Press release

Reducing Water Losses by Intelligent VAG Pressure Management

Leaks in water pipes and leaking valves in urban water distribution systems and pipeline networks, mainly in developing and threshold countries, are the reasons for water losses of up to 50% in relation to the water quantity being produced in the water works.General Problem

To overcome this problem, more than often investments which are made in the water sector, are first of all made under the aspect of increasing the production, and not to generate programs to reduce the water losses.

To change this way of thinking, the most economic - and ecological - solution therefore is to reduce the water losses in the distribution systems and not permanently increase the water production. Whilst production capacities are being increased, the structure of the pipeline system, originally designed for much smaller output volumes, remains the same. In particular, the valves which have to regulate the flows and pressures to maintain a constant supply of potable water cannot do their job in an adequate way. If those valves cannot be controlled exactly, this will lead to high pressure differences in the piping system, to pipe bursts, and, ultimately, to a complete collapse of the entire distribution system.

This is the task for regulating and control valves, which will control flows and pressures, or just open and close water distribution pipelines.

How to Reduce Water Loss and Pipe Bursts?

With an innovative concept VAG-Armaturen GmbH offers 3 different solutions to make an important contribution to the reduction of water loss. The systematic reduction of pressure in the main water supply system enables the utilities to reduce their water loss to sustainable economic levels.

Method

A control device (Plunger Valve) and a pressure sensor together with a flow meter are installed at the supply area's feed point. A programmable logic controller (PLC) records, processes and archives the measured sensor data that are needed to control the Plunger Valve. Depending on the supply system's topography and consumption, the valve is moved into the position that optimally reduces the supply pressure. Reducing the supply pressure reduces the amount of lost water. Positive side effect: Reducing the supply pressure reduces the risk of new leaks occurring in the supply system.

24 hours x 365 days monitoring of the supply system

The feeding volume and supply pressure are constantly monitored and available for the customers review and further analysis. Secure cellular technology is used to transfer the data to a PC that is connected to the internet. A software programme enables the utility to follow the valve's operation online, making laborious journeys to remote supply points a thing of the past. Failures are sent directly to the responsible service team of the utilities in the form of an SMS alert. Their service personnel is only notified when they're needed, saving them time and of course additionally expense. A local control cabinet enables the utilities to monitor the pressure and operate the valves by hand. All of the important operating information can be viewed on a text display. Control parameters can be viewed and changed on site without any assistance from VAG.

System

The system solution from VAG consists of several components (as you can see in picture 1). The picture displays a by-pass solution that enables a water utility to mechanically override the control device at any time. At the heart of the system is a VAG Plunger Valve. Based on the type of local power supply in the utilities network system, the control valve is powered by a DC, AC, or three-phase actuator. A flow meter continuously records the actual volume of water that is supplied to the distribution area. The pressure sensor behind the by-pass is used as actual value for the pressure reduction function of the PLC. Status information about the volume taken, the measured pressure and the actuator converge here.

Inexpensive Installation

There is a certain amount of civil works required for installation, however compared to the large savings potential, the initial investment is very small. VAG will assist utilities to determine the right place for the installation and create a list of the required activities. Each customer of VAG will receive a proven, total system consisting of a Plunger Valve, pressure sensor, flow meter, a programmed controller and, optionally, a cellular modem to transfer data to the customers central control station. In addition to the usual quality tests performed at VAG facilities, the system is put into operation at site by one of the qualified VAG engineers. A training course for the engineers of the utilities could also be part of the VAG package.

The VAG RIKO® Plunger Valve can reduce the pressure in the customers’ network by using the following modes:

Time Based Modulation

Flow or Demand Based Modulation

Remote Node Based Modulation

Each mode of operation offers different control characteristics and benefits which may be selected to meet the budget and the engineering requirements as described in the following text.

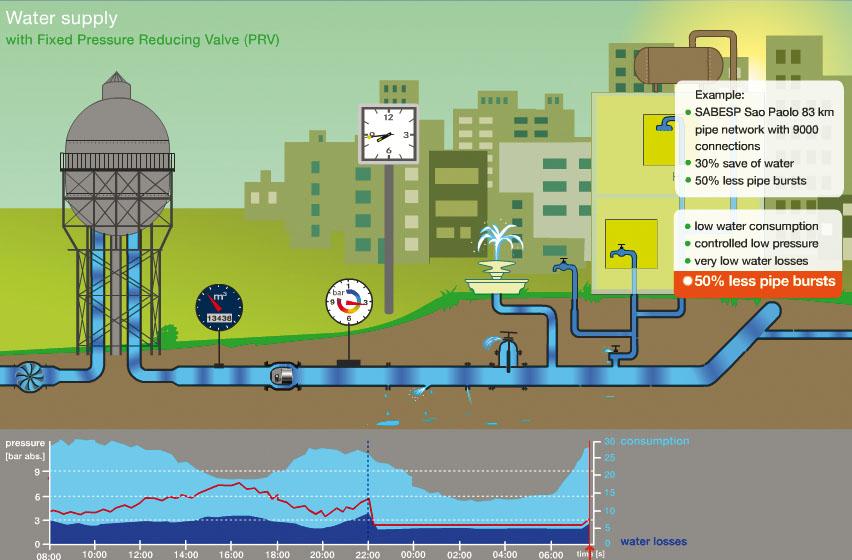

1. Time Based Modulation (picture 2)

This method is achieved by using a controller with an internal timer to change the set point of the fixed outlet control. Control is affected in time-bands in accordance with the demand profiles.

Time based modulation is very effective for areas with stable demand profiles and head loss and is usually used where cost is an issue, but a more proactive pressure management is desired, for example where night time pressure is to be reduced for a number of hours to reduce the effects of leakage. The step before the Time Based Modulation is the so-called Fixed Outlet Modulation which is the most basic control and which is achieved by simply modulating the valve to provide a steady outlet pressure (set point) as system flow demands change, and which VAG Plunger Valves can of course handle as well.

2. Flow or Demand Based Modulation (picture 3)

More water can be saved and more pipe bursts can be avoided when the pressure is following the demand cycle during the whole day, week, month and year.

A flow meter in the main supply pipeline recognizes the current demand for water in the network. This value is sent to a computer, where an evaluated curve specifically for this network is stored. The curve shows the minimum pressure which is necessary to maintain the related flow rate. This method has in the past proven to be the best type of control for areas with changing conditions, head loss, fire flow requirements and the need for proactive control. As demand is reduced primarily at night, pressures are reduced then and when demands peak, higher pressures can be applied to the district. The effect is an efficient control of pressure and the water losses. Additionally as pressures are smoothed out at the weaker extremities of the system the number of new pipe breaks is reduced.

3. Remote Node Based Modulation (picture 4)

With the Remote Node Based Modulation the pressure will be measured directly in the network at a critical point. The signal is sent via a wireless connection to the control valve.

This type of control is probably the most proactive and is affected by connecting a remote pressure sensor to the valve controller, by means of radio or GSM. The remote sensor is usually placed at a critical point in the district and the controller set to change the pressure at the valve to always maintain the desired pressure in the network system. As with the flow based modulation discussed above this mode of operation also smooth’s the system pressure at the weaker extremities and has the added effect of reducing the number of new pipe breaks.

The Heart of VAG Pressure Management

The VAG RIKO® Plunger Valve precisely regulates the pressure in a piping system and guarantees the constant supply of water at any time, at any condition, in perfect coordination of both flow rate and network pressure.

Previously, only the term of needle valve was used for valves having a controlling function. Today, the term Plunger Valve is very common due to the design features shown in picture 5:

- The cross-section of the flow is annular in each position of the valve

- The axially movable closing device is shaped like a piston or a plunger

VAG-Armaturen has redesigned the existing Plunger Valve which was already established in the market for many decades. Today the new VAG RIKO® Plunger Valve is available in nominal widths from DN 150 up to DN 1600 and in the pressures ranging from PN 10 up to PN 40. The compact and single-piece body is made of high quality ductile cast iron (GGG-40) with an inner body which is connected to the outer body by cast ribs. On the upstream side, the inner body has a spherical shape and the shape of the annular space results in a continuous narrowing towards the seat on the downstream side. Depending on the hydraulic conditions, there are different outlet parts available (picture 6-8). The cross-section is reduced in its flow, which is symmetrical to the axis, until the fully closed position of the piston is reached and the valve is absolutely drop-tight. The piston or plunger is normally made of stainless steel and is operated by an internal piston-drive made of ductile cast iron or stainless steel. An essential advantage of the new VAG RIKO® Plunger Valve is its piston guiding which is made of welded bronze. The piston-drive is connected by a stainless steel shaft to a gear box assembled to a connecting flange on the outside of the body. New sealing systems for pistons, shaft bearings and seats guaranty a good corrosion protection and high performance combined with a long life time.

Range of application

Plunger Valves are designed to fulfil special control functions in the water supply systems. Unlike Butterfly or Gate Valves which assume only shut-off functions in pipeline systems, Plunger Valves meet the special requirements of regulating operations. VAG Plunger Valves can be used for potable water up to 50°C (122°F). Due to the linear regulating characteristic the VAG RIKO® Plunger Valve guarantees best cavitation behaviour with lowest friction-loss at the same time.

The project Santo Amaro in the Metropolitan area of São Paulo, Brasilia

The water consumption in the Metropolitan area of Sao Paulo is continuously increasing. Today, for the local water suppliers -namely the state owned company SABESP – Companhia de Saneamento Básico do Estado de São Paulo - it is a challenge to meet the demand of the 17 Million people of Sao Paulo and ensure a constant supply of potable water in sufficient quantities. Despite the quality service provided by SABESP it is possible to experience periods of rotational supply caused by lack of resource during a dry period. One reason for lack of water supply is the high volume of - physical- water losses which occur during operation by leakage at critical points like mains and fittings, if the pressure can be managed effectively, then water loss will be reduced.

The VAG Task

The VAG task was to combat head loss and to apply pressure to the pipeline system when required and reduce pressure off the pipeline system when legitimate demand is at it lowest. This was achieved by installation of an intelligent pressure reducing valve - the VAG RIKO® Plunger Valve - operating on a remote node modulation basis.

The VAG Solution

Supported by the German Government and in co-operation with the DEG - Germany Society of Development- and SABESP, VAG-Armaturen GmbH started a PPP-Project for Sustainable Water and Natural Resources Management in Sao Paulo in March 2004, and in August 2005. VAG and SABESP installed in a pilot site in the District of Santo Amaro with a population of about 30.000 people and 80 kilometres of distribution pipes consisting of a highly sophisticated water loss reduction system consisting of pressure regulating valves, control panels, telemetry installations, and the supporting software. This pilot site has demonstrated that modulated pressure management significantly reduces both the volume of water loss and the frequency of new pipe breaks occurring. For the Santo Amaro district this means a reduction of up to 50% of new pipe breaks and 30% volume, which is sufficient to supply an additional 8.000 people with potable water this is of particular significance in a fast growing Metropolis like Sao Paulo, and also important for other municipalities all over the world.

In the meantime the VAG Pressure Management System is approved in several applications worldwide. The savings caused by reducing water loss and by the reduction of new pipe breaks are very high and the investments will be amortised within a short time period. You will find further details of VAG Pressure Management on the animations below www.vag-armaturen.com.

VAG-Armaturen GmbH

Peter Oppinger

Head of Marketing

Carl-Reuther Strasse 1

68305 Mannheim - Germany

Phone: +49 621/ 749-2106

Fax: +49 621/ 749-292106

E-Mail: p.oppinger@vag-armaturen.com

Internet:www.vag-armaturen.com

VAG-Armaturen GmbH is a German company with more than 130 years of experience in the design and manufacturing of heavy-duty valves for all kinds of water applications. With nearly 1,000 employees worldwide the valve manufacturer is a globally active company and is setting new standards as a solution and system provider in water and wastewater technology. With over 180 sales representatives, 11 subsidiaries and 3 production facilities VAG is at home around the world.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Reducing Water Losses by Intelligent VAG Pressure Management here

News-ID: 43143 • Views: …

More Releases from VAG-Armaturen GmbH

VAG hands over donation to hospital hit by earthquake in Santiago de Chile

Last week, the VAG Group was able to hand over a donation cheque in the amount of € 10,000 to the Dr Felix Bulnes hospital in Santiago de Chile, the hospital which was destroyed by the earthquake.

Built as early as 1940, the hospital now ranges among the city’s largest hospitals and is the place to turn to for over one million inhabitants of the western parts of the city.…

First “Actuator Day” of the VAG Group

On 4 March, the first “Actuator Day” of the VAG Group took place in Hodonín (Czech Republic). On this day, JMA, VAG’s Czech subsidiary, offered seven well-known manufacturers of actuators the possibility of presenting their range of products. Visitors to the in-house trade show included 200 prospective customers from the general industry, water supply industry, generation of energy sector and technology companies.

Manufacturers exhibiting their products included AUMA, REGADA and…

VAG Valves UK, “Building a Stronger Team”

VAG Valves UK in Partnership with Glasgow Caledonian University and Knowledge Transfer Partnerships (KTP) are undertaking a 2 year graduate development programme.

Knowledge Transfer Partnerships is Europe’s leading programme helping businesses to improve their skills base through better use of knowledge and technology that already exists within the UK.

VAG Valves UK along with Glasgow Caledonian University will employ a Graduate Engineer to work on new market opportunities for VAG in the…

First symposium on “Valves in Nuclear Power Plants”

From 9 to 10 February 2010, the first symposium on the subject of valves in nuclear power plants took place at VAG’s Mannheim headquarters.

During the two-day event, guests from ten German nuclear power plant locations attended expert talks, went on a guided tour through VAG’s Visitor Center and were also able to gain insights into the manufacture of special valves at the Mannheim plant.

The expert talks covered all relevant subjects,…

More Releases for VAG

First “Actuator Day” of the VAG Group

On 4 March, the first “Actuator Day” of the VAG Group took place in Hodonín (Czech Republic). On this day, JMA, VAG’s Czech subsidiary, offered seven well-known manufacturers of actuators the possibility of presenting their range of products. Visitors to the in-house trade show included 200 prospective customers from the general industry, water supply industry, generation of energy sector and technology companies.

Manufacturers exhibiting their products included AUMA, REGADA and…

VAG Valves UK, “Building a Stronger Team”

VAG Valves UK in Partnership with Glasgow Caledonian University and Knowledge Transfer Partnerships (KTP) are undertaking a 2 year graduate development programme.

Knowledge Transfer Partnerships is Europe’s leading programme helping businesses to improve their skills base through better use of knowledge and technology that already exists within the UK.

VAG Valves UK along with Glasgow Caledonian University will employ a Graduate Engineer to work on new market opportunities for VAG in the…

VAG-Valves UK awarded Yorkshire Water Framework

VAG-Valves UK and its UK Distribution and Logistics Partner Fusion Provida have recently been awarded the prestigious Yorkshire Water Framework for the supply of Resilient Seated Gate Valves (50mm – 300mm) for three years with an optional addition of two years.

VAG-Valves UK, Yorkshire Water and Fusion Provida recently visited the VAG manufacturing plants in Mannheim and Hodonin to sign the agreement and see firsthand the fantastic production and logistics facilities.

VAG-Valves…

VAG Awarded British Standard Kitemark approval for VAG BS750 Hydrant

VAG-Valves UK Ltd. is pleased to announce the award of the British Standards Institute Kitemark for our BS750 Underground Hydrant.

The award is the culmination of many months of hard work and effort by our manufacturing plants in Mannheim, Germany and Hodonin, Czech Republic.

This award further establishes VAG’s long term commitment to supply products to the UK Water Industry and its dedication to providing products to the highest achievable standards.

Well…

VAG Group also successful in Italy

VAG’s participation in the 9th ACCADUEO Exhibition and Conference in Ferrara (Italy) with over 10,000 visitors once again confirmed the valve manufacturer’s success in the Italian market.

The VAG Group received an overwhelmingly positive feedback from visitors for the products exhibited at the stand and the solutions provided in the areas of water, waste water and industrial applications. Besides giving various presentations on the subject of pressure management, VAG was…

New VAG UseCAD® 6.0

The new, sixth version of VAG UseCAD® is now available, just in time for IFAT. A total of five components were added to the previous version 5.0 that will assist demanding VAG customers in planning projects as well as in searching for specific product information about valves for water and sewage management.

An overview of the new program components:

• 3D images

• VAG screen saver

• Sound volume calculation for plunger valves

• Lay-out program for air and…