Press release

Polyvinylpyrrolidone Production Plant (DPR) 2025: Machinery, Raw Materials, and Financial Outlook

Setting up a polyvinylpyrrolidone production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Polyvinylpyrrolidone Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a polyvinylpyrrolidone production plant cost, covering everything from product overview and production processes to detailed financial insights.

What is Polyvinylpyrrolidone?

Polyvinylpyrrolidone (PVP) production involves synthesizing a versatile, water-soluble polymer widely used in pharmaceuticals, cosmetics, food, and industrial applications. It is manufactured through the polymerization of N-vinylpyrrolidone using free-radical initiators under controlled temperature and pressure conditions. The resulting polymer solution undergoes purification, drying, and milling to achieve different molecular weights and grades suited for specific uses. Strict quality control ensures consistency in viscosity, purity, and solubility. PVP is valued for its binding, film-forming, dispersing, and stabilizing properties. Production facilities prioritize efficiency, safety, and regulatory compliance, delivering high-quality PVP for various formulation and processing needs.

What is Driving the Polyvinylpyrrolidone Market?

Concerning Polyvinylpyrrolidone, the largest end-user is the pharmaceutical industry. PVP applies to manufacturing tablets and other dosage forms because it binds, disintegrates, and stabilizes. PVP dissolves excellently and is compatible with active pharmaceutical ingredients, thereby making it a widely used excipient. The cosmetics and personal care industry is rising in the skincare and haircare markets because PVP is used for film-forming and thickening properties. The growing use of PVP in food, adhesives, coatings, and other industrial applications is driving market growth too. Rising healthcare spending, increasing manufacturing capacities, and continuous innovations in drug formulation technologies will likely drive the global market for PVP over the long term.

Request For a Sample Report: https://www.imarcgroup.com/polyvinylpyrrolidone-manufacturing-plant-project-report/requestsample

Key Steps Required to Set Up a Polyvinylpyrrolidone Production Plant

1. Market Analysis

The report provides insights into the landscape of the polyvinylpyrrolidone industry at the global level. The report also provides a segment-wise and region-wise breakup of the global polyvinylpyrrolidone industry. Additionally, it also provides the price analysis of feedstocks used in the production of polyvinylpyrrolidones, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the polyvinylpyrrolidone production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Buy now: https://www.imarcgroup.com/checkout?id=10060&method=2142

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for polyvinylpyrrolidone production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for polyvinylpyrrolidone production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a polyvinylpyrrolidone production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=10060&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

Browse Other Reports:

• Sodium Tripolyphosphate Production Plant Cost: https://www.imarcgroup.com/sodium-tripolyphosphate-manufacturing-plant-project-report

• Sorbic Acid Production Plant Cost: https://www.imarcgroup.com/sorbic-acid-manufacturing-plant-project-report

• Streptomycin Sulphate Production Plant Cost: https://www.imarcgroup.com/streptomycin-sulphate-manufacturing-plant-project-report

• Tea-Lauryl Sulfate Production Plant Cost: https://www.imarcgroup.com/tea-lauryl-sulfate-manufacturing-plant-project-report

• Tetraethyl Orthosilicate (Teos) Production Plant Cost: https://www.imarcgroup.com/tetraethyl-orthosilicate-manufacturing-plant-project-report

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polyvinylpyrrolidone Production Plant (DPR) 2025: Machinery, Raw Materials, and Financial Outlook here

News-ID: 4302230 • Views: …

More Releases from IMARC Group

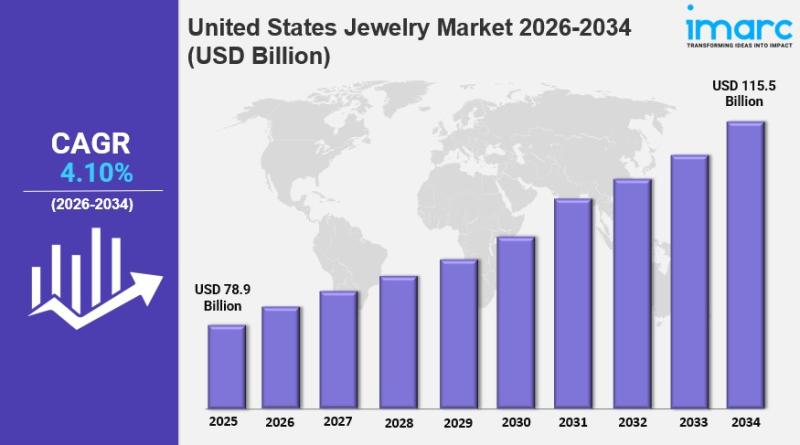

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

Mexico Medical Tourism Market 2026 : Industry Size to Reach USD 10.6 Billion by …

IMARC Group has recently released a new research study titled "Mexico Medical Tourism Market Size, Share, Trends and Forecast by Type, Treatment Type, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Medical Tourism Market Overview

The Mexico medical tourism market size reached USD 2.1 Billion in 2025. Looking forward, the market is projected…

Saudi Arabia Pilates & Yoga Studios Market Size to Surpass USD 3.6 Billion by 20 …

Saudi Arabia Pilates & Yoga Studios Market Overview

Market Size in 2024: USD 1.6 Billion

Market Forecast in 2033: USD 3.6 Billion

Market Growth Rate 2025-2033: 8.20%

According to IMARC Group's latest research publication, "Saudi Arabia Pilates & Yoga Studios Market Size, Share, Trends and Forecast by Activity Type, Application, and Region, 2025-2033", the Saudi Arabia pilates & yoga studios market size reached USD 1.6 Billion in 2024. Looking forward, IMARC Group expects the…

More Releases for Product

Product Launch

CHENNAI, INDIA - ShiningBot Data Analytics Private Limited, a leader in consumer behavior intelligence, today announced the official launch of ShiningBot version 2.0, a cloud-based platform designed to turn standard Guest WiFi into a sophisticated "intelligence layer" for physical businesses.

In an era where brick-and-mortar establishments struggle to match the data-rich insights of e-commerce, ShiningBot bridges the gap. By leveraging existing WiFi infrastructure, the platform allows Shopping Malls, Hotels, Hospitals, and…

Genstore Ranks #1 Product of the Day on Product Hunt

Los Angeles - September 11, 2025 - Genstore [https://www.genstore.ai/], an AI-native e-commerce platform, ranked #1 Product of the Day on Product Hunt and emerged as one of the week's top-trending products. The recognition underscores strong community support for Genstore's mission to make advanced commerce simple, accessible, and cost-efficient for small and medium-sized businesses worldwide.

Image: https://www.globalnewslines.com/uploads/2025/09/ab03aa9cb9a17e4c42e998d53f216bde.jpg

"Genstore lets anyone start selling online with just a prompt. But of course, that's just the…

Large Volume Parenteral Product Market New Product Development & Latest Trends

The global Large Volume Parenteral (LVP) market is poised for significant growth, projected to reach a value of approximately $12.5 billion in 2024. During the forecast period from 2025 to 2034, the market is expected to expand at a robust Compound Annual Growth Rate (CAGR) of 6.5%, culminating in an estimated market value of $22 billion by 2034.

Exactitude Consultancy., Ltd. released a research report offers a comprehensive examination of the…

Product technology, product usage tips, industry trends

Product Craftsmanship: Yiwu LABON Stationery Co., Ltd. Showcases Superior Craftsmanship in OEM Notebooks

Yiwu LABON Stationery Co., Ltd., established in 2003, has built a reputation for exceptional craftsmanship in the OEM notebook industry. Our factory-based company combines traditional techniques with modern innovation to create notebooks that stand out for their quality and design. Each notebook crafted by Yiwu LABON represents a meticulous process where attention to detail and precision are paramount.…

Product List: The Ultimate Destination for Product and Deal Discovery

Finding the right product or tool to suit your needs can be a daunting task, and securing the best deal on them can be equally challenging.

Each day, plenty of tools are launched, each with unique use cases. Individuals across various industries can benefit from these tools as they simplify their tasks compared to traditional methods. However, it's essential to consider the cost, as some tools are free while others come…

Logistics Packaging Market Enhance Product Safety, Maintain Product Quality, Ext …

MarketResearchReports.Biz presents this most up-to-date research on "Logistics Packaging Market: Global Industry Analysis 2013-2017 and Opportunity Assessment 2018-2028"

The global logistics sector continues to develop at an impressive rate. As a result, the packaging industry is undergoing enormous changes with specified focus on posing innovative packaging tools/products to various industry verticals. Logistics packaging is primarily done to enhance product safety, maintain product quality, extended product storage, and cater to other aspects…