Press release

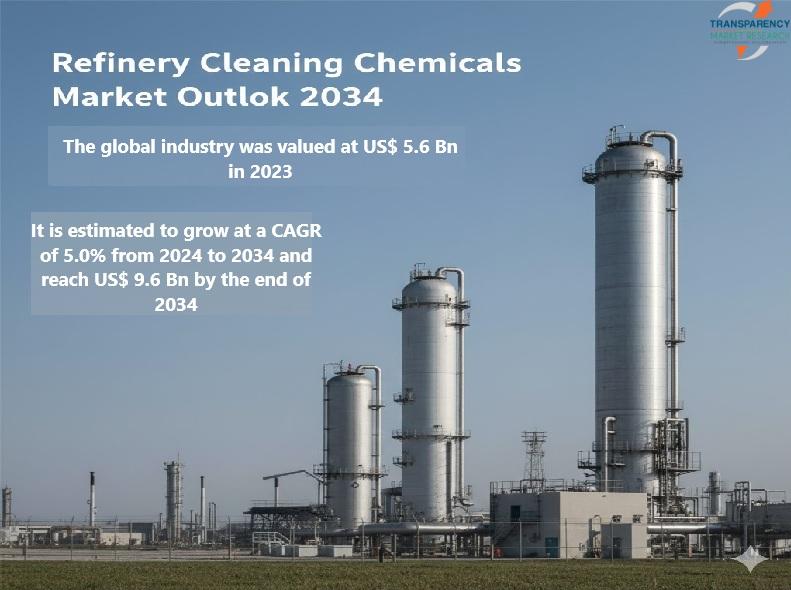

Refinery Cleaning Chemicals Market to Hit US$ 9.6 Billion by 2034 as Global Refineries Combat Fouling, Efficiency Loss, and Regulatory Pressure

The global refinery cleaning chemicals market was valued at US$ 5.6 Bn in 2023. It is projected to grow at a CAGR of 5.0% from 2024 to 2034, reaching US$ 9.6 Bn by the end of 2034. Growth is driven by the rising need for refinery maintenance, stricter environmental compliance mandates, expansion of downstream oil capacities, and increasing adoption of advanced chemical formulations that improve operational efficiency, cleaning speed, and safety.Dive Deeper into Data: Get Your In-Depth Sample Now!

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86022

Market Overview

The refinery cleaning chemicals market plays a foundational role in ensuring that refineries operate safely, efficiently, and with minimal downtime. As crude oil processing introduces contaminants such as sludge, scale, coke deposits, corrosive substances, and paraffinic residues, cleaning chemicals are required to remove these impurities from equipment and pipelines. These products enhance plant reliability, extend asset lifetime, and reduce maintenance-related disruptions. Over the past decade, the increasing complexity of crude blends and the rising demand for optimal plant throughput have driven refiners to adopt more sophisticated cleaning formulations. This includes a shift from traditional solvent-based cleaners to eco-friendly, high-performance chemicals that meet regulatory and occupational safety standards. The result is a market steadily evolving in terms of formulation chemistry, application methodologies, and sustainability requirements.

Introduction

Refinery cleaning chemicals are essential for maintaining process equipment such as heat exchangers, distillation columns, pipelines, reactors, vessels, storage tanks, and boilers. These chemicals help dissolve fouling deposits, break down hydrocarbon residues, remove rust and mineral scale, and prepare units for shutdown inspections or startup operations. With the constant push for higher operational efficiency and reduced downtime, refineries today rely on cleaning methods that offer faster action, reduced manual intervention, and improved environmental compatibility. The growing use of heavy and sour crudes, which contain higher levels of sulfur, metals, and asphaltenes, has increased fouling intensity across refinery units. As a result, the demand for advanced cleaning formulations has accelerated, particularly in regions where refinery modernization and capacity expansion projects are ongoing. The shift toward greener chemistries is further influencing product development, making sustainability a defining theme of the market.

Key Market Drivers

One of the key forces driving the refinery cleaning chemicals market is the continuous expansion of global refining capacities, especially in Asia and the Middle East. New refinery complexes require large volumes of chemicals for pre-commissioning cleaning, pipeline flushing, and system preparation. Another major driver is the growing reliance on heavy and opportunity crudes, which create more challenging fouling conditions due to their higher impurity levels. This directly increases the frequency and intensity of cleaning activities. In addition, refiners across the world are prioritizing operational efficiency to reduce production losses and unplanned shutdowns. Advanced cleaning chemicals that improve heat exchanger performance, restore flow rates, and minimize fouling-induced energy losses are increasingly in demand. Environmental regulations are becoming stricter each year, pushing refiners to choose low-toxicity, biodegradable, and low-VOC formulations. The aging of refinery infrastructure in North America and Europe has also led to a rise in maintenance cycles, further boosting chemical consumption. Finally, technological advancements and digital integration in refinery maintenance are creating new opportunities for chemical manufacturers to deliver more precise, effective, and sustainable solutions.

Technology Landscape

The technological landscape of refinery cleaning chemicals is undergoing rapid transformation as refineries demand safer, more efficient, and environmentally responsible formulations. Modern cleaning chemicals rely on advanced surfactants that enhance the emulsification and dispersion of hydrocarbon residues, enabling deep cleaning with lower product consumption. Inhibited acid formulations have also gained popularity, especially for descaling applications, as they can dissolve mineral deposits without causing significant corrosion to metal surfaces. Solvent-free and water-based degreasers are experiencing high adoption due to their reduced environmental footprint and improved worker safety profile.

Bio-based formulations, including enzymatic cleaners derived from plant and microbial sources, represent another emerging segment, offering biodegradability and performance benefits when compared to traditional products. Foam-based cleaning technologies are enhancing coverage inside complex refinery units, improving cleaning uniformity and reducing application time. Online cleaning technologies, which allow heat exchangers and pipelines to be cleaned without disrupting operations, are witnessing strong acceptance as refineries aim to reduce downtime. Collectively, these innovations signal a broader industry shift toward chemistries that combine performance, efficiency, and sustainability.

Buy Now: https://www.transparencymarketresearch.com/checkout.php?rep_id=86022<ype=S

Market Challenges

Despite the strong growth outlook, the refinery cleaning chemicals market faces several challenges. One of the most significant barriers is the cost associated with treating and disposing of hazardous waste generated after cleaning operations. Effluents often contain hydrocarbons, heavy metals, and toxic residues that must be treated under strict regulatory guidelines. This increases operating costs and slows down cleaning cycles.

Worker safety is another key concern. Many conventional cleaning chemicals contain acids, caustics, and powerful solvents that can pose risks if not handled appropriately. Ensuring worker safety requires training, protective equipment, and specialized application processes, all of which add to expenses.

In addition, eco-friendly cleaning chemicals, although preferable, generally come at a higher cost. Many refineries, especially in developing markets, hesitate to adopt premium products due to budget constraints. Lastly, the global shift toward renewable energy and electrification raises long-term uncertainties over growth rates in the oil refining sector, although near-term impacts remain minimal.

Regional Insights

North America represents one of the most advanced markets for refinery cleaning chemicals because of its large number of aging refineries that require frequent maintenance. The region's strict environmental norms also accelerate adoption of eco-friendly formulations. Europe similarly emphasizes sustainable and regulatory-compliant solutions, with demand supported by refinery modernization and planned maintenance cycles.

Asia Pacific is the fastest-growing market, driven by expanding refining capacity in China, India, and Southeast Asia. The region's rapid industrialization and rising fuel consumption make refinery cleaning a recurring necessity. In the Middle East, national oil companies continue to invest in large-scale refinery complexes, thereby generating substantial demand for both offline and online cleaning chemicals. Latin America and Africa show moderate but steady growth thanks to refinery upgrades in Brazil, Mexico, and parts of Sub-Saharan Africa.

Competitive Landscape

The competitive landscape is moderately consolidated, with leading companies focusing on developing advanced chemical formulations, expanding service portfolios, and strengthening their presence in emerging markets. Many suppliers now offer combined chemical and mechanical cleaning services, providing refineries with integrated maintenance solutions. Innovation remains the central competitive strategy, with companies investing in cleaner, safer, and more efficient chemical technologies. Strategic collaborations with refinery equipment manufacturers and engineering service providers also help vendors broaden their market reach.

BASF SE

Evonik

Clariant

Dow

Solvay

Ecolab

DuPont

Stepan Company

Future Outlook

Looking ahead to 2034, the refinery cleaning chemicals market is expected to grow steadily as refineries seek to maximize operational reliability, comply with environmental standards, and maintain competitiveness. The transition toward green chemistry will intensify, driving the development of biodegradable and low-toxicity cleaning agents. Automation and digitalization will further transform cleaning operations, with remote monitoring, predictive maintenance, and automated foam cleaning systems becoming more widespread.

Although long-term shifts in global energy consumption may influence refinery activity, the industry's maintenance needs will remain robust for the foreseeable future. Refinery cleaning chemicals will continue to be indispensable for sustaining efficiency, optimizing throughput, and meeting regulatory expectations worldwide.

Explore Latest Research Reports by Transparency Market Research:

Vegan Chocolate Market: https://www.transparencymarketresearch.com/vegan-chocolate-market.html

Polyhydroxyalkanoate Market: https://www.transparencymarketresearch.com/polyhydroxyalkanoate-market.html

Flooring Market : https://www.transparencymarketresearch.com/flooring-market.html

Produced Water Treatment Market: https://www.transparencymarketresearch.com/produced-water-treatment-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact Us:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Refinery Cleaning Chemicals Market to Hit US$ 9.6 Billion by 2034 as Global Refineries Combat Fouling, Efficiency Loss, and Regulatory Pressure here

News-ID: 4302165 • Views: …

More Releases from Transparency Market Research

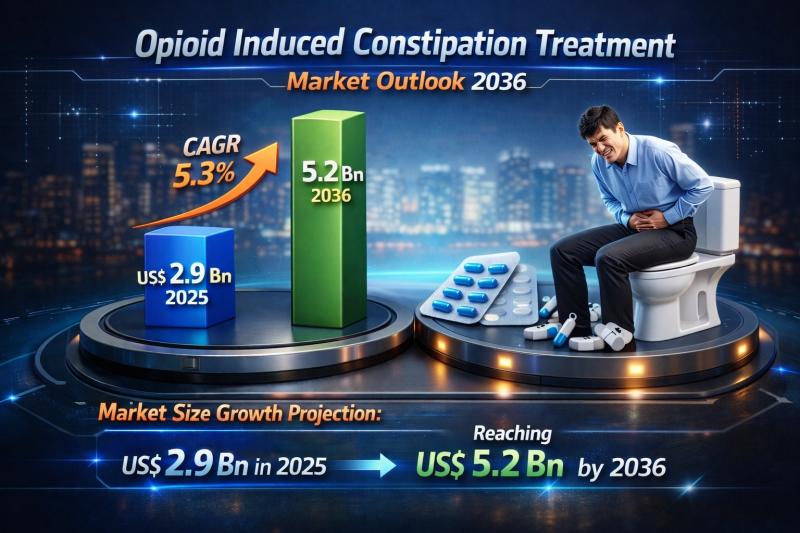

Global Opioid Induced Constipation Treatment Market Set to Reach USD 5.2 Billion …

The global opioid induced constipation (OIC) treatment market is witnessing steady and sustained growth as healthcare systems worldwide place increasing emphasis on comprehensive pain management and supportive care. Valued at US$ 2.9 billion in 2025, the market is projected to reach US$ 5.2 billion by 2036, expanding at a compound annual growth rate (CAGR) of 5.3% from 2026 to 2036. Growth is primarily fueled by the rising prevalence of chronic…

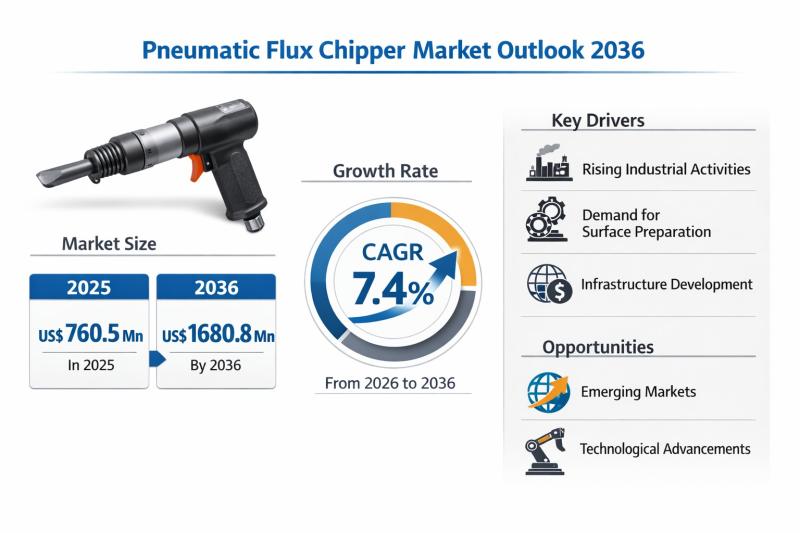

Pneumatic Flux Chipper Market Expanding at 7.4% CAGR Through 2036 - By Product T …

The global Pneumatic Flux Chipper Market is set to witness sustained and resilient growth over the next decade, underpinned by expanding heavy manufacturing activities, rising welding and fabrication demand, and continuous investments in industrial infrastructure across emerging and developed economies. According to the latest industry analysis, the market was valued at US$ 760.5 Mn in 2025 and is projected to reach US$ 1,680.8 Mn by 2036, expanding at a compound…

AI in Automotive Market Outlook 2036: Global Industry to Surge from US$ 19.8 Bil …

The AI in automotive market is entering a phase of exponential expansion, supported by rapid digitization of vehicles, growing safety mandates, and consumer demand for intelligent mobility. The global market was valued at US$ 19.8 Bn in 2025 and is projected to reach US$ 244.4 Bn by 2036, registering a remarkable CAGR of 27% from 2026 to 2036.

This growth trajectory reflects the transition of automobiles from mechanically driven products to…

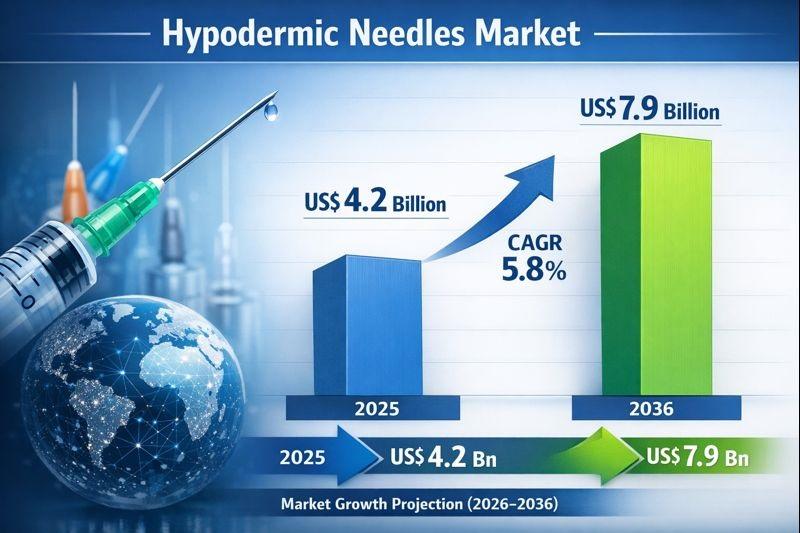

Hypodermic Needles Market to Reach US$ 7.9 Billion by 2036 on Rising Injectable …

The global hypodermic needles market was valued at approximately US$ 4.2 billion in 2025 and is projected to reach around US$ 7.9 billion by 2036, expanding at a CAGR of nearly 5.8% from 2026 to 2036, driven by the rising prevalence of diabetes, cancer, and chronic diseases, growing demand for injectable drugs and biologics, and the expansion of global vaccination and immunization programs; increasing adoption of safety-engineered and disposable needles,…

More Releases for Refinery

Refinery Catalyst Market: Refinery Catalyst Market Projections: Innovations and …

Market Overview:

Refinery catalysts are used in petroleum refining operations to facilitate and accelerate chemical reactions for conversion of crude oil into useful petroleum products like gasoline, diesel, jet fuel etc. Without catalysts, refining processes would be inefficient or not commercially viable.

Get Sample Report with Global Industry Analysis @ https://www.coherentmarketinsights.com/insight/request-sample/736

Major Players Are:

✤ BP Global and Royal Dutch Shell. Other key industry participants include YARA International

✤ Foster Wheeler AG

✤ OXEA GmbH

✤ W…

Refinery, Re-refinery, and Bio Fuel Catalysts Market, Key Vendors, Segment, Grow …

Refinery, Re-refinery, and Bio Fuel Catalysts Market analysis report has recently added which helps to make informed business decisions. This research report further identifies the market segmentation along with their sub-types. The Global Refinery, Re-refinery, and Bio Fuel Catalysts Market is expected to reach at a huge CAGR during the forecast period. Various factors are responsible for the market's growth, which are studied in detail in this research report.

The report…

Crude Oil Refinery Market to Watch: Spotlight on Isla Oil Refinery, Paraguana Re …

Global Crude Oil Refinery Market Report 2020 by Key Players, Types, Applications, Countries, Market Size, Forecast to 2026 (Based on 2020 COVID-19 Worldwide Spread) is latest research study released by HTF MI evaluating the market, highlighting opportunities, risk side analysis, and leveraged with strategic and tactical decision-making support. The study provides information on market trends and development, drivers, capacities, technologies, and on the changing investment structure of the Global Crude…

Oil Refining Market And Top Key Players are Baton Rouge Refinery (ExxonMobil), G …

The global oil refining market is estimated to grow from US$XX in 2017 to US$XX in 2022, at a CAGR of XX% during the forecast period .Currently, crude oil is one of the most present and essential' resources. It is processed at an oil refinery and converted into more useful forms such as gasoline, diesel fuel, naptha, kerosene etc. Typically oil refineries are large, sprawling industrial complexes with extensive piping…

Global Refinery Maintenance Review Report 2017: Refinery Maintenance Soars in As …

A latest research report titled as ” Global Refinery Maintenance Review Report 2017: Refinery Maintenance Soars in Asia ” has been recently added to the vast portfolio of Market Research Hub (MRH) online research offerings. This report is a professional and in-depth analysis on the present state and future prospect for the global market. It provides valuable information to the industry insiders, potential entrants or investors. It includes an exhaustive…

Refinery, Re-refinery, and Bio Fuel Catalysts 2017 Global Market Key Players - R …

Refinery, Re-refinery, and Bio Fuel Catalysts Market

Wiseguyreports.Com Adds “Refinery, Re-refinery, and Bio Fuel Catalysts Market -Market Demand, Growth, Opportunities, Manufacturers, Analysis of Top Key Players and Forecast to 2022” To Its Research Database.

Description:

The 2016 study has 36 pages, 18 tables and figures in excel. Worldwide Refinery, Re-refinery, and Bio Fuel Catalysts markets are poised to achieve significant growth with the shift in types of feedstock being…