Press release

The Global Aseptic and Hygienic Valve Market is projected to reach a market size of $11.04 billion by 2030.

According to the report published by Virtue Market Research in 2024, the Aseptic and Hygienic Valve Market was valued at $8.57 billion, and is projected to reach a market size of $11.03 billion by 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 4.3%.Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/asceptic-and-hygenic-valve-market/request-sample

The aseptic and hygienic valve market has been gaining significant importance across industries where cleanliness, precision, and contamination-free processes are crucial. These valves are designed to ensure sterile conditions in the production of food, beverages, pharmaceuticals, and biotechnology products. Over time, their demand has been shaped by technological progress, stricter safety regulations, and the growing focus on product integrity. The market continues to evolve as manufacturers invest in advanced materials, automated systems, and smart monitoring technologies that enhance efficiency and reduce operational risks.

A major long-term driver for the aseptic and hygienic valve market is the global shift toward higher food safety and pharmaceutical quality standards. As consumer awareness about contamination risks increases, manufacturers are prioritizing hygienic processing systems that can guarantee sterile production environments. The implementation of regulatory frameworks such as the FDA's Current Good Manufacturing Practices and the European Hygienic Engineering & Design Group guidelines has also fueled the adoption of aseptic valves.

These regulations demand precise control over microbial contamination, pushing industries to upgrade their legacy systems with modern, self-draining, and easy-to-clean valve solutions. Additionally, the rise of biologics, plant-based foods, and ready-to-drink beverages has accelerated the long-term demand, as these segments depend heavily on sterile operations to maintain product stability and safety.

The COVID-19 pandemic had a profound effect on the aseptic and hygienic valve market. During the early phase of the pandemic, supply chain disruptions and factory shutdowns slowed production and delayed equipment installations. However, as the pandemic progressed, the market experienced a strong rebound, especially from the pharmaceutical and food sectors.

The surge in vaccine manufacturing, injectable drug production, and packaged food demand led to increased installation of aseptic valves across facilities worldwide. Manufacturers also began emphasizing automation to minimize human contact and reduce contamination risk, resulting in the development of smart valves equipped with sensors and digital control systems. This shift not only improved efficiency but also established a more resilient foundation for future crises where hygiene and sterility remain top priorities.

In the short term, the growing demand for ready-to-consume and convenience food products is acting as a major market driver. Urbanization, busy lifestyles, and the increasing number of dual-income households have encouraged food producers to adopt aseptic processing techniques that can extend shelf life without compromising quality. To meet this demand, food and beverage manufacturers are upgrading their production lines with hygienic valves that minimize product loss, improve process reliability, and ensure consistent taste and safety. The strong recovery of the hospitality and food service sectors after COVID-19 has also contributed to a higher volume of production, indirectly boosting the need for hygienic valves.

A significant opportunity lies in the rising integration of smart monitoring and automation technologies into aseptic valve systems. With Industry 4.0 transforming industrial operations, manufacturers are exploring IoT-enabled valve solutions that can provide real-time data on flow rates, pressure, and temperature.

These advanced valves help identify potential contamination or leakage issues before they affect production, leading to predictive maintenance and reduced downtime. The integration of artificial intelligence and cloud-based analytics offers even greater control and traceability across the production chain. As industries move toward fully digitalized plants, companies offering connected and data-driven valve systems stand to gain a competitive edge.

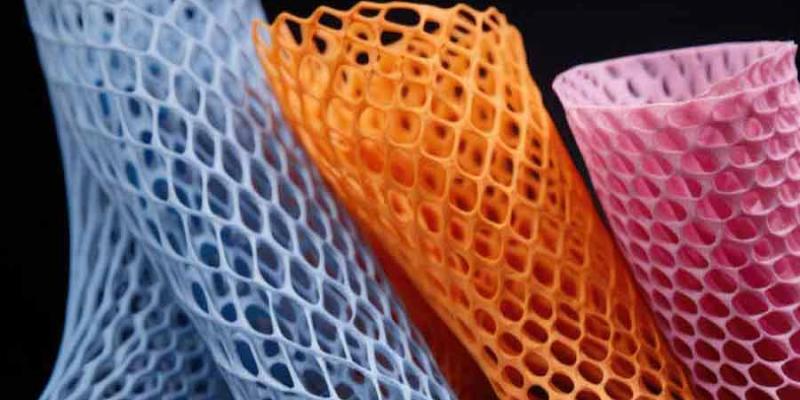

One of the most notable trends shaping the aseptic and hygienic valve market is the transition toward sustainability and material innovation. Manufacturers are increasingly focusing on eco-friendly production processes, energy-efficient designs, and recyclable materials. The use of stainless steel and high-performance polymers with enhanced corrosion resistance has become widespread, ensuring long-term durability and reduced maintenance costs. Additionally, valve producers are adopting cleaner manufacturing techniques to minimize waste and energy consumption. This trend aligns with the broader industrial movement toward sustainability, where every component-from raw material selection to system design-plays a role in achieving greener operations.

Segmentation Analysis:

By Operation Type: Manual, Air-actuated

The aseptic and hygienic valve market by operation type includes manual and air-actuated valves, both serving essential roles in maintaining sterile process control. Manual valves are operated by hand and are widely preferred in smaller facilities or where process automation is not a key requirement. These valves are simple, cost-effective, and reliable for low-volume operations where control precision is easily managed by human operators. Air-actuated valves, on the other hand, are increasingly being adopted in automated systems that require fast response times and precise control over fluid movement.

These valves use pneumatic actuators to manage flow remotely, improving consistency and hygiene in high-speed production lines. With industries such as food and pharmaceuticals shifting toward automation to enhance efficiency, air-actuated valves have gained notable traction. As digitalization continues to reshape industrial processes, the adoption of sensor-equipped valves capable of real-time monitoring is expanding rapidly. These advanced designs help minimize downtime and contamination risks, making them indispensable in modern production environments. The largest in this segment is manual, and the fastest growing during the forecast period is air-actuated.

By End-User: Processed Food, Dairy, Alcoholic Beverage, Non-Alcoholic Beverage, Pharmaceuticals, and Others

The aseptic and hygienic valve market by end-user demonstrates diverse applications across multiple industries, each requiring different hygiene standards and operational precision. In processed food manufacturing, these valves are crucial for maintaining product safety and preventing microbial growth during production and packaging. The dairy industry, with its strict sanitation norms and high sensitivity to contamination, remains a dominant user, integrating hygienic valves in milk, yogurt, and cheese processing lines. The pharmaceutical sector relies heavily on aseptic valves to ensure sterile conditions in drug production, particularly for injectables and biopharmaceuticals.

Non-alcoholic beverage producers use these valves to sustain long shelf life and preserve flavor integrity, while alcoholic beverage manufacturers deploy them in brewing and fermentation processes to maintain purity. Other sectors, including cosmetics and biotechnology, are increasingly adopting hygienic valve systems for precision-controlled operations. The market is evolving with increasing preference for modular valve designs that simplify maintenance and improve productivity. Growing consumer demand for safe, packaged, and high-quality consumables continues to influence adoption trends across all these industries. The largest in this segment is dairy, and the fastest growing during the forecast period is pharmaceuticals.

By Valve Type: Hygienic Single Seat Valves, Hygienic Double Seat Valves (Mix Proof Valves), Hygienic Butterfly Valves, Hygienic Control Valves, and Aseptic Valves

The aseptic and hygienic valve market by valve type showcases a range of technologies engineered to ensure cleanliness and operational efficiency across industries. Hygienic single-seat valves are commonly utilized for simple flow control tasks in systems where product separation is not required. Double-seat valves, also known as mix-proof valves, prevent cross-contamination between incompatible fluids, making them ideal for complex production lines. Hygienic butterfly valves, lightweight and compact, are often chosen for applications demanding quick shutoff and ease of cleaning.

Control valves, designed for precise regulation of pressure, temperature, and flow, have seen strong adoption in industries demanding tight process control. Aseptic valves, meanwhile, are built to maintain sterile barriers, particularly in pharmaceuticals and biotechnology, where any contamination could compromise product integrity. The trend toward flexible valve solutions with integrated automation capabilities is expanding rapidly. With rising investments in sterile manufacturing technologies, these valve types are witnessing ongoing design innovation for improved reliability and performance. The largest in this segment is hygienic butterfly valves, and the fastest growing during the forecast period is aseptic valves.

Read More @ https://virtuemarketresearch.com/report/asceptic-and-hygenic-valve-market

Regional Analysis:

The aseptic and hygienic valve market shows strong regional variations driven by industrial infrastructure, regulatory standards, and technological readiness. North America maintains a solid position owing to its advanced food processing and pharmaceutical industries that demand consistent hygiene and automation in production systems. Europe, home to some of the world's strictest food safety and manufacturing regulations, continues to lead innovation with high-quality valve designs that meet EU compliance standards.

Asia-Pacific, with its rapidly industrializing economies such as China and India, is witnessing a surge in demand due to the expansion of packaged food, beverage, and pharmaceutical production facilities. The growing emphasis on automation, hygiene, and quality in these countries is encouraging significant investment in aseptic technology. South America is gradually increasing adoption driven by the food and dairy sectors, while the Middle East & Africa are emerging markets with a growing focus on modernizing food and beverage processing infrastructure. The evolving consumer preference for safety and convenience continues to influence regional growth patterns. The largest in this segment is Europe, and the fastest growing during the forecast period is Asia-Pacific.

Latest Industry Developments:

• Digitization and predictive maintenance adoption (one sentence heading): Companies are accelerating deployment of IoT-enabled valves, remote monitoring, and analytics-driven maintenance programs to cut unplanned downtime and demonstrate measurable uptime improvements. In modern plants, sensor-equipped actuators and cloud telemetry stream valve health data-vibration, cycle count, seat leakage, and pressure differentials-into predictive models that trigger service only when needed. This reduces labor, shortens mean time to repair, and extends seal life while giving buyers traceable hygiene records for audits. The push toward wireless monitoring and standardized IIoT protocols also lowers integration costs for OEMs and system integrators, encouraging broader retrofit and greenfield uptake across food, beverage, and pharma sectors.

• Portfolio extension and aftermarket service expansion (one sentence heading): A clear trend is the expansion of product portfolios paired with value-added aftermarket services - spare parts programs, rapid-repair networks, field service contracts, and certified refurbishment - to lock in customers and create recurring revenue. Manufacturers bundle modular valve families with performance guarantees, validation support, and on-site commissioning to reduce buyer switching. Regional spare-parts hubs and training for end-users shorten downtime and raise total lifetime value, while certified refurbishment and parts-as-a-service lower capex barriers for smaller processors. This servitization strategy also lets suppliers gather anonymized usage data to refine designs and tailor uptime-focused commercial offerings for large multi-site operators.

• Sustainability, materials innovation, and localized manufacturing (one sentence heading): Firms are prioritizing lower-environmental-footprint valves using recyclable stainless grades, reduced-waste machining, and lighter actuator assemblies, while investing in localized production to cut lead times and tariff exposure. Material choices and process redesigns aim to minimize maintenance frequency and enable easier clean-in-place cycles, reducing water and chemical consumption in hygiene routines. Local assembly centers and co-located service teams also support faster delivery for growing APAC and Latin American demand, helping suppliers meet region-specific certifications. This twin focus on greener manufacturing and regional footprint expansion strengthens tender competitiveness and aligns product claims with corporate ESG goals.

customize the Full Report Based on Your Requirements @ https://virtuemarketresearch.com/report/asceptic-and-hygenic-valve-market/customization

contact Us:

Virtue Market Research

Kumar Plaza, #103, SRPF Rd, Ramtekadi, Pune, Maharashtra 411013, India

About Us:

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Global Aseptic and Hygienic Valve Market is projected to reach a market size of $11.04 billion by 2030. here

News-ID: 4312837 • Views: …

More Releases from Virtue Market Research

The Global Vodka Seltzer Market is projected to reach a market size of USD 16.22 …

The Vodka Seltzer Market was valued at USD 9.4 billion in 2024 and is projected to reach a market size of USD 16.21 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 8.1%.

Request Sample @ https://virtuemarketresearch.com/report/vodka-seltzer-market/request-sample

The vodka seltzer market has grown from a niche beverage choice into a mainstream favorite, supported by shifting consumer lifestyles and evolving…

The Global Telehealth Services Market and is projected to reach a market size of …

The Global Telehealth Services Market was valued at USD 126.1 billion and is projected to reach a market size of USD 302.49 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 15.7%.

Request Sample @ https://virtuemarketresearch.com/report/telehealth-services-market/request-sample

The perennial shift towards patient-centric healthcare has been a pivotal long-term market driver for telehealth services. Over the years, the industry has witnessed…

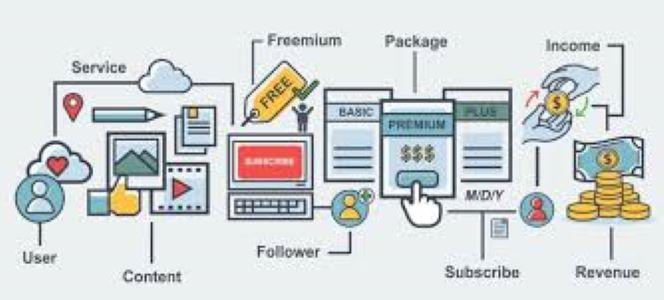

The Subscription Box/Subscription E-Commerce Market is projected to reach a mark …

The Subscription Box/Subscription E-Commerce Market is valued at USD 47.19 billion in 2024 and is projected to reach a market size of USD 97.73 billion by the end of 2030. Over the outlook period of 2025-2030, the market is anticipated to grow at a CAGR of 12.9%.

Request Sample @ https://virtuemarketresearch.com/report/subscription-e-commerce-market/request-sample

The subscription e-commerce market has grown into one of the most dynamic parts of the digital economy. It began as a…

The Global Aramid Fibre Reinforced Polymer Composites Market is projected to rea …

According to the report published by Virtue Market Research in Aramid Fibre Reinforced Polymer Composites Market was valued at USD 5.55 billion and is projected to reach a market size of USD 8.57 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 7.5%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/aramid-fibre-reinforced-polymer-composites-market/request-sample

The Aramid Fibre Reinforced Polymer Composites…

More Releases for Hygienic

Hygienic Pipeline Market Demand Analysis Report 2025

"Global Hygienic Pipeline Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031" is published by Global Info Research. It covers the key influencing factors of the Hygienic Pipeline market, including Hygienic Pipeline market share, price analysis, competitive landscape, market dynamics, consumer behavior, and technological impact, etc.At the same time, comprehensive data analysis is conducted by national and regional sales, corporate competition rankings, product types and applications. This report…

Global Hygienic Pumps and Valves Market

The global hygienic pumps and valves market size is estimated to grow from USD 2.3 billion in 2023 to USD 2.8 billion by 2028, at a CAGR of 3.7%. The manufacturers of pharmaceuticals, food, beverages, and dairy products must adhere to the regulations formed by various governments, which, in turn, has compelled them to install multiple types of hygienic valves and pumps to maintain safety and sanitary practices in industrial…

Hygienic and Aseptic Valves Market - Emphasis on Eliminating Preservatives Leads …

Global Hygienic and Aseptic Valves Market: Scope

The “Hygienic and Aseptic Valves Market” report provides analysis of the Hygienic and Aseptic Valves market for the period 2015–2025, wherein the years from 2016 to 2025 is the forecast period and 2015 is considered as the base year. The report precisely covers all the major trends and technologies playing a major role in the hygienic and aseptic valves market growth over the forecast…

Busch introduces the first hygienic vacuum pump

The first vacuum pump with hygienic design in the world has been introduced by Busch Vacuum Pumps and Systems. This new rotary vane vacuum pump was developed specially for foodstuffs packaging with tray sealers and thermoforming machines, and is designed to be cleaned using steam jets and conventional detergents. The unit surfaces are smooth and slightly inclined, allowing water and detergent to drain away after cleaning to leave a residue-free…

New connectivity variants in 'Hygienic Design'

Halver, 11 May 2015 – The connector- and housing manufacturer ESCHA is extending its portfolio with Food&Beverage-connectors in the so called ‚Hygienic Design‘. The existing M8x1- and M12x1 product lines are now even more comprehensive through the new LED-versions, 5-pin designs as well as variants with PVC-cable quality.

Connectors in Hygienic Design

Since the beginning of 2014, the connector- and housing specialist ESCHA has had its current connector generation for Food&Beverage-applications on…

Hygienic checkweighing in food production

Bizerba presents checkweighers at Anuga FoodTec in Cologne

Balingen, 14th February 2012 – At Anuga FoodTec 2012, the international trade fair for food and beverage technology in Cologne, from 27 to 30 March, Bizerba will be presenting the checkweighers CWP Neptune for unpackaged and easily perishable foodstuffs and CWL Eco, which now even weighs in a tilted position and in accordance with requirements (hall 10.1, stand 070).

To the exact gram:…