Press release

Hydrogen Bromide Production Plant Setup: Attractive Long-Term Investment Plan

Setting up a hydrogen bromide production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Hydrogen Bromide Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a hydrogen bromide production plant setup cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/hydrogen-bromide-manufacturing-plant-project-report/requestsample

What is Hydrogen Bromide?

The cost of setting up a hydrogen bromide production plant depends on several critical factors, including plant capacity, production technology, raw material availability, location, utility requirements, and compliance with environmental standards. Establishing a medium- to large-scale hydrogen bromide plant generally requires significant capital investment, often ranging in the tens of millions of dollars, due to the need for specialized synthesis reactors, absorption columns, and purification systems. Major cost components include land acquisition, site development, reactor units, direct synthesis facilities, absorption towers, storage infrastructure, utilities, wastewater treatment, and safety systems. Additionally, the procurement of feedstock such as hydrogen gas and bromine, along with advanced corrosion-resistant equipment and safety containment systems, adds substantially to initial expenses. Operating costs further involve labor, energy, maintenance, and logistics. The setup cost also varies depending on whether the plant uses direct synthesis of hydrogen and bromine, hydrobromic acid concentration processes, or bromide salt acidification methodologies. Compliance with strict international and regional regulatory frameworks, particularly regarding hazardous chemical production standards, Occupational Safety and Health Administration (OSHA) requirements, Environmental Protection Agency (EPA) regulations, and corrosive substance handling controls, can significantly increase both capital and operational costs. However, while initial investment is substantial, hydrogen bromide production plants offer attractive long-term returns due to the product's wide applications in pharmaceuticals, flame retardants, organic synthesis, semiconductor manufacturing, and specialty chemical production, making them a strategic venture for specialized chemical and industrial gas investors.

What is Driving the Hydrogen Bromide Market?

The hydrogen bromide production plant cost market is primarily driven by rising demand for pharmaceutical intermediates, flame retardants, and specialty chemical applications across manufacturing, electronics, and processing sectors. With growing consumption of hydrogen bromide as a reagent in pharmaceutical synthesis, alkyl bromide production, bromination reactions, and semiconductor etching processes, the need for high-purity hydrogen bromide has surged, influencing plant expansion and setup costs. Rapid advancement in pharmaceutical manufacturing and semiconductor production in regions such as North America, Europe, and Asia-Pacific has also increased investment in specialized chemical gas production infrastructure, creating strong incentives for new plant developments. Additionally, volatility in raw material prices for hydrogen and bromine directly impacts feedstock availability and cost structure, thereby shaping overall project economics. Regulatory compliance and the integration of advanced, environmentally controlled chemical production processes further contribute to escalating capital investment requirements. Pharmaceutical companies, electronics manufacturers, and specialty chemical producers are also demanding production facilities with enhanced purity levels, improved safety protocols, and higher output efficiency, driving up initial setup expenditures. Furthermore, supply chain optimization, specialized storage infrastructure for hazardous corrosive materials, and dedicated transportation logistics for controlled substances add to the financial outlay. Despite the high cost, favorable return on investment, coupled with growing demand for pharmaceutical intermediates, flame retardant precursors, and semiconductor processing chemicals, continues to stimulate market interest in hydrogen bromide production projects, making it a strategic sector for chemical manufacturing development and industrial supply chain competitiveness.

Buy Now: https://www.imarcgroup.com/checkout?id=10956&method=2142

Key Steps Required to Set Up a Hydrogen Bromide Plant

1. Market Analysis

The report provides insights into the landscape of the hydrogen bromide industry at the global level. The report also provides a segment-wise and region-wise breakup of the global hydrogen bromide industry. Additionally, it also provides the price analysis of feedstocks used in the production of hydrogen bromide, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the hydrogen bromide production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for hydrogen bromide production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for hydrogen bromide production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Request for Customization: https://www.imarcgroup.com/request?type=report&id=10956&flag=E

4. Project Economics

A detailed analysis of the project economics for setting up a hydrogen bromide production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Hydrogen Bromide Production Plant Setup: Attractive Long-Term Investment Plan here

News-ID: 4299995 • Views: …

More Releases from IMARC Group

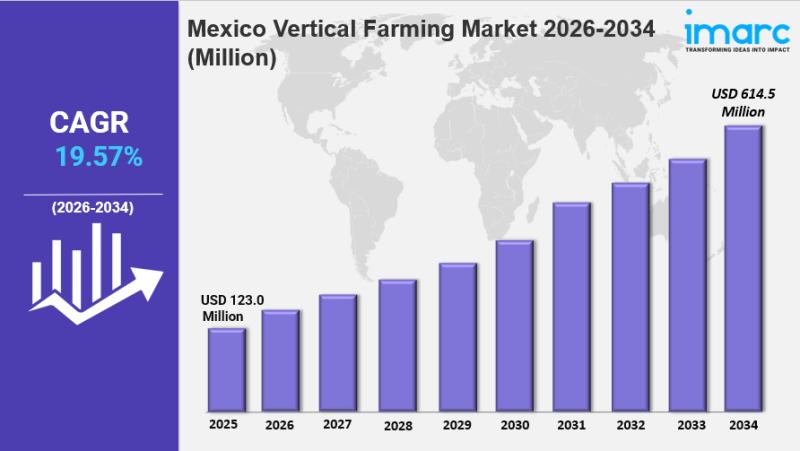

Mexico Vertical Farming Market Size, Share, Industry Overview, Trends and Foreca …

IMARC Group has recently released a new research study titled "Mexico Vertical Farming Market Size, Share, Trends and Forecast by Component, Structure, Growth Mechanism, Application and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Vertical Farming Market Overview

The Mexico vertical farming market size reached USD 123.0 Million in 2025. Looking forward, IMARC Group…

Indonesia Logistics Market Expected to Reach USD 132.2 Billion by 2034, Industry …

IMARC Group's latest research publication "Indonesia Logistics Market Size, Share, Trends and Forecast by Model Type, Transportation Mode, End Use, and Region, 2026-2034" the Indonesia logistics market size reached USD 72.4 Billion in 2025. The market is expected to reach USD 132.2 Billion by 2034, exhibiting a growth rate (CAGR) of 6.91% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/indonesia-logistics-market/requestsample

What is Logistics?

Logistics refers to the comprehensive process of planning, implementing, and controlling…

South East Asia Medical Tourism Market Expected to Reach USD 35.5 Billion by 203 …

IMARC Group's latest research publication "South East Asia Medical Tourism Market Size, Share, Trends and Forecast by Treatment Type, Service Provider, and Country, 2026-2034" the South East Asia medical tourism market size reached USD 6.1 Billion in 2025. The market is expected to reach USD 35.5 Billion by 2034, exhibiting a growth rate (CAGR) of 21.68% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/south-east-asia-medical-tourism-market/requestsample

What is Medical Tourism?

Medical tourism refers to the practice…

Bamboo Plywood Manufacturing Plant Cost 2026: Detailed Project Report & Profit A …

Setting up a Bamboo Plywood Manufacturing Plant positions investors in a growing and sustainable segment of the engineered wood and construction materials industry, backed by sustained global demand driven by eco-conscious construction, renewable material adoption, and increasing requirements for sustainable furniture and interior solutions. As urbanization accelerates and demand for environmentally friendly building products rises, bamboo plywood offers dual benefits: reducing reliance on traditional hardwoods while providing a strong, durable,…

More Releases for Hydrogen

Green Hydrogen Boosting Hydrogen Generation Market Growth Worldwide

According to a new report published by Allied Market Research, the hydrogen generation market was valued at $136.3 billion in 2021 and is projected to reach $262.0 billion by 2031, growing at a CAGR of 6.8% from 2022 to 2031. The steady expansion of industrialization, growing environmental concerns, and strong government initiatives toward decarbonization are key factors accelerating the growth of the hydrogen generation market globally.

Download PDF Brochure: https://www.alliedmarketresearch.com/request-sample/1575

Hydrogen production…

White Natural Hydrogen Market Growth 2025-2032 | Clean & Renewable Hydrogen Sour …

New York, U.S. - Worldwide Market Reports unveils its latest evaluation of the White Natural Hydrogen Market, highlighting the growing interest in naturally occurring, untapped hydrogen resources that can support decarbonization initiatives and supplement green and blue hydrogen production. Increasing exploration in geological formations, coupled with rising demand for low-carbon energy carriers, is driving adoption across industrial, energy, and mobility sectors. Near-term growth is expected from subsurface hydrogen reservoirs, renewable…

Hydrogen Electrolyzer Market, Fueling the Green Hydrogen Revolution Worldwide

Overview of the Market

The hydrogen electrolyzer market is rapidly transforming into a cornerstone of the global clean energy transition, driven by increasing investments in sustainable technologies and government-led decarbonization efforts. A hydrogen electrolyzer is a device that splits water into hydrogen and oxygen using electricity, enabling the generation of green hydrogen when powered by renewable sources. This exponential rise is attributed to the surging demand for clean fuels, rising…

Hydrogen economy: hydrogen as an energy carrier is changing companies

The energy transition and climate protection have put the focus on a sustainable energy supply. Hydrogen is considered one of the most important energy sources of the future and plays a key role in the decarbonization of industry. Investments in the hydrogen economy are increasing worldwide. Germany is also increasingly focusing on promoting this technology.

But what impact will this have on companies, the labor market and the competitiveness of Germany…

Hydrogen Generator Market Growth: Powering the Green Hydrogen Economy

According to a new report published by Allied Market Research, The global hydrogen generator market size was valued at $1.2 billion in 2020, and hydrogen generator market forecast to reach $2.2 billion by 2030, growing at a CAGR of 5.8% from 2021 to 2030.

Global shift toward the use of eco-friendly and renewable resources and several government initiatives toward development of eco-friendly hydrogen production technologies, coupled with rapidly increasing demand for…

Hydrogen Generator Market Dynamics: Trends Shaping the Hydrogen Economy

According to a new report published by Allied Market Research, The global hydrogen generator market size was valued at $1.2 billion in 2020, and hydrogen generator market forecast to reach $2.2 billion by 2030, growing at a CAGR of 5.8% from 2021 to 2030.

Global shift toward the use of eco-friendly and renewable resources and several government initiatives toward development of eco-friendly hydrogen production technologies, coupled with rapidly increasing demand for…