Press release

X-Ray Inspection System Market to Reach USD 1.3 Billion by 2034 Driven by Food Safety and Security Demands | TMR

The global X-ray Inspection System Market is undergoing a phase of strong technological evolution, driven by rising consumer safety expectations, expanding industrial applications, and increasing regulatory stringency across multiple sectors. X-ray inspection systems are essential non-destructive testing (NDT) solutions that employ high-energy electromagnetic radiation to penetrate materials and capture their internal structure for quality control, defect detection, and security verification. Historically used in sectors such as medical imaging and security, the technology has now become indispensable in diverse industries such as food processing, pharmaceuticals, electronics manufacturing, packaging, automotive, aerospace, and public security.Unlock crucial data and key findings from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=35627

These systems detect contaminants, structural anomalies, and assembly inconsistencies with high precision and speed-making them integral to modern automated manufacturing lines and security checkpoints. As industries transition toward digitization and automation, X-ray inspection solutions are evolving from traditional film-based mechanisms to advanced digital imaging and 3D radiography, providing improved sensitivity, higher throughput, and superior defect visibility. Furthermore, the integration of AI and ML algorithms into imaging platforms has transformed X-ray inspection into a predictive and smart quality assurance tool capable of advanced classification and pattern recognition.

With growing emphasis on food safety compliance, increasing risk of contraband smuggling, and expanding semiconductor fabrication, the global market outlook for X-ray inspection systems remains robust. Market players are focusing on faster processing speeds, compact system designs, enhanced detection capabilities, and real-time analytics to meet changing industry demands. As a result, the X-ray inspection system market is poised for continuous expansion through 2034.

Market Overview

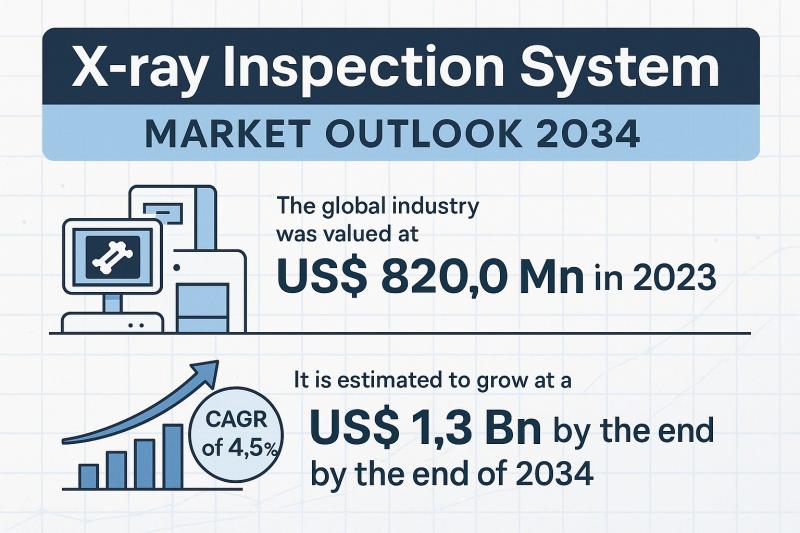

According to the latest global assessment, the X-ray Inspection System Market was valued at US$ 820.0 Mn in 2023 and is expected to reach US$ 1.3 Bn by 2034, expanding at a CAGR of 4.5% from 2024 to 2034. This growth is driven by rising safety and compliance requirements, increasing adoption of automated inspection processes, and technological innovations in digital radiography and 3D X-ray imaging.

An X-ray inspection system functions by emitting controlled X-rays through a material and capturing the transmitted radiation using sensors. The captured information is converted into detailed images that reveal defects, inconsistencies, contaminants, or hidden components.

The shift toward digital imaging, which offers higher sensitivity, faster image processing, and improved storage efficiency, is transforming the market. Additionally, the introduction of AI-powered algorithms is enabling automated anomaly detection with minimal human intervention, improving accuracy and reducing inspection time.

Market Drivers

1. Rising Need for Safety, Quality, and Compliance in the Food Industry

Food manufacturers face increasing pressure to maintain product safety, prevent contamination, comply with regulations, and protect brand integrity. X-ray inspection systems have become one of the most reliable solutions for identifying metal, glass, mineral stones, calcified bone, plastics, and other contaminants in packaged food products.

Key factors driving adoption include:

Non-destructive, high-precision imaging that does not damage product packaging

Ability to detect low-density contaminants that metal detectors often miss

Support for HACCP, BRC, GFSI, and FDA standards

Fill level inspection, seal integrity testing, and packaging defect detection

Manufacturers are increasingly investing in advanced inspection systems to minimize product recalls, reduce costs associated with waste, and ensure consistent quality across production lines.

A notable development took place in September 2022, when Mettler-Toledo Product Inspection introduced a next-generation X-ray detection platform with dramatically improved sensitivity to detect even low-density foreign objects. This launch enabled food manufacturers to boost compliance, avoid recalls, and protect brand identity-further supporting market expansion.

2. Growth in Demand for Security Applications in Public Places

Security threats-ranging from smuggling and terrorism to illegal trafficking-have led governments and private institutions to adopt advanced X-ray screening systems for real-time threat detection. X-ray inspection machines are widely used at:

Airports and seaports

Railway stations and metro systems

Border checkpoints

Government buildings

Corporate offices and public venues

These systems are capable of detecting:

Weapons

Explosives

Narcotics

Contraband items

Hazardous substances concealed within baggage or shipments

With rising crime rates and growing geopolitical instability, countries across Asia Pacific, Europe, and North America are accelerating investments in advanced scanning infrastructure. The availability of 3D X-ray scanners, computerized tomography (CT) systems, and AI-enabled automatic threat recognition software further enhances the speed and accuracy of security screening.

3. Expansion of High-Precision Manufacturing Industries

Modern manufacturing sectors-including electronics, semiconductors, automotive, aerospace, and energy-require highly precise inspection solutions to meet stringent quality standards. X-ray inspection systems are essential in these industries for:

Measuring solder joint quality

Verifying printed circuit board (PCB) alignment

Inspecting turbine blades and engine components

Ensuring structural integrity of advanced materials

Miniaturization in electronics and rising production of EV components have significantly boosted demand for real-time inline X-ray inspection solutions.

4. Technological Advancements in Digital and 3D Imaging

Digitized X-ray imaging systems have replaced film-based imaging due to advantages such as:

Enhanced image resolution

Real-time monitoring

Lower operational cost

Faster processing

Easier storage and retrieval

Advanced analytics compatibility

The introduction of 3D computed tomography (CT) has revolutionized the inspection of:

Complex geometric components

Battery cells and modules

Aerospace parts

Semiconductor chips

Automotive assemblies

Leading companies are investing heavily in 3D technology to offer deeper penetration, volumetric imaging, and greater defect visibility.

Access detailed insights by visiting our full report -

https://www.transparencymarketresearch.com/xray-inspection-system-market.html

Market Restraints

Despite strong growth prospects, the market faces challenges such as:

High installation and operational costs, especially for 3D CT systems

Radiation safety concerns, requiring regulated handling and compliance

Complexity of system maintenance and calibration

Lack of skilled technicians in developing markets

Slow adoption in small-scale manufacturing units due to limited budgets

However, increasing miniaturization, declining costs of digital sensors, and ongoing technological improvements are expected to reduce these barriers over the forecast period.

Emerging Opportunities

The next decade presents promising opportunities for market players:

1. Integration of AI and ML in X-ray Image Analysis

AI-powered inspection enables:

Faster screening

Lower false positives

More accurate detection

Real-time automated decision-making

AI-enabled platforms are increasingly being used in food, pharma, semiconductor, and security sectors.

2. Rising Adoption of Automated Inspection Systems

Industries are moving toward fully automated assembly lines, creating demand for automated X-ray solutions that operate with minimal human oversight.

3. Growing Investments in EV Battery Manufacturing

Battery defects, thermal risks, and quality inconsistencies demand high-precision CT inspection, creating a massive opportunity for 3D imaging vendors.

4. Increasing Role of X-ray Inspection in Pharmaceuticals

Applications include:

Tablet inspection

Seal integrity analysis

Packaging verification

Regulatory tightening in the pharmaceutical sector is expected to accelerate adoption.

Regional Outlook

Asia Pacific - The Leading and Fastest-Growing Region

Asia Pacific dominated the global X-ray inspection system market in 2023, driven by:

Rapid expansion of electronics and semiconductor manufacturing

Growing packaged food industry

Rising consumer awareness for food safety

Government initiatives to enhance security screening

Strong presence of pharmaceutical production hubs in China, India, South Korea, and Japan

Technological advancements such as improved detector sensitivity, enhanced throughput, and AI-enabled inspection are further boosting adoption in the region.

Other Regional Highlights

North America:

A mature market driven by strong security infrastructure, advanced aerospace manufacturing, and high adoption of automation technologies.

Europe:

Growth driven by strict food safety regulations (EFSA, EC standards), automotive leadership (Germany), and expanding renewable energy component manufacturing.

Middle East & Africa:

Increasing need for airport security, border control, and packaged food inspection supports demand.

South America:

Adoption is growing in food processing, packaging, and oil & gas industries.

Competitive Landscape

The X-ray inspection system market is moderately consolidated, with leading manufacturers focusing on:

3D imaging innovation

AI and ML integration

Compact and portable X-ray system development

Enhancing software capabilities

Strategic acquisitions

Regional expansions

Key Market Players

METTLER TOLEDO

Nordson Corporation

Comet Group

Anritsu

Viscom SE

North Star Imaging Inc.

Nikon Corporation

ISHIDA CO., LTD.

OMRON Corporation

Toshiba IT & Control Systems Corporation

3DX-RAY

Sesotec GmbH

Visiconsult GmbH

Scienscope

Notable Strategic Developments

July 2023: Nikon Americas Inc. acquired Avonix Imaging LLC, strengthening its position in CT X-ray technologies.

May 2023: Mettler-Toledo launched the X2 Series, making advanced X-ray inspection more accessible for small and medium food manufacturers.

Market Segmentation

By Type

Digital Imaging

Film-based Imaging

Digital imaging dominates due to superior clarity, operational efficiency, and reduced cost over time.

By Dimension

2D

3D

3D systems are rapidly gaining traction, particularly in automotive, aerospace, and semiconductor inspection.

By Function

Manual

Automated

Automated systems are expected to record higher CAGR due to Industry 4.0 adoption.

By End-use Industry

Electronics & Semiconductors

Oil & Gas

Aerospace

Government Infrastructure

Automotive

Power Generation

Food & Pharmaceuticals

Packaging

Others

Food & pharmaceuticals and electronics sectors remain the highest adopters.

Buy this Premium Research Report to explore detailed market trends -

https://www.transparencymarketresearch.com/checkout.php?rep_id=35627

Porter's Five Forces Analysis

1. Threat of New Entrants - Moderate

High initial investment and regulatory compliance requirements make market entry challenging.

2. Bargaining Power of Suppliers - Low to Moderate

Components such as detectors and sensors are sourced from multiple vendors, keeping supplier power balanced.

3. Bargaining Power of Buyers - Moderate to High

Industrial buyers demand high accuracy and competitive pricing, giving them negotiation leverage.

4. Threat of Substitutes - Low

Alternative NDT methods (ultrasound, visual inspection) lack penetration and resolution capabilities of X-rays.

5. Industry Rivalry - High

Technology-driven competition pushes companies to innovate continuously.

Future Outlook (2024-2034)

The next decade is expected to see:

Rapid adoption of AI-integrated X-ray platforms

Expansion of real-time inline inspection systems

Growth of portable and handheld X-ray devices

Rising demand for EV battery and semiconductor inspection

Increasing use of high-energy X-ray and CT systems for aerospace and heavy machinery industries

As automation and digital transformation accelerate across industries, X-ray inspection systems will remain central to quality assurance, security management, and supply chain safety.

Explore Latest Research Reports by Transparency Market Research:

Ambient Light Sensors Market - https://www.transparencymarketresearch.com/ambient-light-sensors-market-report.html

Silicon Carbide Power Semiconductors Market - https://www.transparencymarketresearch.com/silicon-carbide-power-semiconductors-market-insights.html

Printed Circuit Board Market for Electric Vehicles - https://www.transparencymarketresearch.com/printed-circuit-board-market-for-electric-vehicles.html

Inspection Equipment Market for Electronics Industry - https://www.transparencymarketresearch.com/inspection-equipment-market-for-electronics-industry.html

Europe Military Free Space Optics Communication Market - https://www.transparencymarketresearch.com/europe-military-free-space-optics-communication-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Follow Us: LinkedIn| Twitter| Blog | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release X-Ray Inspection System Market to Reach USD 1.3 Billion by 2034 Driven by Food Safety and Security Demands | TMR here

News-ID: 4287428 • Views: …

More Releases from Transparency Market Research

Automotive Thermal Management System Market Poised to Reach USD 173.8 Billion by …

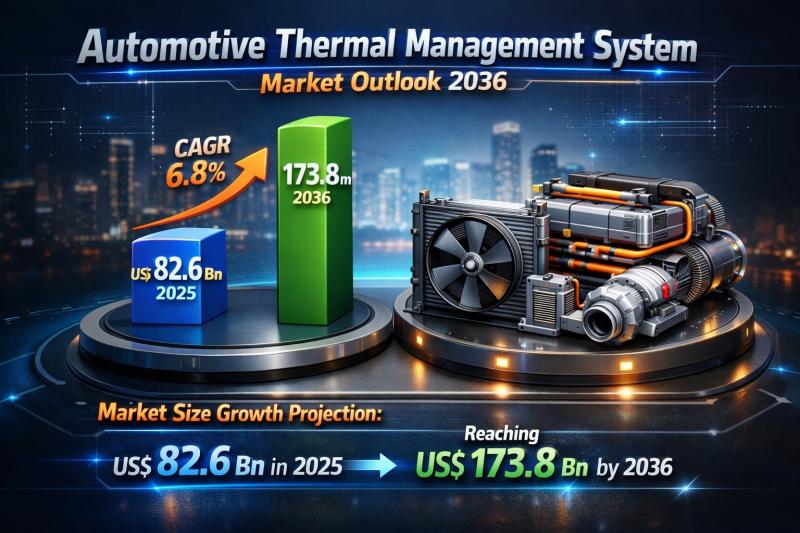

The global automotive thermal management system market is entering a high-growth phase, fueled by the rapid electrification of vehicles, stricter emission norms, and rising expectations for vehicle safety, comfort, and efficiency. Valued at US$ 82.6 billion in 2025, the market is projected to nearly double and reach US$ 173.8 billion by 2036, expanding at a robust CAGR of 6.8% from 2026 to 2036.

Thermal management has become a mission-critical function in…

Thermal-Management Exterior Coatings for High-Altitude Aircraft Market to be Wor …

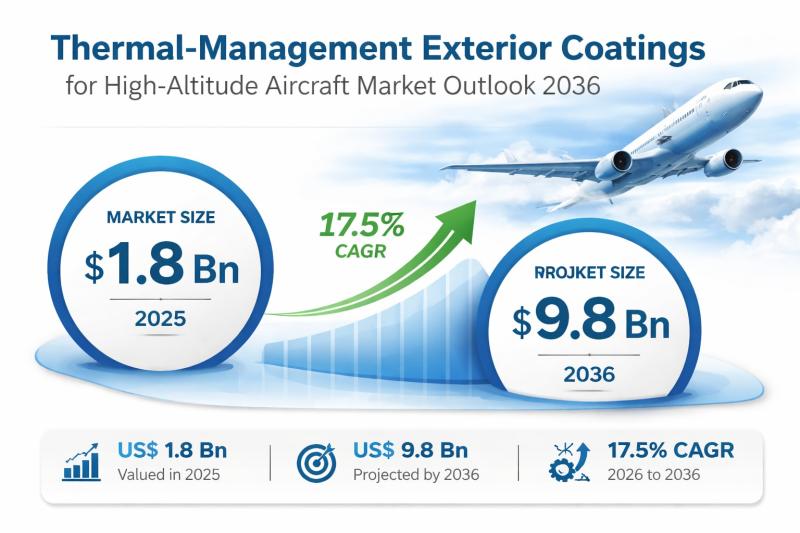

The global Thermal-Management Exterior Coatings for High-Altitude Aircraft Market was valued at US$ 1.8 Bn in 2025 and is projected to reach US$ 9.8 Bn by 2036, expanding at a robust CAGR of 17.5% during the forecast period from 2026 to 2036.

Review critical insights and findings from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86920

This strong growth trajectory reflects the rising importance of advanced exterior coating technologies that ensure aircraft performance, safety,…

Epithelioma Treatment Market Outlook 2035: Rising Skin Cancer Burden, Breakthrou …

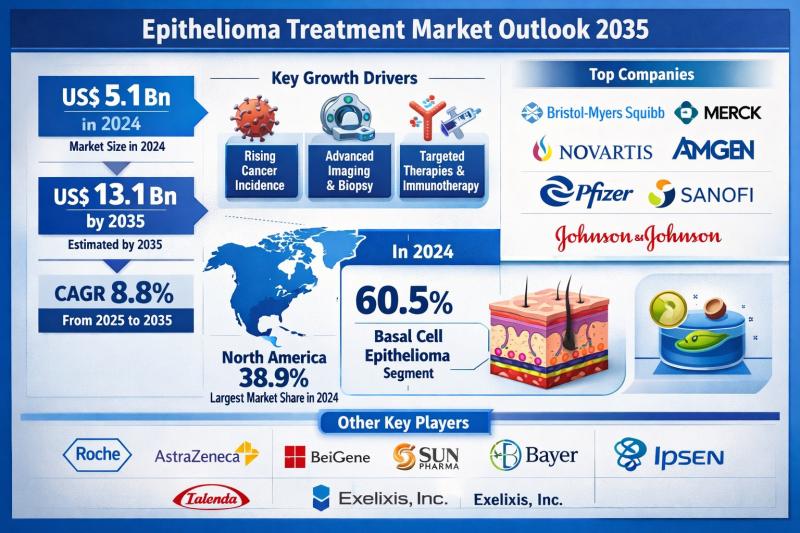

The global epithelioma treatment market has entered a decisive growth phase, supported by rising cancer prevalence and rapid therapeutic innovation. In 2024, the market was valued at US$ 5.1 Bn, reflecting the growing demand for advanced diagnostic and therapeutic solutions targeting epithelial-origin tumors. Over the forecast period from 2025 to 2035, the industry is projected to expand at a robust compound annual growth rate (CAGR) of 8.8%, reaching a valuation…

Tablet Hardness Testers Market to Reach USD 427.9 Mn by 2036, Driven by Rising P …

The Tablet Hardness Testers Market is a critical part of the pharmaceutical quality-control ecosystem. Tablet hardness testers are used to measure the mechanical strength of tablets to ensure they can withstand handling, packaging, transportation, and storage without breaking, while still dissolving correctly once ingested. As regulatory oversight becomes stricter and pharmaceutical production expands globally, the demand for accurate and reliable hardness testing equipment continues to rise.

The global Tablet Hardness Testers…

More Releases for Inspection

In-Pipe Inspection Robot Market, Revolutionizing Pipeline Integrity with Autonom …

Market Overview and Growth Dynamics

The global in-pipe inspection robot market is witnessing a significant transformation, driven by the increasing demand for reliable infrastructure monitoring and non-disruptive pipeline inspection methods. These robotic systems are designed to navigate through the interiors of pipelines to detect leaks, corrosion, cracks, and blockages-issues that could potentially lead to hazardous failures if left undetected. As urban infrastructure continues to age and expand, especially in developing economies,…

Railway Inspection Services Market Outlook : Solutions, Inspection Vehicles & Sy …

Railway inspection is the practice of examining rail tracks for flaws that lead to catastrophic failures causing accidents. According to the U.S. Federal Railroad Administration Office of Safety Analysis, track defects are the second cause of railway accidents in U.S. Some of the reasons causing track defects are shear stresses, wheel/rail contact stresses, thermal stresses, residual stresses, and dynamic effects. Moreover, due to contact stresses defects such as tongue lipping,…

Surface Inspection Market: Surface Inspection Market to Grow to USD 10.29B by 20 …

Surface Inspection Market Scope:

Key Insights : Surface Inspection Market size was valued at USD 5.02 billion in 2022 and is poised to grow from USD 5.44 billion in 2023 to USD 10.29 billion by 2031, growing at a CAGR of 8.3% in the forecast period (2024-2031).

Discover Your Competitive Edge with a Free Sample Report :https://www.skyquestt.com/sample-request/surface-inspection-market

Access the full 2024 Market report for a comprehensive understanding @https://www.skyquestt.com/report/surface-inspection-market

In-Depth Exploration of the global…

Thermal Drone Inspection Market Soars as Industries Embrace Efficient and Safe I …

The global thermal drone inspection market is estimated to exceed US$ 282.4 million by the end of 2023, by growing at an impressive CAGR of 13.4% over the assessment period of 2023-2033.

The deployment of thermal cameras with infrared sensors and high quality image processors has significantly expanded the applications of the thermal drones. They can be utilized in various industries, for instance, firefighting, search & rescue, ariel utility and advanced…

beXel launched different inspection modules to improve inspection quality

beXel launched a Variety of modules to facilitate the inspection process and provide smart solutions for the customers such as

(Drops Inspection, Job order management, Lifting Inspection, NDT inspection, Tubular Inspection, Desktop Offline App).

A quality inspection involves measuring, examining, testing, or gauging various characteristics of a product and comparing those results with specified requirements to determine whether there is conformity.

Quality Control (QC) is critical to build and deliver products that meet…

Carlsbad, CA Mold Inspection and Asbestos Testing Services Offered by Murrieta M …

Carlsbad, CA, December 16, 2019 – EZ Mold Inspections continues expanding its service area in San Diego County and now provides asbestos testing and mold inspections in Carlsbad, California. The inspection company is based in the Murrieta-Temecula area. The company now serves nine areas in Riverside County and two cities in San Diego County including Oceanside, CA and Carlsbad, CA.

With more than two decades of experience in real estate and…