Press release

Why Metal Sealing Rings Matter Now: High-Growth Opportunities Across Asia and Southeast Asia Uncovered

The market for metal sealing rings plays a critical role across heavy industry, energy, transport and high-reliability manufacturing where metal-to-metal or metal-backed sealing solutions are required for extreme temperature, pressure and chemical environments. This report presents a concise industry explanation and global overview, then dives into technology, Asia and ASEAN regional perspectives (with a spotlight on Indonesia), industry challenges, strategic guidance and leading suppliers. The report closes with conclusions, an investor analysis and practical purchase rationale. Metal sealing rings are engineered components often spring-energized, metal C-rings, X-rings or metal-faced seals that provide hermetic or high-integrity seals where polymer-only solutions cannot meet reliability or environmental requirements. They are widely used in rotating equipment, valves, high-pressure flanges, cryogenic and high-temperature systems, and in specialty applications where long life and minimal leakage are essential.In 2024 the global market value for metal sealing rings amounted to USD 2,205 million with an expected compound annual growth rate of 5.2% through 2031, reaching market size USD 3,138 million by 2031. With an average selling price of USD 100K per K unit, the market corresponds to approximately 22,050 K units sold globally in 2024. At factory gross margin of 35%, the factory gross profit is at USD 35.000 per K unit and cost of goods sold is USD 65.000 per K unit. The COGS breakdown is raw materials, direct labor, manufacturing overhead, finishing/heat treatment & surface processing and packaging & logistics. A single line full machine capacity production is around 150K units per line per year. Downstream demand is concentrated in automotive, industrial machinery, oil & gas & petrochemical, power generation, aerospace, medical and life sciences.

Latest Trends and Technological Developments

Manufacturers and service providers in 2024 to 2025 have emphasized digital development, emissions-reducing seal designs for rotating equipment, and simulation-driven R&D. Notably, John Crane announced the launch of a next-generation coaxial separation/dry gas sealing product (Type 93AX) on June 2025, highlighting reductions in ancillary nitrogen consumption and lifecycle cost improvements for energy and process customers. Freudenberg Sealing Technologies has invested in advanced simulation and micro-seal development and published press materials in mid-2025 describing digital simulation workflows that accelerate custom seal design and miniaturized metal-backed seals for medical and high-precision applications (August 2025). Industry events and technical short courses through 2025 have also focused on sustainability (PFAS impact), seal selection for low-emission equipment, and replacement/serviceability improvements to reduce downtime and lifetime total cost of ownership.

Kuwait Oil Company purchases a batch of high-temperature, high-pressure API 6A metal sealing rings from Vallourec S.A. for use in critical wellhead assemblies, with the procurement valued around USD 185 per unit for specialized nickel-alloy rings under a contract totaling USD 9,250 for 50 units.

In the Ichthys LNG Project offshore Australia, corrosion-resistant Inconel 718 metal sealing rings supplied by TechnipFMC were installed in subsea manifold systems to ensure long-term integrity under extreme pressure and saline conditions. The rings, procured at a cost of USD 200 per unit, were integral to a manifold sealing package worth over USD 50,000, preventing hydrocarbon leaks in depths exceeding 250 meters.

Asia driven by China, Japan, South Korea, India and growing manufacturing bases in Southeast Asia remains the largest regional demand center for metal sealing rings because of automotive manufacturing, petrochemical plants, power generation projects and growing semiconductor and medical-device sectors. Investment in electrified vehicle manufacturing, hydrogen and renewable energy infrastructure is creating demand for specialised metal seals (hydrogen service, high temperature/cryogenic). China continues to be a dominant production hub for commodity metal seals while Japan and Korea lead in high-precision engineering and materials science. Regional supply chains show increasing vertical integration, with several Asian companies expanding material treatment and surface-engineering capabilities to improve lifetime performance and to serve OEM customers locally. Broader regional growth and aftermarket replacement demand continue to outpace mature markets, supported by government infrastructure projects and regional manufacturing reshoring.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5517689

Metal Sealing Rings by Type:

Type C

Type O

Others

Metal Sealing Rings by Product Category:

Stainless Steel

Nickel Alloy

Others

Metal Sealing Rings by Market Segment:

High-Temperature Type

Low-Temperature Type

Metal Sealing Rings by Usage:

Oil and Gas Pipeline and Valves

Industrial Pumps and Compressors

Semiconductor and Vacuum Processing Equipment

Chemical Processing Plant

Others

Metal Sealing Rings by Size:

Small diameter (100 mm)

Others

Metal Sealing Rings by Application:

Aerospace

Automobile Industry

Nuclear Industry

Marine Industry

Others

Global Top 15 Key Companies in the Metal Sealing Rings Market

Fluorocarbon

Technetics Group

Omniseal Solutions

M Barnwell Services

Eurosealings NV

Freudenberg Oil & Gas Technologies

Munaco Sealing

ROC Carbon

JETSEAL

Cross Manufacturing

American Tube Technology

Smalley

Parker

Trelleborg Group

NOK

Regional Insights

Within ASEAN, demand drivers vary by country: Indonesia and Malaysia show strong demand from oil & gas, mining and downstream petrochemical investments; Thailand and Vietnam are expanding automotive and component manufacturing; and Singapore functions as a regional engineering, testing and aftermarket service hub. In Indonesia specifically, metal sealing rings are in high demand for the oil & gas sector, pulp & paper mills, shipping and growing ammonia/hydrogen pilot projects. Local sourcing is increasing to reduce lead times and import costs, but high-specification rings (for extreme pressure, cryogenic or aerospace) are still frequently supplied by global Tier-1 vendors or through regional partners. ASEAN manufacturers are investing in heat treatment, CNC finishing and inspection equipment to capture more of the value chain and to comply with increasingly stringent standards required by international OEMs and energy companies.

The industry faces several persistent challenges: raw material cost volatility (stainless steels, speciality alloys and spring alloys), tightening environmental regulation (e.g., PFAS restrictions affecting some lubricants and sealants), and the technical difficulty of scaling precision finishing and quality assurance without eroding margins. Long lead times for specialty alloys and the capital intensity of automated finishing and testing limit rapid capacity expansion. Another challenge is the required certification and qualification cycles for critical industries (aerospace, nuclear, medical), which lengthen sales cycles and increase development costs. Finally, aftermarket competition from low-cost suppliers puts pressure on prices in commodity applications while higher-spec niches demand continuous R&D investment.

Producers should prioritize a two-track strategy: first, defend and grow margins in high-value, high-spec niches (hydrogen service, cryogenic, aerospace and semiconductor) where technical barriers and certification requirements raise switching costs; second, pursue cost leadership and near-market manufacturing for commodity segments (automotive, basic industrial) through regional plants, strategic partnerships, and modular automated lines to reduce lead times. Investment in simulation-led design, surface-treatment capabilities, and in-situ condition monitoring (to support predictive maintenance agreements with OEMs and end-users) will differentiate suppliers. Companies should also formalize aftermarket service offeringsfast-turn replacement rings, refurbishment and engineered upgrade kitsto increase lifetime revenue per installation.

Product Models

Metal sealing rings are precision-engineered components used to provide leak-tight, high-pressure, and high-temperature sealing in industries such as oil & gas, aerospace, chemical processing, and power generation.

Type C is a C-shaped metal sealing rings feature a curved, open-cavity profile that enables elastic deformation under load. Notable products include:

MetalliSeal C-Ring Technetics Group: Precision metal C-ring for extreme environments with excellent springback properties.

CMS High-Temp C-Seal Custom Metal Seals: A corrosion-resistant C-style seal used in chemical and refinery systems.

Inconel C-Ring Seal EagleBurgmann: Durable C-profile seal engineered for compressors and turbo machinery.

UltraSeal C-Profile Saint-Gobain Seals: Designed for aerospace propulsion and cryogenic systems.

C-Metallic Ring Seal Klinger: General industrial C-seal providing strong resilience and chemical resistance.

Type O is a O-shaped metal sealing rings are continuous circular rings with a solid or hollow core, delivering consistent compression and uniform sealing performance. Notable products include:

O-Ring Metal Seal 700 Series Parker Hannifin: A metal O-ring for static sealing in high-pressure gas systems.

Metal O-Ring LevelShield Technetics Group: Hollow metal O-ring offering superior temperature resistance.

MO-Series Metallic O-Seal Custom Metal Seals: Designed for vacuum systems and semiconductor equipment.

Inconel O-Metal Ring EagleBurgmann: A robust O-ring for high-pressure valves and heavy-duty pumps.

Metallic O-Seal H-Line Garlock: A corrosion-resistant O-ring used in chemical processing plants

The metal sealing rings market is mature but technically evolving: steady demand from traditional heavy industries is being complemented by new opportunities in low-emission energy, electric mobility, hydrogen systems and medical/semiconductor miniaturization. With a 2024 market value of USD 2,205 million and an expected 5.2% CAGR to 2031, the sector offers predictable replacement and aftermarket flows alongside pockets of premium growth for advanced materials and engineered designs. Competitive advantage will accrue to firms that combine regional manufacturing scale with technological differentiation and aftermarket service models.

Investor Analysis

Product innovation (spring-energized and metal-faced seal advances), qualification wins in hydrogen/aerospace projects, regional production expansion in Asia/ASEAN, and margin trends as lines are automated. New product launches and R&D-driven simulation capabilities indicate higher barriers to entry and potential for premium pricing; regional capacity builds in Southeast Asia indicate opportunities to capture local OEM sourcing and reduce logistic costs; aftermarket service programs create recurring revenue and improve lifetime margins. Predictable replacement cycles and high-value niche contracts (e.g., hydrogen compressors, cryogenic valves) create visibility for cash flow, while cost-control measures and local manufacturing can protect margins as demand volumes scale making well-positioned suppliers attractive for strategic or financial investors seeking a mix of steady income and selective growth exposure.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/4399161

5 Reasons to Buy This Report

Obtain a concise, region-focused view of the 2024 metal sealing rings market value and unit economics.

Understand Asia and ASEAN demand dynamics and country-level drivers, including Indonesia.

See up-to-date technological and product development headlines relevant to revenue and margin outlook.

Get practical factory-level economics: selling price, COGS breakdown, factory gross profit per unit and typical line capacity.

Receive actionable strategic recommendations and investor-impact analysis linking product, operations and market opportunities.

5 Key Questions Answered

What was the market size and unit volume for metal sealing rings in 2024?

How is the selling price, COGS structure and factory margin typically distributed for these products?

Which end-user sectors drive the majority of demand (global & regionally for Asia/ASEAN)?

What are the latest product and R&D developments that may change competitive dynamics?

Which suppliers dominate the global market and what are the levers they use to protect margins?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Metal Sealing Rings Market Research Report 2025

https://www.qyresearch.com/reports/3591557/metal-sealing-rings

Metal Sealing Rings - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/5517689/metal-sealing-rings

Global Metal Sealing Rings Market Outlook, InDepth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/5423765/metal-sealing-rings

Global Metal Sealing Rings Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/3601824/metal-sealing-rings

Global Metal Ring Seals Market Research Report 2025

https://www.qyresearch.com/reports/3698756/metal-ring-seals

Global Metal O-ring Seals Market Research Report 2025

https://www.qyresearch.com/reports/4779236/metal-o-ring-seals

Global Metal Spring Energy Storage Seal Ring Market Research Report 2025

https://www.qyresearch.com/reports/4584956/metal-spring-energy-storage-seal-ring

Global Metal V-Seals Market Research Report 2025

https://www.qyresearch.com/reports/4584967/metal-v-seals

Global Metal E-Seals Market Research Report 2025

https://www.qyresearch.com/reports/4584963/metal-e-seals

Global Metal Gasket Seals Market Research Report 2025

https://www.qyresearch.com/reports/4781702/metal-gasket-seals

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Why Metal Sealing Rings Matter Now: High-Growth Opportunities Across Asia and Southeast Asia Uncovered here

News-ID: 4301192 • Views: …

More Releases from QY Research

High Margins, High Growth: Inside the Global Luxury Beauty Opportunity

Luxury beauty encompasses premium skincare, cosmetics, fragrance, haircare, dermo-cosmetics, and prestige personal care products positioned with superior ingredients, branding, exclusivity, and high ASPs.

Core value drivers include brand heritage, innovation in active ingredients, dermatological efficacy, sustainability claims, and experiential retail.

Consumers increasingly view luxury beauty as self-care + wellness investment, not discretionary spending alone.

Distribution mix: specialty beauty retail, department stores, travel retail, e-commerce, brand boutiques, medical aesthetic clinics.

Global Market Snapshot

Market size (2025):…

Security Seals Market 20252032: Smart Tech, Recurring Revenue, and Investor Upsi …

Single use security seals are tamper-evident mechanical or plastic locking devices designed for one-time application to secure containers, trucks, meters, ballot boxes, airline carts, cash bags, and logistics assets

Core function: theft deterrence, chain-of-custody control, compliance with customs, transport, and regulated industries

Widely used in logistics, utilities, aviation catering, banking, postal, healthcare, and e-commerce fulfillment

Market characterized by high volume, low ASP consumables with recurring replacement demand

Global Overview

Global market size (2025): USD 352…

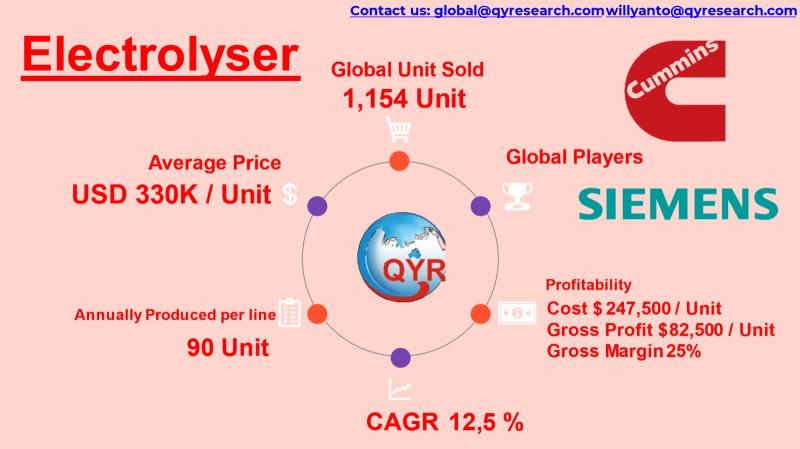

Hydrogen Infrastructure Surge: Why Electrolysers Are the Next Energy Investment …

Electrolyser systems are core equipment for producing green hydrogen through water electrolysis, converting electricity (increasingly renewable) into hydrogen and oxygen.

The industry underpins decarbonization across refining, fertilizers, steelmaking, mobility, and grid storage, making electrolysers a critical enabling technology for the global energy transition.

Technology categories include alkaline (AEL), proton exchange membrane (PEM), and solid oxide (SOEC), each optimized for different cost, efficiency, and operating profiles.

Global Market Overview

Global market size (2025): USD 381…

Top 30 Indonesian Dairy Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Indofood Sukses Makmur Tbk (INDF)

PT Indofood CBP Sukses Makmur Tbk (ICBP)

PT Ultrajaya Milk Industry & Trading Company Tbk (ULTJ)

PT Cisarua Mountain Dairy Tbk (CMRY)

PT Diamond Food Indonesia Tbk (DMND)

PT Mulya Boga Raya Tbk

PT Campina Ice Cream Industry Tbk

PT Kurniamitra Duta Sentosa Tbk

PT Greenfields Indonesia

PT Indolakto (subsidiary/brand under Indofood)

PT Ultra Jaya Frozen Foods (group affiliate)

PT Heilala Dairy Indonesia (export arm/processing)

PT Diamond Milk Products (non-listed…

More Releases for Seal

Tanggu Water-Seal Valve: Global Leading Water Seal Valve Supplier

Tanggu Water-Seal Valve: Global Leading Water Seal Valve Supplier

In the critical arena of global water management, the infrastructure that supports our cities, industries, and ecosystems depends on a single, vital element: reliable flow control. As we navigate the challenges of 2026-marked by rapid urbanization, aging municipal networks, and the urgent need for sustainable wastewater treatment-the role of high-performance valve technology has never been more paramount. Standing at the forefront of…

SEAL IT Seal Coating & Power Washing Expands Seal Coating Services to Meet Growi …

The company's service portfolio now also includes more specialized options, such as aggregate seal coating, which has been introduced to cater to the diverse needs of modern infrastructure. Aggregate seal coating is particularly valued for its enhanced texture and improved skid resistance, making it suitable for high-traffic areas, public spaces, and commercial zones requiring additional surface safety.

Special emphasis has been placed on expanding services in the state of Tennessee, with…

Customer Satisfaction Soars with SEAL IT Seal Coating & Power Washing New Techno …

This advancement has not only improved the efficiency and effectiveness of their seal coating and power washing processes but has also led to a surge in customer satisfaction. This blog will explore the innovative technology employed by SEAL IT, highlighting its impact on seal coating and the use of driveway coat sealers.

In the competitive world of home maintenance, customer satisfaction stands as a vital indicator of success. SEAL IT Seal…

Seal Systems Market Next Big Thing | Seal Systems, Hanel PT, John Crane

SMI's latest published intelligence report "Seal Systems Market 2023" offers in-depth market insights that assist global businesses to obtain growth opportunities. Understand how the purchase of the report can have a direct impact on your revenue. The demand for Seal Systems is expected to upward jostle in the future with the surge in the number of Seal Systems market players. The market is estimated to grow at an enormous CAGR…

Gusset Seal Market

Data Bridge Market Research analyses that the gusset seal market will project a CAGR of 4.00% for the forecast period of 2022-2029 and is likely to reach the USD 1,513.05 million by 2029.

Get Full Report: https://www.databridgemarketresearch.com/reports/global-gusset-seal-market

The bottom of a gusseted trash bag is sealed, and the sides are tucked in to produce gussets, or extensions. Trash in gusset sealed bags tends to spread to all sections of…

Weatherstrip Seal Market Forecast Report on Weatherstrip Seal Market 2018 to 202 …

Weatherstripping is the way toward sealing the openings, for example, windows, doors, and trunks of the components. The term is also used for the materials used to complete such sealing procedures. The objective of weatherstripping is to keep rain and water from entering partially or completely achieves this by either rerouting or returning the water leakage. Another objective of weatherstripping is to keep inside air in, in this manner energy…