8 billion by 20 …

The global HFO (Hydrofluoroolefin) Blowing Agent Market is forecast to grow substantially over the coming decade, driven by stringent environmental regulations, rising demand for energy-efficient insulation materials, and accelerated adoption of low-global-warming-potential (GWP) technologies across construction, refrigeration, and automotive sectors.

Industry analysts estimate that the market, valued at approximately USD 1.9 billion in 2025, is expected to exceed USD 3.6 billion by 2035, registering a compound annual growth rate (CAGR)…

HFO Blowing Agent Market is Estimated to Grow to USD 2.7 billion in 2026

The global HFO (Hydrofluoroolefin) Blowing Agent Market is forecast to grow substantially over the coming decade, driven by stringent environmental regulations, rising demand for energy-efficient insulation materials, and accelerated adoption of low-global-warming-potential (GWP) technologies across construction, refrigeration, and automotive sectors. Industry analysts estimate that the market, valued at approximately USD 1.9 billion in 2025, is expected to exceed USD 3.6 billion by 2035, registering a compound annual growth rate (CAGR)…

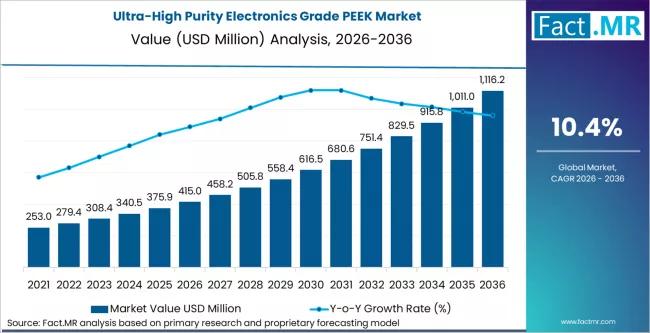

Ultra-High Purity Electronics Grade PEEK Market FOrecasted CAGR is 10.4% 2036

The global ultra-high purity (UHP) electronics-grade Polyether Ether Kitone (PEEK) market is projected to grow from USD 215.4 million in 2026 to approximately USD 458.6 million by 2036. This represents a strong compound annual growth rate (CAGR) of 7.8% over the ten-year forecast period.

The market is being driven by the relentless miniaturization of semiconductors and the shift toward 2nm and 3nm process nodes, where even microscopic material impurities can…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…