Press release

How Phenolic Aldehyde Resins Saved a Tire Plant

A tire manufacturing plant in Indonesia experienced inconsistent curing performance and poor bonding strength between rubber layers in its high-performance radial tires. Traditional tackifiers based on rosin esters and terpene resins degraded under high temperatures and oxidative environments inside the curing press. This caused delamination, void formation, and reduced mechanical integrity-forcing the plant to reject large batches and increasing production losses.To resolve the issue, the materials engineering team switched to Phenolic Aldehyde Resins, thermosetting phenolic polymers synthesized through the condensation of phenol with aldehydes such as formaldehyde or furfural. These resins exhibit excellent thermal stability, oxidation resistance, and strong adhesive properties at elevated temperatures. In rubber compounding, phenolic aldehyde resins act as efficient tackifiers and curing aids that improve adhesion between rubber layers, enhance green tack, and stabilize the compound during vulcanization. Their crosslinking structure provides superior cohesion and mechanical strength under sustained heat and pressure.

After integrating phenolic aldehyde resins into the tread and carcass rubber formulations, the tire manufacturer achieved far more uniform curing, a 28% improvement in interlayer bonding strength, and a substantial reduction in internal defects. Rate decreased by 40%, and the plant reported more consistent tire performance during high-speed durability testing. Phenolic aldehyde materials are now widely used in tire manufacturing, friction materials (brake pads and clutches), laminates, foundry binders, abrasive wheels, coatings, and industrial adhesives requiring robust thermal and mechanical performance.

https://www.qyresearch.com/reports/5516452/phenolic-aldehyde

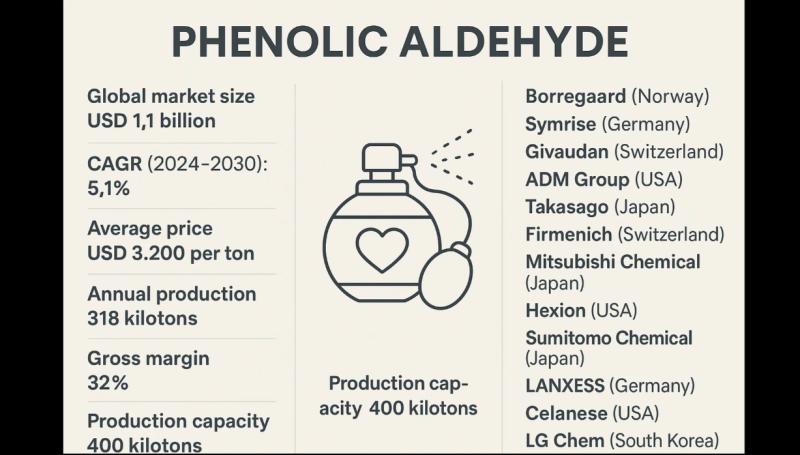

Core market data:

Global market size: USD 1.1 billion

CAGR (2024-2030): 5.1%

Average price: USD 3,200 per ton

Annual production: 318 kilotons

Gross margin: 32%

Production capacity: 400 kilotons

List of Main players:

Borregaard (Norway)

Symrise (Germany)

Givaudan (Switzerland)

ADM Group (USA)

Takasago (Japan)

Firmenich (Switzerland)

Mitsubishi Chemical (Japan)

Hexion (USA)

Sumitomo Chemical (Japan)

LANXESS (Germany)

Celanese (USA)

LG Chem (South Korea)

ExxonMobil Chemical (USA)

1. By Aldehyde Type

Formylation-derived

Oxidation-derived

Lignin-derived

2. By Purity Level

Industrial Grade (85-92%)

High-Purity Grade (Over 95%)

3. By Physical Form

Ortho-substituted Phenolic Aldehyde

Meta-substituted Phenolic Aldehyde

Para-substituted Phenolic Aldehyde

4. By Application

Pharmaceutical

Food Additive

Agrochemical

Polymer, Resin & Coating

Case study for bidding

Time: July 2023

Supplier: SI Group (U.S.)

Buyer: Knauf Insulation (Germany)

Product: High-Purity Phenolic-Formaldehyde Aldehyde (95% purity, resin-grade)

Quantity: 12,500 tons

Contract Value: USD 41 million

Delivery Timeline: June 2024

Detailed Application Scenario

Knauf Insulation used SI Group's high-purity phenolic aldehyde to produce thermosetting resins for mineral wool insulation binders. The aldehyde intermediate enabled controlled crosslinking, producing a durable binder with strong adhesion, thermal resistance, and low smoke generation-key performance requirements in building insulation materials.

The high reactivity of the aldehyde ensured reduced curing time and improved production efficiency in continuous insulation manufacturing lines. Its consistent purity minimized VOC emissions, helping Knauf meet EU environmental and indoor air quality regulations.

Knauf selected this phenolic aldehyde grade due to its stable reactivity, high thermal durability, and compatibility with large-scale resin systems, outperforming alternative aldehyde intermediates in binder strength, aging resistance, and sustainability metrics.

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

For Inquiries:

USA: +1-626-295-2442

Canada: +1-778-907-6631

China: +86-150-1303-8387

Japan: +81-90-3800-9273

South Korea: +82-2883-1278

India: +91-866-9986-909

Indonesia: +62-818-510-991

Germany: +49-15788468916

Switzerland: +41-765899438

Portugal: +351-910983247

Email: global@qyresearch.com

www.qyresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How Phenolic Aldehyde Resins Saved a Tire Plant here

News-ID: 4297599 • Views: …

More Releases from QY Research

Top 30 Indonesian Dairy Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Indofood Sukses Makmur Tbk (INDF)

PT Indofood CBP Sukses Makmur Tbk (ICBP)

PT Ultrajaya Milk Industry & Trading Company Tbk (ULTJ)

PT Cisarua Mountain Dairy Tbk (CMRY)

PT Diamond Food Indonesia Tbk (DMND)

PT Mulya Boga Raya Tbk

PT Campina Ice Cream Industry Tbk

PT Kurniamitra Duta Sentosa Tbk

PT Greenfields Indonesia

PT Indolakto (subsidiary/brand under Indofood)

PT Ultra Jaya Frozen Foods (group affiliate)

PT Heilala Dairy Indonesia (export arm/processing)

PT Diamond Milk Products (non-listed…

High-Margin Growth: Inside the Global Injectable Veterinary Analgesics Boom

Injected veterinary pain management drugs are parenteral analgesics and anti-inflammatory therapeutics administered via IV, IM, or SC routes for rapid pain control in livestock and companion animals.

Used widely in Surgical recovery, Trauma and orthopedic treatment, Mastitis and inflammatory disease, Post vaccination pain mitigation and Companion animal chronic pain (arthritis, cancer).

Drug classes include NSAIDs, Opioids, Alpha-2 agonists, Local anesthetics and Multimodal combination injectables

Demand growth driven by rising pet humanization, expansion of…

From Fiber to LiDAR: Why PIN Photodiodes Are the Silent Engine of Optical Tech

PIN photodiodes are semiconductor light sensors that convert photons into electrical current using a P-Intrinsic-N structure for higher sensitivity, faster response time, and lower capacitance than PN devices.

Core components in optical communications, LiDAR, medical imaging, industrial automation, consumer electronics, and scientific instrumentation.

Manufacturing concentrated in Japan, China, Taiwan, South Korea, with backend packaging in ASEAN.

Demand growth is tied to Fiber optic network expansion, Autonomous driving sensors, Industrial machine vision, Wearables and…

Bidirectional DC-DC Converter Market 2025: Asia Leads as EV & Storage Demand Sur …

The global Bidirectional DC-DC Converter market is expanding rapidly as electrification, renewable energy storage, and vehicle electrification accelerate worldwide.

These converters enable two-way power flow, allowing energy transfer between batteries, supercapacitors, DC buses, and loads, making them critical for EVs, battery energy storage systems (BESS), UPS, telecom power systems, and microgrids.

Increasing demand for high-efficiency power management, fast charging, and distributed energy systems is driving industrial adoption across Asia and Southeast Asia…

More Releases for Phenolic

Market Overview - Ablation Resistant Phenolic Resin

QY Research has recently published a comprehensive market study on Ablation Resistant Phenolic Resin, a class of thermosetting resins engineered to provide reliable thermal protection through controlled char formation and surface recession under extreme heat flux. Ablation resistant phenolic resins are foundational materials for rocket motor insulation, re-entry heat shields, nozzle liners, and high-temperature structural composites used in aerospace, defense, and space exploration.

The market is transitioning from legacy phenolic systems…

Market Overview - Ablation Resistant Phenolic Resin

QY Research has recently published a comprehensive market study on Ablation Resistant Phenolic Resin, a class of thermosetting resins engineered to provide reliable thermal protection through controlled char formation and surface recession under extreme heat flux. Ablation resistant phenolic resins are foundational materials for rocket motor insulation, re-entry heat shields, nozzle liners, and high-temperature structural composites used in aerospace, defense, and space exploration.

The market is transitioning from legacy phenolic systems…

Phenolic Resins Powering Eco-Friendly Lightweight Automotive Solutions: Key Fact …

The Phenolic Resins Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Expected Phenolic Resins Market Size During the Forecast Period?

There has been a robust increase in the size of the phenolic resins market in recent times. The market, valued at $14.17 billion…

How Big is the Phenolic Resin Market

According to Fact.MR's newly released report on phenolic resins, the global market is expected to be worth USD 14,685.1 million in 2022, rising at a CAGR of around 5.4% between 2022 and 2032. Furthermore, Fact.MR expects the phenolic resins market to be worth more than USD 24,782.1 million by the end of 2032, owing to rising demand for phenolic resins in the building & construction and electrical & electronics industries.

enhanced…

Phenolic Antioxidant Market: Anticipating Growth in Phenolic Additives (2023-202 …

Phenolic Antioxidant Market Set to Reach US$ 2.78 Billion by 2029

In 2022, the Phenolic Antioxidant Market recorded a valuation of US$ 1.96 billion, with expectations to surge at a Compound Annual Growth Rate (CAGR) of 5.10% over the forecast period, ultimately reaching US$ 2.78 billion by 2029. This revelation comes from a comprehensive market report aiming to provide insights, historical data, and industry-validated market projections.

Market Dynamics and Application Insights:

Phenolic antioxidants…

Global Phenolic Board Market Growth 2019-2024

LP INFORMATION offers a latest published report on Phenolic Board Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Phenolic Board market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019. In particular,…