Press release

European Thermal Management Materials Market Outlook 2025-2035: Key Developments and Future Scope

The global thermal management materials market is set for strong and sustained expansion, supported by rapid advancements in electronics, accelerated EV adoption, and increasing thermal challenges in high-power applications.According to the latest analysis, the market is projected to grow from USD 4.32 billion in 2025 to USD 7.96 billion by 2035, reflecting an absolute growth of USD 3.64 billion and a CAGR of 6.3% over the forecast period.

Thermal management materials-including thermal interface materials (TIMs), phase change materials, thermal pads, adhesives, and insulators-are becoming essential components in heat-intensive devices and systems. As industries prioritize energy efficiency, system reliability, and miniaturization, demand for advanced heat-dissipation solutions is accelerating globally.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=12011

Key Market Drivers

Rising Heat Challenges in Electronics and Semiconductors

The rapid development of compact, high-power electronic devices-from 5G infrastructure to gaming consoles and consumer electronics-has intensified the need for efficient heat transfer materials. Manufacturers are increasingly incorporating TIMs, thermal greases, and thermal gels to enhance device reliability and performance amid rising thermal loads.

Electric Vehicle (EV) and Battery Thermal Management Gains Momentum

Thermal management is critical for EV battery longevity, charging efficiency, and safety. As global EV adoption accelerates, demand for thermal gap fillers, phase change materials, and insulation solutions is rising. Automotive OEMs and battery manufacturers are prioritizing materials that provide high thermal conductivity, low weight, and design flexibility.

Expansion of Industrial Automation and High-Performance Computing

Industries including aerospace, defense, telecommunications, and data centers are investing heavily in automation and high-performance computing (HPC). Thermal management materials enable stable system operations and prevent overheating in power electronics, servers, sensors, and industrial equipment.

Browse Full Report: https://www.factmr.com/report/thermal-management-materials-market

Sustainability and Energy Efficiency Initiatives

With industries shifting toward energy-efficient and eco-friendly manufacturing, advanced thermal materials are being adopted to reduce power consumption and enhance operational lifespans. Innovations in recyclable, halogen-free, and low-VOC thermal management materials are shaping the next generation of sustainable solutions.

Regional Growth Highlights

North America: Leading Innovation in Electronics & EVs

The United States continues to dominate demand driven by consumer electronics, data centers, and a strong EV production ecosystem. Increasing investments in semiconductor fabrication and 5G networks further propel the region's market trajectory.

Europe: Strong Growth in Automotive and Industrial Applications

Germany, the UK, and France are major markets driven by widespread industrial automation and leadership in electric and hybrid vehicle manufacturing. Europe's sustainability-focused policies accelerate adoption of advanced thermal solutions.

Asia-Pacific: Fastest-Growing Manufacturing Hub

China, Japan, South Korea, and India represent the world's largest base for consumer electronics and semiconductor production. APAC's robust supply chain, rising EV penetration, and government-backed tech manufacturing make it the fastest-growing region.

Rest of the World: Expanding Telecom and Energy Infrastructure

The Middle East, Africa, and Latin America are witnessing steady adoption due to expanding telecom infrastructure, renewable energy projects, and industrial modernization.

Market Segmentation Insights

By Product Type

Thermal Interface Materials (TIMs) - Widely used across electronics, EVs, and telecom equipment.

Phase Change Materials (PCMs) - Increasing adoption in high-performance computing and battery systems.

Ceramic & Metal-Based Thermal Materials - Preferred in high-stress industrial and aerospace applications.

Thermal Pads & Gap Fillers - Gaining demand for compact device assemblies.

By Application

Consumer Electronics

Automotive & EV Batteries

Telecommunication Equipment

Industrial Machinery

Data Centers & Servers

Aerospace & Defense

Market Challenges

Despite strong growth prospects, several factors restrain the market:

High Material Costs: Advanced materials like phase change systems and high-conductivity composites remain expensive.

Complex Manufacturing Requirements: Achieving consistent material performance and conductivity requires advanced processing techniques.

Thermal Runaway Risks in EV Batteries: Growing EV complexity increases the need for strict safety and testing protocols.

Supply Chain Volatility: Fluctuations in raw material availability can impact production timelines and cost structures.

Competitive Landscape

The thermal management materials market is moderately consolidated, with companies focusing on R&D, high thermal conductivity solutions, and application-specific product innovations. Strategic partnerships, technology licensing, and vertical integration are key strategies.

Prominent Market Players Include:

3M

Henkel AG & Co. KGaA

Dow Inc.

Parker Hannifin Corporation

Laird Performance Materials

Shin-Etsu Chemical Co.

Aavid Thermalloy

Honeywell International

Momentive Performance Materials

These companies are enhancing portfolios with advanced TIMs, thermal adhesives, and sustainable heat management materials to meet global demand.

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: https://www.factmr.com/checkout/12011

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@factmr.com

Future Outlook: Toward High-Efficiency, Sustainable, and Intelligent Thermal Solutions

Over the next decade, thermal management materials will play a pivotal role in reshaping high-tech industries. As electronic devices become more compact and powerful, and as EVs and renewable energy systems expand, demand for advanced thermal materials will surge.

Manufacturers that focus on high conductivity, miniaturization support, sustainability, and smart thermal systems are expected to gain a competitive advantage. With widespread digitalization and electrification underway, the thermal management materials market is positioned for robust and long-term growth.

Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release European Thermal Management Materials Market Outlook 2025-2035: Key Developments and Future Scope here

News-ID: 4307376 • Views: …

More Releases from Fact.MR

Organic Rice Syrup Market is forecasted to increase at a CAGR of 5.1% and US$ 1. …

The global Organic Rice Syrup Market is projected to expand steadily over the coming decade, driven by rising consumer demand for natural, clean-label sweeteners and growing awareness of health and wellness trends. Industry analysts estimate that the organic rice syrup market, valued at approximately USD 450 million in 2025, is expected to reach nearly USD 880 million by 2035, registering a compound annual growth rate (CAGR) of about 7.1% during…

Compound Horse Feedstuff Market is Estimated to Grow at a CAGR of 4.6%, Reaching …

The global compound horse feedstuff market is galloping toward steady growth, projected to expand from a valuation of USD 3.8 billion in 2026 to approximately USD 5.4 billion by 2036. This represents a compound annual growth rate (CAGR) of 3.6% over the ten-year forecast period.

The market is being driven by the "humanization" of equine companions, the professionalization of equestrian sports, and a significant shift toward specialized performance nutrition that…

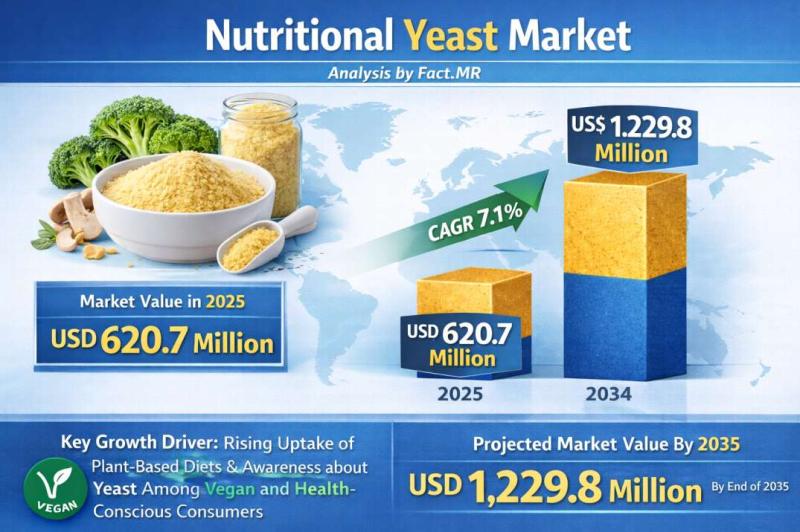

Nutritional Yeast Market Forecasted CAGR is 7.1% by 2035 | Fact.MR Report

The global nutritional yeast market is experiencing a significant surge in demand, projected to grow from a valuation of USD 515.2 million in 2026 to approximately USD 1.2 billion by 2036. This represents a robust compound annual growth rate (CAGR) of 8.8% over the ten-year forecast period.

The market is being propelled by the global explosion of plant-based diets and the "clean-label" movement, with nutritional yeast emerging as the primary…

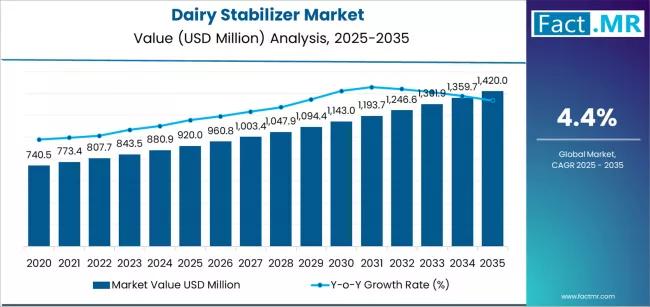

Dairy Stabilizer Market is Expected to Reach USD 1,420.0 million by 2035 | Resea …

The global Dairy Stabilizers Market is projected to sustain solid growth over the next decade as consumer demand for high-quality dairy and dairy-based products continues to expand across foodservice and retail sectors. Industry analysts estimate that the dairy stabilizers market, valued at approximately USD 2.4 billion in 2025, is expected to reach around USD 4.3 billion by 2035, registering a compound annual growth rate (CAGR) of about 6.5% during the…

More Releases for Thermal

EV Thermal System Market: Advancing Thermal Management for Next-Gen Electric Veh …

The EV Thermal System Market is experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs), advancements in battery thermal management systems (BTMS), and the rising demand for efficient cooling solutions. As EV manufacturers focus on improving battery efficiency, fast charging capabilities, and overall vehicle performance, the need for high-performance thermal systems has become critical.

As per FMI analysis the market is projected to reach USD 3.3 billion in…

Thermal Weeder Market

Thermal Weeder Market Value is Anticipated to Increase at a Stable CAGR over the Forecast Period (2023 to 2029). It provides an in-depth analysis of the market segments which include products, applications, and competitor analysis.

Important changes in the business allow key players to attain larger profits. This Thermal WeederMarket study report is the best way to make changes with the help of entire market condition and metrics provided here. These…

Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market …

According to Market Study Report, Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market provides a comprehensive analysis of the Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC,…

What is the Difference Between Direct Thermal and Thermal Transfer Labels?

Northern Label Systems, specialists in supplying high quality labels explain the differences between Direct Thermal https://www.northern-label-systems.co.uk/labels-by-type/direct-thermal-labels and Thermal Transfer Labels https://www.northern-label-systems.co.uk/labels-by-type/thermal-transfer-labels

Thermal Transfer printing uses an ink ribbon to transfer the printed image from the heated printhead of the label printer onto the surface of the label while Direct Thermal printing transfers the image directly onto a heat sensitive material.

There are advantages and disadvantages to both methods. Direct Thermal label…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) …

Qyresearchreports include new market research report "Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Sales Market Report 2018" to its huge collection of research reports.

This report studies the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market status and forecast, categorizes the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market size (value & volume) by key players, type, application, and…