Press release

India's Automotive Composite Leaf Springs Market Hits USD 85 Million by 2035

The India Automotive Composite Leaf Springs Market is valued at USD 50 million in 2025 and is projected to reach USD 85 million by 2035, registering a 7.5% CAGR over the forecast period. Growth is fueled by automakers, fleet operators, and performance-focused vehicle owners seeking lightweight, durable suspension components that deliver repeatable performance, improved fuel efficiency, and predictable load handling. Advanced composites and smarter manufacturing processes are enabling these gains, positioning composite leaf springs as a critical upgrade over conventional steel designs.The adoption of composite leaf springs is being accelerated by government mandates, rising EV penetration, and growing commercial vehicle demand. The combination of lower weight, high strength-to-weight ratios, and enhanced durability is redefining vehicle suspension. Manufacturers are deploying High-Pressure Resin Transfer Molding (HP-RTM) and Prepreg Layup Process to produce components with precise fiber orientation and consistent resin distribution, achieving smooth finishes, reduced material waste, and cost-effective scalability.

Composite leaf springs are no longer limited to niche applications. Across India's automotive spectrum-from passenger cars to medium and heavy-duty commercial vehicles (MHDVs)-demand is surging. Passenger cars benefit from improved fuel economy and smoother ride quality, LCVs gain enhanced payload and suspension performance, and MHDVs leverage toughness and longevity to manage heavy loads over long distances.

Get access to comprehensive data tables and detailed market insights - request your sample report today!

https://www.futuremarketinsights.com/reports/sample/rep-gb-20015

Fast Facts

• Market 2025: USD 50 million

• Market 2035: USD 85 million

• CAGR (2025-2035): 7.5%

• Top Process Share: HP-RTM 50%

• Secondary Process: Prepreg Layup 35%

• Other Processes: 15%

• Top Installation Share: Longitudinal 65%

• Transversal Installation: 35%

• Top Location Type: Rear Leaf Spring 60%

• Front Leaf Spring: 40%

• Top Vehicle Share: MHDVs 45%

• Passenger Cars: 30%

• LCVs: 25%

• Key Region CAGR: India 7.4%, China 5.4%, Japan 4.2%, Germany 3.0%, US 3.0%

What is Winning, and Why

Composite leaf springs offer consistent pedal feel, heat control, and predictable suspension behavior. These components improve vehicle dynamics, reduce unsprung mass, and allow for fine-tuned calibration, delivering advantages across the spectrum of passenger and commercial vehicles.

• Power adders: Lightweight designs improve fuel economy and payload efficiency.

• Chassis/Brakes: Reduced unsprung mass enhances handling, braking stability, and safety.

• Digital tuning: Material consistency allows for precise, repeatable suspension calibration.

Market Trends Shaping Adoption

Shift toward Lightweight Materials: Weight reduction is central to fuel efficiency, emissions reduction, and EV range optimization. Fiber-reinforced polymer composites deliver superior strength-to-weight ratios compared with steel.

Advanced Manufacturing Techniques: HP-RTM and Prepreg Layup enable precise fiber placement and resin control, producing high-strength components suitable for complex geometries, high loads, and extended operational life.

Rising Commercial Vehicle Demand: India's logistics sector is expanding rapidly. LCVs and MHDVs increasingly incorporate composite leaf springs to optimize payload capacity and handling performance while reducing component fatigue.

Fuel Efficiency and Emission Compliance: Lightweight composite springs contribute to regulatory compliance, particularly in EVs, by reducing energy consumption and improving range.

Sustainability and Eco-Friendly Production: Composites are recyclable, supporting automakers' environmental objectives and aligning with government policies promoting eco-friendly materials and processes.

Where to Play: Channels & Regions

Both aftermarket and OEM channels are active. Aftermarket demand is driven by retrofits and specialty upgrades, while OEMs integrate composites into new passenger, commercial, and electric vehicle models.

Key regional growth opportunities:

• India: 7.4% CAGR; driven by commercial vehicle expansion and EV adoption.

• China: 5.4% CAGR; increasing MHDV fleets and urban logistics.

• Japan: 4.2% CAGR; adoption in premium LCVs and tech-driven passenger vehicles.

• Germany: 3.0% CAGR; high-value commercial vehicles and specialty applications.

• US: 3.0% CAGR; selective adoption in heavy-duty and performance fleets.

Segmentation Insights

By Installation Type: Longitudinal (65%) dominates MHDVs for stability and load distribution, while transversal (35%) is common in passenger cars for compact layouts.

By Process Type: HP-RTM (50%) delivers strength and finish; Prepreg Layup (35%) suits complex geometries; Others (15%) include hand lay-up and filament winding.

By Location Type: Rear leaf springs (60%) handle heavier payloads, while front leaf springs (40%) maintain ride quality and steering control.

By Vehicle Type: MHDVs (45%) lead adoption, followed by passenger cars (30%) and LCVs (25%). Growth is fastest in LCVs (8.0% CAGR) and MHDVs (7.8%), reflecting commercial demand and payload requirements.

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here:

Buy Full Report - India Automotive Composite Leaf Springs Market

https://www.futuremarketinsights.com/checkout/20015

What Teams Should Do Next

R&D

• Optimize composite leaf springs for MHDV load management and durability.

• Develop intercooling, material, and lightweight design innovations.

• Expand calibration libraries for repeatable performance across vehicles.

Marketing & Sales

• Showcase dyno-tested performance metrics.

• Develop bundled upgrades for passenger, LCV, and MHDV markets.

• Engage creators and installers for high-visibility demonstration campaigns.

Regulatory & QA

• Ensure emissions, noise, and vibration compliance.

• Maintain accurate fitment documentation for OEMs and aftermarket.

• Clarify warranty coverage for both retrofit and OEM programs.

Sourcing & Operations

• Implement dual-sourcing for high-demand composite components.

• Pre-kit critical parts for OEM and aftermarket installations.

• Regionalize on-demand production for high-growth MHDV markets.

Three Quick Plays This Quarter

• Test HP-RTM rear spring modules in targeted LCV fleets.

• Launch bundled EV retrofit packages with performance validation.

• Audit rear leaf spring fitment and durability across MHDV fleet segments.

The Take

India's automotive composite leaf springs market is poised for strong growth through 2035. Lightweight, durable designs, combined with precise calibration, deliver measurable performance improvements, regulatory compliance, and customer satisfaction. Investments in advanced materials, process optimization, and channel execution will yield repeatable performance gains, higher payload efficiency, and stronger aftermarket loyalty. For OEMs and aftermarket brands alike, this market represents a clear path to operational efficiency, fuel savings, and long-term differentiation in a competitive automotive ecosystem.

Media line

For analyst briefings or custom cuts by product, vehicle, channel, and region, contact Future Market Insights.

Similar Industry Reports

India Sustainable Tourism Market

https://www.futuremarketinsights.com/reports/india-sustainable-tourism-market

India Decorative Veneer Industry

https://www.futuremarketinsights.com/reports/decorative-veneer-industry-analysis-in-india

India Outbound Tourism Market

https://www.futuremarketinsights.com/reports/india-outbound-tourism-market

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release India's Automotive Composite Leaf Springs Market Hits USD 85 Million by 2035 here

News-ID: 4309098 • Views: …

More Releases from Future Market Insights

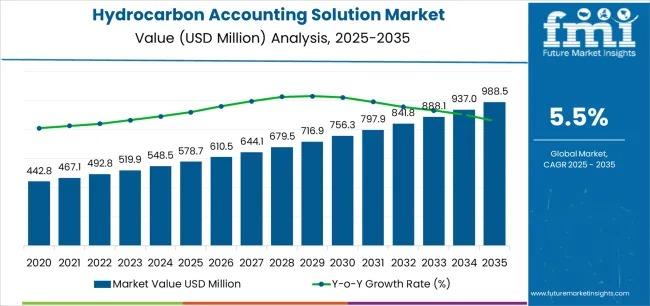

Hydrocarbon Accounting Solution Market Set to Reach USD 988.4 Million by 2035 as …

The global hydrocarbon accounting solution market is projected to expand from USD 578.7 million in 2025 to USD 988.4 million by 2035, registering a steady compound annual growth rate (CAGR) of 5.5%. This expansion reflects a structural shift across the oil and gas industry toward digital platforms capable of delivering accurate production allocation, automated reconciliation, and regulatory compliance in increasingly complex operational environments. As production portfolios expand across unconventional resources,…

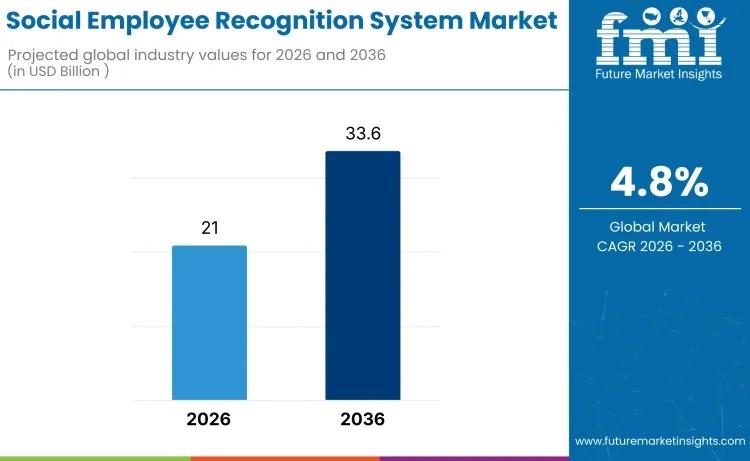

Social Employee Recognition System Market to Reach USD 33.6 Billion by 2036 as D …

The global social employee recognition system market is entering a new phase of strategic expansion, projected to grow from USD 21.0 billion in 2026 to USD 33.6 billion by 2036, reflecting a compound annual growth rate (CAGR) of 4.8%. This sustained growth trajectory highlights the increasing importance of employee engagement technologies in shaping organizational culture, enhancing workforce productivity, and supporting talent retention initiatives across diverse industries.

Organizations worldwide are prioritizing digital…

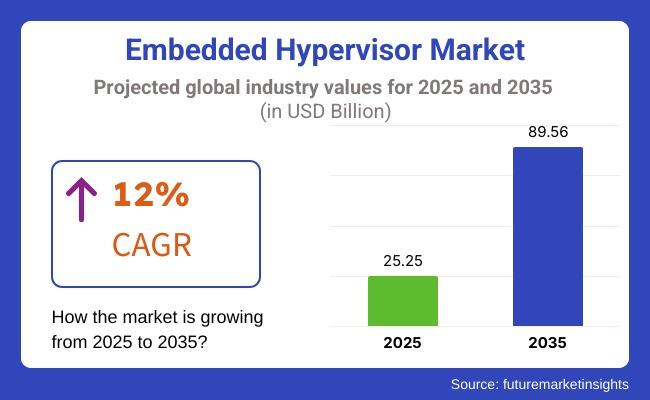

Embedded Hypervisor Market Set for Strong Expansion as Software-Defined Vehicles …

The global embedded hypervisor market is entering a period of accelerated expansion, driven by rising adoption of software-defined architectures across automotive, aerospace, industrial automation, and telecommunications industries. The market is projected to grow from USD 25.25 billion in 2025 to USD 89.56 billion by 2035, advancing at a compound annual growth rate (CAGR) of 12%, reflecting the increasing importance of secure, high-performance virtualization in mission-critical embedded systems.

Embedded hypervisors-specialized software layers…

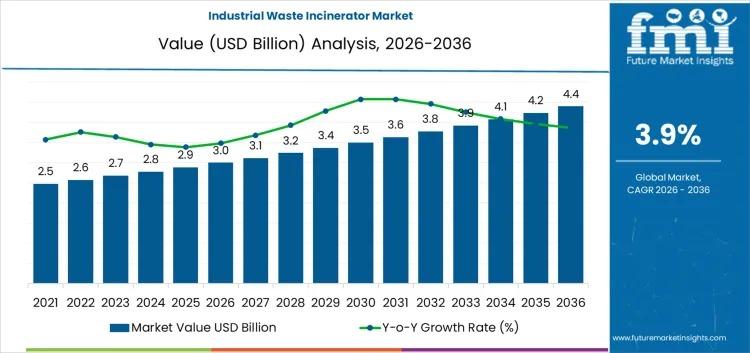

Industrial Waste Incinerator Market to Reach USD 4.4 Billion by 2036 as Industri …

The global industrial waste incinerator market is projected to grow from USD 3 billion in 2026 to USD 4.4 billion by 2036, registering a compound annual growth rate (CAGR) of 3.90% over the forecast period. This steady expansion reflects increasing global pressure on industrial operators to adopt sustainable waste management practices, comply with stringent environmental regulations, and reduce landfill dependence while improving operational efficiency.

As industrial sectors expand production capacity and…

More Releases for MHDV

India Automotive Composite Leaf Springs Market Poised for 7.5% CAGR Growth, Driv …

The India Automotive Composite Leaf Springs Market is entering a defining growth phase. Valued at approximately USD 50 million in 2025, the market is projected to expand steadily at a compound annual growth rate (CAGR) of 7.5%, ultimately reaching USD 85 million by 2035. This surge reflects the automotive industry's rapid transformation, shaped by rising demand for lightweight materials, government regulations promoting efficiency, and continuous innovations in manufacturing.

For manufacturers, this…