Press release

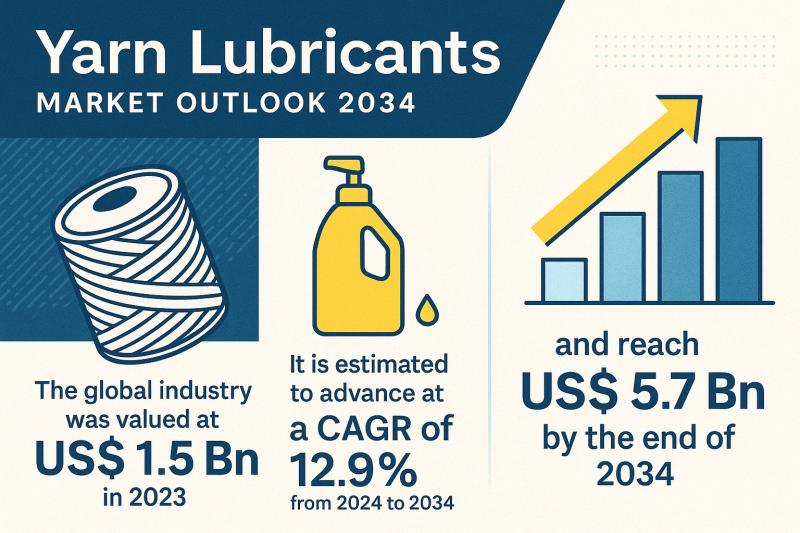

Yarn Lubricants Market Set to Reach USD 5.7 Bn by 2034 Driven by Surge in Biodegradable Textile Chemicals | TMR

The global yarn lubricants market, valued at US$ 1.5 Bn in 2023, is set for robust expansion, projected to reach US$ 5.7 Bn by 2034, registering an impressive CAGR of 12.9%. Growth is driven by the accelerating shift toward sustainable textile manufacturing, adoption of biodegradable lubricants, and rising investments in advanced weaving and spinning technologies. Textile manufacturers worldwide increasingly prioritize lubricants that not only enhance yarn performance but also reduce environmental footprint, improve operational efficiency, and enable high-speed production systems.Gain a preview of important insights from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=74471

Yarn lubricants-comprising spin finishes, coning oils, knitting oils, and grease-are essential formulations used across polyester, nylon, acrylic, and other fiber types. They improve fiber processing by reducing friction, minimizing static electricity, enhancing yarn strength, and enabling smoother mechanical operations across spinning, twisting, weaving, knitting, and dyeing processes.

As global textile manufacturers adopt automated and smart machinery, the need for high-performance and eco-friendly lubricants becomes critical. The growing emphasis on resource efficiency, wastewater reduction, and circular manufacturing aligns with the increasing adoption of sustainable yarn lubricants, reshaping the market dynamics during the forecast period.

Market Introduction

Yarn lubricants are non-reactive compositions of waxes, oils, emulsions, esters, and additives applied to natural and synthetic fibers during production and processing stages. Their primary function is to reduce friction between fibers, yarns, and textile machinery, ensuring high-quality output and lower downtime. These lubricants are particularly essential in the processing of synthetic fibers, which naturally exhibit higher friction and static build-up.

Types of Yarn Lubricants

Spin Finish

Spin finish is applied during fiber extrusion or immediately after filament formation. Spin finishes contain oils, emulsifiers, and antistatic agents that ensure smooth fiber movement during drawing, texturing, and winding.

Coning Oil

Also known as texturizing or winding oil, coning oil provides anti-static protection and ensures clean, efficient yarn rewinding. These are emulsifiable and easily removable during fabric finishing.

Knitting Oil

Used for lubricating knitting machinery, these oils reduce friction, prevent overheating, and enhance productivity in circular, flatbed, and warp knitting operations.

Grease

High-viscosity greases are used in specific high-load applications within spinning and weaving machines.

The yarn lubricants market includes applications in polyester, nylon, and acrylic yarn manufacturing, with polyester representing the largest share due to its dominance in global fiber production.

Analyst Viewpoint

Market analysts highlight a strong shift toward biodegradable and sustainable lubricant formulations, driven by environmental regulations and rising consumer sensitivity toward eco-friendly textile products. Key players are focusing on reducing carbon footprint, enhancing biodegradability, and developing advanced emulsification technologies for higher machine compatibility.

The competitive landscape is further shaped by innovations in smart lubrication systems, which integrate sensors and automation to deliver precision-based lubrication. While the global textile industry is moving toward value-added production, challenges such as declining yarn exports and fluctuating cotton production may restrain growth in specific regions.

Delve into our report to discover detailed insights -

https://www.transparencymarketresearch.com/yarn-lubricants-market.html

Key Market Drivers

1. Rising Demand for Biodegradable Yarn Lubricants

Environmental sustainability is becoming a strategic imperative in the textile industry. Conventional lubricants based on mineral oils and petrochemicals are increasingly being replaced by plant-derived, biodegradable formulations. Textile production accounts for nearly 20% of global wastewater pollution-a major concern for regulators and manufacturers.

Key factors driving adoption of biodegradable lubricants include:

Stringent environmental standards (EU REACH, ZDHC, EPA norms)

Growing consumer demand for green textiles

Reduction in ecological toxicity and wastewater load

Improved biodegradation and safety profiles

Companies like Textilchemie Dr. Petry GmbH are pioneering eco-friendly sewing thread lubricants such as PERIXEN FDA, suitable for polyester and polyamide threads. These innovations demonstrate a clear move toward replacing silicone and mineral oil-based products with greener options.

2. R&D in Weaving and Smart Manufacturing Technologies

The next generation of textile machinery focuses on automation, IoT, and predictive maintenance. Smart lubrication systems-equipped with sensors and advanced control modules-optimize lubricant use, reduce wastage, and maintain consistent machine performance.

These advancements enable:

Higher production speeds

Lower breakdown rates

Improved yarn quality

Enhanced energy efficiency

As weaving, spinning, and knitting mills upgrade to Industry 4.0-enabled equipment, demand for high-performance lubricants capable of supporting high-speed operations is projected to rise sharply.

3. Growth in Global Textile Production and Consumption

The textile industry is expanding due to rising disposable income, increasing fashion consumption, and rapid growth in e-commerce. Fibers such as polyester and nylon remain central to global textile supply chains, driving demand for yarn lubricants.

4. Emphasis on Improving Yarn Quality and Operational Efficiency

Modern textile mills prioritize:

Reduced machine wear

Higher throughput

Uniform yarn strength

Reduced static buildup

Yarn lubricants play a crucial role in achieving these objectives, making them indispensable for production efficiency.

Market Restraints

1. Declining Yarn Exports in Key Countries

According to OEC data, retail cotton yarn exports declined by 18.6% in 2022, falling from US$ 366 Mn to US$ 298 Mn. Such declines, particularly in major textile economies like India, reduce yarn production volume and subsequently impact lubricant demand.

India's cotton exports dropped by 61% in September 2022, affecting the yarn manufacturing ecosystem.

2. Volatility in Raw Material Prices

Lubricant manufacturers depend on petroleum, esters, waxes, and additives-materials prone to price fluctuations influenced by geopolitical and economic factors.

3. Impact of Low-quality Pesticides and Climate Conditions on Cotton Production

Cotton yield declines in India and other nations impact natural fiber processing, directly affecting lubricant consumption in spinning mills.

Market Opportunities

1. Sustainable and Green Chemistry Innovations

The transition toward bio-based plant oils, synthetic esters, and water-soluble formulations offers major opportunities for companies developing next-generation lubricants.

2. Increasing Demand for High-speed Texturing Lubricants

High-speed yarn manufacturing (texturing, air-jet spinning, and friction spinning) requires lubricants with:

Excellent thermal stability

Non-misting characteristics

Anti-splash properties

Low residue formation

Companies offering specialized grades stand to benefit significantly.

3. Expansion of Textile Manufacturing in Asia Pacific and Africa

With competitive labour prices and expanding industrial zones, regions like Vietnam, India, Bangladesh, Indonesia, and Ethiopia offer strong growth opportunities.

Market Segmentation Analysis

By Product Type

1. Spin Finish (Largest Segment)

Spin finish holds the dominant share in the yarn lubricants market due to its essential role in synthetic filament production.

2. Coning Oil

Coning oils are witnessing increased demand owing to the high output in texturing and winding operations, especially in polyester and nylon segments.

3. Knitting Oil

Growth is driven by rising knitting machine installations globally, especially in Asia.

4. Grease

Used in high-load textile machinery; stable but small segment.

By Application

1. Polyester (Leading Segment)

Polyester accounts for the largest market share due to its dominance in global textile production. Polyester lifecycles require consistent lubrication for drawing, texturing, and weaving, making it the most significant revenue driver.

2. Nylon

Nylon yarn production in sports apparel, hosiery, and industrial fabrics increases lubricant usage.

3. Acrylic

Demand remains stable in winter wear and carpets.

Buy this Premium Research Report for expert-driven insights and conclusions -

https://www.transparencymarketresearch.com/checkout.php?rep_id=74471<ype=S

Regional Outlook

Asia Pacific - The Global Leader

Asia Pacific holds the largest market share and will continue to dominate through 2034 due to:

Massive textile exports from China, India, Vietnam, and Bangladesh

Rising domestic consumption of apparel

Large fiber production capacity

Rapid adoption of modern spinning technologies

Key highlights:

Southeast Asia accounts for ~55% of global textile exports (2019)

Vietnam exported textile and garment products worth US$ 37.6 Bn in 2022

However, challenges include:

Cotton yield decline due to pesticide misuse

Climate-related crop failures

Lower yarn exports in recent years

Europe

Europe shows strong demand for biodegradable and premium lubricants due to strict environmental standards. Germany, Italy, and Turkey represent key manufacturing hubs.

North America

Steady growth driven by technological advancements, automation, and rising demand for high-performance clothing.

Latin America & Middle East/Africa

These regions are emerging markets benefiting from expanding textile infrastructure, especially in Brazil, Mexico, GCC, and South Africa.

Competitive Landscape

The yarn lubricants market is moderately consolidated, with global and regional players offering specialized formulations for the textile value chain. Companies compete based on green chemistry innovation, performance enhancements, global distribution, and R&D capabilities.

Key Players

Achitex Minerva S.p.A.

Clearco Products Co., Inc.

Rudolf GmbH

SIAM PRO DYECHEM GROUP

Giovanni Bozzetto S.p.A.

Klüber Lubrication

SAR Lubricants

SCHILL+SEILACHER GMBH

TAKEMOTO OIL & FAT CO., LTD.

Matsumoto Yushi-Seiyaku Co., Ltd.

Strategic Initiatives

Product development focused on biodegradable, non-toxic lubricants

Partnerships with textile manufacturers

Expansion into emerging Asian markets

Investments in R&D and state-of-the-art testing labs

Recent Developments

2023: Textilchemie Dr. Petry completed acquisition of the textile auxiliary division of Industrie-Chemie Stein GmbH, strengthening its specialty chemicals portfolio.

2023: Rudolf GmbH expanded operations in Nantong, China, enhancing global presence and local customer service capabilities.

Porter's Five Forces Analysis

1. Threat of New Entrants - Moderate

High R&D cost and regulatory compliance create significant entry barriers.

2. Bargaining Power of Suppliers - Moderate to High

Raw material price volatility influences production costs.

3. Bargaining Power of Buyers - High

Large textile manufacturers demand high performance at competitive prices.

4. Threat of Substitutes - Low

Lubricants are essential with no direct substitutes.

5. Competitive Rivalry - High

Market players continuously innovate in formulation, sustainability, and performance.

Market Trends

1. Shift Toward Green Textile Chemistry

Manufacturers increasingly prefer biodegradable, non-toxic, water-efficient products.

2. Growing Use of Synthetic Esters and Bio-based Oils

Offers superior lubrication, thermal stability, and biodegradability.

3. Automation & Industry 4.0 Integration

Smart lubrication systems enhance operational precision and reduce downtime.

4. Rising Demand from High-speed Machinery

Advanced spinning and weaving machines require high-performance lubrication systems.

5. Circular Economy Adoption in Textiles

Companies are prioritizing renewable raw materials and environmentally friendly formulations.

Value Chain Analysis

Raw materials → Formulation & blending → Testing → Packaging → Distribution → Yarn manufacturers → Textile & apparel producers

The value chain is shifting toward sustainable sourcing, efficient emulsification technologies, and digitalized production practices.

Future Outlook (2024-2034)

The market is projected to grow substantially due to:

Accelerated adoption of bio-based lubricants

Investments in textile automation

Expansion of synthetic fiber production

Government initiatives promoting clean manufacturing

Key opportunities lie in:

High-performance lubricants for aerospace textiles, industrial fabrics, and technical yarns

Zero-residue, water-soluble lubricant technologies

Customized lubricant solutions for smart factories

Overall, the market will benefit from the intersection of sustainability regulations, technological modernization, and evolving textile industry demands.

Explore Latest Research Reports by Transparency Market Research:

Pipeline Chemical Cleaners Market - https://www.transparencymarketresearch.com/pipeline-chemical-cleaners-market.html

Green Ammonia Market - https://www.transparencymarketresearch.com/green-ammonia-market.html

Carbon Concrete Market - https://www.transparencymarketresearch.com/carbon-concrete-market.html

White Coal Market - https://www.transparencymarketresearch.com/white-coal-market.html

India Biomass Market - https://www.transparencymarketresearch.com/india-biomass-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Follow Us: LinkedIn| Twitter| Blog | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Yarn Lubricants Market Set to Reach USD 5.7 Bn by 2034 Driven by Surge in Biodegradable Textile Chemicals | TMR here

News-ID: 4287407 • Views: …

More Releases from Transparency Market Research

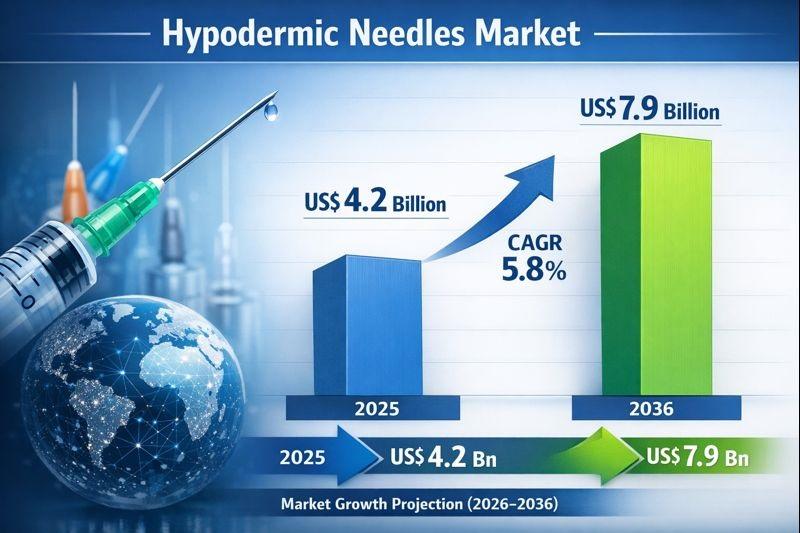

Hypodermic Needles Market to Reach US$ 7.9 Billion by 2036 on Rising Injectable …

The global hypodermic needles market was valued at approximately US$ 4.2 billion in 2025 and is projected to reach around US$ 7.9 billion by 2036, expanding at a CAGR of nearly 5.8% from 2026 to 2036, driven by the rising prevalence of diabetes, cancer, and chronic diseases, growing demand for injectable drugs and biologics, and the expansion of global vaccination and immunization programs; increasing adoption of safety-engineered and disposable needles,…

Connected Car Market to Reach US$ 467.2 Billion by 2036, Driven by Rising Adopti …

The global connected car market is entering a high-growth phase as vehicles increasingly evolve into software-defined, data-driven mobility platforms. Valued at US$ 100.8 billion in 2025, the market is projected to reach an impressive US$ 467.2 billion by 2036, expanding at a robust CAGR of 12.3% from 2026 to 2036. This growth is fueled by rapid advancements in automotive connectivity, rising consumer demand for intelligent features, and strong integration of…

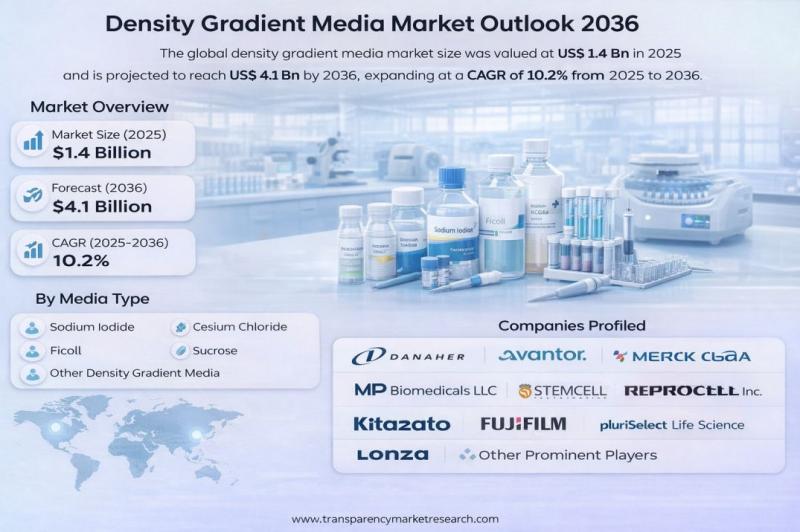

Density Gradient Media Market to Reach US$ 4.1 Billion by 2036, Driven by Rapid …

The global density gradient media market was valued at US$ 1.4 Billion in 2025 and is projected to reach US$ 4.1 Billion by 2036, expanding at a robust CAGR of 10.2% from 2025 to 2036. The market's rapid growth is primarily driven by increasing demand for rapid infectious disease screening, expanding cell therapy and immunology research, and continuous technological advancements improving sensitivity and multiplexing in laboratory workflows.

Access key findings and…

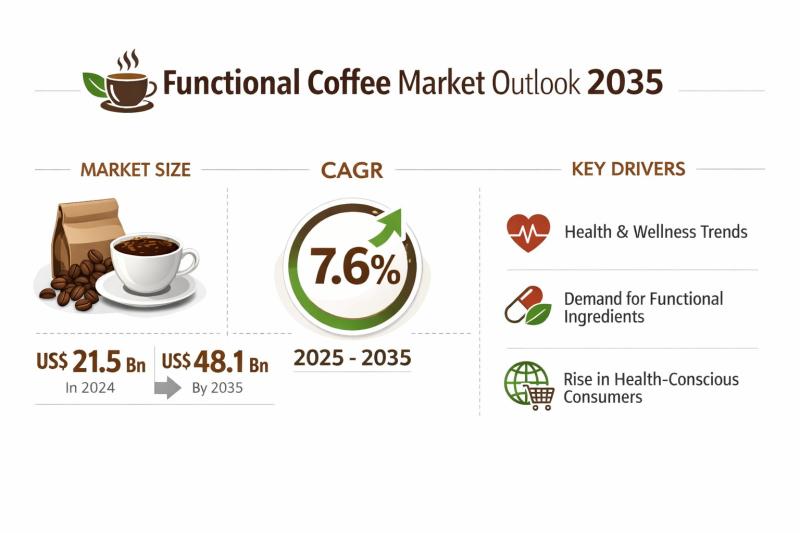

Functional Coffee Market Expanding at 7.6% CAGR Through 2035 - By Product Type / …

The global functional coffee market was valued at US$ 21.5 Bn in 2024 and is projected to reach US$ 48.1 Bn by 2035, expanding at a compound annual growth rate (CAGR) of 7.6% from 2025 to 2035. This steady growth trajectory reflects the strong convergence of coffee consumption habits with rising demand for functional and wellness-oriented beverages. Functional coffee has transitioned from a niche category to a mainstream product offering,…

More Releases for Yarn

Yarn Winding Machine Market Outlook, Driving Quality and Speed in Modern Yarn Pr …

Market Overview

The Yarn Winding Machine Market has seen significant growth in recent years, fueled by increasing automation in textile manufacturing, rising global demand for efficient yarn processing, and advancements in machinery technology. Yarn winding machines play a critical role in the textile value chain, converting yarns into convenient packages suitable for further processes like weaving or knitting. The growth rate is expected to be driven by high demand for compact…

Alpaca Fiber Market Key Companies Zeilinger Wool, The Natural Fiber, The Alpaca …

In a world increasingly driven by sustainability, ethical sourcing, and high-performance materials, alpaca fiber is emerging as a luxury textile solution that is as functional as it is environmentally responsible. Commonly associated with traditional Andean garments or artisanal handicrafts, alpaca fiber is often overlooked in the broader context of technical and sustainable textile markets. However, this rare natural fiber offers exceptional performance attributes-lightweight warmth, hypoallergenic properties, and natural durability-that make…

High Quality Yarn Dyed polyamide Yarn

high quality FD/sD/BR nylon 6 fdy/dty/poy yarn dyed polyamide yarn

Image: https://www.abnewswire.com/uploads/3ccc6dd1b3651c70c11419409b163a7d.png

Short Description:

Colorant mixes well with the melt through dope dyed technology in the production process to form colored fiber after spinning. The dope dyed yarn [https://www.nylonhscc.com/] is considered as an EcO- friendly yarn. No dyeing process is needed after the knitting/weaving process. This helps to save water and energy consumption, avoid dyeing pollution, and reduce cO2 emission.

What's the meaning of…

Yarn Tension and Yarn Strength

CHINA, HEFEI (April 01, 2024)--In general, "yarn tension" refers to the degree of tension in the yarn after being exposed to an external force. https://fyitester.com/yarn-tension/

In the spinning process, tensions exist between roving yarns and fine yarns. To elaborate further, consider the twisting and winding process: The tension of the yarn from the front roller to the yarn guide hook is termed spinning tension; the tension of the yarn from the…

Global Yarn Market Report, Yarn Market Size, Analysis - Forecasts to 2026

Yarn Market: By Source

On the basis of source, the global yarn market is segmented into animal, chemical, and plant, among others. The animal segment is expected grow during the forecast period, owing to its smooth and shimmering appearance. There are different varieties of animal yarn including Sheep, Camel, Yak and Musk Ox among others. The market for plant is also expected to increase during the forecast period owing to increase…

Global Yarn Market Report, Yarn Market Size, Analysis - Forecasts to 2026

Yarn Market: By Source

On the basis of source, the global yarn market is segmented into animal, chemical, and plant, among others. The animal segment is expected grow during the forecast period, owing to its smooth and shimmering appearance. There are different varieties of animal yarn including Sheep, Camel, Yak and Musk Ox among others. The market for plant is also expected to increase during the forecast period owing to increase…